Abstract

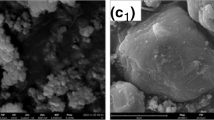

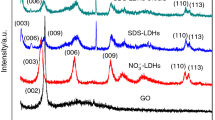

A new N–P–Cu containing supermolecular assembly network (MPCSN) was fabricated with titanium carbide (Ti3C2Tx) nanosheets through intermolecular forces, and then, the flame-retardant thermoplastic polyurethane (TPU) nanocomposites were synthesized by melt blending. The obtained results of the TPU/Ti3C2Tx-MPCSN system indicated that the temperature corresponding to T5% of TPU nanocomposites by adding 2% Ti3C2Tx or 2% MPCSN decreased to 269.1 and 311.5 °C, respectively. Simultaneously, a well dispersion of the loading of 1.0 mass% Ti3C2Tx-MPCSN was found in TPU matrix. Accordingly, the thermal stability of TPU can be found to be substantially improved in the thermogravimetric analysis, which was embodied in the mass loss of TPU/Ti3C2Tx-MPCSN-1.0 reached up to 8.47 mass%. Moreover, the cone calorimeter tests revealed that the peak of heat release rate, the total heat release, carbon monoxide production rate and total carbon monoxide yield of the TPU nanocomposite were prominently diminished by 16.1%, 37.5%, 18.8% and 37.6%, respectively. This provides clues to the flame-retardant mechanism of TPU nanocomposites: The modified Ti3C2Tx is combined with MPCSN through a cross-linked network grown on the surface of the carbon layer, which not only prevents the leakage of combustible gas, but also catalyzes the formation of the carbon layer. This work demonstrates a novel design for improved Ti3C2Tx with supramolecularly assembled networks to reduce potential fire risk in practical TPU applications, applying to applications in polymer materials.

Similar content being viewed by others

References

Cai W, Li Z, Liu J, Qiu S, Pan Y, Xu Z, et al. Recyclable and removable functionalization based on Diels-Alder reaction of black phosphorous nanosheets and its dehydration carbonization in fire safety improvement of polymer composites. Compos A. 2021;140:106157–70. https://doi.org/10.1016/j.compositesa.2020.106157.

Xie M, He J, Li X, Yang R. Ammonium polyphosphate/montmorillonite nanocomposite with a completely exfoliated structure and charring–foaming agent flame retardant thermoplastic polyurethane. Mater Sci Eng, B. 2022;283:115825–37. https://doi.org/10.1016/j.mseb.2022.115825.

Zhang J, Wang H, Sun W, Zhang Z, Li H, Zhang S, et al. Surface modification on ammonium polyphosphate and its enhanced flame retardancy in thermoplastic polyurethane. Polym Adv Technol. 2021;32:2879–86. https://doi.org/10.1002/pat.5299.

Chen K, Yang D, Shi Y, Feng Y, Fu L, Liu C, et al. Synergistic function of N–P–Cu containing supermolecular assembly networks in intumescent flame retardant thermoplastic polyurethane. Polym Adv Technol. 2021;32:4450–63. https://doi.org/10.1002/pat.5448.

Tu B, Zhou K, Zhou Q, Gong K, Hu D. Waste to resource: preparation of an efficient adsorbent and its sustainable utilization in flame retardant polyurethane composites. RSC Adv. 2021;11:9942–54. https://doi.org/10.1039/d0ra10873a.

Chen X, Chen X, Li S, Jiao C. Copper metal-organic framework toward flame-retardant enhancement of thermoplastic polyurethane elastomer composites based on ammonium polyphosphate. Polym Adv Technol. 2021;32:2829–42. https://doi.org/10.1002/pat.5260.

Gnanasekar P, Feng M, Yan N. Facile synthesis of a phosphorus-containing sustainable biomolecular platform from vanillin for the production of mechanically strong and highly flame-retardant resins. ACS Sustain Chem Eng. 2020;8:17417–26. https://doi.org/10.1021/acssuschemeng.0c05610.

Chen K, Feng Y, Shi Y, Wang H, Fu L, Liu M, et al. Flexible and fire safe sandwich structured composites with superior electromagnetic interference shielding properties. Compos A. 2022;160:107070–82. https://doi.org/10.1016/j.compositesa.2022.107070.

Luo Y, Wang H, Wang H, Cheng X, Du Z. Enhanced flame retardancy and mechanical properties of waterborne polyurethane based on the phosphorus and nitrogen containing polybutadiene acrylonitrile. J Appl Polym Sci. 2020;138:50432–44. https://doi.org/10.1002/app.50432.

Mir S, Rahidi A, Naderifar A, Alaei M. A novel and facile preparation of superhydrophilic/superoleophobic nanofilter using carbon nitride nanosheet for W/O emulsion separation. Sep Purif Technol. 2022;284:120279–90. https://doi.org/10.1016/j.seppur.2021.120279.

Wang X, Kalali EN, Wang D-Y. An in situ polymerization approach for functionalized MoS2/nylon-6 nanocomposites with enhanced mechanical properties and thermal stability. J Mater Chem A. 2015;3:24112–20. https://doi.org/10.1039/c5ta06071k.

Sabet M, Soleimani H, Mohammadian E, Hosseini S. The effect of graphene oxide on the mechanical, thermal characteristics and flame retardancy of polyurethane. Plast, Rubber Compos. 2020;50:61–70. https://doi.org/10.1080/14658011.2020.1833557.

Shi Y, Fu L, Chen X, Guo J, Yang F, Wang J, et al. Hypophosphite/graphitic carbon nitride hybrids: preparation and flame-retardant application in thermoplastic polyurethane. Nanomaterials. 2017;7:259–71. https://doi.org/10.3390/nano7090259.

Qian Y, Su W, Li L, Fu H, Li J, Zhang Y. Synthesis of 3D hollow layered double hydroxide-molybdenum disulfide hybrid materials and their application in flame retardant thermoplastic polyurethane. Polymers. 2022;14:1506–22. https://doi.org/10.3390/polym14081506.

Song Q, Chen B, Zhou Z, Lu C. Flexible, stretchable and magnetic Fe3O4@Ti3C2Tx/elastomer with supramolecular interfacial crosslinking for enhancing mechanical and electromagnetic interference shielding performance. Sci China Mater. 2021;64:1437–48. https://doi.org/10.1007/s40843-020-1539-2.

Naguib M, Kurtoglu M, Presser V, Lu J, Niu J, Heon M, et al. Two-dimensional nanocrystals produced by exfoliation of Ti3 AlC2. Adv Mater. 2011;23:4248–53. https://doi.org/10.1002/adma.201102306.

Yan X, Fang J, Gu J, Zhu C, Qi D. Flame retardancy, thermal and mechanical properties of novel intumescent flame retardant/mXene/poly(vinyl alcohol) nanocomposites. Nanomaterials. 2022;12:477–94. https://doi.org/10.3390/nano12030477.

Yan Y, Wei Z. Ca2C MXene monolayer as a superior material for detection of toxic pnictogen hydrides. Mater Chem Phys. 2022;281:125869–74. https://doi.org/10.1016/j.matchemphys.2022.125869.

Luo Y, Xie Y, Geng W, Dai G, Sheng X, Xie D, et al. Fabrication of thermoplastic polyurethane with functionalized MXene towards high mechanical strength, flame-retardant, and smoke suppression properties. J Colloid Interface Sci. 2022;606:223–35. https://doi.org/10.1016/j.jcis.2021.08.025.

Chen X, Yu H, Gao Y, Wang L, Wang G. The marriage of two-dimensional materials and phase change materials for energy storage, conversion and applications. EnergyChem. 2022;4:100071–103. https://doi.org/10.1016/j.enchem.2022.100071.

Zhao Q, Wang B, Qin C, Li Q, Liu C, Shen C, et al. Nonisothermal melt and cold crystallization behaviors of biodegradable poly(lactic acid)/Ti3C2Tx MXene nanocomposites. J Therm Anal Calorim. 2021;147:2239–51. https://doi.org/10.1007/s10973-020-10502-7.

Shi Y, Liu C, Duan Z, Yu B, Liu M, Song P. Interface engineering of MXene towards super-tough and strong polymer nanocomposites with high ductility and excellent fire safety. Chem Eng J. 2020;399:125829–42. https://doi.org/10.1016/j.cej.2020.125829.

Liu C, Wu W, Shi Y, Yang F, Liu M, Chen Z, et al. Creating MXene/reduced graphene oxide hybrid towards highly fire safe thermoplastic polyurethane nanocomposites. Compos B. 2020;203:108486–99. https://doi.org/10.1016/j.compositesb.2020.108486.

Gong K, Zhou K, Qian X, Shi C, Yu B. MXene as emerging nanofillers for high-performance polymer composites: a review. Compos B. 2021;217:108867–906. https://doi.org/10.1016/j.compositesb.2021.108867.

Wan M, Shi C, Qian X, Qin Y, Jing J, Che H. Metal-organic framework ZIF-67 functionalized MXene for enhancing the fire safety of thermoplastic polyurethanes. Nanomaterials. 2022;12:1142–56. https://doi.org/10.3390/nano12071142.

Zhou K, Gong K, Wang C, Zhou M, Xiao J. Construction of Ti(3)C(2) MXene based fire resistance nanocoating on flexible polyurethane foam for highly efficient photothermal conversion and solar water desalination. J Colloid Interface Sci. 2023;630:343–54. https://doi.org/10.1016/j.jcis.2022.10.009.

Pan Y, Fu L, Zhou Q, Wen Z, Lin CT, Yu J, et al. Flammability, thermal stability and mechanical properties of polyvinyl alcohol nanocomposites reinforced with delaminated Ti3C2Tx (MXene). Polym Compos. 2019;41:210–8. https://doi.org/10.1002/pc.25361.

Zhu S-E, Wang F-D, Liu J-J, Wang L-L, Wang C, Yuen ACY, et al. BODIPY coated on MXene nanosheets for improving mechanical and fire safety properties of ABS resin. Compos B. 2021;223:109130–41. https://doi.org/10.1016/j.compositesb.2021.109130.

Yi Z, Yang J, Liu X, Mao L, Cui L, Liu Y. Enhanced mechanical properties of poly(lactic acid) composites with ultrathin nanosheets of MXene modified by stearic acid. J Appl Polym Sci. 2019;137:48621–8. https://doi.org/10.1002/app.48621.

Wondu E, Lule ZC, Kim J. Fabrication of high dielectric properties and higher thermal conductivity thermoplastic polyurethane composites with CNT-covered SrTiO3. Polym Test. 2022;110:107576–84. https://doi.org/10.1016/j.polymertesting.2022.107576.

Peng H, Wang D, Li M, Zhang L, Liu M, Fu S. N-P-Zn-containing 2D supermolecular networks grown on MoS2 nanosheets for mechanical and flame-retardant reinforcements of polyacrylonitrile fiber. Chem Eng J. 2019;372:873–85. https://doi.org/10.1016/j.cej.2019.04.209.

Shi C, Wan M, Hou Z, Qian X, Che H, Qin Y, et al. Co-MOF@MXene hybrids flame retardants for enhancing the fire safety of thermoplastic polyurethanes. Polym Degrad Stab. 2022;204:110119–29. https://doi.org/10.1016/j.polymdegradstab.2022.110119.

Luo Z, Zhang L, Liang Y, Wen S, Liu L. Improved the dielectric properties of thermoplastic polyurethane elastomer filled with MXene nanosheets and BaTiO3 nanofibers. Polym Test. 2022;111:107592–601. https://doi.org/10.1016/j.polymertesting.2022.107592.

Liu X, Yang J, Wang J, Zhang Y, Wu J, Yang F. MXene-modified silicone rubber composites with high thermal stability: Preparation and properties. Mater Lett. 2021;304:130639–42. https://doi.org/10.1016/j.matlet.2021.130639.

Wang H, Qiao H, Guo J, Sun J, Li H, Zhang S, et al. Preparation of cobalt-based metal organic framework and its application as synergistic flame retardant in thermoplastic polyurethane (TPU). Compos B. 2020;182:107498–508. https://doi.org/10.1016/j.compositesb.2019.107498.

Xu W, Cheng C, Qin Z, Zhong D, Cheng Z, Zhang Q. Improvement of thermoplastic polyurethane’s flame retardancy and thermal conductivity by leaf-shaped cobalt-zeolitic imidazolate framework—odified graphene and intumescent flame retardant. Polym Adv Technol. 2020;32:228–40. https://doi.org/10.1002/pat.5078.

Hu Q, Zou L, Liu Z, Chen J, Liu J, Liu X. Flame-retardant polyurethane elastomer based on aluminum salt of monomethylphosphinate. J Therm Anal Calorim. 2020;143:2953–61. https://doi.org/10.1007/s10973-020-09480-7.

Qian Y, Han H, Li L, Qiao P, Chang G. Flame retardancy and smoke suppression effect of bis(4-nitrophenyl) phosphate modified layered double hydroxides derived from red mud in thermoplastic polyurethanes. J Mater Cycles Waste Manage. 2020;22:1648–61. https://doi.org/10.1007/s10163-020-01055-w.

Wang J, Zhang D, Zhang Y, Cai W, Yao C, Hu Y, et al. Construction of multifunctional boron nitride nanosheet towards reducing toxic volatiles (CO and HCN) generation and fire hazard of thermoplastic polyurethane. J Hazard Mater. 2019;362:482–94. https://doi.org/10.1016/j.jhazmat.2018.09.009.

Li L, Qian Y, Jiao CM. Synergistic flame retardant effect of melamine in ethylene–vinyl acetate/layered double hydroxides composites. J Therm Anal Calorim. 2012;114:45–55. https://doi.org/10.1007/s10973-012-2808-2.

Yan X, Zhou W, Zhao X, Xu J, Liu P. Preparation, flame retardancy and thermal degradation behaviors of polyacrylonitrile fibers modified with diethylenetriamine and zinc ions. J Therm Anal Calorim. 2015;124:719–28. https://doi.org/10.1007/s10973-015-5180-1.

Hou Y, Liao C, Qiu S, Xu Z, Mu X, Gui Z, et al. Preparation of soybean root-like CNTs/bimetallic oxides hybrid to enhance fire safety and mechanical performance of thermoplastic polyurethane. Chem Eng J. 2022;428:132338–47. https://doi.org/10.1016/j.cej.2021.132338.

Zhou K, Gong K, Gao F, Yin L. Facile strategy to synthesize MXene@LDH nanohybrids for boosting the flame retardancy and smoke suppression properties of epoxy. Compos A. 2022;157:106912–23. https://doi.org/10.1016/j.compositesa.2022.106912.

Yin L, Gong K, Zhou K, Qian X, Shi C, Gui Z, et al. Flame-retardant activity of ternary integrated modified boron nitride nanosheets to epoxy resin. J Colloid Interface Sci. 2022;608:853–63. https://doi.org/10.1016/j.jcis.2021.10.056.

Luo J, Shi C, Yin L, Gong K, Qian X, Zhou K. Killing three birds with one stone: a novel regulate strategy for improving the fire safety of thermoplastic polyurethane. Compos A. 2023;168:107491–500. https://doi.org/10.1016/j.compositesa.2023.107491.

Liu C, Yang D, Sun M, Deng G, Jing B, Wang K, et al. Phosphorous-nitrogen flame retardants engineering MXene towards highly fire safe thermoplastic polyurethane. Compos Commun. 2022;29:101055–60. https://doi.org/10.1016/j.coco.2021.101055.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant No. 52173070). The authors thank Dr. Jianhang Lin and Dr. Liangjun Xu of Fujian College Association Instrumental Analysis Center for assisted analysis of SEM images and FTIR spectra, respectively.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nie, C., Yang, J., Deng, G. et al. Supermolecular assembly networks functionalized MXene toward fire-resistant thermoplastic polyurethane nanocomposites. J Therm Anal Calorim 148, 10051–10063 (2023). https://doi.org/10.1007/s10973-023-12366-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12366-z