Abstract

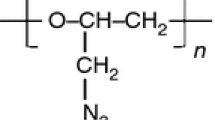

Azide polymers are currently a major research hotspot in the field of energetic materials, with the advantages of high energy, low sensitivity and good thermal stability. A series of new azide polymer-modified nitrocellulose (NC) spherical powder were prepared by the internal solution method with introducing different azide polymers (GAP, GAPA, GAPE, and GAP-ETPE) into NC. The effect of different azide polymers on the performance of NC spherical powder was investigated. The addition of azide polymers led to a decrease in the average particle size of the spherical powder. The addition of azide polymer substantially reduced the mechanical sensitivities of NC spherical powder and improved their thermal stability. The critical temperature of thermal explosion (Tb) and self-accelerated decomposition temperature (TSADT) of the modified spherical powder were 5~10 °C higher than those of the NC spherical powder. Meanwhile, the mechanical sensitivities of the azide polymer-modified spherical powder were significantly reduced, in which the impact sensitivity was reduced by about 30.3%~65.3%, and the friction sensitivity was reduced by about 23.3%~41.1%. Therefore, the azide polymer-modified spherical powder have more excellent thermal stability and safety performance, and probably have a broader application prospect.

Similar content being viewed by others

References

Chai H, Duan Q, Cao H, Li M, Sun J. Effects of nitrogen content on pyrolysis behavior of nitrocellulose. Fuel. 2020;264(15):116853. https://doi.org/10.1016/j.fuel.2019.116853.

Dourari M, Tarchoun AF, Trache D, Abdelaziz A, Bekhouche S, Harrat A, et al. Unraveling the effect of MgAl/CuO nanothermite on the characteristics and thermo-catalytic decomposition of nanoenergetic formulation based on nanostructured nitrocellulose and hydrazinium nitro-triazolone. Catalysts. 2022;12(12):1573. https://doi.org/10.3390/catal12121573.

Tarchoun AF, Sayah ZBD, Trache D, Klapötke TM, Belmerabt M, Abdelaziz A, et al. Towards investigating the characteristics and thermal kinetic behavior of emergent nanostructured nitrocellulose prepared using various sulfonitric media. J Nanostruct Chem. 2022;12(5):963–77. https://doi.org/10.1007/s40097-021-00466-x.

Kim H-S. Improvement of mechanical properties of plastic bonded explosive using neutral polymeric bonding agent. Propellants Explos Pyrotech. 1999;24(2):96–8. https://doi.org/10.1002/(SICI)1521-4087(199904)24:2%3c96::AID-PREP96%3e3.0.CO;2-X.

Zhang W, Fan X, Wei H, Li J. Application of nitramines coated with nitrocellulose in minimum signature isocyanate-cured propellants. Propellants Explos Pyrotech. 2008;33(4):279–85. https://doi.org/10.1002/prep.200800220.

Wu Y, Luo Y, Ge Z. Properties and application of a novel type of glycidyl azide polymer (GAP)-modified nitrocellulose powders. Propellants Explos Pyrotech. 2015;40(1):67–73. https://doi.org/10.1002/prep.201400005.

Singh H, Khire V. Studies on low vulnerability gun propellants based on conventional binder and energetic plasticizers. Int J Energ Mater Chem Propuls. 2008;7(3):187–92. https://doi.org/10.1615/IntJEnergeticMaterialsChemProp.v7.i3.20.

Ampleman G. Development of a new generation of insensitive explosives and gun propellants. Int J Energ Mater Chem Propuls. 2010;9(2):107–32. https://doi.org/10.1615/IntJEnergeticMaterialsChemProp.v9.i2.10.

Meng X, Xiao Z. Synthesis, thermal properties and sensitivity of ladder-like nitrocellulose grafted by polyethylene glycol. Propellants Explos Pyrotech. 2018;43(3):300–7. https://doi.org/10.1002/prep.201700193.

Trache D, Khimeche K, Mezroua A, Benziane M. Physicochemical properties of microcrystalline nitrocellulose from Alfa grass fibres and its thermal stability. J Therm Anal Calorim. 2016;124(3):1485–96. https://doi.org/10.1007/s10973-016-5293-1.

Xiao Z, Ying S, He W, Xu F, Sun P. Synthesis, morphology, component distribution, and mechanical properties of nitrocellulose/gradient poly(ethylene glycol dimethacrylate) semi-IPN material. J Appl Polym Sci. 2007;105(2):510–4. https://doi.org/10.1002/app.26171.

Davenas A. Development of modern solid propellants. J Propul Power. 2003;19(6):1108–28. https://doi.org/10.2514/2.6947.

Zhang Y, Zhao J, Yang P, He S, Huang H. Synthesis and characterization of energetic GAP-b-PAEMA block copolymer. Polym Eng Sci. 2012;52(4):768–73. https://doi.org/10.1002/pen.22140.

Hu Y, Jian X, Xiao L, Zhou W. Microphase separation and mechanical performance of thermoplastic elastomers based on poly(glycidyl azide)/poly(oxytetramethylene glycol). Polym Eng Sci. 2018;58(S1):E167–73. https://doi.org/10.1002/pen.24831.

Sun Q, Sang C, Wang Z, Luo Y. Improvement of the creep resistance of glycidyl azide polyol energetic thermoplastic elastomer-based propellant by nitrocellulose filler and its mechanism. J Elastomers Plast. 2017;50(7):579–95. https://doi.org/10.1177/0095244317742680.

Kumari D, Anjitha S, Pant CS, Patil M, Singh H, Banerjee S. Synthetic approach to novel azido esters and their utility as energetic plasticizers. RSC Adv. 2014;4(75):39924–33. https://doi.org/10.1039/C4RA06530A.

Niehaus M. Compounding of glycidyl azide polymer with nitrocellulose and its influence on the properties of propellants. Propellants Explos Pyrotech. 2000;25(5):236–40. https://doi.org/10.1002/1521-4087(200011)25:5%3c236::AID-PREP236%3e3.0.CO;2-C.

Schedlbauer F. LOVA gun propellants with GAP binder. Propellants Explos Pyrotech. 1992;17(4):164–70. https://doi.org/10.1002/prep.19920170404.

Kumari D, Singh H, Patil M, Thiel W, Pant CS, Banerjee S. Synthesis, characterization, thermal and computational studies of novel tetra-azido esters as energetic plasticizers. Thermochim Acta. 2013;562:96–104. https://doi.org/10.1016/j.tca.2013.03.042.

Yadav A, Pant CS, Das S. Research advances in bonding agents for composite propellants. Propellants Explos Pyrotech. 2020;45(5):695–704. https://doi.org/10.1002/prep.201900329.

Cheng T. Polymers review of novel energetic polymers and binders–high energy propellant ingredients for the new space race. Des Monomers Polym. 2019;22(1):54–65. https://doi.org/10.1080/15685551.2019.1575652.

Gaur B, Lochab B, Choudhary V, Varma I. Azido polymers—energetic binders for solid rocket propellants. J Macromol Sci Part C: Polym Rev. 2003;43(4):505–45. https://doi.org/10.1081/MC-120025976.

Wang Z, Zhang T, Zhao B, Luo Y. Effect of nitrocellulose (NC) on morphology, rheological and mechanical properties of glycidyl azide polymer based energetic thermoplastic elastomer/NC blends. Polym Int. 2017;66(5):705–11. https://doi.org/10.1002/pi.5312.

Guo M, Ma Z, He L, He W, Wang Y. Effect of varied proportion of GAP-ETPE/NC as binder on thermal decomposition behaviors, stability and mechanical properties of nitramine propellants. J Therm Anal Calorim. 2017;130(2):909–18. https://doi.org/10.1007/s10973-017-6351-z.

Wu Y, Yi Z, Luo Y, Ge Z, Du F, Chen S, et al. Fabrication and properties of glycidyl azide polymer-modified nitrocellulose spherical powders. J Therm Anal Calorim. 2017;129(3):1555–62. https://doi.org/10.1007/s10973-017-6387-0.

Meng X, Pu C, Cui P, Xiao Z. Preparation, thermal and sensitivity properties of nano-sized spherical nitrocellulose composite crystal. Propellants Explos Pyrotech. 2020;45(8):1194–203. https://doi.org/10.1002/prep.201900319.

Zhang Z, Wang G, Wang Z, Zhang Y, Ge Z, Luo Y. Synthesis and characterization of novel energetic thermoplastic elastomers based on glycidyl azide polymer (GAP) with bonding functions. Polym Bull. 2015;72(8):1835–47. https://doi.org/10.1007/s00289-015-1375-7.

Tarchoun AF, Trache D, Abdelaziz A, Bekhouche S, Boukeciat H. Exploration of palm fronds as a prominent alternative resource for the production of energetic cellulose-rich biopolymers. Mater Today: Proc. 2022;53:31–5. https://doi.org/10.1016/j.matpr.2021.12.218.

Tarchoun AF, Trache D, Klapötke TM, Abdelaziz A, Bekhouche S, Boukeciat H, et al. Making progress towards promising energetic cellulosic microcrystals developed from alternative lignocellulosic biomasses. J Energ Mater. 2022. https://doi.org/10.1080/07370652.2022.2032484.

Touidjine S, Boulkadid KM, Trache D, Belkhiri S, Mezroua A. Preparation and characterization of polyurethane/nitrocellulose blends as binder for composite solid propellants. Propellants Explos Pyrotech. 2022;47(1):e202000340. https://doi.org/10.1002/prep.202000340.

Zou X, Zhang W, Zhang Z, Gu Y, Fu X, Ge Z, et al. Study on properties of energetic plasticizer modified double-base propellant. Propellants Explos Pyrotech. 2021;46(11):1662–71. https://doi.org/10.1002/prep.202100085.

Acknowledgements

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jin, P., Li, J., Zhang, X. et al. Preparation and properties of different azide polymer-modified nitrocellulose spherical powder. J Therm Anal Calorim 148, 9661–9671 (2023). https://doi.org/10.1007/s10973-023-12321-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12321-y