Abstract

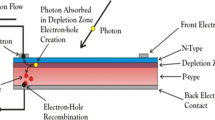

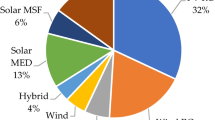

Solar energy offers a sustainable solution to address the increasing energy demand and environmental concerns in both industrial and domestic applications. To enhance the efficiency of solar collectors, researchers have integrated heat pipes, which are passive devices for effectively transferring heat to a working fluid. This integration has a wide range of applications for solar thermal collectors, including water and space heating, drying processes, and desalination. Conventional solar collectors have limitations in high-temperature applications. When heat pipes are integrated with these collectors, they have demonstrated a higher temperature range and improved performance. This paper presents a comprehensive review of the various techniques and innovations adopted by researchers over the last few decades to maximize the thermal performance of heat pipe solar collectors (HPSC). The review begins by covering the fundamental concept and working principle of heat pipes. Heat pipes are sealed copper tubes with an inner wick structure and a small amount of working fluid. Researchers have explored several techniques and innovations to enhance the thermal performance of HPSC. These include optimizing geometrical parameters such as length, diameter, and orientation of heat pipes to maximize heat transfer. Improvements in wick structure design and the selection of working fluids have also been investigated to enhance heat transfer efficiency. This review provides an overview of the techniques and innovations employed by researchers to enhance the efficiency of heat pipe solar collectors. By addressing the identified research gaps, further advancements can be achieved in maximizing the thermal performance of HPSC, leading to more efficient utilization of solar energy.

Similar content being viewed by others

References

Abd-Elhady MS, Nasreldin M, Elsheikh MN. Improving the performance of evacuated tube heat pipe collectors using oil and foamed metals. Ain Shams Eng J. 2018;9:2683–9. https://doi.org/10.1016/j.asej.2017.10.001.

Abo-Elfadl S, Hassan H, El-Dosoky MF. Energy and exergy assessment of integrating reflectors on thermal energy storage of evacuated tube solar collector-heat pipe system. Sol Energy. 2020;209:470–84. https://doi.org/10.1016/j.solener.2020.09.009.

Al-Waeli, A.H.A., Kazem, H.A., Chaichan, M.T., Sopian, K., 2019. Photovoltaic/thermal (PV/T) systems: principles, design, and applications, photovoltaic/thermal (PV/T) systems: principles, design, and applications. https://doi.org/10.1007/978-3-030-27824-3

Alammar AA, Al-Dadah RK, Mahmoud SM. Numerical investigation of effect of fill ratio and inclination angle on a thermosiphon heat pipe thermal performance. Appl Therm Eng. 2016;108:1055–65. https://doi.org/10.1016/j.applthermaleng.2016.07.163.

Allouhi A, Benzakour Amine M, Buker MS, Kousksou T, Jamil A. Forced-circulation solar water heating system using heat pipe-flat plate collectors: Energy and exergy analysis. Energy. 2019;180:429–43. https://doi.org/10.1016/j.energy.2019.05.063.

Alshukri MJ, Eidan AA, Najim SI. Thermal performance of heat pipe evacuated tube solar collector integrated with different types of phase change materials at various location. Renew Energy. 2021;171:635–46. https://doi.org/10.1016/j.renene.2021.02.143.

Alshukri MJ, Eidan AA, Najim SI. The influence of integrated Micro-ZnO and Nano-CuO particles/paraffin wax as a thermal booster on the performance of heat pipe evacuated solar tube collector. J Energy Storage. 2021;37:102506. https://doi.org/10.1016/j.est.2021.102506.

Andraka CE, Kruizenga AM, Hernandez-sanchez BA, Coker EN. Metallic phase change material thermal storage for dish stirling. Energy Procedia. 2015;69:726–36. https://doi.org/10.1016/j.egypro.2015.03.083.

Arab M, Soltanieh M, Shafii MB. Experimental investigation of extra-long pulsating heat pipe application in solar water heaters. Exp Therm Fluid Sci. 2012;42:6–15. https://doi.org/10.1016/j.expthermflusci.2012.03.006.

Aref L, Fallahzadeh R, Reza S, Hosseinzadeh M. A novel dual-diameter closed-loop pulsating heat pipe for a flat plate solar collector. Energy. 2021;230:120751. https://doi.org/10.1016/j.energy.2021.120751.

Azad E. Theoretical and experimental investigation of heat pipe solar collector. Exp Therm Fluid Sci. 2008;32:1666–72. https://doi.org/10.1016/j.expthermflusci.2008.05.011.

Bastakoti D, Zhang H, Li D, Cai W, Li F. An overview on the developing trend of pulsating heat pipe and its performance. Appl Therm Eng. 2018;141:305–32. https://doi.org/10.1016/j.applthermaleng.2018.05.121.

Bazri S, Badruddin IA, Usmani AY, Anwar Khan S, Kamangar S, Naghavi MS, Rahman Mallah A, Abdelrazek AH. Thermal hysteresis analysis of finned-heat-pipe-assisted latent heat thermal energy storage application for solar water heater system. Case Stud Therm Eng. 2022;40:102490. https://doi.org/10.1016/j.csite.2022.102490.

Bhagwat VV, Roy S, Das B, Shah N, Chowdhury A. Performance of finned heat pipe assisted parabolic trough solar collector system under the climatic condition of North East India. Sustain Energy Technol Assessments. 2021;45:101171. https://doi.org/10.1016/j.seta.2021.101171.

Bhuwakietkumjohn N, Rittidech S. Internal flow patterns on heat transfer characteristics of a closed-loop oscillating heat-pipe with check valves using ethanol and a silver nano-ethanol mixture. Exp Therm Fluid Sci. 2010;34:1000–7. https://doi.org/10.1016/j.expthermflusci.2010.03.003.

Brahim T, Dhaou MH, Jemni A. Theoretical and experimental investigation of plate screen mesh heat pipe solar collector. Energy Convers Manag. 2014;87:428–38. https://doi.org/10.1016/j.enconman.2014.07.041.

Chamsa-ard W, Sukchai S, Sonsaree S, Sirisamphanwong C. Thermal performance testing of heat pipe evacuated tube with compound parabolic concentrating Solar collector BY ISO 9806–1. Energy Procedia. 2014;56:237–46. https://doi.org/10.1016/j.egypro.2014.07.154.

Chaudhry HN, Hughes BR, Ghani SA. A review of heat pipe systems for heat recovery and renewable energy applications. Renew Sustain Energy Rev. 2012;16:2249–59. https://doi.org/10.1016/j.rser.2012.01.038.

Chen H, Zhang H, Li M, Liu H, Huang J. Experimental investigation of a novel LCPV/T system with micro-channel heat pipe array. Renew Energy. 2018;115:773–82. https://doi.org/10.1016/j.renene.2017.08.087.

Chen H, Zhang L, Jie P, Xiong Y, Xu P, Zhai H. Performance study of heat-pipe solar photovoltaic/thermal heat pump system. Appl Energy. 2017;190:960–80. https://doi.org/10.1016/j.apenergy.2016.12.145.

Chen Y, He Y, Zhu X. Flower-type pulsating heat pipe for a solar collector. Int J Energy Res. 2020;44:7734–45. https://doi.org/10.1002/er.5505.

Chernysheva MA, Pastukhov VG, Maydanik YF. Analysis of heat exchange in the compensation chamber of a loop heat pipe. Energy. 2013;55:253–62. https://doi.org/10.1016/j.energy.2013.04.014.

Chopra K, Tyagi VV, Pathak AK, Pandey AK, Sari A. Experimental performance evaluation of a novel designed phase change material integrated manifold heat pipe evacuated tube solar collector system. Energy Convers Manag. 2019;198:111896. https://doi.org/10.1016/j.enconman.2019.111896.

Reay DA, Kew PA, McGlen RJ 2019. Chapter 3: historical developments. 73–112. https://doi.org/10.31826/9781463235796-005

Dewangan D, Ekka JP, Arjunan TV. Solar photovoltaic thermal system: a comprehensive review on recent design and development, applications and future prospects in research. Int J Ambient Energy. 2022;43:7247–71. https://doi.org/10.1080/01430750.2022.2063386.

Diallo TMO, Yu M, Zhou J, Zhao X, Shittu S, Li G, Ji J, Hardy D. Energy performance analysis of a novel solar PVT loop heat pipe employing a microchannel heat pipe evaporator and a PCM triple heat exchanger. Energy. 2019;167:866–88. https://doi.org/10.1016/j.energy.2018.10.192.

Eldin SAS, Abd-Elhady MS, Kandil HA. Feasibility of solar tracking systems for PV panels in hot and cold regions. Renew Energy. 2016;85:228–33. https://doi.org/10.1016/j.renene.2015.06.051.

Eltaweel, M., Abdel-rehim, A.A., Attia, A.A.A., 2020. Energetic and exergetic analysis of a heat pipe evacuated tube solar collector using MWCNT / water nanofluid. Case Stud. Therm. Eng. 22

Ersöz MA. Effects of different working fluid use on the energy and exergy performance for evacuated tube solar collector with thermosyphon heat pipe. Renew Energy. 2016;96:244–56. https://doi.org/10.1016/j.renene.2016.04.058.

Essa MA, Rofaiel IY, Ahmed MA. Experimental and theoretical analysis for the performance of evacuated tube collector integrated with helical finned heat pipes using PCM energy storage. Energy. 2020;206:118166. https://doi.org/10.1016/j.energy.2020.118166.

Faegh M, Shafii MB. Experimental investigation of a solar still equipped with an external heat storage system using phase change materials and heat pipes. Desalination. 2017;409:128–35. https://doi.org/10.1016/j.desal.2017.01.023.

Faghri A. Heat pipes: review, opportunities and challenges. Front Heat Pipes. 2014. https://doi.org/10.5098/fhp.5.1.

Fallahzadeh R, Aref L, Gholamiarjenaki N, Nonejad Z, Saghi M. Experimental investigation of the effect of using water and ethanol as working fluid on the performance of pyramid-shaped solar still integrated with heat pipe solar collector. Sol Energy. 2020;207:10–21. https://doi.org/10.1016/j.solener.2020.06.032.

Fathabadi H. Novel low-cost parabolic trough solar collector with TPCT heat pipe and solar tracker: Performance and comparing with commercial flat-plate and evacuated tube solar collectors. Sol Energy. 2020;195:210–22. https://doi.org/10.1016/j.solener.2019.11.057.

Gang P, Huide F, Jie J, Tin-tai C, Tao Z. Annual analysis of heat pipe PV / T systems for domestic hot water and electricity production. Energy Convers Manag. 2012;56:8–21. https://doi.org/10.1016/j.enconman.2011.11.011.

Gang P, Huide F, Tao Z, Jie J. A numerical and experimental study on a heat pipe PV/T system. Sol Energy. 2011;85:911–21. https://doi.org/10.1016/j.solener.2011.02.006.

Grissa K, Benselama AM, Romestant C, Bertin Y, Grissa K, Lataoui Z, Jemni A. Performance of a cylindrical wicked heat pipe used in solar collectors: Numerical approach with Lattice Boltzmann method. Energy Convers Manag. 2017;150:623–36. https://doi.org/10.1016/j.enconman.2017.08.038.

Han X, Zhao X, Chen X. Design and analysis of a concentrating PV/T system with nanofluid based spectral beam splitter and heat pipe cooling. Renew Energy. 2020;162:55–70. https://doi.org/10.1016/j.renene.2020.07.131.

Hao T, Ma H, Ma X. Heat transfer performance of polytetrafluoroethylene oscillating heat pipe with water, ethanol, and acetone as working fluids. Int J Heat Mass Transf. 2019;131:109–20. https://doi.org/10.1016/j.ijheatmasstransfer.2018.08.133.

He W, Hong X, Zhao X, Zhang X, Shen J, Ji J. Theoretical investigation of the thermal performance of a novel solar loop-heat-pipe façade-based heat pump water heating system. Energy Build. 2014;77:180–91. https://doi.org/10.1016/j.enbuild.2014.03.053.

Höhne T. CFD simulation of a heat pipe using the homogeneous model. Int J Thermofluids. 2022. https://doi.org/10.1016/j.ijft.2022.100163.

Hou L, Quan Z, Zhao Y, Wang L, Wang G. An experimental and simulative study on a novel photovoltaic-thermal collector with micro heat pipe array (MHPA-PV/T). Energy Build. 2016;124:60–9. https://doi.org/10.1016/j.enbuild.2016.03.056.

Huang BJ, Chong TL, Wu PH, Dai HY, Kao YC. Spiral multiple-effect diffusion solar still coupled with vacuum-tube collector and heat pipe. Desalination. 2015;362:74–83. https://doi.org/10.1016/j.desal.2015.02.011.

Huang HJ, Shen SC, Shaw HJ. Design and fabrication of a novel hybrid-structure heat pipe for a concentrator photovoltaic. Energies. 2012;5:4340–9. https://doi.org/10.3390/en5114340.

Huang X, Wang Q, Yang H, Zhong S, Jiao D, Zhang K, Li M, Pei G. Theoretical and experimental studies of impacts of heat shields on heat pipe evacuated tube solar collector. Renew Energy. 2019;138:999–1009. https://doi.org/10.1016/j.renene.2019.02.008.

Hudon, K., 2013. Solar Energy - Water Heating. Futur. Energy Improv. Sustain. Clean Options our Planet, 45: 433–451. https://doi.org/10.1016/B978-0-08-099424-6.00020-X

Hussein AK. Applications of nanotechnology to improve the performance of solar collectors - recent advances and overview. Renew Sustain Energy Rev. 2016;62:767–92. https://doi.org/10.1016/j.rser.2016.04.050.

Hussein AK, Li D, Kolsi L, Kata S, Sahoo B. A review of nano fluid role to improve the performance of the heat pipe solar collectors. Energy Procedia. 2017;109:417–24. https://doi.org/10.1016/j.egypro.2017.03.044.

Hussein HMS, El-Ghetany HH, Nada SA. Performance of wickless heat pipe flat plate solar collectors having different pipes cross sections geometries and filling ratios. Energy Convers Manag. 2006;47:1539–49. https://doi.org/10.1016/j.enconman.2005.08.009.

Ismail KAR, Abogderah MM. Performance of a heat pipe solar collector. J Sol Energy Eng Trans ASME. 1998;120:51–9. https://doi.org/10.1115/1.2888047.

Jack S, Parzefall J, Luttmann T, Janßen P, Giovannetti F. Flat plate aluminum heat pipe collector with inherently limited stagnation temperature. Energy Procedia. 2014;48:105–13. https://doi.org/10.1016/j.egypro.2014.02.013.

Jafarkazemi F, Abdi H. Evacuated tube solar heat pipe collector model and associated tests. J Renew Sustain Energy. 2012. https://doi.org/10.1063/1.3690958.

Jouhara H, Chauhan A, Nannou T, Almahmoud S, Delpech B, Wrobel LC. Heat pipe based systems - advances and applications. Energy. 2017;128:729–54. https://doi.org/10.1016/j.energy.2017.04.028.

Kabeel AE, Khairat Dawood MM, Shehata AI. Augmentation of thermal efficiency of the glass evacuated solar tube collector with coaxial heat pipe with different refrigerants and filling ratio. Energy Convers Manag. 2017;138:286–98. https://doi.org/10.1016/j.enconman.2017.01.048.

Kaya M, Gürel AE, Ağbulut Ü, Ceylan İ, Çelik S, Ergün A, Acar B. Performance analysis of using CuO-Methanol nanofluid in a hybrid system with concentrated air collector and vacuum tube heat pipe. Energy Convers Manag. 2019. https://doi.org/10.1016/j.enconman.2019.111936.

Li, H., Liu, H., Li, M., 2021. Review on heat pipe based solar collectors : classi fi cations , performance evaluation and optimization , and effectiveness improvements

Liu, Y., 2016. Principle, Application and Development of Heat Pipe Technology 723–728. https://doi.org/10.2991/iccte-16.2016.122

Lu L, Liu ZH, Xiao HS. Thermal performance of an open thermosyphon using nanofluids for high-temperature evacuated tubular solar collectors. Part 1: Indoor experiment. Sol Energy. 2011;85:379–87. https://doi.org/10.1016/j.solener.2010.11.008.

Maghrabie HM, Olabi AG, Alami AH, Al RM, Zwayyed F, Salamah T, Wilberforce T, Abdelkareem MA. Numerical simulation of heat pipes in different applications. Int J Thermofluids. 2022;16:100199. https://doi.org/10.1016/j.ijft.2022.100199.

Mahjoub S, Mahtabroshan A. Numerical simulation of a conventional heat pipe. Int Sch Sci Res Innov. 2008;2:97–102.

Malakar S, Arora VK, Nema PK. Design and performance evaluation of an evacuated tube solar dryer for drying garlic clove. Renew Energy. 2021;168:568–80. https://doi.org/10.1016/j.renene.2020.12.068.

Malan DJ, Dobson RT, Dinter F. Solar thermal energy storage in power generation using phase change material with heat pipes and fins to enhance heat transfer. Energy Procedia. 2015;69:925–36. https://doi.org/10.1016/j.egypro.2015.03.176.

Mathew AA, Thangavel V. A novel thermal energy storage integrated evacuated tube heat pipe solar dryer for agricultural products: Performance and economic evaluation. Renew Energy. 2021;179:1674–93. https://doi.org/10.1016/j.renene.2021.07.029.

Moradgholi M, Nowee SM, Abrishamchi I. Application of heat pipe in an experimental investigation on a novel photovoltaic/thermal (PV/T) system. Sol Energy. 2014;107:82–8. https://doi.org/10.1016/j.solener.2014.05.018.

Mosleh HJ, Mamouri SJ, Shafii MB, Sima AH. A new desalination system using a combination of heat pipe, evacuated tube and parabolic through collector. Energy Convers Manag. 2015;99:141–50. https://doi.org/10.1016/j.enconman.2015.04.028.

Naghavi MS, Ong KS, Badruddin IA, Mehrali M, Silakhori M, Metselaar HSC. Theoretical model of an evacuated tube heat pipe solar collector integrated with phase change material. Energy. 2015;91:911–24. https://doi.org/10.1016/j.energy.2015.08.100.

ONOSI Solar, n.d. ONOSI Solar. https://www.onosisolar.com/solar-collectors/

Patel VD. To improve the thermal performance of heat pipe in evacuated tube solar collector. Int J Eng Res Technol ISSN. 2021;9:2020–2.

Pawar VR, Sobhansarbandi S. Design optimization and heat transfer enhancement of energy storage based solar thermal collector. Sustain Energy Technol Assessments. 2021;46:101260. https://doi.org/10.1016/j.seta.2021.101260.

Pawar VR, Sobhansarbandi S. CFD modeling of a thermal energy storage based heat pipe evacuated tube solar collector. J Energy Storage. 2020;30:101528. https://doi.org/10.1016/j.est.2020.101528.

Pereira H, Haug F, Silva P, Wu J, Koettig T. Cryogenic loop heat pipes for the cooling of small particle detectors at cern. AIP Conf Proc. 2010;1218:1039–46. https://doi.org/10.1063/1.3422264.

Peyghambarzadeh SM, Shahpouri S, Aslanzadeh N, Rahimnejad M. Thermal performance of different working fluids in a dual diameter circular heat pipe. Ain Shams Eng J. 2013;4:855–61. https://doi.org/10.1016/j.asej.2013.03.001.

Pise GA, Salve SS, Pise AT, Pise AA. Investigation of solar heat pipe collector using nanofluid and surfactant. Energy Procedia. 2016;90:481–91. https://doi.org/10.1016/j.egypro.2016.11.215.

Ramsey JW, Gupta BP, Knowles GR. Experimental evaluation of a cylindrical parabolic solar collector. Am Soc Mech Eng. 1976;99:163–8.

Rassamakin B, Khairnasov S, Zaripov V, Rassamakin A, Alforova O. Aluminum heat pipes applied in solar collectors. Sol Energy. 2013;94:145–54. https://doi.org/10.1016/j.solener.2013.04.031.

Reay DA, Kew PA, McGlen RJ. Special types of heat pipe. Heat Pipes. 2014. https://doi.org/10.1016/b978-0-08-098266-3.00006-6.

Reay DA, Kew PA, McGlen RJ. Heat pipe components and materials. Heat Pipes. 2014. https://doi.org/10.1016/b978-0-08-098266-3.00003-0.

Ren X, Yu M, Zhao X, Li J, Zheng S, Chen F, Wang Z, Zhou J, Pei G, Ji J. Assessment of the cost reduction potential of a novel loop-heat-pipe solar photovoltaic/thermal system by employing the distributed parameter model. Energy. 2020;190:116338. https://doi.org/10.1016/j.energy.2019.116338.

Rittidech S, Wannapakne S. Experimental study of the performance of a solar collector by closed-end oscillating heat pipe (CEOHP). Appl Therm Eng. 2007;27:1978–85. https://doi.org/10.1016/j.applthermaleng.2006.12.005.

Roslan MEBM, Hassim I. Solar PV system with pulsating heat pipe cooling, Indones. J Electr Eng Comput Sci. 2019;14:311–8. https://doi.org/10.11591/ijeecs.v14.i1.pp311-318.

Rybár R, Beer M, Cehlár M. Thermal power measurement of the novel evacuated tube solar collector and conventional solar collector during simultaneous operation. Meas J Int Meas Confed. 2016;88:153–64. https://doi.org/10.1016/j.measurement.2016.03.054.

Sabiha MA, Saidur R, Hassani S, Said Z, Mekhilef S. Energy performance of an evacuated tube solar collector using single walled carbon nanotubes nanofluids. Energy Convers Manag. 2015;105:1377–88. https://doi.org/10.1016/j.enconman.2015.09.009.

Sarafraz MM, Pourmehran O, Yang B, Arjomandi M. Assessment of the thermal performance of a thermosyphon heat pipe using zirconia-acetone nanofluids. Renew Energy. 2019;136:884–95. https://doi.org/10.1016/j.renene.2019.01.035.

Saravanan M, Karunakaran N. Experimental analysis of heat pipe with V-trough solar collector. Int J Res Advent Technol. 2014;53:12–3.

Sekhar YR, Sharma KV, Karupparaj RT, Chiranjeevi C. Heat transfer enhancement with Al2O3 nanofluids and twisted tapes in a pipe for solar thermal applications. Procedia Eng. 2013;64:1474–84. https://doi.org/10.1016/j.proeng.2013.09.229.

Senthil R, Madurai Elavarasan R, Pugazhendhi R, Premkumar M, Vengadesan E, Navakrishnan S, Islam MR, Natarajan SK. A holistic review on the integration of heat pipes in solar thermal and photovoltaic systems. Sol Energy. 2021;227:577–605. https://doi.org/10.1016/j.solener.2021.09.036.

Sha M, Mohiabadi MZ. Experimental investigation of heat pipe solar collector using MgO nano fluids. Sol Energy Mater Sol Cells. 2019;191:91–9. https://doi.org/10.1016/j.solmat.2018.10.025.

Shafieian A, Khiadani M, Nosrati A. Strategies to improve the thermal performance of heat pipe solar collectors in solar systems: a review. Energy Convers Manag. 2019;183:307–31. https://doi.org/10.1016/j.enconman.2018.12.115.

Shafieian A, Khiadani M, Nosrati A. A review of latest developments, progress, and applications of heat pipe solar collectors. Renew Sustain Energy Rev. 2019;95:273–304. https://doi.org/10.1016/j.rser.2018.07.014.

Shafiey Dehaj M, Ahmadi M, Zamani Mohiabadi M. Assessment of a heat pipe solar collector with nanofluids. Environ Sci Pollut Res. 2021;28:5316–31. https://doi.org/10.1007/s11356-020-10797-x.

Sharma C. A review of heat pipes : its types and applications. Int J Eng Res Technol. 2019;8:103–6.

Shukla KN. Heat pipe for aerospace applications—an overview. J Electron Cool Therm Control. 2015;05:1–14. https://doi.org/10.4236/jectc.2015.51001.

Somasundaram S, Zhu Y, Lu Z, Adera S, Bin H, Mengyao W, Tan CS, Wang EN. Thermal design optimization of evaporator micropillar wicks. Int J Therm Sci. 2018;134:179–87. https://doi.org/10.1016/j.ijthermalsci.2018.07.036.

Sweidan A, Ghaddar N, Ghali K. Optimized design and operation of heat-pipe photovoltaic thermal system with phase change material for thermal storage. J Renew Sustain Energy. 2016. https://doi.org/10.1063/1.4943091.

Vengadesan E, Senthil R. A review on recent developments in thermal performance enhancement methods of flat plate solar air collector. Renew Sustain Energy Rev. 2020;134:110315. https://doi.org/10.1016/j.rser.2020.110315.

Wallin P (2012) Heat pipe, selection of working fluid. Proj Rep MVK160 Heat Mass Transf 1–7

Wang N, Zeng S, Zhou M, Wang S. Numerical study of flat plate solar collector with novel heat collecting components. Int Commun Heat Mass Transf. 2015;69:18–22. https://doi.org/10.1016/j.icheatmasstransfer.2015.10.012.

Wei L, Yuan D, Tang D, Wu B. A study on a flat-plate type of solar heat collector with an integrated heat pipe. Sol Energy. 2013;97:19–25. https://doi.org/10.1016/j.solener.2013.07.025.

Wu SY, Zhang QL, Xiao L, Guo FH. A heat pipe photovoltaic/thermal (PV/T) hybrid system and its performance evaluation. Energy Build. 2011;43:3558–67. https://doi.org/10.1016/j.enbuild.2011.09.017.

Xu RJ, Zhang XH, Wang RX, Xu SH, Wang HS. Experimental investigation of a solar collector integrated with a pulsating heat pipe and a compound parabolic concentrator. Energy Convers Manag. 2017;148:68–77. https://doi.org/10.1016/j.enconman.2017.04.045.

Xu X, Zhang X, Storage E, Zhang X, Storage E. Finite time thermodynamics analysis and research of pulsating heat pipe cold storage device. Energy Storage Sav. 2022;1:33–43.

Yang L, Ling X, Peng H, Duan LF, Chen X. Starting characteristics of a novel high temperature flat heat pipe receiver in solar power tower plant based of“Flat-front”Startup model. Energy. 2019;183:936–45. https://doi.org/10.1016/j.energy.2019.07.007.

Yu M, Chen F, Zheng S, Zhou J, Zhao X, Wang Z, Li G, Li J, Fan Y, Ji J, Diallo TMO, Hardy D. Experimental investigation of a novel solar micro-channel loop-heat-pipe photovoltaic/thermal (MC-LHP-PV/T) system for heat and power generation. Appl Energy. 2019. https://doi.org/10.1016/j.apenergy.2019.113929.

Zhang D, Tao H, Wang M, Sun Z, Jiang C. Numerical simulation investigation on thermal performance of heat pipe flat-plate solar collector. Appl Therm Eng. 2017;118:113–26. https://doi.org/10.1016/j.applthermaleng.2017.02.089.

Zhang J, Zhai H, Wu Z, Wang Y, Xie H, Zhang M. Enhanced performance of photovoltaic–thermoelectric coupling devices with thermal interface materials. Energy Rep. 2020;6:116–22. https://doi.org/10.1016/j.egyr.2019.12.001.

Zhang T, Yan Z, Pei G, Zhu Q, Ji J. Experimental optimization on the volume-filling ratio of a loop thermosyphon photovoltaic/thermal system. Renew Energy. 2019;143:233–42. https://doi.org/10.1016/j.renene.2019.05.014.

Zhang X, You S, Ge H, Gao Y, Xu W, Wang M, He T, Zheng X. Thermal performance of direct-flow coaxial evacuated-tube solar collectors with and without a heat shield. Energy Convers Manag. 2014;84:80–7. https://doi.org/10.1016/j.enconman.2014.04.014.

Zhang X, Zhao X, Xu J, Yu X. Characterization of a solar photovoltaic/loop-heat-pipe heat pump water heating system. Appl Energy. 2013;102:1229–45. https://doi.org/10.1016/j.apenergy.2012.06.039.

Zhong G, Tang Y, Ding X, Rao L, Chen G, Tang K, Yuan W, Li Z. Experimental study of a large-area ultra-thin flat heat pipe for solar collectors under different cooling conditions. Renew Energy. 2020;149:1032–9. https://doi.org/10.1016/j.renene.2019.10.093.

Zhu T, Diao Y, Zhao Y, Ma C. Performance evaluation of a novel flat-plate solar air collector with micro-heat pipe arrays (MHPA). Appl Therm Eng. 2017. https://doi.org/10.1016/j.applthermaleng.2017.02.076.

Zhu TT, Diao YH, Zhao YH, Deng YC. Experimental study on the thermal performance and pressure drop of a solar air collector based on flat micro-heat pipe arrays. Energy Convers Manag. 2015;94:447–57. https://doi.org/10.1016/j.enconman.2015.01.052.

Zohuri B (2020) Heat pipe infrastructure, functionality, advancements and industrial applications of heat pipes. https://doi.org/10.1016/b978-0-12-819819-3.00001-8

Zohuri B. Heat pipe design and technology: modern applications for practical thermal management. 2nd ed. London: Springer; 2016.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ekka, J.P., Dewangan, D. A comprehensive review on recent developments, applications and future aspects of heat pipe-assisted solar collectors. J Therm Anal Calorim 148, 11173–11201 (2023). https://doi.org/10.1007/s10973-023-12396-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12396-7