Abstract

Structural, thermal and energetic properties of quinoa, kiwicha and kañiwa native Andean-pseudocereal flours have been studied. Moisture, protein and fat contents and also metallic and semi-metallic levels were, in general, within of the range values reported in the literature. Empirical formulas of quinoa, kiwicha and kañiwa flours have been determined as CH1.87O0.81N0.06S0.0015, CH1.90O0.82N0.05S0.0019 and CH1.76O0.73N0.06S0.0017, respectively. The elemental carbon concentration (Cflour) in organic matter follows the trend, Ckañiwa (45.6%) > Ckiwicha (43.2%) ≈ Cquinoa (43.3%), which reflects the greater structural similarity between the quinoa and kiwicha flours, with respect to kañiwa flour. Regarding thermal and energetic properties: (i) in the temperature range of 261.15–343.15 K, we found no significant differences among the specific heat capacities of the three flours, which are ranged between 1.3 and 1.9 J g−1 K−1; (ii) the organic matter decomposition temperature (Tdec) followed the trend, Tdec,kañiwa (489.8 ± 1.6 K) > Tdec,kiwicha (479.1 ± 1.5 K) ≥ Tdec,quinoa (477.1 ± 1.5 K) indicating a greater thermal stability range of kañiwa flour; (iii) the gelatinization temperatures and also the gelatinization enthalpy of kañiwa flour (4.3 ± 1.6 J g−1) were lower than corresponding thermal gelatinization parameters of quinoa and kiwicha flours; and (iv) the standard massic energy of combustion (− Δcu°) or its associated net calorific value (qNCV) of kañiwa flour (18.77 ± 0.15 kJ g−1 or 4487 ± 36 kcal kg−1) was slightly greater than for kiwicha (18.47 ± 0.11 kJ g−1 or 4415 ± 26 kcal kg−1) and quinoa (18.60 ± 0.16 kJ g−1 or 4445 ± 39 kcal kg−1) flours. Taking into account the associated uncertainties, qNCV trend is similar to the Cflour and Tdec trends. Accordingly, our results indicate a greater range thermal stability and greater net calorific value for kañiwa flour than for kiwicha and quinoa flours.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Quinoa (Chenopodium quinoa Willd.), achita or kiwicha/amaranth (Amaranthus caudatus) and kañiwa or cañihua (Chenopodium pallidicaule Allen) are native Andean-pseudocereals—starchy dicotyledonous seeds—with high nutritional contents, such as gluten-free sources of protein and fiber, rich in polyunsaturated fatty acids, balanced aminoacids, phenolic and other antioxidants, minerals and vitamins. These products are, the oldest crops, widely cultivated in Andean region, being Perú (in Huamanga−Ayacucho province, quinoa was produced before 5000 BC) [1, 2] and Bolivia the major producing countries [3]. All of them have been associates with health benefits (healthier foods) and are considered as potential healthy alternatives to gluten-containing cereals [4]. FAO (Food and Agriculture Organization of the United Nations) nominated quinoa as a crop most likely to significant contribute to global food security in the twenty-first century [4]. The United Nations has declared 2013 the International Year of Quinoa.

Pseudocereals, such as buckwheat, kiwicha and particularly quinoa have received a lot of attention in the last decades, and their crops and consumptions have been introduced practically throughout the world, mainly as seeds and flours [5, 6] and also as novel ingredients in food products, enhancing and improving the nutritional and functional properties (with antioxidant, antimicrobial and anti-inflammatory activities) and other characteristics [7,8,9]. Kañiwa, despite all these interesting properties, has been the least studied.

Quinoa, kiwicha and kañiwa flours are high in protein-quality content (9−24%, see Table 1), rich in, (i) dietary fibers (9−21%), e.g., several times higher than in rice [10,11,12], (ii) antioxidant and bioactive products (involving those with cytotoxic activities [9, 13] such as phenolic compounds (gallic-, dihydroxybenzoic-, vanillic-, ferulic- and caffeic-acids; sesamin, tyrosol or cardol) [14, 15], flavonoids (anthocyanins, flavones, flavanones, isoflavonoids and flavanols) [6, 15, 16], vitamin E [6]; (iii) minerals, including among other metals Ca, K, Mg, Fe or Zn that are related to the-called “ash content” (0.23 to 5%) [6, 8, 11, 17,18,19,20] which is higher than that of rice (0.5%), wheat (1.8%) and most other grains [21].

Starch is the major component of the pseudocereal flour, accounting for between 50 and 75% of its content [18, 22]. This carbohydrate has low amylose level, between 4 and 23.7% [10, 11, 21, 23,24,25], mainly kiwicha flour is considered as waxi variety. The amylose content is in general less than in well-known cereals such as corn (20−30%), wheat (28%) or rice (14−25%) [17]. On the other hand, kiwicha and quinoa flours have higher carbohydrate content than soya flour (34.1%) but lower than wheat (78.4%) and maize flours (81.1%) (Muchekeza et al. [26] and references therein).

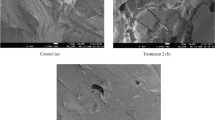

Starch granules of the pseudocereals have usually polygonal shapes and are small in diameter (below 3.5 μm) [8, 24, 27, 28]. In quinoa and kiwicha, the starch granules have comparable particle size distributions, whereas kañiwa has a minor size distribution (below 2 μm) instead [3, 24]. The impact of particle size was evaluated by Ahmed et al. [29], who showed significant changes in composition (e.g., protein, dietary fiber and fat) and functionality with a reduction in particle size due to its increase in surface to volume ratio.

Thermal and energetic properties of pseudocereal flours, such as specific heat capacity, thermal diffusivity, total energy content, gelatinization enthalpy, or gelatinization temperatures, are important parameters that can be useful to the cereal processing industry related to treatments such as drying, storage, refrigeration or to characterize functional and nutritional qualities of both starch and flour cereals. The literature practically does not report consistent experimental values of some of these parameters. This is the case of caloric value or massic energy [30], usually obtained by empirical estimations of protein, carbohydrates, and fat contents. In this work, we have determined, using combustion calorimetry technique, the total massic energy content or net-calorific value qNCV [31] of quinoa, kiwicha and kañiwa flours, which is the amount of energy (J, kJ or kcal) released by each unit of biomass (g, 100 g or kg). qNCV is related to the complete combustion of biomass (basically constituting C, H, O, N) at constant volume in an oxygen atmosphere, implying the absence of C and CO in the final combustion products.

In this work, we have summarized, grouping into ranges, the data available in the literature (abundant for quinoa and rather scarce for kañiwa) on both, structural (organic and inorganic composition) and thermal-energetic properties of the quinoa, kiwicha and kañiwa flours. This information has allowed us to guarantee the reliability and consistency of our data, particularly those that have not been previously reported. In this way, we highlight the differences and similarities of the structural and thermo-energetic properties among the flours of the three most important Andean-pseudocereals.

Materials and methods

Materials

Quinoa (C. quinoa Willd.), achita/kiwicha/amaranth (A. caudatus), cereal grains were supplied by Tambillo (Ayacucho- Perú) farmers, while kañiwa/cañihua (C. pallidicaule Allen, Cupi-Puno variety) red-grains were bought in the market. All the grains were studied once processed (scarified and de-saponified, particularly for quinoa) and manufactured as food products. The flours were obtained by milling the cereals in a hammer mill and then drying under vacuum, using rotatory pump, at room temperature for 2 h. The flours were passed through a 100-mesh (0.147 mm) screen for gelatinization experiments.

Combustion calorimetry

The combustion experiments were performed in an isoperibol calorimeter, built in our laboratory and equipped with a static bomb (0.38 dm3) and an isothermal water jacket. The calorimetric temperatures were measured to within ± 10–4 K by means 100 Ω platinum resistance thermometer, using a calibrated resistance bridge (Model F300, Automatic System Laboratories Ltd.). The flour samples (between 0.49 and 0.521 g) were pressed in pellet forms and ignited in oxygen at 3.04 MPa with 1 cm3 of water added to the bomb, following a procedure similar to that described in reference [30]. The combustion bomb was flushed with oxygen before to combustion experiment. In order to obtain complete reactions of combustion, benzoic acid was used as auxiliary substance. The initial temperature of the combustion experiments was approximately 296.65 K, and the energy of reaction was always referred to the final temperature of 298.15 K. Previously, the pellet sample was connected to the ignition system (0.84 J, energy discharge of a capacitor) by means of a cotton thread fuse, which the empirical formula (CH1.740O0.871) and massic energy of combustion (− 17,410 ± 37) J g−1 were determined in our laboratory. The mass of the samples, platinum crucible and cotton thread were all measured on a Mettler H33AR balance (sensitivity ± 10–4 g). The energy equivalent of the calorimeter, ε, was determined from the combustion of benzoic acid, NIST standard reference sample 39j, having a massic energy of combustion under the conditions specified on the certificate of − 26 434 ± 3 J g−1. We obtained a value of ε = 14 249.6 ± 5.2 J K−1 from five calibration experiments, where the uncertainty quoted is the standard uncertainty of the mean. To verify complete combustion, at the end of each experiment, the total quantity of gas in the bomb was slowly released through Dräger tubes. No traces of CO were detected. Finally, the liquid phase in the bomb was transferred to a flask with rinsing water. To determine the total acid, this solution was titrated with standard alkali, 0.1N NaOH(aq).

Differential scanning calorimetry (DSC)

The thermal properties of the samples were determined by differential scanning calorimetry, using a DSC PerkinElmer Pyris 1 calorimeter equipped with an intra-cooler unit. Temperature and power scales were calibrated by measuring the melting parameters of the recommended high-purity indium, gallium and tin as reference materials [32]. Curves of samples hermetically sealed in aluminum or stainless steel capsules were recorded in a nitrogen atmosphere at 10 K min−1. The mass of the encapsulated samples were measured on a Mettler AT21 microbalance, with a detection limit of ± 10–6 g. Specific heat capacities c.e. were determined by the “scanning method” following the experimental methodology previously described [33] with synthetic sapphire (α-aluminum oxide) as reference material. For gelatinization studies, stainless steel high-pressure capsules of 3 × 10–5 dcm3 of internal volume were used. These capsules are practically a mini-autoclave; they include a base and cover of stainless steel and gold plated as a gasket. The flour samples, between 6 and 8 mg, were introduced into base-pans. Water, between 2.0 and 2.2 × 10–5 dcm3, was added from a microsyringe and the capsules were then hermetically sealed and placed on a rotatory agitator at room temperature (~ 298.15 K) for at least 12 h before measurements were made.

Metallic and semi-metallic analysis

The content of metallic and semi-metallic elements in the samples was analyzed by inductively coupled plasma-atomic emission spectrometer (ICP-OES PerkinElmer Optima 4300 DV). The samples were previously digested in hot solution of nitric and perchloric acids.

Results and discussion

Elemental analysis: proximate composition of flours

The elemental analysis (m%, on dry matter) of the pseudocereals studied is given in Table 1. The percentage of oxygen and other elements non-detected in the analysis amounts up to 44% of the total content. The elemental carbon concentration (Cflour) in kañiwa flour (Ckañiwa) was higher than in kiwicha (Ckiwicha) and quinoa (Cquinoa) flours. These values followed the trend, Ckañiwa (45.6%) > Ckiwicha (43.2%) ≈ Cquinoa (43.3%). Taking into account the presence of most significant elements (C, H, O, N, S), the empirical formula of quinoa, kiwicha and kañiwa flours would be CH1.87O0.81N0.06S0.0015, CH1.90O0.82N0.05S0.0019 and CH1.76O0.73N0.06S0.0017, respectively. We can appreciate the similarity between these formulas, barely distinguishable—within the uncertainties of measurements—for those of quinoa and kiwicha. It is important to mention that the literature report scarce information on the elemental quantification of S, particularly in the kañiwa case, despite the fact that all these pseudocereals contain compounds with S, such as sulfured amino acids.

The concentration of crude protein (mass % respect to dry flour) was determined as % nitrogen content (%N) × 6.25 [34], and the fat concentration was estimated taking into account the protein/fat ratio of 2.2:1, which was updated and taken as average value from literature data consigned in Table S1 of Supporting Information.

The moisture, protein and fat contents of quinoa, kiwicha and kañiwa flours are reported in Table 1. The obtained results in this work are within of the range values reported in the literature (See Table S1). The wide range in moisture, protein and fat data would be explained by varietal difference, agronomic and environmental factors such as soil condition, fertilizer among other conditions used in the cultivation, harvesting and treatment of grains.

The literature shows that pseudocereal flours studied have an excellent nutritional profile with a good source of high-quality protein, fat and other nutritious constituents. Although the protein content, in the range of 9 to 24%, is lower than that of legumes, it is in general comparable or higher than other cereals such as rice (< 7%), corn (< 9.5%), barley (< 10%), rye (< 10.5%), sorghum (10.7%) and wheat (< 13.7%) [35, 36]. The high protein content is related to the presence of essential and sulfured amino acids such as of lysine, methionine, histidine, isoleucine or cysteine. Our results, in good accordance with the literature, showed no significant difference between protein content in quinoa (17.4 ± 1.7%) and kañiwa (18.6 ± 0.9%) flours and a slightly lower for kiwicha flour (15.8 ± 1.3%). On the other hand, fat content of kañiwa flour (8.4 ± 0.4%) was comparable to the quinoa (7.9 ± 0.8%) and slightly higher than for kiwicha (7.2 ± 0.6%). Shotts et al. [37] reported that the highest percentage of fatty acids in these flours is Omega 6 (linoleic acid), being 50% for quinoa, ranging from 33 to 44% for kiwicha [38] and 43% for kañiwa. Huamani et al. [39] reported linoleic acid values between 45.8 and 49.6% for three kañihua ecotypes.

Metallic and semi-metallic composition (Table 2)

Pseudocereal flours are an excellent alternative to other known flours, such as wheat, since they not only by the content of vitamins, phytochemicals (saponins, polyphenols, phytosterols, etc.) and other interesting health-benefit compounds, but also they are important source of minerals (based on Ca, Fe, Zn, Cu, Mg, P etc. metallic and metalloid elements). Their Ca, Mg, Zn and Fe contents are comparable or even higher than in common grains, such as rice [11, 22]. It is important to mention that the literature does not report K, Mg, Na, Mn and Cu contents in kañiwa flour.

Taking into account the uncertainty values, S, Na, Zn and Cu levels were comparable among the three flours (See Tables 1 and 2). The literature reports scarce information on the quantification of S in these pseudocereals, despite the fact that all of them include important sulfur compounds.

It is interesting to mention that Ca content was almost twice in kiwicha (1000 mg kg−1) that in quinoa and kañiwa flours, and these values are within the reported ranges by the literature (See Table 2). Compared to other gluten-free flours, such as rice, maize, oat, millet, buckwheat, chickpea, tiger nut, or plantain, the Ca level in kiwicha is the highest [25]. About the metallic and metalloid levels in kañiwa (the least studied pseudocereal) flour: (i) Fe content (125 mg kg−1) was close to the value reported by Repo-Carrasco et al. [22] and higher than in kiwicha and quinoa flours. The Fe levels in kañiwa and kiwicha flours were higher than in several gluten-free flours analyzed by Coletu et al. [25]; (ii) Zn content (26 mg kg−1) was consistent with the value reported by Repo-Carrasco et al. [40] and comparable to the contents in kiwicha and quinoa flours; (iii) Mg, P and Mn contents were comparable to the corresponding levels in quinoa flour; and (iv) K content (4653 mg kg−1) was comparable to the level in kiwicha but lower than in quinoa (6608 mg kg−1).

Thermal and energetic properties

Specific heat capacities, c.e, of quinoa, kiwicha and kañiwa flours were determined (by DSC) in the temperature range of 261.15–343.15 K (See Fig. 1). For this range, we found no significant differences among the heat capacities of the flours, which are ranged between 1.3 and 1.9 J g−1 K−1. The similarity of the c.e. (T) trend of the three flours, would be related to the similarity among their corresponding empirical formulas (Table 1).c.e./J g−1 K−1 ranged from 261.15 to 313.15 K was fitted to quadratic polynomial function with R2 higher than 0.9:

Quinoa:\(c.e \left(T/\mathrm{K}\right)=5.1\bullet {10}^{-5 }\bullet {\left(T-{T}_{\mathrm{o}}\right)}^{2}+4.89\bullet {10}^{-3}\bullet (T-{T}_{\mathrm{o}})+1.367\)

Kiwicha:\(c.e \left(T/\mathrm{K}\right)=3.5\bullet {10}^{-5 }\bullet ({T-{T}_{\mathrm{o}})}^{2}+5.09\bullet {10}^{-3}\bullet (T-{T}_{\mathrm{o}})+1.387\)

Kañiwa:\(c.e (T/\mathrm{K})=5.6\bullet {10}^{-5 }\bullet {\left(T-{T}_{\mathrm{o}}\right)}^{2}+4.55\bullet {10}^{-3}\bullet (T-{T}_{\mathrm{o}})+1.360\)where To = 273.15 K. At room temperature (298.15 K), c.e./J g−1 K−1 of quinoa (1.54), kiwicha (1.52) and kañiwa (1.51) values were (i) lower than for corn-starch (2.07) and for the pseudocereal flours estimated by Muchekeza el al. [26]; (ii) comparable to millet grains and flours determined (using mixture method) by Subramanian and Viswanathan [41].

Figure 2 shows the thermal stability ranges, between 323.15 and 503.15 K, of the studied flours. We can define as up limit of the thermal-stability range to the decomposition temperature Tdec, which is associated with the typical decomposition thermal peak of organic matter (protein, lipids and fibers). For kiwicha flour, Bet et al. [27] found, using TG/TDG techniques, a stability range up to close 499 K. Their results indicate that at temperatures above 428.15–430.15 K, the lipids began to oxidase, leading the progressive decomposition of the sample.

Tdec followed the trend: Tdec, kañiwa (489.8 ± 1.6 K) > Tdec,kiwicha (479.1 ± 1.5 K) ≥ Tdec,quinoa (477.1 ± 1.5 K). This result indicates that thermal stability range of kañiwa flour is greater than of kiwicha and quinoa flours. The Tdec trend is the same as that of Cflour, which would be a consequence of the structural similarity among the three studied flours, where the empirical formulas of quinoa and kiwicha are barely distinguishable.

Gelatinization properties of the quinoa, kiwicha and kañiwa flours have been determined, using the DSC technique (See Fig. 3). Taking in account the uncertainty values, both temperature and enthalpy gelatinization parameters determined in this work are within of the range values reported in the literature (See Table 3). It is interesting to note for kañiwa flour, (i) the gelatinization-temperatures (onset Ti, final Tf and gelatinization-peak Tmax) were lower, between 1 and 4 K, than corresponding temperatures of quinoa and kiwicha flours; (ii) the gelatinization enthalpy ΔHgel (= 4.3 ± 1.6 J g−1) was very close to the reported by Luna-Mercado and Repo-Carrasco [23] (Illpa Inia variety) and Salas-Valero et al. [18] (Illpa Inia and Cupi varieties); and (iii) ΔHgel was lower than for kiwicha (5.7 J g−1) and quinoa flour (7.9 J g−1). This last trend is maintained for the corresponding starches, although ΔHgel of the flours are between 3 and 8 J g−1 less than for the starches [3, 28].

The variation in the thermal gelatinization properties of the different flours is related to characteristics of the starch granules (morphology, composition and molecular structure), presence and structure of compounds, such as amylopectins, proteins, dietary fibers and water contents, among other factors [25, 42]. In this context, the lower values of thermal gelatinization parameters of kañiwa flour would be due the presence of very small starch granules (> 2 μm), compared those of kiwicha and quinoa (both > 3.5 μm) [3, 43], which require less time to reach low gelatinization temperatures and to stabilize emulsions investing less energy to break their molecular interactions.

The combustion of the studied pseudocereal flours was complete, without the presence of residual biomass, traces of CO (checked by Dräger tubes) and neither C soot. The results are given in Table 4 (for more details, see Table S4). The absolute value of average standard massic energy of combustion (⟨Δcuo⟩, for four experiments) has been associated with the total energy content or net calorific value of the sample qNCV.

Within of the uncertainty values, qNCV of kiwicha flour (18.47 ± 0.11 kJ g−1 or 4415 ± 26 kcal kg−1) was comparable to the quinoa flour (18.60 ± 0.16 kJ g−1 or 4445 ± 39 kcal kg−1) and both slightly less than for kañiwa (18.77 ± 0.15 kJ g−1 or 4433 ± 35 kcal kg−1). These values are between, (i) 85 and 195 kcal kg−1 lower than those reported by Ortiz-Chura et al. [19] as “gross energy” and performed by combustion technique; (ii) 205 and 1822 kcal kg−1 higher than those reported by Pereira et al. [44], Luna-Mercado and Repo-Carrasco [23], Ayseli et al. [36], Navruz-Varli et al. [21], Burgos and Armada [45], Moscoso-Mujica et al. [46] and Nowak et al. [47] as “energy content” estimations considering protein + carbohydrates + fat contents. The closest value (less than 245 kcal kg−1) corresponds to the quinoa flour, estimated by Pereira et al. [44] applying the relation 4× (g protein) + 4 × (g carbohydrates) + 9 × (g fat). It is important to mention that Huang et al. [48] also estimated for quinoa flour, using the content protein/carbohydrates/fat relation of 9:4:4, a very high “energy” value (6879.4 kcal kg−1) which is not been considered in Table 4.

It is interesting to note that the net calorific value qNCV of kañiwa is slightly higher than the comparable values of kiwicha and quinoa flours. This result, supported by the combustion experiments, is consistent with the elemental analysis, given that the empirical formulas of quinoa and kiwicha flours are, within uncertainty of measurements, barely distinguishable. So, the qNCV trend is similar to the Cflour (elemental carbon concentration) and also to Tdec (decomposition temperature) trends. These results can be explained in terms of flour composition: a slightly higher Cflour concentration in kañiwa flour that in quinoa and kiwicha flours (which are rather similar). Cflour would be present in organic structures including, among others, C–C strong bonds.

Conclusions

In this work, we have been studied structural, thermal and energetic properties of quinoa (C. quinoa Willd.), kiwicha (A. caudatus) and particularly kañiwa (C. pallidicaule Allen) pseudocereal flours.

Taking into account the presence of most significant elements (C, H, O, N, S), we have determined the empirical formula of quinoa, kiwicha and kañiwa flours: CH1.87O0.81N0.06S0.0015, CH1.90O0.82N0.05S0.0019 and CH1.76O0.73N0.06S0.0017, respectively. The empirical formulas of quinoa and kiwicha flours are, within uncertainty of measurements, barely distinguishable and it is reflected on the elemental-carbon concentration (Cflour, mass %) which follows the trend, Ckañiwa (45.6%) > Ckiwicha (43.2%) ≈ Cquinoa (43.3%).

Our results showed no significant difference between protein content in kañiwa (18.6 ± 0.9%) and quinoa (17.4 ± 1.7%) flours and a slightly lower for kiwicha flour (15.8 ± 1.3%). This trend was also maintained for moisture and fat contents among the three flours. To estimate the fat concentration, we have proposed a new protein/fat ratio, 2.2:1.

With respect to metallic and semi-metallic contents, S, Na, Zn and Cu levels were comparable among the three flours. Fe content in kañiwa flour (125 mg kg−1) was higher than in kiwicha and quinoa flours, while K in quinoa (6608 mg kg−1) was the highest.

Our thermal and energetic results, using DSC technique, showed no significant differences of specific heat capacities c.e. among the three flours. This result would be a consequence of the similarity among the corresponding empirical formulas. Although, the decomposition temperature Tdec associates with the organic matter (protein, lipids and fibers) decomposition, followed the trend, 489.8 ± 1.6 K (kañiwa) > 479.1 ± 1.5 K (kiwicha) ≥ 477.1 ± 1.5 K (quinoa), which is the same as that of Cflour. About thermal gelatinization parameters of kañiwa flour, onset Ti (332.1 ± 2.2 K), final Tf (347.8 ± 2.0 K) and gelatinization peak Tmax (340.3 ± 2.2 K) temperatures were between 1 and 4 K, lower than the corresponding temperatures in quinoa and kiwicha flours. Its gelatinization enthalpy ΔHgel (= 4.3 ± 1.6 J g−1) was also lower than in quinoa (7.9 ± 0.6 J g−1) and kiwicha flour (5.7 ± 1.0 J g−1).

The total energy content or net calorific value qNCV, performed with combustion calorimetry, of kañiwa (4487 ± 36 kcal kg−1) was slightly greater than for the comparable values of kiwicha and quinoa flours, 4415 ± 26 and 4445 ± 39 kcal kg−1, respectively. Within corresponding uncertainty values, the qNCV trend is the same to the Tdec (decomposition temperature) and Cflour (elemental carbon concentration) trends. These results would indicate that kañiwa has a greater thermal stability range and also a greater energetic content than kiwicha and quinoa flours.

References

Taylor JR, Parker ML. Quinoa. In: Taylor JRN, Belton PS, editors. Pseudocereals and less common cereals. New York: Springer; 2002. p. 93–122.

Valencia-Chamorro SA. Quinoa: overview. In: Corke H, Faubion J, Seetheraman K, Wrigley C, editors. Encyclopedia of food grains. 2nd ed. Oxford: Academic Press; 2016. p. 341–8.

Perez-Rea D, Antezana-Gomez R. Chapter 12 The functionality of pseudocereal starches. In: Starch in food. Elsevier; 2018. p. 509–42.

FAO Food and Agriculture Organization of the United Nations. Quinoa: an ancient crop to contribute to World Food Security. Regional Office for Latin America and the Caribbean, Vitacura, Santiago de Chile; 2012.

Jacobsen SE, Mujica A, Ortiz R. The global potential for quinoa and other Andean crops. Food Rev Int. 2003. https://doi.org/10.1081/FRI-120018880.

Niro S, D’Agostino A, Fratianni A, Cinquanta L, Panfili G. Gluten-free alternative grains: nutritional evaluation and bioactive compounds. 2019. Foods. https://doi.org/10.3390/foods8060208.

Gil JV, Esteban-Muñoz A, Fernández-Espinar MT. Changes in the polyphenolic profile and antioxidant activity of wheat bread after incorporating quinoa flour. Antioxidants. 2022. https://doi.org/10.3390/antiox11010033.

Romano A, Masia P, Nicolai MA, Falciano A, Ferranti P. Quinoa (Chenopodium quinoa Willd). Flour as novel and safe ingredient in bread formulation. Chem Eng Trans. 2019. https://doi.org/10.3303/CET1975051.

Choque-Delgado GT, Carlos-Tapia KV, Pacco-Huamani MC, Hamaker BR. Peruvian Andean grains: nutritional, functional properties and industrial uses. Crit Rev Food Sci Nutr. 2022. https://doi.org/10.1080/10408398.2022.2073960.

Shi D, Fidelis M, Ren Y, Stone AK, Ai Y, Nickerson MT. The functional attributes of Peruvian (Kankolla and Blanca juli blend) and Northern quinoa (NQ94PT) flours and protein isolates, and their protein quality. Food Res Int. 2020. https://doi.org/10.1016/j.foodres.2019.108799.

Nascimento AC, Mota C, Coelho I, Gueifão S, Santos M, Matos AS, Gimenez A, Lobo M, Samman N, Castanheira I. Characterisation of nutrient profile of quinoa (Chenopodium quinoa), amaranth (Amaranthus caudatus), and purple corn (Zea mays L.) consumed in the North of Argentina: proximates, minerals and trace elements. Food Chemistry. 2014. https://doi.org/10.1016/j.foodchem.2013.09.155.

Alvarez-Jubete L, Arendt EK, Gallagher E. Nutritive value and chemical composition of pseudocereals as gluten-free ingredient. Int J Food Sci Nutr. 2009. https://doi.org/10.1080/09637480902950597.

Paśko P, Tyszka-Czochara M, Namieśnik J, Jastrzębski Z, Leontowicz H, Drzewiecki J, Martínez-Ayala AL, Nemirovski A, Baraschg D, Gorinstein S. Cytotoxic, antioxidant and binding properties of polyphenols from the selected gluten-free pseudocereals and their by-products: in vitro model. J Cereal Sci. 2019. https://doi.org/10.1016/j.jcs.2019.04.009.

De Bock P, Daelemans L, Selis L, Raes K, Varmeir P, Eeckhout M. Comparison of the chemical and technological characteristics of whole meal flours obtained from Amaranth (Amaranthus sp.), Quinoa (Chenopodium quinoa) and Buckwheat (Fagopyrum sp.) Seeds. 2021. Foods. https://doi.org/10.3390/foods10030651.

Martínez-Villaluenga C, Peñas E, Hernández-Ledesma B. Pseudocereal grains: nutritional value, health benefits and current applications for the development of gluten-free foods. Food Chem Toxicol. 2020. https://doi.org/10.1016/j.fct.2020.111178.

Gorinstein S, Lojek A, Cíz M, Pawelzik E, Delgado-Licon E, Medina OJ, Moreno M, Salas IA, Goshev I. Comparison of composition and antioxidant capacity of some cereals and pseudocereals. Int J Food Sci Nutr. 2008. https://doi.org/10.1080/09637480310001622305.

Contreras-Jiménez B, Torres-Vargas OL, Rodríguez-García ME. Physicochemical characterization of quinoa (Chenopodium quinoa) flour and isolated starch. Food Chem. 2019. https://doi.org/10.1016/j.foodchem.2019.124982.

Salas-Valero LM, Tapia-Blácido DR, Menegalli FC. Biofilms based on canihua flour (Chenopodium Pallidicaule): design and characterization. Quím Nova. 2015. https://doi.org/10.5935/0100-4042.20140275.

Ortiz-Chura A, Pari-Puma RM, Rodríguez-Huanca FH, Cerón-Cucchi ME, Araníbar-Araníbar MJ. Apparent digestibility of dry matter, organic matter, protein and energy of native Peruvian feedstuffs in juvenile rainbow trout (Oncorhynchus mykiss). Fish Aquat Sci. 2018. https://doi.org/10.1186/s41240-018-0111-2.

Repo-Carrasco-Valencia R, Acevedo de La Cruz A, Icochea Alvarez JC, Kallio H. Chemical and functional characterization of Kañiwa (Chenopodium pallidicaule) grain, extrudate and bran. Plant Foods Hum Nutr. 2009. https://doi.org/10.1007/s11130-009-0109-0.

Navruz-Varli S, Sanlier N. Nutritional and health benefits of quinoa (Chenopodium quinoa Willd.). J Cereal Sci. 2016. https://doi.org/10.1016/j.jcs.2016.05.004.

Repo-Carrasco R, Espinoza C, Jacobsen SE. Nutritional value and use of the Andean crops quinoa (Chenopodium quinoa) and Kañiwa (Chenopodium pallidicaule). Food Rev Int. 2003. https://doi.org/10.1081/FRI-120018884.

Luna-Mercado G, Repo-Carrasco R. Gluten-free bread applications: thermo-mechanical and techno-functional characterization of Kañiwa flour. Cereal Chem. 2021. https://doi.org/10.1002/cche.10386.

Steffolani ME, León AE, Pérez GT. Study of the physicochemical and functional characterization of quinoa and kañiwa starches. Starch. 2013. https://doi.org/10.1002/star.201200286.

Culetu A, Susman IE, Duta DE, Belc N. Nutritional and functional properties of gluten-free flours. Appl Sci. 2021. https://doi.org/10.3390/app11146283.

Muchekeza JT, Jombo TZ, Magogo C, Mugari A, Manjeru P, Manhokwe S. Proximate, physico-chemical, functional and sensory properties OF quinoa and amaranth flour AS potential binders in beef sausages. Food Chem. 2021. https://doi.org/10.1016/j.foodchem.2021.130619.

Bet DC, de Oliveira SC, Colman TAD, Bisinella RZB, Beninca C, Lacerda LG, Ramos AP, Schnitzler E. Aqueous extraction of organic amaranth starch and their by-products: characterisation before and after degreasing. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08374-7.

Fuentes C, Perez-Rea D, Bergenstáhl B, Carballo S, Sjööa M, Nilsson L. Physicochemical and structural properties of starch from five Andean crops grown in Bolivia. Int J Biol Macromol. 2019. https://doi.org/10.1016/j.ijbiomac.2018.12.120.

Ahmed J, Thomas L, Arfat YA. Functional, rheological, microstructural and antioxidant propertied of quinoa flour in dispersions as influenced by particle size. Food Res Int. 2019. https://doi.org/10.1016/j.foodres.2018.08.039.

Dávalos JZ, Roux MV, Jiménez P. Evaluation of poultry litter as a feasible fuel. Thermochim Acta. 2002. https://doi.org/10.1016/S0040-6031(02)00256-3.

Toscano G, Pedretti EF. Calorific value determination of solid biomass fuel by simplified method. J Agric Eng. 2009. https://doi.org/10.4081/jae.2009.3.1.

Gatta GD, Richardson MJ, Sarge S, Stølen S. Standards, calibration, and guidelines in microcalorimetry. Part 2. Calibration standards for differential scanning calorimetry* (IUPAC technical report). Pure Appl Chem. 2006. https://doi.org/10.1351/pac200678071455.

Callanan JE, Sullivan SA. Development of standard operating procedures for differential scanning calorimeters. Rev Sci Instrum. 1986. https://doi.org/10.1063/1.1139063.

Mariotti F, Tomé D, Mirand P. Converting nitrogen into protein—beyond 6.25 and Jones’ factors. Food Sci. Nutr. 2008. https://hal.archives-ouvertes.fr/hal-02105858.

Alizadeh-Bahaabadi G, Lakzadeh L, Forootanfar H, Akhavan H-R. Optimization of gluten-free bread production with low aflatoxin level based on quinoa flour containing xanthan gum and laccase enzyme. Int J Biol Macromol. 2022. https://doi.org/10.1016/j.ijbiomac.2021.12.091.

Ayseli MT, Yilmaz MT, Cebi N, Sagdic O, Ozmen D, Capanoglu E. Physicochemical, rheological, molecular, thermal and sensory evaluation of newly developed complementary infant (6–24 months old) foods prepared with quinoa (Chenopodium quinoa Willd.) flour. Food Chem. 2020. https://doi.org/10.1016/j.foodchem.2020.126208.

Shotts ML, Pujolras MP, Rossell C, Rodriguez-Saona L. Authentication of indigenous flours (Quinoa, Amaranth and kaniwa) ~ from the Andean region using a portable ATR-Infrared device in combination with pattern recognition analysis. J Cereal Sci. 2018. https://doi.org/10.1016/j.jcs.2018.04.005.

Repo-Carrasco R, Peña J, Kallio H, Salminen S. Dietary fiber and other functional components in two varieties of crude and extruded kiwicha (Amaranthus caudatus). J Cereal Sci. 2009. https://doi.org/10.1016/j.jcs.2008.10.003.

Huamaní F, Tapia M, Portales R, Doroteo V, Ruiz C, Rojas R. Proximate analysis, phenolics, betalains, and antioxidant activities of three ecotypes of kañiwa (chenopodium pallidicaule aellen) from Perú. PhOL 2020. http://pharmacologyonline.silae.it.

Repo-Carrasco-Valencia RAM, Encina CR, Binaghi MJ, Greco CB, de Ferrer PAR. Effects of roasting and boiling of quinoa, kiwicha and kañiwa on composition and availability of minerals in vitro. J Sci Food Agric. 2010. https://doi.org/10.1002/jsfa.4053.

Subramanian S, Viswanathan R. Thermal properties of minor millet grains and flours. Biosyst Eng. 2003. https://doi.org/10.1016/S1537-5110(02)00222-2.

Schirmer M, Jekle M, Becker T. Starch gelatinization and its complexity for analysis. Starch/Stärke. 2015. https://doi.org/10.1002/star.201400071.

Cornejo-Ramírez YI, Martínez-Cruz O, Del Toro-Sánchez CL, Wong-Corral FJ, Borboa-Flores J, Cinco-Moroyoqui FJ. The structural characteristics of starches and their functional properties. CyTA J Food. 2018. https://doi.org/10.1080/19476337.2018.1518343.

Pereira E, Encina-Zelada C, Barros L, Gonzales-Barrona U, Cadavez V, Ferreira ICFR. Chemical and nutritional characterization of Chenopodium quinoa Willd (quinoa) grains: a good alternative to nutritious food. Food Chem. 2019. https://doi.org/10.1016/j.foodchem.2018.12.068.

Burgos VE, Armada M. Characterization and nutritional value of precooked products of kiwicha grains (Amaranthus caudatus). Food Sci Technol. 2015. https://doi.org/10.1590/1678-457X.6767.

Moscoso-Mujica G, Zavaleta A, Mujica A, Santos M, Calixto R. Fractionation and electrophoretic characterization of (Chenopodium pallidicaule Aellen) kanihua seed proteins. Rev Chil Nutr. 2017. https://doi.org/10.4067/S0717-75182017000200005.

Nowak V, Du J, Charrondière UR. Assessment of the nutritional composition of quinoa (Chenopodium quinoa Willd.). Food Chem. 2016. https://doi.org/10.1016/j.foodchem.2015.02.111.

Huang R, Huang K, Guan X, Li S, Cao H, Zhang Y, Lao X, Bao Y, Wang J. Effect of defatting and extruding treatment on the physicochemical and storage properties of quinoa (Chenopodium quinoa Wild) flour. LWT Food Sci Technol. 2021. https://doi.org/10.1016/j.lwt.2021.111612.

Hubbard WN, Scott DW, Waddington G. Chap. 5 Experimental thermochemistry. Rossini FD, editor. Interscience: New York; 1956.

Acknowledgements

This work is dedicated to Ing. Clemente Limaylla (UNSCH-Ayacucho). JZDP appreciates the facilities of the Thermochemical laboratory of IQFR-CSIC (Madrid). GCS acknowledges the support from the Peruvian funding “Vice Presidency of Research and the Faculty of International Business Administration of the UNISCJSA (Satipo).” ATR and VRC acknowledge to Peruvian funding agency CONCYTEC (DE N° 077-2014 FONDECYT).

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature.

Author information

Authors and Affiliations

Contributions

JZDP involved in data analysis and writing—original draft. ATR involved in data combustion and review. VRC involved in DSC experiments and review. GCS involved in elemental analysis and review. FGG involved in data analysis, metallic analysis and review. All authors commented on previous versions of the manuscript, read, and approved the final version.

Corresponding author

Ethics declarations

Conflict of interest

The authors of this paper declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Dávalos, J.Z., Tirado, A., Romero, V. et al. Structural, thermal and energetic properties of Andean-pseudocereal flours with high nutritional values. J Therm Anal Calorim 148, 7207–7215 (2023). https://doi.org/10.1007/s10973-023-12224-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12224-y