Abstract

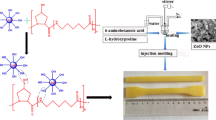

Polysilsesquioxanes are extensively studied as durable and anti-adherent coatings for medical devices due to their superhydrophobic properties. However, their particular influence on the thermo-mechanical properties and biocompatibility of poly(lactic acid) (PLA)-based materials obtained by melt compounding is scarce. Herein, a facile and promising method to improve the performances of PLA for biomedical applications via the incorporation of different mass proportions of POSS nanoparticles with allyl-heptaisobutyl (AH-POSS) substituent through a melt-blending technique is proposed. The thermal, morpho-structural, mechanical properties at room (RT) and body temperatures (BT), and in vitro biocompatibility of the developed PLA/AH-POSS nanohybrids were investigated. AH-POSS nanoparticles were found to have simultaneous nucleation and plasticizing effects on the PLA nanohybrids, inducing enhanced thermal resistance and easy control of crystallinity while preserving PLA’s biocompatibility. An interesting effect of AH-POSS on the mechanical properties of PLA at body temperature was observed. These results indicate the considerable potential of the PLA/AH-POSS nanohybrids obtained by melt compounding in the fabrication of biomedical devices.

Similar content being viewed by others

References

He L, Song F, Guo ZW, Zhao X, Yang N, Wang XL. Toward strong and super-toughened PLA via incorporating a novel fully bio-based copolyester containing cyclic sugar. Compos Part B: Eng. 2021;207:108558.

Inácio EM, Lima MCP, Souza DHS, Sirelli L, Dias ML. Crystallization, thermal and mechanical behavior of oligosebacate plasticized poly(lactic acid) films. Polímeros. 2018;28(5):381–8.

Sirin H, Kodal M, Ozkoc G. The influence of POSS type on theproperties of PLA. PolymCompos. 2016;37:1497–506.

Najaf OB, Davachi SM, Hejazi I, Seyfi J, Khonakdar HA, Abbaspourrad A. Enhancedcompatibility of starch with poly(lactic acid) and poly(ɛ-caprolactone) by incorporation of POSS nanoparticles: Study on thermalproperties. Int J Biol Macromol. 2019;141:578–84.

Rezaei H, Seifi S, Moeinifar E, Hejazi I, Seyfi J, Khonakdar HA. Effect of nanoparticletypeand content on morphology, rheology, andcrystallinity of poly(lactic acid) using titanium dioxide and polyhedral oligomeric silsesquioxane nanoparticles. PolymCompos. 2020;41:1551–60.

Jia L, Tong B, Li D, Zhang W, Yang R. Crystallization and flame-retardant properties of polylactic acid composites with polyhedral octaphenyl silsesquioxane. Polym Adv Technol. 2019;30:648–65.

Popa MS, Frone AN, Panaitescu DM. Polyhydroxybutyrate blends: A solution for biodegradable packaging? Int J Biol Macromol. 2022;207:263–77.

Dandan DM, Aynali F, Doganci E, Ozkoc G. Mechanical, thermalandmorphologicalproperties of poly(lactic acid) byusing star-shapedpoly(ε-caprolactone) with POSS core. EurPolym J. 2019;121:109316.

Nofar M, Salehiyan R, Ciftci U, Jalali A, Durmuş A. Ductility improvements of PLA-based binary and ternary blends with controlled morphology using PBAT, PBSA, and nanoclay. Compos Part B: Eng. 2020;182:107661.

Frone AN, Batalu D, Chiulan I, Oprea M, Gabor AR, Nicolae CA, Raditoiu V, Trusca R, Panaitescu DM. Morpho-structural, thermal and mechanical properties of PLA/PHB/cellulose biodegradable nanocomposites obtained by compression molding, extrusion, and 3D printing. Nanomaterials. 2019;10:51.

Liu Z, Hu D, Huang L, Li W, Tian J, Lu L, Zhou C. Simultaneous improvement in toughness, strength and biocompatibility of poly(lactic acid) with polyhedral oligomeric silsesquioxane. ChemEng J. 2018;346:649–61.

Wasti S, Triggs E, Farag R, Auad M, AdhikariS BD, Li M, Ragauskas AJ. Influence of plasticizers on thermal and mechanical properties of biocomposite filaments made from lignin and polylactic acid for 3D printing. Compos Part B Eng. 2021;205:108483.

Shen H, Li Y, Yao W, Yang S, Yang L, Pan F, et al. Solvent-free cellulose nanocrystal fluids for simultaneous enhancement of mechanical properties, thermal conductivity, moisture permeability and antibacterial properties of polylactic acid fibrous membrane. Compos Part B Eng. 2021;222:109042.

Raftopoulos KN, Pielichowski K. Segmental dynamics in hybrid polymer/POSS nanomaterials. ProgPolym Sci. 2016;52:136–87.

Frone AN, Perrin FX, Radovici C, Panaitescu DM. Influence of branched or un-branched alkyl substitutes of POSS on morphology, thermal and mechanical properties of polyethylene. Compos Part B Eng. 2013;50:98–106.

Li B, Zhang Y, Wang S, Ji J. Effect of POSS on morphology and properties of poly(2,6-dimethyl-1,4-phenylene oxide)/polyamide 6 blends. EurPolym J. 2009;45:2202–10.

Turan D, Sirin H, Ozkoc G. Effects of POSS particles on the mechanical, thermal, and morphological properties of PLA and plasticised PLA. J ApplPolym Sci. 2011;121:1067–75.

Panaitescu DM, Frone AN, Radovici C, Nicolae C, Perrin FX. Influence of octyl substituted octakis(dimethylsiloxy)octasilsesquioxane on the morphology and thermal and mechanical properties of low density polyethylene. Polym Int. 2013;63:228–36.

Mihelčič M, Gaberšček M, Salzano de Luna M, Lavorgna M, Giuliani C, Di Carlo G, et al. Influence of silsesquioxane addition on polyurethane-based protective coatings for bronze surfaces. Appl Surf Sci. 2019;467:912–25.

Perrin FX, Panaitescu DM, Frone AN, Radovici C, Nicolae C. The influence of alkyl substituents of POSS in polyethylene nanocomposites. Polymer. 2013;54:2347–54.

Swapna VP, Abhisha VS, Stephen R. Polymer/polyhedral oligomeric silsesquioxane nanocomposite membranes for pervaporation. In: Thomas S, George SC, Jose T, editors. Polymer Nanocomposite Membranes for Pervaporation. Elsevier; 2020. p. 201–29.

Yilmaz S, Kodal M, Yilmaz T, Ozkoc G. Fracture toughness analysis of O-POSS/PLA composites assessed by essential work of fracture method. Compos Part B: Eng. 2014;56:527–35.

Blanco I, Abate L, Bottino F, Bottino P. Hepta isobutyl polyhedral oligomeric silsesquioxanes (hib-POSS). J Therm Anal Calorim. 2011;108:807–15.

Lu Y, Dong S, Pa Z, Liu X, Wang X. Preparation of a polylactic acid knitting mesh for pelvic floor repair and in vivo evaluation. J MechBehav Biomed Mater. 2017;74:204–13.

Haaparanta AM, Järvinen E, Cengiz IF, Ellä V, Kokkonen HT, Kiviranta I, Kellomäki M. Preparation and characterization of collagen/PLA, chitosan/PLA, and collagen/chitosan/PLA hybrid scaffolds for cartilage tissue engineering. J Mater Sci Mater Med. 2014;25:1129–36.

Jinescu G, Bacalbasa N, EvtodievA MI-A, Chiulan I, Radu ER, Frone AN, Costea R, Raita S. Perspectives of silicone elastomere implants use in preventing postoperative complications in pelvic exenteration for advanced cancers. Rev Chim. 2020;71:45–50.

Park S, Jung S, Heo J, Hong J. Facile synthesis of polysilsesquioxane toward durable superhydrophilic/superhydrophobic coatings for medical devices. J IndEng Chem. 2019;77:97–104.

Hwangbo S, Heo J, Lin X, Choi M, Hong J. Transparent superwetting nanofilms with enhanced durability at model physiological condition. Sci Rep. 2016;6:9178.

Chen Y, Liu S, Zhou Y, Zeng G, Liu W. Biodegradable PLA-based composites modified by POSS particles. PolymPlast Tech Mat. 2020;59:998–1009.

Soong SY, Cohen RE, Boyce MC, Mulliken AD. Rate-dependent deformation behavior of POSS-filled and plasticized poly(vinyl chloride). Macromolecules. 2006;39:2900–8.

Zhong J, Liu X, Wei D, Yan J, Wang P, Sun G, He D. Effect of incubation temperature on the self-assembly of regenerated silk fibroin: a study using AFM. Int J BiolMacromol. 2015;76:195–202.

Park ES, Ro HW, Nguyen CV, Jaffe RL, Yoon DY. Infrared spectroscopy study of microstructures of poly(silsesquioxane)s. Chem Mater. 2008;20:1548–54.

Zhang W, Yang R. Synthesis of phosphorus-containing polyhedral oligomeric Silsesquioxanes via hydrolytic condensation of a modified Silane. J ApplPolym Sci. 2011;122:3383–9.

Deschner T, Lønstad BT, Widenmeyer M, Anwander R. Functionalization of MCM-41 and SBA-1 with titanium(IV) (silyl)amides. J Mater Chem. 2011;21:5620–8.

Bianchi O, Martins JN, Luvison C, Echeverrigaray SG, Dal Castel C, Oliveira RVB (2014) Melt crystallization kinetics of polyhedral oligomeric silsesquioxane under non-isothermal conditions. J Non Cryst Solids. pp 394–395

Morici E, BartoloA Di, Arrigo R, Dintcheva NT. POSS grafting on polyethylene and maleic anhydride-grafted polyethylene by one-step reactive melt mixing. AdvPolym Technol. 2018;37:349–57.

Zhao H, She W, Shi D, Wu W, Zhang Q. Polyurethane/POSS nanocomposites for superior hydrophobicity and high ductility. Compos Part B: Eng. 2019;177:107441.

Bocchini S, Fukushima K, Di Blasio A, Fina A, Frache A, Geobaldo F. Polylactic acid and polylactic acid-based nanocomposite photooxidation. Biomacromol. 2010;11:2919–26.

El-hadi AM. Increase the elongation at break of poly (lactic acid) composites for use in food packaging films. Sci Rep. 2017;7:46767.

Sourkouni G, Kalogirou C, Moritz P, Gödde A, Pandis PK, Höfft O, Vouyiouka S, Zorpas AA, Argirusis C. Study on the influence of advanced treatment processes on the surface properties of polylactic acid for a bio-based circular economy for plastics. UltrasonSonochem. 2021;76:105627.

Pan P, Liang Z, Zhu B, Dong T, Inoue Y. Roles of physical aging on crystallization kinetics and induction period of poly(l-lactide). Macromolecules. 2008;41:8011–9.

Frone AN, Berlioz S, Chailan JF, Panaitescu DM. Morphology and thermal properties of PLA–cellulose nanofibers composites. CarbohydrPolym. 2013;91:377–84.

Baptista C, Azagury A, Baker CM, Mathiowitz E. The characterization and quantification of the induced mesophases of poly-l-lactic acid. Polym. 2021;226:123822.

Wang W, Jie X, Fei M, Jiang H. Synthesis of core-shell particles by batch emulsion polymerization of styrene and octavinyl polyhedral oligomeric silsesquioxane. J Polym Res. 2011;18:13–7.

Harris AM, Lee EC. Improving mechanical performance of injection molded PLA by controlling crystallinity. J ApplPolym Sci. 2008;107:2246–55.

Frone AN, Panaitescu DM, Chiulan I, Nicolae CA, Vuluga Z, Vitelaru C, Damian CM. The effect of cellulose nanofibers on the crystallinity and nanostructure of poly(lactic acid) composites. J Mater Sci. 2016;51:9771–91.

Xu JZ, Chen T, Yang CL, Li ZM, Mao YM, Zeng BQ, Hsiao BS. Isothermal crystallization of poly(l-lactide) induced by graphene nanosheets and carbon nanotubes: a comparative study. Macromolecules. 2010;43:5000–8.

Meaurio E, Lopez-Rodrıguez N, Sarasua JR. Infrared spectrum of poly(l-lactide): application to crystallinity studies. Macromolecules. 2006;9:9291–301.

Silverajah VSG, Ibrahim NA, Yunus WMZW, Hassan HA, Woei CB. A comparative study on the mechanical, thermal and morphological characterization of poly(lactic acid)/epoxidized palm oil blend. Int J Molec Sci. 2012;13:5878–98.

Liu Y, Zheng S. Inorganic-organic nanocomposites of polybenzoxazine with octa(propylglycidyl ether) polyhedral oligomeric silsesquioxane. J PolymSci Part A Polym Chem. 2006;44:1168–81.

Xu S, Tahon JF, De-Waele I, Stoclet G, Gaucher V. Brittle-to-ductile transition of PLA induced by macromolecular orientation. eXPRESS Polym Lett. 2020;14(11):1037–47.

Chen Y, Zhao L, Pan H, Jia S, Han L. Impact of d-isomer content on the microstructure and mechanical properties of uniaxially pre-stretched poly(lactic acid). Polymer. 2020;186:122022.

Chen Y, Han L, Chen H, Jia S, Dong L. Effect of nanoscale dispersed silica on the fabrication of microporous poly(l-lactic acid) by uniaxial stretching. Compos Part A App Sci. 2018;112:423–31.

Van Loock F, Fleck NA. Deformation and failure maps for PMMA in uniaxial tension. Polymer. 2018;148:259–68.

Arif MF, Saintier N, Meraghni F, Fitoussi J, Chemisky Y, Robert G. Multiscale fatigue damage characterization in short glass fiber reinforced polyamide-66. Comp Part B Eng. 2014;61:55–65.

Kim CH, Khil MS, Kim HY, Lee HU, Jahng KY. An improved hydrophilicity via electrospinning for enhanced cell attachment and proliferation. J Biomed Mater Res Part B. 2006;2006(78B):283–90.

Acknowledgements

This work was supported by a grant of the Ministry of Research, Innovation and Digitization, CNCS/CCCDI – UEFISCDI, project number 67TE/2020, within PNCDI III

Author information

Authors and Affiliations

Contributions

ANF contributed to conceptualization, methodology, funding acquisition, and writing—review and editing; DDB contributed to formal analysis and investigation; MSP contributed to methodology and investigation; CAN contributed to investigation and data curation; ARG, MFR and RCF contributed to investigation; DMP contributed to writing—review and editing and validation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Frone, A.N., Baciu, D.D., Popa, M.S. et al. Thermal behavior and thermo-mechanical properties of biocompatible poly(lactic acid)/allyl-POSS nanohybrids. J Therm Anal Calorim 148, 10465–10479 (2023). https://doi.org/10.1007/s10973-023-12196-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12196-z