Abstract

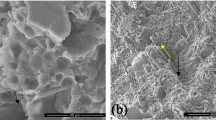

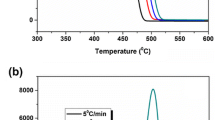

In this study, recycled high-density polyethylene (REHDPE)/black shale (B-shale) composites were prepared by a melt-blending method using a B-shale nucleating agent and polyolefin elastomer (POE) and acrylic impact modifier (ACR) as plasticizers. The melt index, microstructure, mechanical properties, and non-isothermal crystallization behavior of REHDPE were analyzed to determine the effects of the nucleating agent and plasticizer. Scanning electron microscopy and the melt index indicated that POE and ACR increased the melt flow rate of the composites and improved the interfacial properties of B-shale and REHDPE. The non-isothermal crystallization processes of the REHDPE and REHDPE composites were successfully described by Hoffmann–Lauritzen theory, demonstrating that B-shale, POE, and ACR can synergistically accelerate the crystallization process of REHDPE. The Friedman method revealed that B-shale, POE and ACR reduced the crystallization activation energy by heterogeneous nucleation and increasing the melt flow, respectively. The POE and ACR further enhanced the nucleation activity of B-shale and the nucleation activity is negatively correlated with the B-shale content according to the Dobreva and Gutzow’s methods. The synergistic effect of nucleating agent and plasticizer improved the mechanical properties of REHDPE and solved the problem in relatively low mechanical properties of recycled plastics. And it will provide a new strategy for the practical production of REHDPE.

Similar content being viewed by others

References

Ghosh A. Performance modifying techniques for recycled thermoplastics. Resour Conserv Recycl. 2021. https://doi.org/10.1016/j.resconrec.2021.105887.

Thiounn T, Smith RC. Advances and approaches for chemical recycling of plastic waste. J Polym Sci. 2020. https://doi.org/10.1002/pol.20190261.

Wang Z, Burra KG, Lei T, Gupta AK. Co-pyrolysis of waste plastic and solid biomass for synergistic production of biofuels and chemicals-a review. Prog Energy Combust. 2021. https://doi.org/10.1016/j.pecs.2020.100899.

Geyer R, Jambeck JR, Law KL. Production, use, and fate of all plastics ever made. Sci Adv. 2017. https://doi.org/10.1126/sciadv.1700782.

Andrady AL. The plastic in microplastics: a review. Mar Pollut Bull. 2017. https://doi.org/10.1016/j.marpolbul.2017.01.082.

Gigault J, El Hadri H, Nguyen B, Grassl B, Rowenczyk L, Tufenkji N, et al. Nanoplastics are neither microplastics nor engineered nanoparticles. Nat Nanotechnol. 2021. https://doi.org/10.1038/s41565-021-00886-4.

Song S, Wang J, Liu C, Wang J, Zhang Y. A facile route to fabricate thermally conductive and electrically insulating polymer composites with 3D interconnected graphene at an ultralow filler loading. Nanoscale. 2019. https://doi.org/10.1039/c9nr05153h.

Mitrano DM, Wick P, Nowack B. Placing nanoplastics in the context of global plastic pollution. Nat Nanotechnol. 2021. https://doi.org/10.1038/s41565-021-00888-2.

Bijaisoradat O, Luttapreecha M, Manuspiya H. Eco composites with synergistic combinations of natural rubber latex and wood flour toughened recycled HDPE. Mater Today Commun. 2020. https://doi.org/10.1016/j.mtcomm.2020.101483.

Arshad M. Kinetics of crystallization mechanisms in high density polyethylene and isotactic polypropylene. Polym Sci A. 2021. https://doi.org/10.1134/S0965545X22030014.

Li H, Huneault MA. Effect of nucleation and plasticization on the crystallization of poly(lactic acid). Polymer. 2007. https://doi.org/10.1016/j.polymer.2007.09.020.

Chen L, Dou Q. Influence of the combination of nucleating agent and plasticizer on the non-isothermal crystallization kinetics and activation energies of poly(lactic acid). J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-019-08507-y.

Jiang L, Shen T, Xu P, Zhao X, Li X, Dong W, et al. Crystallization modification of poly(lactide) by using nucleating agents and stereocomplexation. E-Polymers. 2016. https://doi.org/10.1515/epoly-2015-0179.

Liu C, Qiu H, Liu C, Zhang J. Study on crystal process and isothermal crystallization kinetics of UHMWPE/CA-MMT composites. Polym Compos. 2012. https://doi.org/10.1002/pc.22339.

Bokobza L. Infrared linear dichroism for the analysis of molecular orientation in polymers and in polymer composites. Polymers. 2022. https://doi.org/10.3390/polym14061257.

Jeziorny A. Parameters characterizing the kinetics of the non-isothermal crystallization of poly(ethylene terephthalate) determined by d.s.c. Polymer. 1978. https://doi.org/10.1016/0032-3861(78)90060-5.

Ozawa T. Kinetics of non-isothermal crystallization. Polymer. 1971. https://doi.org/10.1016/0032-3861(71)90041-3.

Liu T, Mo Z, Wang S, Zhang H. Nonisothermal melt and cold crystallization kinetics of poly(aryl ether ether ketone ketone). Polym Eng Sci. 1997. https://doi.org/10.1002/pen.11700.

Liu T, Mo Z, Zhang H. Nonisothermal crystallization behavior of a novel poly(aryl ether ketone): PEDEKmK. J Appl Polym Sci. 1998. https://doi.org/10.1002/(SICI)1097-4628(19980131)67:5%3c815::AID-APP6%3e3.0.CO;2-W.

Wu Z, Zhang Z, Mai K. Non-isothermal crystallization kinetics of UHMWPE composites filled by oligomer-modified CaCO3. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-019-08428-w.

Ong M, Chow W. Kinetics of crystallization for polypropylene/polyethylene/halloysite nanotube nanocomposites. J Thermoplast Compos Mater. 2020. https://doi.org/10.1177/0892705718807953.

Ahmad IA, Kim HK, Deveci S, Kumar RV. Non-Isothermal crystallisation kinetics of carbon black- graphene-based multimodal-polyethylene nanocomposites. Nanomater (Basel). 2019. https://doi.org/10.3390/nano9010110.

Huang R, Teng Z. Non-isothermal crystallization and thermal degradation properties of three phase composites from wood flour, high-density polyethylene and basalt fibers. Wood Sci Technol. 2022. https://doi.org/10.1007/s00226-022-01391-0.

Zhang Q, Yi W, Li Z, Wang L, Cai H. Mechanical properties of rice husk biochar reinforced high density polyethylene composites. Polymers. 2018. https://doi.org/10.3390/polym10030286.

Dolçà C, Fages E, Gonga E, Garcia-Sanoguera D, Balart R, Quiles-Carrillo L. The effect of varying the amount of short hemp fibers on mechanical and thermal properties of wood-plastic composites from biobased polyethylene processed by injection molding. Polymers. 2021. https://doi.org/10.3390/polym14010138.

Jose JP, Chazeau L, Cavaillé JY, Varughese KT, Thomas S. Nucleation and nonisothermal crystallization kinetics in cross-linked polyethylene/zinc oxide nanocomposites. RSC Adv. 2014. https://doi.org/10.1039/C4RA03731F.

Mofokeng TG, Ray SS, Ojijo V. Influence of selectively localised nanoclay particles on non-isothermal crystallisation and degradation behaviour of PP/LDPE blend composites. Polymers. 2018. https://doi.org/10.3390/polym10030245.

Haq S, Srivastava R. Wood polypropylene (PP) composites manufactured by mango wood waste with virgin or recycled PP: mechanical, morphology, melt flow index and crystalline behaviour. J Polym Environ. 2017. https://doi.org/10.1007/s10924-016-0845-9.

Carvalho MSD, Azevedo JB, Barbosa JDV. Effect of the melt flow index of an HDPE matrix on the properties of composites with wood particles. Polym Test. 2020. https://doi.org/10.1016/j.polymertesting.2020.106678.

Wu J, Chen C, Wu Y, Wu G, Kuo M, Tsai Y. Mechanical properties, morphology, and crystallization behavior of polypropylene/elastomer/talc composites. Polym Compos. 2015. https://doi.org/10.1002/pc.22914.

Bakar AA, Hassan A, Yusof AFM. Effect of oil palm empty fruit bunch and acrylic impact modifier on mechanical properties and processability of unplasticized poly(vinyl chloride) composites. Polym Plast Technol. 2002. https://doi.org/10.1081/PTE-200065237.

Qiao Y, Jalali A, Yang J, Chen Y, Wang S, Jiang Y, et al. Non-isothermal crystallization kinetics of polypropylene/polytetrafluoroethylene fibrillated composites. J Mater Sci. 2021. https://doi.org/10.1007/s10853-020-05328-5.

Zhu W, Xiang B, Zhang J. Toughening modification of (Acrylonitrile-styrene-acrylic copolymer)/(-Methylstyrene-acrylonitrile copolymer) binary blend via using different impact modifiers. J Vinyl Addit Technol. 2016. https://doi.org/10.1002/vnl.21448.

Zhou H, Ye L, Li S, Li Z, Wei Z, Huang Z, et al. A bio-based compatibilizer (ESO-g-S-HPG) to improve the compatibility and mechanical properties of CaCO3/HDPE composites. Compos Sci Technol. 2022. https://doi.org/10.1016/j.compscitech.2021.109251.

Zhu C, Chen Y, Cong R, Ran F, Fang G. Improved thermal properties of stearic acid/high density polyethylene/carbon fiber composite heat storage materials. Sol Energy Mat Sol C. 2020. https://doi.org/10.1016/j.solmat.2020.110782.

Choi M, Choi WK, Jung CH, Kim SB. The surface modification and characterization of SiO2 nanoparticles for higher foam stability. Sci Rep. 2020. https://doi.org/10.1038/s41598-020-76464-w.

Selman AM, Kadhim MJ. Fabrication of high sensitivity and fast response IR photodetector based on VO (2) nanocrystalline thin films prepared on the silicon substrate. Opt Mater. 2022. https://doi.org/10.1016/j.optmat.2022.112664.

Papajanı B, Vataj E, Hasımı AV, Sınanaj A. The study of the influence of additives in the crystallinity of recycled LDPE by IR and XRD analysis. RAD Conf Proc. 2018;3:236–40. https://doi.org/10.21175/RadProc.2018.49.

Wu N, Ding M, Zhang J, Lin R. Mechanical properties and crystallization of Poly(L-lactide) films with several percents of ACR nanoparticles. Mater Lett. 2012. https://doi.org/10.1016/j.matlet.2012.06.001.

Jhu Y, Yang T, Hung K, Xu J, Wu T, Wu JH. Nonisothermal crystallization kinetics of acetylated bamboo fiber-reinforced polypropylene composites. Polymers. 2019. https://doi.org/10.3390/polym11061078.

Yarici T, Kodal M, Ozkoc G. Non-isothermal crystallization kinetics of poly(butylene succinate) (PBS) nanocomposites with different modified carbon nanotubes. Polymer. 2018. https://doi.org/10.1016/j.polymer.2018.05.060.

Qu D, Gao H, Wang Q, Bai Y, Li N. Non-isothermal crystallization kinetics of bio-based poly(butylene-co-isosorbide succinate) (PBIS). J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-019-08570-5.

Layachi A, Makhlouf A, Frihi D, Satha H, Belaadi A, Seguela R. Non-isothermal crystallization kinetics and nucleation behavior of isotactic polypropylene composites with micro-talc. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08262-0.

Khosravi A, Fereidoon A, Khorasani MM, Berthe V, Vahabi H, Paran SMR, et al. Nonisothermal crystallization kinetics of polylactic acid under the influence of polyolefin elastomers. J Compos Sci. 2020. https://doi.org/10.3390/jcs4020065.

Lv C, Liu D, Tian H, Xiang A. Non-isothermal crystallization kinetics of polyvinyl alcohol plasticized with glycerol and pentaerythritol. J Polym Res. 2020. https://doi.org/10.1007/s10965-020-2038-4.

Bin-Dahman OA, Shehzad F, Al-Harthi MA. Influence of graphene on the non-isothermal crystallization kinetics of poly(vinyl alcohol)/starch composite. J Polym Res. 2018. https://doi.org/10.1007/s10965-017-1400-7.

Vyazovkin S. Nonisothermal crystallization of polymers: Getting more out of kinetic analysis of differential scanning calorimetry data. Polym Cryst. 2018. https://doi.org/10.1002/pcr2.10003.

Vyazovkin S. Modification of the integral isoconversional method to account for variation in the activation energy. J Comput Chem. 2001. https://doi.org/10.1002/1096-987X(20010130)22:2%3c178::AID-JCC5%3e3.0.CO;2-#.

Ortega A. A simple and precise linear integral method for isoconversional data. Thermochim Acta. 2008. https://doi.org/10.1016/j.tca.2008.05.003.

Friedman HL. Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J Polym Sci C. 1964. https://doi.org/10.1002/polc.5070060121.

Lauritzen JI, Hoffman JD. Extension of theory of growth of chain folded polymer crystals to large undercoolings. J Appl Phys. 1973. https://doi.org/10.1063/1.1661962.

Tarani E, Wurm A, Schick C, Bikiaris DN, Chrissafis K, Vourlias G. Effect of graphene nanoplatelets diameter on non-isothermal crystallization kinetics and melting behavior of high density polyethylene nanocomposites. Thermochim Acta. 2016. https://doi.org/10.1016/j.tca.2016.09.018.

Dobreva A, Gutzow I. Activity of substrates in the catalyzed nucleation of glass-forming melts. 1.Theory. J Noncryst Solids. 1993. https://doi.org/10.1016/0022-3093(93)90736-H.

Dobreva A, Gutzow I. Activity of substrates in the catalyzed nucleation of glass-forming melts. 2. Experimental evidence. J Noncryst Solids. 1993. https://doi.org/10.1016/0022-3093(93)90737-I.

Nofar M, Zhu W, Park CB. Effect of dissolved CO2 on the crystallization behavior of linear and branched PLA. Polymer. 2012. https://doi.org/10.1016/j.polymer.2012.04.054.

Nofar M, Tabatabaei A, Park CB. Effects of nano-/micro-sized additives on the crystallization behaviors of PLA and PLA/CO2 mixtures. Polymer. 2013. https://doi.org/10.1016/j.polymer.2013.02.049.

SenGupta R, Bhattacharya M, Bandyopadhyay S, Bhowmick AK. A review on the mechanical and electrical properties of graphite and modified graphite reinforced polymer composites. Prog Polym Sci. 2011. https://doi.org/10.1016/j.progpolymsci.2010.11.003.

Acknowledgements

This work is financially supported by the Science and Technology Project of Guangxi (AB21220060) and Guangxi Natural Science Youth Foundation (2021GXNSFBA220043).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, analysis and the first draft of the manuscript were written by [Liangdong Ye]. Funding acquisition by [Shaorong Lu], [Ziwei Li], and all authors have commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ye, L., Liu, H., Chen, D. et al. Non-isothermal crystallization analysis of recycled high-density polyethylene/black shale composites. J Therm Anal Calorim 148, 5719–5732 (2023). https://doi.org/10.1007/s10973-023-12075-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12075-7