Abstract

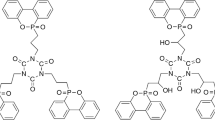

Thermoplastic polyurethane elastomer (TPU) is a kind of multipurpose engineering thermoplastic, with high strength, high toughness, wear resistance and other excellent properties. However, the flammability and droplet properties of TPU limit its application, so it is very important to improve the flame retardancy of TPU. In general, flame retardants are mixed directly into TPU material to improve its flame retardancy. However, this will greatly reduce the mechanical properties of TPU itself, because of the poor compatibility between the flame retardant and the substrate. This work improved the flame retardancy of TPU by using a bio-based intumescent flame retardant (PAMAD). In order to improve the compatibility between PAMAD and TPU, PAMAD was modified by in situ polymerization and bio-based flame retardant microcapsule (POPM) was prepared. Then, POPM was added to TPU by melt blending to prepare flame retardant TPU composites (PTPU). A layer of intrinsically flame retardant polyurethane molecular chain segment on the surface of POPM can form hydrogen bonds with TPU molecules, which was conducive to enhancing the compatibility between them. When the POPM-5 content was 30 mass%, the residual carbon rate of PTPU30 was 27%, and the limiting oxygen index (LOI) value was 32.7%, reaching the vertical burning test (UL-94) V-0 level. Compared with pure TPU, peak heat release rate (PHRR), peak total heat release (THR) and peak total smoke emission (TSR) decreased by 71.0%, 51.4% and 70.7%, respectively. At the same time, the release rate of CO and CO2 decreased significantly.

Similar content being viewed by others

References

Xu W, Xu B, Wang G, Wang X, Liu L. Synergistic effect of expandable graphite and α-type zirconium phosphate on flame retardancy of polyurethane elastomer. J Appl Polym Sci. 2017;134(32):45188.

Chen X, Wang W, Jiao C. para-Aramid fiber modified by melamine polyphosphate and its flame retardancy on thermoplastic polyurethane elastomer. RSC Adv. 2017;7(84):53172–80.

Wei Z, Chen X, Jiao C. Thermal degradation and flame retardancy of fumaric acid in thermoplastic polyurethane elastomer. Polym Adv Technol. 2019;30(2):475–82.

Hu X, Yang H, Jiang Y, He H, Liu H, Huang H, Wan C. Facile synthesis of a novel transparent hyperbranched phosphorous/nitrogen-containing flame retardant and its application in reducing the fire hazard of epoxy resin. J Hazard Mater. 2019;379: 120793.

Wang X. Research development of environment friendly fire retardant. Chem Eng J. 2006;020(003):33–5.

Ai L, Chen S, Yang L, Liu P. Synergistic flame retardant effect of organic boron flame retardant and aluminum hydroxide on polyethylene. Fiber Polym. 2021;22(2):354–65.

Shang S, Yuan B, Sun Y, Chen G, Huang C, Yu B, He S, Dai H, Chen X. Facile preparation of layered melamine-phytate flame retardant via supramolecular self-assembly technology. J Colloid Interface Sci. 2019;553:364–71.

Zhang L, Xue W, Gu L. Study on properties and application of pyrophosphate flame retardant microcapsules prepared from hemicellulose maleate. Cellulose. 2020;27(7):3931–46.

Ye G, Huo S, Wang C, Shi Q, Liu Z, Wang H. One-step and green synthesis of a bio-based high-efficiency flame retardant for poly (lactic acid). Polym Degrada Stab. 2021;192: 109696.

Yang Y, Wang D, Haurie L, Liu Z, Zhang L. Combination of corn pith fiber and biobased flame retardant: a novel method toward flame retardancy, thermal stability, and mechanical properties of polylactide. Polymers. 2021;13(10):1562.

Gu L, Shi Y, Zhang L. Synthesis and characterization of bio-based “three sources in one” intumescent flame retardant monomer and the intrinsic flame retardant waterborne polyurethane. J Polym Res. 2022;29(5):189.

Cui Q, Cao L, Yang H. The preparation and sustained release of thiamethoxam wrapped by urea-formaldehyde resin. Hubei Agri Sci. 2016;55(22):5830–4.

Gu L, Luo Y. Flame retardancy and thermal decomposition of phosphorus-containing waterborne polyurethanes modified by halogen-free flame retardants. Ind Eng Chem Res. 2015;54(9):2431–8.

Gu L, Ge Z, Huang M, Luo Y. Halogen-free flame-retardant waterborne polyurethane with a novel cyclic structure of phosphorus−nitrogen synergistic flame retardant. J Appl Polym Sci. 2015;132(3):765.

Gu L, Luo Y. Synthesis and performance of soft segment and hard segment co-modified waterborne polyurethanes. Polym Mater Sci Eng. 2015;31(8):1–5.

Huang S, Deng C, Wang S, Wei W, Chen H, Wang Y. Electrostatic action induced interfacial accumulation of layered double hydroxides towards highly efficient flame retardance and mechanical enhancement of thermoplastic polyurethane/ammonium polyphosphate. Polym Degrad Stab. 2019;165:126–36.

Lei W, Pei H, Fang C, Zhou X, Zhang X, Pu M. Influence of nanocrystalline cellulose extracted from different precursors on properties of polyurethane elastomer composites. Compos Sci Technol. 2022;218: 109159.

Yan J, Xu P, Zhang P, Fan H. Surface-modified ammonium polyphosphate for flame-retardant and reinforced polyurethane composites. Colloid Surf A. 2021;626:127092–103.

Zhang T, Yuan Y, Cui X, Yin H, Gu J, Huang H, Shu J. Impact of side-chain length on the phase structures of P3ATs and P3AT:PCBM films as revealed by SSNMR and FTIR. J Polym Sci Polym Phys. 2018;56(9):751–61.

Lu R, Wang J, Li YM, Xu KZ, Zheng XY. Influencing factors of encapsulating rate of melamine-formaldehyde resin microcapsule phase change material. Chem Eng. 2011;39(12):26–2146.

Ni J, Lei S, Yuan H, Ping Z, Xing W. Preparation and characterization of microencapsulated ammonium polyphosphate with polyurethane shell by in situ polymerization and its flame retardance in polyurethane. Polym Adv Technol. 2009;20(12):999–1005.

Yang Y, Jiang H, Zhang B, Liu X, Wang H, Liu X, Tang G. Preparation and properties of flame retardant rigid polyurethane foam composites based on microencapsulated ammonium polyphosphate and microencapsulated expanded graphite. Acta Materiae Compos Sinica. 2021;38(5):1387–94.

Liu X, Sun J, Zhang S, Guo J, Tang W, Li H, Gu X. Effects of carboxymethyl chitosan microencapsulated melamine polyphosphate on the flame retardancy and water resistance of thermoplastic polyurethane. Polym Degrad Stabil. 2019;160:168–76.

Tang G, Zhou Z, Wang H, Chen J, Liu C. Preparation and flame retardant properties of Al(H2PO2)3/thermoplastic polyurethane composites. Fuhe Cailiao Xuebao/Acta Materiae Compos Sinica. 2018;35(9):2414–23.

Chen X, Huo L, Liu J, Jiao C, Li S, Qian Y. Combustion properties and pyrolysis kinetics of flame-retardant polyurethane elastomers. J Thermoplast Compos. 2015;30(2):255–72.

Liu W, Chen W, Dong H, Piao J, Ren J, Wang Y, Wang Y, Feng T, Jiao C, Chen X. Covalent synthesis of 3-chloropropyltrimethoxysilane onto para-aramid nanofibers for TPU composites: flame retardancy, toxicity reduction, and mechanical property. Mater Today Commun. 2022;31: 103355.

Chen C, Zhao X, Shi C, Chen J. Synergistic effect between carbon nanoparticle and intumescent flame retardant on flammability and smoke suppression of copolymer thermoplastic polyurethane. J Mater Sci. 2018;53(8):6053–64.

Bian XC, Tang JH, Li ZM. Flame retardancy of hollow glass microsphere/rigid polyurethane foams in the presence of expandable graphite. J Appl Polym Sci. 2008;109(3):1935–43.

Zhu H, Xu S. Preparation of flame-retardant rigid polyurethane foams by combining modified melamine-formaldehyde resin and phosphorus flame retardants. ACS Omega. 2020;5(17):9658–67.

Chen X, Wang W, Jiao C. A recycled environmental friendly flame retardant by modifying para-aramid fiber with phosphorus acid for thermoplastic polyurethane elastomer. J Hazard Mater. 2017;331:257–64.

Feng L, Wang W, Song B, Zhu X, Wang L, Shao R, Li T, Pei X, Wang L, Qian X, Xu Z. Synthesis of P, N and Si-containing waterborne polyurethane with excellent flame retardant, alkali resistance and flexibility via one-step synthetic approach. Prog Org Coat. 2023;174: 107286.

Zhang S, Tang W, Jia G, Jin X, Li H, Gu X, Sun J. Improvement of flame retardancy and thermal stability of polypropylene by P-type hydrated silica aluminate containing lanthanum. Polym Degrad Stabil. 2018;154:276–84.

Zhang S, Liu X, Jin X, Li H, Sun J, Gu X. The novel application of chitosan: effects of cross-linked chitosan on the fire performance of thermoplastic polyurethane. Carbohydr Polym. 2018;189:313–21.

Zheng Z, Qiang L, Yang T, Wang B, Cui X, Wang H. Preparation of microencapsulated ammonium polyphosphate with carbon source- and blowing agent-containing shell and its flame retardance in polypropylene. J Polym Res. 2014;21(5):1–15.

Acknowledgements

This research did not receive any specific grant from funding agencies in the public, commercial or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

All authors have read and approved this version of the article, and due care has been taken to ensure the integrity of the work. The manuscript has not been previously published, is not currently submitted for review to any other journal, and will not be submitted elsewhere before a decision is made by this journal. LG was main and first author contributed to conceptualization, methodology and writing—original draft. YS contributed to investigation, writing—original draft and formal analysis. LZ contributed to writing—review and editing and project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gu, L., Shi, Y. & Zhang, L. Study on surface modification and properties of bio-based intumescent flame retardant. J Therm Anal Calorim 148, 9519–9535 (2023). https://doi.org/10.1007/s10973-023-12323-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12323-w