Abstract

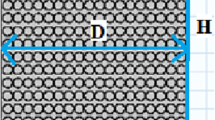

In the present numerical analysis, the influences of incorporating a central plate into the enclosure of a phase change material (PCM) on the solidification enhancement of a latent heat energy storage system are explored numerically. This study focuses mainly on determining the role of the central plate in enhancing the PCM discharging process. To evaluate the capability of the central plate in enhancing the PCM phase change process, various scenarios are considered in the present study. Firstly, the solidification performances of the states with no fin as well as uniform fins without the inserted central plate are compared with the discharging capability of the case equipped with the central plate. The liquid fraction as well as the PCM temperature contours are compared to assess the effectiveness of the central plate location on the PCM discharging mode, secondly. After the case with the best thermal performance is determined, the influences of adding the uniform fins and central plate into the PCM enclosure are investigated simultaneously. Then, the impacts of various configurations, namely the inline and staggered scenarios, on the PCM discharging phenomenon are analyzed in the central plate presence. As the last step, the effects of various PCMs on discharging mode of the thermal unit are studied to evaluate the PCM role in enhancing the discharging process. The numerical results reveal that the influences of the central plate incorporation on improving the solidification performance are greater than that of the melting case in the absence of the uniform fins. Time saving percentages of case VII (case with the central plate and uniform fins) compared to the no-fin case are 68.91, 71.02, and 74.84% for RT-35, RT-35HC, and n-eicosane, respectively. Furthermore, the case with RT-35HC as the PCM experienced the highest discharging rate compared to other cases.

Graphical abstract

Similar content being viewed by others

Abbreviations

- GA:

-

Genetic algorithm

- HTF:

-

Heat transfer fluid

- LHTESS:

-

Latent heat thermal energy storage system

- PCM:

-

Phase change material

- LTES:

-

Latent thermal energy storage

- TES:

-

Thermal energy storage

- A m :

-

Mushy zone constant

- C p (JKg− 1 K− 1):

-

Thermal energy storage

- \(d\) (mm):

-

Interior fin distance from the bottom plate

- \(g\) (ms− 2):

-

Gravity

- h (Jkg− 1):

-

Sensible enthalpy

- h ref (Jkg− 1):

-

Sensible enthalpy at reference temperature

- H (Jkg− 1):

-

Total enthalpy

- \(k\) (Wm− 1 K− 1):

-

Thermal conductivity

- \({L}_{\mathrm{f}}\) (Jkg− 1):

-

Latent heat of fusion

- \(m\) (kg):

-

Mass of PCM

- \(P\) (Pa):

-

Pressure

- \(Q\) (kJ):

-

Thermal energy storage capacity

- \(\dot{Q}\) (kJs− 1):

-

Heat storage rate

- t :

-

Time (s)

- \({t}_{\mathrm{s}}\) (s):

-

Solidification time

- \(T\) (K):

-

Temperature

- TDER:

-

Time-dependent enhancement ratio

- \({T}_{\mathrm{e}}\)(K):

-

End temperature

- \({T}_{\mathrm{i}}\)(K):

-

Initial temperature

- \({T}_{\mathrm{Liquidus}}\)(K):

-

Liquidus temperature

- \({T}_{\mathrm{ref}}\)(K):

-

Reference temperature

- \({T}_{\mathrm{Solidus}}\)(K):

-

Solidus temperature

- \(\overrightarrow{V}\) (m/s):

-

Velocity vector

- \(\beta \) (K− 1):

-

Thermal Expansion coefficient

- \(\lambda \) :

-

Liquid fraction

- \(\mu \) (kgm− 1 s− 1):

-

Viscosity

- \(\rho \) (kgm− 3):

-

Density

- \({\rho }_{\mathrm{ref}}\) (kgm− 3):

-

Density at reference temperature

- \(\Delta H\) (Jkg− 1):

-

PCM Latent heat

- l :

-

Liquid

- ref:

-

Reference

- s :

-

Solid

References

Martins F, Felgueiras C, Smitkova M, Caetano N. Analysis of fossil fuel energy consumption and environmental impacts in European Countries. Energies. 2019. https://doi.org/10.3390/en12060964.

Mozafari M, Lee A, Cheng S. A novel dual-PCM configuration to improve simultaneous energy storage and recovery in triplex-tube heat exchanger. Int J Heat Mass Transf. 2022;186:122420. https://doi.org/10.1016/j.ijheatmasstransfer.2021.122420.

Senthil R, Punniakodi BMS, Balasubramanian D, Nguyen XP, Hoang AT, Nguyen VN. Numerical investigation on melting and energy storage density enhancement of phase change material in a horizontal cylindrical container. Int J Energy Res. 2022;46:19138–58. https://doi.org/10.1002/er.8228.

Luo J, Zou D, Wang Y, Wang S, Huang L. Battery thermal management systems (BTMs) based on phase change material (PCM): a comprehensive review. Chem Eng J. 2022;430:132741. https://doi.org/10.1016/j.cej.2021.132741.

Yi F, Jiaqiang E, Zhang B, Zuo H, Wei K, Chen J, Zhu H, Zhu H, Deng Y. Effects analysis on heat dissipation characteristics of lithium-ion battery thermal management system under the synergism of phase change material and liquid cooling method. Renew Energy. 2022;181:472–89. https://doi.org/10.1016/j.renene.2021.09.073.

Subramanian M, Hoang AT, Kalidasan B, Nižetić S, Solomon JM, Balasubramanian D, Subramaniyan C, Thenmozhi G, Metghalchi H, Nguyen XP. A technical review on composite phase change material based secondary assisted battery thermal management system for electric vehicles. J Clean Prod. 2021;322:129079. https://doi.org/10.1016/j.jclepro.2021.129079.

Mozafari M, Lee A, Mohammadpour J. Thermal management of single and multiple PCMs based heat sinks for electronics cooling. Therm Sci Eng Prog. 2021;23:100919. https://doi.org/10.1016/j.tsep.2021.100919.

Mozafari M, Lee A, Cheng S. Improvement on the cyclic thermal shock resistance of the electronics heat sinks using two-objective optimization. J Energy Storage. 2022;46:103923. https://doi.org/10.1016/j.est.2021.103923.

Velmurugan K, Karthikeyan V, Sharma K, Korukonda TB, Kannan V, Balasubramanian D, Wongwuttanasatian T. Contactless phase change material based photovoltaic module cooling: a statistical approach by clustering and correlation algorithm. J Energy Storage. 2022;53:105139. https://doi.org/10.1016/j.est.2022.105139.

Faizan M, Ahmed R, Ali HM. A critical review on thermophysical and electrochemical properties of Ionanofluids (nanoparticles dispersed in ionic liquids) and their applications. J Taiwan Inst Chem Eng. 2021;124:391–423. https://doi.org/10.1016/j.jtice.2021.02.004.

Mourad A, Aissa A, Mebarek-Oudina F, Jamshed W, Ahmed W, Ali HM, Rashad AM. Galerkin finite element analysis of thermal aspects of Fe3O4-MWCNT/water hybrid nanofluid filled in wavy enclosure with uniform magnetic field effect. Int Commun Heat Mass Transf. 2021;126:105461. https://doi.org/10.1016/j.icheatmasstransfer.2021.105461.

Saleem M, Algahtani A, Rehman SU, Javed MS, Irshad K, Ali HM, Malik MZ, Ali A, Tirth V, Islam S. Solution processed Zn1−x−ySmxCuyO nanorod arrays for dye sensitized solar cells. Nanomaterials. 2021. https://doi.org/10.3390/nano11071710.

Ali A, Al-Sulaiman FA, Al-Duais INA, Irshad K, Malik MZ, Shafiullah M, Zahir MH, Ali HM, Malik SA. Renewable portfolio standard development assessment in the Kingdom of Saudi Arabia from the perspective of policy networks theory. Processes. 2021. https://doi.org/10.3390/pr9071123.

Jeon J, Lee J-H, Seo J, Jeong S-G, Kim S. Erratum to: Application of PCM thermal energy storage system to reduce building energy consumption. J Therm Anal Calorim. 2014;116:539. https://doi.org/10.1007/s10973-012-2408-1.

Refahi A, Rostami A, Amani M. Energy analysis of the building integrated with a double PCM wallboard system in various climate regions of Iran. J Therm Anal Calorim. 2023. https://doi.org/10.1007/s10973-023-11999-4.

Dileep K, Arun KR, Dishnu D, Srinivas M, Jayaraj S. Numerical studies on the effect of location and number of containers on the phase transition of PCM-integrated evacuated tube solar water heater. J Therm Anal Calorim. 2021;143:737–49. https://doi.org/10.1007/s10973-019-09151-2.

Krupakaran RL, Palampalle B, Balasubramanian D, Reddy GV (2020) Influence of Titanium Oxide Nanoparticle on Solar Desalination with Phase Change Material. https://doi.org/10.4271/2020-28-0464

Alkan C, Sarı A, Karaipekli A, Uzun O. Preparation, characterization, and thermal properties of microencapsulated phase change material for thermal energy storage. Sol Energy Mater Sol Cells. 2009;93:143–7. https://doi.org/10.1016/j.solmat.2008.09.009.

Zauner C, Hengstberger F, Etzel M, Lager D, Hofmann R, Walter H. Experimental characterization and simulation of a fin-tube latent heat storage using high density polyethylene as PCM. Appl Energy. 2016;179:237–46. https://doi.org/10.1016/j.apenergy.2016.06.138.

Sharifi N, Bergman TL, Allen MJ, Faghri A. Melting and solidification enhancement using a combined heat pipe, foil approach. Int J Heat Mass Transf. 2014;78:930–41. https://doi.org/10.1016/j.ijheatmasstransfer.2014.07.054.

Mahdi JM, Nsofor EC. Solidification enhancement of PCM in a triplex-tube thermal energy storage system with nanoparticles and fins. Appl Energy. 2018;211:975–86. https://doi.org/10.1016/j.apenergy.2017.11.082.

Nada SA, El-Nagar DH, Hussein HMS. Improving the thermal regulation and efficiency enhancement of PCM-Integrated PV modules using nano particles. Energy Convers Manag. 2018;166:735–43. https://doi.org/10.1016/j.enconman.2018.04.035.

Nada SA, Alshaer WG. Experimental investigation of thermal conductivity enhancement of carbon foam saturated with PCM and PCM/MWCNTs composite for energy storage systems. Heat Mass Transf. 2019;55:2667–77. https://doi.org/10.1007/s00231-019-02610-4.

Kandelousi MS. Effect of spatially variable magnetic field on ferrofluid flow and heat transfer considering constant heat flux boundary condition. Eur Phys J Plus. 2014;129:248. https://doi.org/10.1140/epjp/i2014-14248-2.

Rashid FL, Rahbari A, Ibrahem RK, Talebizadehsardari P, Basem A, Kaood A, Mohammed HI, Abbas MH, Al-Obaidi MA. Review of solidification and melting performance of phase change materials in the presence of magnetic field, rotation, tilt angle, and vibration. J Energy Storage. 2023;67:107501. https://doi.org/10.1016/j.est.2023.107501.

Gürtürk M, Kok B. A new approach in the design of heat transfer fin for melting and solidification of PCM. Int J Heat Mass Transf. 2020;153:119671. https://doi.org/10.1016/j.ijheatmasstransfer.2020.119671.

Nie C, Deng S, Liu J. Effects of fins arrangement and parameters on the consecutive melting and solidification of PCM in a latent heat storage unit. J Energy Storage. 2020;29:101319. https://doi.org/10.1016/j.est.2020.101319.

Oliveski RDC, de Quadro Tacques Filho A, Schröer IA. Melting and solidification in thermal storage: influence of fin aspect ratio and positioning in a full charging and discharging cycle. J Energy Storage. 2022;50:104303. https://doi.org/10.1016/j.est.2022.104303.

Shukla A, Kant K, Biwole PH, Pitchumani R, Sharma A. Melting and solidification of a phase change material with constructal tree-shaped fins for thermal energy storage. J Energy Storage. 2022;53:105158. https://doi.org/10.1016/j.est.2022.105158.

Iranmanesh A. Intensifying the melting process of a triple-tube latent heat energy storage unit via inserting a middle plate into the phase change material container. J Energy Storage. 2022;56:105982. https://doi.org/10.1016/j.est.2022.105982.

Zheng Z-J, Cai X, Yang C, Xu Y. Improving the solidification performance of a latent heat thermal energy storage unit using arrow-shaped fins obtained by an innovative fast optimization algorithm. Renew Energy. 2022;195:566–77. https://doi.org/10.1016/j.renene.2022.06.031.

Sarani I, Payan S, Nada SA, Payan A. Numerical investigation of an innovative discontinuous distribution of fins for solidification rate enhancement in PCM with and without nanoparticles. Appl Therm Eng. 2020;176:115017. https://doi.org/10.1016/j.applthermaleng.2020.115017.

Alizadeh M, Nabizadeh A, Fazlollahtabar A, Ganji DD. An optimization study of solidification procedure in a wavy- wall storage unit considering the impacts of NEPCM and curved fin. Int Commun Heat Mass Transf. 2021;124:105249. https://doi.org/10.1016/j.icheatmasstransfer.2021.105249.

Mozafari M, Hooman K, Lee A, Cheng S. Numerical study of a dual-PCM thermal energy storage unit with an optimized low-volume fin structure. Appl Therm Eng. 2022;215:119026. https://doi.org/10.1016/j.applthermaleng.2022.119026.

Ravi R, Rajasekaran K. Experimental study of solidification of paraffin wax in solar based triple concentric tube thermal energy storage system. Therm Sci. 2018;22:973–8.

GmbH RT, RT35 data sheet, (n.d.).

Benbrika M, Teggar M, Benbelhout M, Ismail KAR. Numerical study of n-eicosane melting inside a horizontal cylinder for different loading rates. J Homepage Http//Iieta Org/Journals/Ijht. 2020;38:125–30.

Arshad A, Jabbal M, Faraji H, Talebizadehsardari P, Bashir MA, Yan Y. Thermal performance of a phase change material-based heat sink in presence of nanoparticles and metal-foam to enhance cooling performance of electronics. J Energy Storage. 2022;48:103882. https://doi.org/10.1016/j.est.2021.103882.

Talebizadeh Sardari P, Walker GS, Gillott M, Grant D, Giddings D. Numerical modelling of phase change material melting process embedded in porous media: Effect of heat storage size. Proc Inst Mech Eng Part A J Power Energy. 2019;234:365–83. https://doi.org/10.1177/0957650919862974.

Mahdi JM, Nsofor EC. Melting enhancement in triplex-tube latent heat energy storage system using nanoparticles-metal foam combination. Appl Energy. 2017;191:22–34. https://doi.org/10.1016/j.apenergy.2016.11.036.

Shahsavar A, Khosravi J, Mohammed HI, Talebizadehsardari P. Performance evaluation of melting/solidification mechanism in a variable wave-length wavy channel double-tube latent heat storage system. J Energy Storage. 2020;27:101063. https://doi.org/10.1016/j.est.2019.101063.

Shahsavar A, Shaham A, Talebizadehsardari P. Wavy channels triple-tube LHS unit with sinusoidal variable wavelength in charging/discharging mechanism. Int Commun Heat Mass Transf. 2019;107:93–105. https://doi.org/10.1016/j.icheatmasstransfer.2019.05.012.

El Idi MM, Karkri M. Heating and cooling conditions effects on the kinetic of phase change of PCM embedded in metal foam. Case Stud Therm Eng. 2020;21:100716. https://doi.org/10.1016/j.csite.2020.100716.

Esapour M, Hamzehnezhad A, Rabienataj Darzi AA, Jourabian M. Melting and solidification of PCM embedded in porous metal foam in horizontal multi-tube heat storage system. Energy Convers Manag. 2018;171:398–410. https://doi.org/10.1016/j.enconman.2018.05.086.

Shahsavar A, Majidzadeh AH, Mahani RB, Talebizadehsardari P. Entropy and thermal performance analysis of PCM melting and solidification mechanisms in a wavy channel triplex-tube heat exchanger. Renew Energy. 2021;165:52–72. https://doi.org/10.1016/j.renene.2020.11.074.

Chiew J, Chin CS, Toh WD, Gao Z, Jia J. Thermal state-of-expansion or melting of phase change material based heat sink for underwater battery power system. J Energy Storage. 2019;26:100956. https://doi.org/10.1016/j.est.2019.100956.

Hasan A, Sarwar J, Alnoman H, Abdelbaqi S. Yearly energy performance of a photovoltaic-phase change material (PV-PCM) system in hot climate. Sol Energy. 2017;146:417–29. https://doi.org/10.1016/j.solener.2017.01.070.

Elmozughi AF, Solomon L, Oztekin A, Neti S. Encapsulated phase change material for high temperature thermal energy storage–Heat transfer analysis. Int J Heat Mass Transf. 2014;78:1135–44. https://doi.org/10.1016/j.ijheatmasstransfer.2014.07.087.

Wang P, Wang X, Huang Y, Li C, Peng Z, Ding Y. Thermal energy charging behaviour of a heat exchange device with a zigzag plate configuration containing multi-phase-change-materials (m-PCMs). Appl Energy. 2015;142:328–36. https://doi.org/10.1016/j.apenergy.2014.12.050.

Ye W-B, Zhu D-S, Wang N. Numerical simulation on phase-change thermal storage/release in a plate-fin unit. Appl Therm Eng. 2011;31:3871–84. https://doi.org/10.1016/j.applthermaleng.2011.07.035.

Mahdi JM, Nsofor EC. Melting enhancement in triplex-tube latent thermal energy storage system using nanoparticles-fins combination. Int J Heat Mass Transf. 2017;109:417–27. https://doi.org/10.1016/j.ijheatmasstransfer.2017.02.016.

Al-Abidi AA, Mat S, Sopian K, Sulaiman MY, Mohammad AT. Experimental study of melting and solidification of PCM in a triplex tube heat exchanger with fins. Energy Build. 2014;68:33–41. https://doi.org/10.1016/j.enbuild.2013.09.007.

Mat S, Al-Abidi AA, Sopian K, Sulaiman MY, Mohammad AT. Enhance heat transfer for PCM melting in triplex tube with internal–external fins. Energy Convers Manag. 2013;74:223–36. https://doi.org/10.1016/j.enconman.2013.05.003.

Shahsavar A, Ali HM, Mahani RB, Talebizadehsardari P. Numerical study of melting and solidification in a wavy double-pipe latent heat thermal energy storage system. J Therm Anal Calorim. 2020;141:1785–99. https://doi.org/10.1007/s10973-020-09864-9.

Chen K, Mohammed HI, Mahdi JM, Rahbari A, Cairns A, Talebizadehsardari P. Effects of non-uniform fin arrangement and size on the thermal response of a vertical latent heat triple-tube heat exchanger. J Energy Storage. 2022;45:103723. https://doi.org/10.1016/j.est.2021.103723.

Sun X, Mohammed HI, Tiji ME, Mahdi JM, Majdi HS, Wang Z, Talebizadehsardari P, Yaïci W. Investigation of heat transfer enhancement in a triple tube latent heat storage system using circular fins with inline and staggered arrangements. Nanomater. 2021. https://doi.org/10.3390/nano11102647.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Iranmanesh, A. Numerical study on discharging process of a latent heat triple-tube heat exchanger in the presence of a central plate using the enthalpy–porosity approach. J Therm Anal Calorim 148, 9673–9699 (2023). https://doi.org/10.1007/s10973-023-12341-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12341-8