Abstract

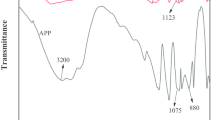

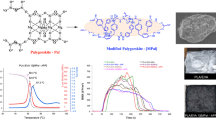

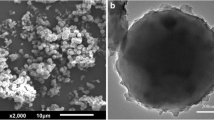

Bio-based flame retardant is highly desirable given today’s increasing environmentally friendly demand. In this article, a bio-based microencapsulated flame retardant SA@(MA/OPC) was prepared. Fourier transform infrared spectra (FTIR), scanning electron microscopy (SEM) and energy-dispersive X-ray spectrometry (EDS) analysis confirmed the effective encapsulation of melamine (MA) and orange peel charcoal (OPC) in sodium alginate (SA). EP/SA@(MA/OPC) composites were prepared by adding SA@(MA/OPC) into epoxy resin (EP). For comparison, EP/(SA/MA/OPC) composites were also prepared by adding unmicroencapsulated mixture SA/MA/OPC into epoxy resin (EP). Thermal stability and combustion behaviors of EP/SA@(MA/OPC) and EP/(SA/MA/OPC) were characterized by thermogravimetric analysis/infrared spectrometry (TG–FTIR), limited oxygen index (LOI), vertical burning test (UL-94), cone calorimeter test and SEM, respectively. The results showed that the peak heat release rate (PHRR), total heat release (THR) and total smoke production (TSP) of EP/SA@(MA/OPC) decreased by 74.2%, 22.0% and 24.7%, respectively, compared to pure EP. The PHRR, THR and TSP of EP/(SA/MA/OPC) were higher than that of EP/SA@(MA/OPC), which indicated that microencapsulated SA@(MA/OPC) had a better flame retardancy than blending SA, MA and OPC with EP. Finally, the flame-retardant mechanism of EP/SA@(MA/OPC) was presented. This work provides a new attempt to build EP composites with bio-based flame retardants.

Similar content being viewed by others

References

Jin FL, Li X, Park SJ. Synthesis and application of epoxy resins: a review. J Ind Eng Chem. 2015;29:1–11.

Gu H, Guo J, He Q, Tadakamalla S, Zhang X, Yan X, et al. Flame-retardant epoxy resin nanocomposites reinforced with polyaniline-stabilized silica nanoparticles. Ind Eng Chem Res. 2013;52(23):7718–28.

Miao J, Yuan L, Guan Q, Liang G, Gu A. Biobased heat resistant epoxy resin with extremely high biomass content from 2,5-furandicarboxylic acid and eugenol. ACS Sustain Chem Eng. 2017;5(8):7003–11.

Liu LB, Xu Y, Xu MJ, Li ZQ, Hu YM, Li B. Economical and facile synthesis of a highly efficient flame retardant for simultaneous improvement of fire retardancy, smoke suppression and moisture resistance of epoxy resins. Compos B. 2019;167:422–33.

You GY, Cheng ZQ, Tang YY, He HW. Functional group effect on char formation, flame retardancy and mechanical properties of phosphonate-triazine-based compound as flame retardant in epoxy resin. Ind Eng Chem Res. 2015;54(30):7309–19.

Salasinska K, Celiński M, Mizera K, Kozikowski P, Leszczyński MK, Gajek A. Synergistic effect between histidine phosphate complex and hazelnut shell for flammability reduction of low-smoke emission epoxy resin. Polym Degrad Stab. 2020;181:109292.

Wu K, Hu Y, Song L, Lu HD, Wang ZZ. Flame retardancy and thermal degradation of intumescent flame retardant starch-based biodegradable composites. Ind Eng Chem Res. 2009;48(6):3150–7.

Huo SQ, Song PA, Yu B, Ran SY, Chevali VS, Liu L, et al. Phosphorus-containing flame retardant epoxy thermosets: recent advances and future perspectives. Prog Polym Sci. 2021;114:101366.

Alongi J, Han ZD, Bourbigot S. Intumescence: tradition versus novelty. A comprehensive review. Prog Polym Sci. 2015;51:28–73.

Zhang F, Wang Y, Li SX, Zhang J. Influence of thermophysical properties on burning behavior of intumescent fire-retardant materials. J Therm Anal Calorim. 2012;113(2):803–10.

Neisius NM, Lutz M, Rentsch D, Hemberger P, Gaan S. Synthesis of DOPO-based phosphonamidates and their thermal properties. Ind Eng Chem Res. 2014;53(8):2889–96.

Velencoso MM, Battig A, Markwart JC, Schartel B, Wurm FR. Molecular firefighting-how modern phosphorus chemistry can help solve the challenge of flame retardancy. Angew Chem Int Ed. 2018;57(33):10450–67.

Yew MC, Sulong NHR, Yew MK, Amalina MA, Johan MR. Fire propagation performance of intumescent fire protective coatings using eggshells as a novel biofiller. Sci World J. 2014.

Chen S, Wu FY, Hu Y, Lin SC, Yu CC, Zhu F, et al. A fully bio-based intumescent flame retardant for poly(butylene succinate). Mater Chem Phys. 2020;252:123222.

Chen PF, Zhang F, Li SX, Cheng YF. Smoke suppression properties of epoxy crosslinked structure and intumescent fire retardant in epoxy-based intumescent fire-retardant coating. J Appl Polym Sci. 2016;133(36).

Gérard C, Fontaine G, Bourbigot S. Synergistic and antagonistic effects in flame retardancy of an intumescent epoxy resin. Polym Adv Technol. 2011;22(7):1085–90.

Yang L, Chen H, Jia SK, Lu X, Huang JT, Yu XX, et al. Influences of ethylene-butylacrylate-glycidyl methacrylate on morphology and mechanical properties of poly(butylene terephthalate)/polyolefin elastomer blends. J Appl Polym Sci. 2014;131(16).

Wang BB, Qian XD, Shi YQ, Yu B, Hong NN, Song L, et al. Cyclodextrin microencapsulated ammonium polyphosphate: preparation and its performance on the thermal, flame retardancy and mechanical properties of ethylene vinyl acetate copolymer. Compos B. 2015;69:22–30.

Thanh TTN, Decsov KE, Bocz K, Marosi G, Szolnoki B. Development of intumescent flame retardant for polypropylene: bio-epoxy resin microencapsulated ammonium-polyphosphate. Period Polytech-Chem. 2022;66(2):313–24.

Fanelli F, Mastrangelo AM, Fracassi F. Aerosol-assisted atmospheric cold plasma deposition and characterization of superhydrophobic organic-inorganic nanocomposite thin films. Langmuir. 2014;30(3):857–65.

Xing YL, Li YQ, Lin ZJ, Ma X, Qu H, Fan RL. Synthesis and characterization of bio-based intumescent flame retardant and its application in polyurethane. Fire Mater. 2020;44(6):814–24.

Sienkiewicz A, Czub P. Flame retardancy of biobased composites-research development. Materials. 2020;13(22):5253.

Hobbs CE. Recent advances in bio-based flame retardant additives for synthetic polymeric materials. Polymers-Basel. 2019;11(2):224.

Chang BP, Thakur S, Mohanty AK, Misra M. Novel sustainable biobased flame retardant from functionalized vegetable oil for enhanced flame retardancy of engineering plastic. Sci Rep. 2019;9:15971.

Ye GF, Huo SQ, Wang C, Shi Q, Liu ZT, Wang H. One-step and green synthesis of a bio-based high-efficiency flame retardant for poly (lactic acid). Polym Degrad Stab. 2021;192:109696.

Wang D, Wang Y, Li T, Zhang S, Ma P, Shi D, et al. A bio-based flame-retardant starch based on phytic acid. ACS Sustain Chem Eng. 2020;8(27):10265–74.

Yang HT, Yu B, Xu XD, Bourbigot S, Wang H, Song PA. Lignin-derived bio-based flame retardants toward high-performance sustainable polymeric materials. Green Chem. 2020;22(7):2129–61.

Jiang D, Pan MZ, Cai X, Zhao YT. Flame retardancy of rice straw-polyethylene composites affected by in situ polymerization of ammonium polyphosphate/silica. Compos A. 2018;109:1–9.

Hidalgo J, Fernández-Blázquez JP, Jiménez-Morales A, Barriere T, Gelin JC, Torralba JM. Effect of the particle size and solids volume fraction on the thermal degradation behaviour of Invar 36 feedstocks. Polym Degrad Stab. 2013;98(12):2546–55.

Shi XH, Chen L, Liu BW, Long JW, Xu YJ, Wang YZ. Carbon fibers decorated by polyelectrolyte complexes toward their epoxy resin composites with high fire safety. Chin J Polym Sci. 2018;36(12):1375–84.

Battegazzore D, Bocchini S, Alongi J, Frache A. Rice husk as bio-source of silica: preparation and characterization of PLA-silica bio-composites. RSC Adv. 2014;4(97):54703–12.

Nabipour H, Wang X, Song L, Hu Y. A fully bio-based coating made from alginate, chitosan and hydroxyapatite for protecting flexible polyurethane foam from fire. Carbohydr Polym. 2020;246:116641.

Liu C, Li P, Xu YJ, Liu Y, Zhu P. Nickel alginate-enhanced fire safety of aluminum diethylphosphinate on epoxy resin. J Appl Polym Sci. 2023;140(9):e53552.

Liu C, Li P, Xu YJ, Liu Y, Zhu P, Wang YZ. Epoxy/iron alginate composites with improved fire resistance, smoke suppression and mechanical properties. J Mater Sci. 2022;57(4):2567–83.

Jiang WJ, Zhou G, Wang CM, Xue YF, Niu CX. Synthesis and self-healing properties of composite microcapsule based on sodium alginate/melamine-phenol-formaldehyde resin. Constr Build Mater. 2021;271:121541.

Vincent T, Vincent C, Dumazert L, Otazaghine B, Sonnier R, Guibal E. Fire behavior of innovative alginate foams. Carbohydr Polym. 2020;250:116910.

Meng H, Nie CY, Li WL, Duan XG, Lai B, Ao ZM, et al. Insight into the effect of lignocellulosic biomass source on the performance of biochar as persulfate activator for aqueous organic pollutants remediation: epicarp and mesocarp of citrus peels as examples. J Hazard Mater. 2020;399:123043.

Xin Z, Sun SQ, Huang QH. Identification of pericarpium citri reticulatae from different years using ftir. Spectrosc Spect Anal. 2008;28(1):72–4.

Sun ZJ, Wong R, Liu YF, Yu M, Liu JX, Spence D, et al. Melamine-graphene epoxy nanocomposite based die attach films for advanced 3D semiconductor packaging applications. Nanoscale. 2022;14(40):15193–202.

Liu C, Li P, Xu YJ, Liu Y, Zhu P. Synergistic effects of iron alginate on improving the fire safety and mechanical properties of epoxy resin/ammonium polyphosphate composites. Macromol Mater Eng. 2022;308(3):2200516.

Luo H, Zhou F, Yang YY, Cao XL, Cai XF. Synergistic flame-retardant behavior and mechanism of tris(3-nitrophenyl) phosphine and DOPO in epoxy resins. J Therm Anal Calorim. 2018;132(1):483–91.

Mohtadizadeh F, Zohuriaan-Mehr MJ, Hadavand BS, Dehghan A. Tetra-functional epoxy-acrylate as crosslinker for UV curable resins: synthesis, spectral, and thermo-mechanical studies. Prog Org Coat. 2015;89:231–9.

Shao ZB, Cui J, Li XL, Palencia JLD, Wang DY. Chemically inorganic modified ammonium polyphosphate as eco-friendly flame retardant and its high fire safety for epoxy resin. Compos Commun. 2021;28:100959.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 21975138).

Author information

Authors and Affiliations

Contributions

JR was involved in investigation, methodology, formal analysis and writing—original draft; FZ participated in supervision, resources, writing—reviewing and editing, formal analysis and funding acquisition; FJ, YB, JY, XL and SL contributed to investigation, software and validation; and YC were responsible for methodology and resources.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ren, J., Jin, F., Bao, Y. et al. Microcapsule preparation of melamine and orange peel charcoal encapsulated by sodium alginate and its effect on combustion performance of epoxy resins. J Therm Anal Calorim 148, 9489–9500 (2023). https://doi.org/10.1007/s10973-023-12338-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12338-3