Abstract

The full characteristic of the crystallization process of aripiprazole crystal is given. Our research reveals that a degree of crystallinity calculated from the analyses of data of light intensity passing through the sample (Thermo-Optical Analysis based on Polarized Light Microscopy—POM), the Canny edge detection algorithm, and Differential Scanning Calorimetry—DSC, are in good agreement. The parameters of Avrami model, the dimensionality of the crystal growth, and the characteristic crystallization temperature, obtained from POM and DSC methods coincide. The obtained values of the Avrami exponent n suggest that the crystal growth is three-dimensional.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

A crystallization process leads to a formation of a solid phase with long-range structural order. Crystallization is a transition from a stochastic system dominated by thermal fluctuations to a deterministic system in which growth is thermodynamically characterized [1]. This process is the result of non-separable phenomena: nucleation and crystal growth, which are determined by the equilibrium between thermodynamic and kinetic factors. Nucleation initiates crystallization, starting with the formation of a nucleus consisting of a small number of molecules, which then grows from microscopic to macroscopic dimensions [2]. Each substance has a specific temperature range where optimal conditions for nucleation and nuclei growth occur. Usually, the nucleation curve N(T) has its maximum at a lower temperature than the maximum of the crystal growth curve G(T). If N(T) and G(T) have no temperature range in common, no crystallization process is observed during cooling, and instead, a glass transition occurs, even at a slow cooling rate. A crystallization is then expected during heating [3]. The crystallization process observed during heating of material under isothermal or non-isothermal conditions is called cold crystallization. Knowledge of the tendency to cold crystallization is crucial in determining the material’s usefulness for industrial applications [4,5,6].

In literature, numerous models describe the phenomenon of cold crystallization [7,8,9,10,11,12,13]. At the very beginning of the cold crystallization study, one needs to calculate the degree of crystallinity, D(t) [14,15,16,17]. The results of the differential scanning calorimetry (DSC) experiment can be used to obtain values of the degree of crystallinity D(t):

where φ is the heat flow after the subtraction of the baseline, t0 is the time when the crystallization process began, and ΔH is the enthalpy change of the crystallization. DSC measurement is a powerful technique used to study phase transitions, and it can distinguish between the first-order and the second-order phase transitions. First-order phase transitions are characterized by well-defined anomalies on DSC curves, while second-order phase transitions result in variations in the flow curve. Additionally, a slight change in the slope of the curve is observed at the transition temperature to the glassy state. However, the correct interpretation of complex thermal events can be challenging when multiple thermal events occur within a narrow temperature range [18, 19].

The degree of crystallinity D(t) obtained from polarizing optical microscope (POM) data is given by Eq. (2):

where SCr is the area of the texture related to the crystal phase in time t, and S is the total surface area of the texture. POM method is commonly used to observe and identify textures (in other words, changes in material birefringence) caused by external factors such as temperature. In addition, a phase transition temperatures between phases can be obtained. One advantage of the POM method is that it does not require a high sample mass and provides direct access to ongoing changes in the sample. Nevertheless, the identification of features corresponding to the phase transitions on the texture relies on the experience of the researcher and is limited by the capabilities of the human eye [20].

Usually, the degree of crystallinity obtained from observation with polarized optical microscopy is determined by manually analyzing textures. If the crystal growth is spherical, the degree of crystallinity may be calculated by measuring the nuclei radius versus time at different crystallization temperatures [21]. Another approach involves the manual analysis of textures using graphics application software such as the GNU Image Manipulation Program (GIMP) [2, 3]. In this approach, the growing crystalline phase regions are marked in black, while the remaining parts of the texture are marked using the white color [16]. Both approaches are time-consuming and are easy to obtain for crystallization processes, where the nucleus growths symmetrically. However, determining the degree of crystallinity for texture with several nuclei growing asymmetrically is not an easy task. For this reason, studies of cold crystallization using polarized optical microscope observations are often skipped [14, 22,23,24].

Any image is a two-dimensional representation of visible light. Images can be stored in various digital forms/formats. The most commonly used one is BGR (format), and each pixel is a combination of the brightness of blue, green and red, ranging from 0 to 255. The black pixel has a value of 0, while the white pixel is associated with a value of 255. The grayscale image is represented by a matrix with values ranging from 0 to 255 [25]. TOApy software [26] transforms colored images of texture to a grayscale image and adds the values of pixels. The values obtained during the such procedure are collected as a function of temperature or time [26].

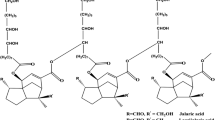

The aim of this publication is to demonstrate, using the example of the cold crystallization process of aripiprazole (AZP), how the degree of crystallization can be determined using thermo-optical analysis. AZP is an antipsychotic drug, and has plenty of polymorphs/forms [27,28,29,30].

Experimental

Aripiprazole, with a purity of an analytical standard higher than 99%, was supplied by Sigma-Aldrich Company. Polarized optical microscope observations have been performed using Leica DM 2700P polarizing light microscope. The temperature has been stabilized using Linkam T96-S temperature controller. The sample has been placed between two glass plates at a temperature above the AZP melting point. In the next step, the sample was cooled to 173 K at a rate of 10 K min−1. Then the sample has been heated (with a rate of 10 K min−1) to one of the chosen temperatures: 333 K, 338 K or 343 K. The collected textures have been analyzed using TOApy software [26] and the Canny edge detector algorithm from the OpenCv package [31].

The DSC curves were performed with DSC 2500 (TA Instruments) calorimeter. The curves were registered according to the following steps: 1/the sample was heated above the melting temperature; 2/cooled down below the glass transition temperature at a rate of 10 K min−1; 3/heated with a rate of 10 K/min to the chosen temperature (339 K, 343 K, or 347 K) and held at isothermal conditions; 4/heated with a rate of 10 K min−1 above the melting temperature afterward.

Results and discussion

The phase transition from the isotropic liquid phase (IL) phase to the crystal phase is indicated by an increase in the values of intensity in the TOA curve. IL phase or its glass do not have optical properties such as birefringence, therefore the texture of this phase observed under a polarizing microscope appears as a black image. It consists of pixels with low intensity values. When a crystal phase occurs, the pixel values associated with the crystal texture increase. The end of crystallization is marked on the TOA plot as a constant value of intensity. This information can be used to obtain the degree of crystallinity by normalizing the TOA data in the region wherein crystallization occurs. The normalization procedure is described by the following equation:

where I(t) is the intensity on the TOA curve in time t, I0 is the intensity on the TOA curve before the crystallization starts, and If is the intensity on the TOA curve after the crystallinity process ends. The scheme of the above procedure is presented in Fig. 1.

The Canny edge detector algorithm may be used to detect the border of objects in a picture [32]. This approach was used to estimate the surface area of the AZP crystal, see Fig. 2. The degree of crystallinity was calculated using normalized data from thermo-optical analysis Eq. (3) and the Canny edge detector algorithm. The results of both methods are presented in Fig. 3, and they overlapped. This observations demonstrates that when the crystallization occurs from the supercooled liquids, the degree of crystallinity can be estimated from the results of the thermo-optical analysis after the normalization procedure.

The crystallization process lasts longer in lower temperatures (see Fig. 3). The crystallization process of AZP lasted 31 min, 56 min, and 162 min at temperatures of 343 K, 338 K and 333 K, respectively. One way to analyze the conversion degree from the liquid phase to the solid phase is by applying the Avrami equation [8]:

where n is the Avrami exponent (its value depends on the nucleation rate and dimensionality of the crystal growth), t0 is the induction time of crystallization, and K is constant, which depends on nucleation and crystal growth rate. The parameter n from Avrami Eq. (4) is dependent on the mechanisms of nucleation and crystal growth. For that reason, it reveals helpful information on the nature of the crystallization. Equation (4) can be given in the following form:

Then the parameters n and K can be determined from the slope and the intercept of the corresponding linear dependencies of log(− ln(1 − D(t))) vs. log(t − t0) from Eq. (5) (see Fig. 4). The details of Avrami equation fit to AZP degree of crystallinity are presented in Table 1. The values of n are about 2. The value of n is described by d-1, where d is the number of dimension [33]. This information suggests that the crystal growth is three-dimensional. The characteristic time of crystallization τCr is defined as the root of \(\mathrm{log}(-\mathrm{ln}\left(1-D(t)\right)\), i.e. \(\mathrm{log}(-\mathrm{ln}\left(1-D\left(t\right)\right)=0\), and, in other words, it is time needed to achieve 63% of crystallinity (for each temperature). One can see that the values of τCr decrease and parameter K increase with increasing temperature, which informs that the kinetics of cold crystallization of AZP depends primarily on diffusion rates [34, 35].

Parameters from Avrami equation fitted to POM data have been compared to results of Avrami equation fit to AZP degree of crystallinity obtained from DSC measurements (see Figs. 5–7 and Table 2). Both methods show similar results. The differences, mainly, in the characteristic time of crystallization τCr of the same systems measured by various experimental techniques, i.e., POM (TOA) or DSC—result from the differences existing between their sample environments (for example, geometry and thickness – the samples for POM measurements are much thinner than for DSC).

Conclusions

The crystallization time of aripiprazole depends on the temperature at which it occurs. The results of the degree of crystallization obtain from the thermos-optical analysis methods, Canny edge detection algorithm, and differential scanning calorimetry experiment are the same. Fitting the Avrami equation to data from polarized optical microscopy and differential scanning calorimetry yields similar values for the parameters n and K. The dimensionality of aripiprazole crystal growth is three-dimensional. The main difference between the TOA/POM and DSC methods is the time of the crystallization process, which is shorter in the calorimetric method.

References

Sleutel M, Lutsko J, Driessche A, Duran-Olivencia M, Maes D. Observing classical nucleation theory at work by monitoring phase transitions with molecular precision. Nat Commun. 2014;5:5598.

Rozwadowski T, Jasiurkowska-Delaporte M, Massalska-Arodź M, Yamamura Y, Saito K. Designing the disorder: the kinetics of nonisothermal crystallization of the orientationally disordered crystalline phase in a nematic mesogen. Phys Chem Chem Phys. 2020;22:24236.

Rozwadowski T, Massalska-Arodź M, Kolek Ł, Grzybowska K, Bak A, Chłędowska K. Kinetics of cold crystallization of 4-cyano-3-fluorophenyl 4-butylbenzoate (4CFPB) glass forming liquid crystal I nonisothermal process as studied by microscopic, calorimetric, and dielectric methods. Cryst Growth Des. 2015;15(6):2891–900.

Baird JA, van Eerdenbrugh B, Taylor LS. A classification system to assess the crystallization tendency of organic molecules from undercooled melts. J Pharm Sci. 2010;99:3787–806.

Blaabjerg LI, Lindenberg E, Lobmann K, Grohganz H, Rades T. Glass forming ability of amorphous drugs investigated by continuous cooling and isothermal transformation. Mol Pharm. 2016;13:3318–25.

Takeuchi A, Inoue A. Quantitative evaluation of critical cooling rate for metallic glasses. Mater Sci Eng A. 2001;304–306:446–51.

Liu T, Mo Z, Wang S, Zhang H. Nonisothermal melt and cold crystallization kinetics of poly(aryl ether ether ketone ketone). Polym Eng Sci. 1997;37:568–75.

Avrami M. Kinetics of phase change. I general theory. J Chem Phys. 1939;7:1103–12.

Malek J. The applicability of Johnson-Mehl-Avrami model in the thermal analysis of the crystallization kinetics of glasses. Thermochim Acta. 2011;520:1–19.

Kissinger HE. Reaction kinetics in differential thermal analysis. Anal Chem. 1957;29:1702–6.

Augis JA, Bennett JE. Calculation of the Avrami parameters for heterogenus solid state reactions using modification of the Kissinger method. J Therm Anal. 1978;13:283–92.

Ozawa T. Kinetics of non-isothermal crystallization. Polymer. 1971;12:150–8.

Matusita K, Komatsu T. Yokota R Kinetics of non-isothermal crystallization process and activation Energy for crystal growth in amorphous materials. J Mater Sci. 1984;19:291–6.

Drzewicz A, Juszyńska-Gałązka E, Jasiurkowska-Delaporte M, Kula P. Insight into cold- and melt crystallization phenomena of a smectogenic liquid crystal. Cryst Eng Commun. 2022;24:3074–87.

Deptuch A, Jasiurkowska-Delaporte M, Juszyńska-Gałązka E, Drzewicz A, Zając W. Urbańska M Molecular dynamics and kinetics of isothermal cold crystallization in the chiral smectogenic 3F7HPhH6 glassformer. Crystals. 2021;11:1487.

Jasiurkowska-Delaporte M, Rozwadowski T, Juszyńska-Gałązka E. Kinetics of non-isothermal and isothermal crystallization in a liquid crystal with highly ordered smectic phase as reflected by differential scanning calorimetry, polarized optical microscopy and broadband dielectric spectroscopy. Crystals. 2019;9:205.

Kołodziejczyk K, Grzybowska K, Wojnarowska Z, Dulski M, Hawelek L, Paluch M. Isothermal cold crystallization kinetics study of sildenafil. Cryst Grow Des. 2014;14:3199–209.

Leyva-Porras C, Cruz-Alcantar P, Espinosa-Solis V, Martinez-Guerra E, Pinon-Balderrama CI, Compean Martinez I, Saalvedra-Leos MZ. Application of differential scanning calorimetry (DSC) and modulated differential scanning calorimetry (MDSC) in food and drug industries. Polymers. 2019;12:5.

Verdonck E, Schaap K, Thomas LC. A discussion of the principles and applications of Modulated Temperature DSC (MTDSC). Int J Pharm. 1999;192:3–20.

Pietrzyk S, Yevchenko T, Dardas D. Brańka AC Phase transitions and physical properties by a coor texture analysis: results for liquid crystals. J Mol Liq. 2022;362:119699.

Papageorgiou GZ, Bikiaris DN, Achilias DS. Effect of molecular weight on the cold-crystallization of biodegradable poly(ethylene succinate). Thermochim Acta. 2007;457:41–5.

Deptuch A, Jasiurkowska-Delaporte M, Zając W, Juszyńska-Gałązka E, Drzewicz A, Urbańska M. Investigation of crystallization kinetics and its relationship with molecular dynamics for chiral fluorinated glassforming smectogen 3F5HPhH6. Phys Chem Chem Phys. 2021;23:19795–810.

Drzewicz A, Jasurkowska-Delaporte M, Juszyńska-Gałązka E, Zając W, Kula P. On the relaxation dynamics of a double glass-forming antiferroelectric liquid crystal. Phys Chem Chem Phys. 2021;23:8673–88.

Deptuch A, Jasiurkowska-Delaporte M, Juszyńska-Gałązka E, Drzewicz A, Zając W, Urbańska M. Molecular dynamics od kinetics of isothermal cold crystallization in the chiral smectogenic 3F7FPhH6 glassformer. Crystals. 2022;12:1588.

Shapiro L, Rosenfeld A. Computer vision and image processing. San Diego: Academic Press Inc; 1992.

Osiecka N, Galewski Z, Massalska-Arodź M. TOApy program for the thermooptical analysis of phase transitions. Termochim Acta. 2017;655:106–11.

Braun DE, Gelbrich T, Kahlenberg V, Tessadri R, Wieser J, Griesser UJ. Conformational polymorphism in Aripiprazole: preparation, stability and structure of five modifications. J Pharm Sci. 2009;98:2010–26.

Delaney SP, Pan D, Yin SX, Smith TM, Korter TM. Evaluating the roles of conformational strain and cohesive binding in crystalline polymorphs of aripiprazole. Cryst Grow Des. 2013;13:2943–52.

Delaney SP, Smith TM, Pan D, Yin SX, Korter TM. Low-temperature phase transition in crystalline aripiprazole leads to an eighth polymorph. Cryst Grow Des. 2014;14:5004–10.

Nanubolu JB, Sridhar B, Babu VSP, Jagadeesh B, Ravikumar K. Sixth polymorph of aripiprazole – an antipsychotic drug. Cryst Eng Commmun. 2012;14:4677–85.

Zhou P, Ye W, Wang Q. An improved Canny algorithm for edge detection. J Comp Inf Syst. 2011;7:1516–23.

Canny J. A computational approach to edge detection. IEEE Trans Pattern Anal Mach Intell. 1986;8:679–98.

Drzewicz A, Juszyńska-Gałązka E, Zając W, Piwowarczyk M, Drzewiński W. Non-isothermal and isothermal cold crystallization of glass-forming chiral smectic liquid crystal (S)-4’-(1-methyloctyloxycaronyl)biphenyl-4-yl 4-[7-2,2,3,3,4,4,4-heptafluorobutoxy) heptyl-1-oxy-benzoate. J Mol Liq. 2020;319:114153.

Deptuch A, Jaworska-Gołąb T, Marzec M, Urbańska M, Tykarska M. Cold crystallization from chiral smectic phase. Phase Trans. 2019;92:205.

Massalska-Arodź M, Williams G, Thomas DK, Jones WJ, Dąbrowski R. Molecular dynamics and crystallization behavior of chiral isooctyloxycyanobiphenyl as studied by dielectric relaxation spectroscopy. J Phys Chem B. 1999;103:4197–205.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Osiecka-Drewniak, N., Juszyńska-Gałązka, E. Determining the degree of crystallization of aripiprazole during cold crystallization using thermo-optical analysis and differential scanning calorimetry. J Therm Anal Calorim 148, 6887–6892 (2023). https://doi.org/10.1007/s10973-023-12235-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12235-9