Abstract

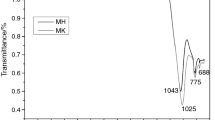

In the recent century, geopolymer materials have grown significantly due to their unique properties applicable in many different fields. In the present work, the heat evolution, thermal and mechanical behavior of inorganic geopolymer composites (IPCs), based on solid solution of feldspathic minerals (pegmatite and granite) or sand quartz that were altered by a low fraction (15–20 mass%) of calcined clay (metakaolin or calcined halloysite). The isothermal calorimeter tests revealed that the heat flow evolution (dQ/dt) of mix design of different compositions was low compared to standard geopolymer materials due to low reactivity in alkaline medium of solid solution used. It was also found that the integrated heat flow during the geopolymerization decreases with the crystallinity of solid solution. The thermogravimetric analysis of all the samples revealed two main changes, before 120 °C and between 700 and 890 °C. The changes are attributed to the loss of water molecules and crystallization of albite and nepheline, respectively with an overall loss of mass which varies from 14.0 to 21.6%. The heating microscope up to 1200 °C shows a shrinkage of 50% for D3C4 and R2C1 samples. The study of mechanical and physical behaviors of geopolymer composites with different compositions showed that samples based on pegmatite and MK developed higher strengths (42.11 MPa and 106.75 MPa for flexural and compression) associated with lower water absorption (7.01%). The high strengths obtained were due to the combination of denser and homogeneous microstructure of IPCs. These materials are potential candidates for eco-friendly construction materials.

Similar content being viewed by others

Data availability

There are no additional available data to upload.

References

Provis JL. Geopolymers and other alkali activated materials: why, how, and what? Mater Struct. 2014;47:11–25. https://doi.org/10.1617/s11527-013-0211-5.

Pasupathy K, Ramakrishnan S, Sanjayan J. 3D concrete printing of eco-friendly geopolymer containing brick waste. Cem Concr Compos. 2022;138:104943. https://doi.org/10.1016/j.cemconcomp.2023.104943.

Nikravan M, Firdous R, Stephan D. Life cycle assessment of alkali-activated materials: a systematic literature review. Low-Carbon Mater Green Constr. 2023;6:1–24. https://doi.org/10.1007/s44242-023-00014-6.

Duxson P, Provis JL, Lukey GC, S. Mallicoat W, Kriven WM, van Deventer JSJ,. Understanding the relationship between geopolymer composition, microstructure and mechanical properties. Coll Surf A: Physicoch Eng Asp. 2022;269(1–3):47–58. https://doi.org/10.1016/j.colsurfa.2005.06.060.

Zhou X, Chen Y, Dong S, Li H. Geopolymerization kinetics of steel slag activated gasification coal fly ash: a case study for amorphous-rich slags. J Clean Prod. 2022;379(1):134671. https://doi.org/10.1016/j.jclepro.2022.134671.

Davidovits J. Geopolymers : ceramic-like inorganic polymers. J Ceram Sci Technol. 2017;8(3):335–50. https://doi.org/10.4416/JCST2017-00038.

Tome S, Etoh M-A, Etame J, Sanjay K. Characterization and leachability behaviour of geopolymer cement synthesised from municipal solid waste incinerator fly ash and volcanic ash blends. Recycling. 2018;3:50–64. https://doi.org/10.3390/recycling3040050.

Djobo JNY, Stephan D. Understanding the binder chemistry, microstructure, and physical properties of volcanic ash phosphate geopolymer binder. J Am Ceram Soc. 2022;105:3226–37. https://doi.org/10.1111/jace.18333.

Nath SK, Kumar S. Role of particle fineness on engineering properties and microstructure of fly ash derived geopolymer. Constr Build Mater. 2020;233:117294. https://doi.org/10.1016/j.conbuildmat.2019.117294.

Ricardo P, Matos D, Dors R, Jean P, Gleize P, De Brito J, Longuini W. Eco-friendly ultra-high performance cement pastes produced with quarry wastes as alternative fillers. J Clean Prod. 2020;269:122308. https://doi.org/10.1016/j.jclepro.2020.122308.

Kürklü G, Görhan G. Investigation of usability of quarry dust waste in fly ash-based geopolymer adhesive mortar production. Constr Build Mater. 2019;217:498–506. https://doi.org/10.1016/j.conbuildmat.2019.05.104.

Wan Q, Zhang Y, Zhang R. Using mechanical activation of quartz to enhance the compressive strength of metakaolin based geopolymers. Cem Concr Compos. 2020;111:103635. https://doi.org/10.1016/j.cemconcomp.2020.103635.

Nana A, Ngouné J, Kaze RC, Boubakar L, Tchounang SK, Tchakouté HK, Kamseu E, Leonelli C. Room-temperature alkaline activation of feldspathic solid solutions : development of high strength geopolymers. Constr Build Mater. 2019;195:258–68. https://doi.org/10.1016/j.conbuildmat.2018.11.068.

Kaze CR, Nana A, Nana LGL, Deutou JGN, Kamseu E. Thermal behaviour and microstructural evolution of metakaolin and meta-halloysite-based geopolymer binders : a comparative study. J Therm Anal Calorim. 2022;147:2055–71. https://doi.org/10.1016/j.dibe.2023.100153.

Narayanan A, Shanmugasundaram P. Evaluation of heat resisting behaviour of basalt fibre reinforced FG tiles. Constr Build Mater. 2018;170:679–89. https://doi.org/10.1016/j.conbuildmat.2018.03.110.

Boum RBE, Owono FM, Kaze RC, Essomba ECJ, Souleymanou B, Nemaleu DGJ, Ntamak-Nida MJ. Thermal behavior of acidic and alkali activated laterite based geopolymer : a comparative study. Geosystem Eng. 2022; 25(5–6):22–238. https://doi.org/10.1080/12269328.2022.2157895.

Scanferla P, Gharzouni A, Texier-Mandoki N, Bourbon X, Rossignol S. Effects of potassium-silicate, sands and carbonates concentrations on metakaolin-based geopolymers for high-temperature applications. Open Ceram. 2022;10:100257. https://doi.org/10.1016/j.oceram.2022.100257.

Hemra K, Aungkavattana P. Effect of cordierite addition on compressive strength and thermal stability of metakaolin based geopolymer. Adv Powder Technol. 2016;27(3):1021–6. https://doi.org/10.1016/j.apt.2016.04.019.

Temuujin J, Van Riessen A, Williams R. Influence of calcium compounds on the mechanical properties of fly ash geopolymer pastes. J Hazardous Mater. 2009;67:82–8. https://doi.org/10.1016/j.jhazmat.2008.12.121.

Dupuy C, Gharzouni A, Sobrados I, Texier-Mandoki N, Bourbon X, Rossignol S. Thermal resistance of argillite based alkali-activated materials. Part 2: Identification of the formed crystalline phases. Mater Chem Phys. 2018;218:262–71.

Tognonvi TM, Petlitckaia S, Gharzouni A, Fricheteau M, Texier-Mandoki N, Bourbon X, Rossignol X. High-temperature, resistant, argillite-based, alkali-activated materials with improved post-thermal treatment mechanical strength. Clays Clay Miner. 2017;68:211–9. https://doi.org/10.1007/s42860-020-00067-9.

Kamseu E, Akono A-T, Nana A, Kaze RC, Leonelli C. Performance of geopolymer composites made with feldspathic solid solutions : micromechanics and microstructure. Cem Concr Compos. 2021;124:104241. https://doi.org/10.1016/j.cemconcomp.2021.104241.

Nana A, Kaze CR, Alomayri TS, Assaedi SH, Deutou NGJ, Ngouné J, Tchakounte HK, Kamseu E, Leonelli C. Innovative porous ceramic matrices from inorganic polymer composites (IPCs): microstructure and mechanical properties. Constr Build Mater. 2021;273:122032. https://doi.org/10.1016/j.conbuildmat.2020.122032.

Pelisser F. Gleize PJP Thermal-mechanical properties of metakaolin-based geopolymer containing silicon carbide microwhiskers. Cem Concr Compos. 2021;123:104168. https://doi.org/10.1016/j.cemconcomp.2021.104168.

Cai J, Li X, Tan J, Vandevyvere B. Thermal and compressive behaviors of fly ash and metakaolin-based geopolymer. J Build Eng. 2020;30:101307. https://doi.org/10.1016/j.jobe.2020.101307.

Sanalkumar KUA, Yang E. Self-cleaning performance of nano-TiO2 modified metakaolin-based geopolymers. Cem Concr Compos. 2020;115:103847. https://doi.org/10.1016/j.cemconcomp.2020.103847.

Zhang Z, Wang H, Provis JL, Bullen F, Reid A, Zhu Y. Quantitative kinetic and structural analysis of geopolymers. Part 1. The activation of metakaolin with sodium hydroxide. Thermochim Acta. 2012;539:23–33. https://doi.org/10.1016/j.tca.2012.03.021.

Trincal V, Multon S, Benavent V, Lahalle H, Balsamo B, Caron A, Bucher R, Caselles LD, Cyr M. Shrinkage mitigation of metakaolin-based geopolymer activated by sodium silicate solution. Cem Concr Res. 2022;162:106993. https://doi.org/10.1016/j.cemconres.2022.106993.

Qing Z, Sui H, Basquiroto F, Souza D, Sagoe-Crentsil K, Duan W. Silane-modified graphene oxide in geopolymer: reaction kinetics, microstructure, and mechanical performance. Cem Concr Compos. 2023;139:104997. https://doi.org/10.1016/j.cemconcomp.2023.104997.

Nana A, Kamseu E, Akono A-T, Ngouné J, Djobo NJY, Tchakouté HK, Bognozzi MC, Leonelli C. Particles size and distribution on the improvement of the mechanical performance of high strength solid solution based inorganic polymer composites : a microstructural approach. Mat Chem Phys. 2021;267:124602–15. https://doi.org/10.1016/j.matchemphys.2021.124602.

Abdel-Gawwd HA, Abo-El-Enein AS. A novel method to produce dry geopolymer cement powder. HBRC J. 2016;12(1):13–24. https://doi.org/10.1016/j.hbrcj.2014.06.008.

Dabbebi R, Baklouti S, Barroso de Aguiar JL, Pacheco-Torgal F, Samet B. Investigations of geopolymeric mixtures based on phosphate washing waste. Sci Technol Mater. 2018;30:1–5. https://doi.org/10.1016/j.stmat.2018.08.001.

Blanco I, Angelo AD, Viola V, Vertuccio L, Catauro M. Metakaolin-based geopolymers filled with volcanic fly ashes: FT-IR, thermal characterization, and antibacterial property. Sci Eng Compos Mater. 2023;30(1):20220192. https://doi.org/10.1515/secm-2022-0192.

Acknowledgements

This project received the contribution of the Royal Society and the African Academy of Science through the funding FLAIR to Dr. Elie Kamseu. Grant; FLR\R1\201402. The contribution of the European Union through financial contribution No. PRICNAC-EEPER: MD2022 and for 2021 TWAS-UNESCO-CSIR Postdoctoral Fellowship FR number 22/FF/CSIR-TWAS/2022. The authors are grateful to Dr. Mirko Braga from Ingessil S.r.l., Verona, Italy, for providing sodium silicate used for these investigations.

Funding

The characterization of samples was supported by Dr. Elie Kamseu, under the FLAIR fellowship of African Academic of Science and the Royal Society N° FLR/R1/201402. Also, the contribution of the European Union through financial contribution No. PRICNAC-EEPER: MD2022 and for 2021 TWAS-UNESCO-CSIR Postdoctoral Fellowship (2021, FR number: 3240321623).

Author information

Authors and Affiliations

Contributions

Achile Nana contributed to conceptualization, methodology, investigation, writing—original draft, funding acquisition. Giovanni Ridolfi contributed to writing—review & editing investigation, writing—original draft. Sybilline C. D. Anensong contributed to writing—review & editing. Serges B. L. Ngomade contributed to writing—review & editing. Adeolu Adesoji Adediran contributed to writing—review & editing. Jean Ngouné contributed to writing—review & editing. Elie Kamseu contributed to conceptualization, methodology, writing—review & editing investigation, funding acquisition. Sanjay Kumar contributed to writing—review & editing. Maria Chiara Bignozzi contributed to writing—review & editing. Cristina Leonelli contributed to writing—review & editing, resources.

Corresponding authors

Ethics declarations

Ethical approval

This manuscript has been published elsewhere in any form or language and has not been submitted to more than one journal for simultaneous consideration.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nana, A., Ridolfi, G., Anensong, C.S.D. et al. Thermal, mechanical, and microstructural properties of inorganic polymer composites from quarry wastes (feldspathic minerals). J Therm Anal Calorim 148, 10021–10035 (2023). https://doi.org/10.1007/s10973-023-12382-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12382-z