Abstract

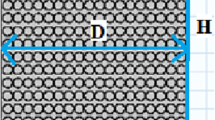

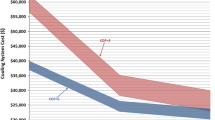

One of the most significant thermodynamic cycles in the refrigeration and air conditioning industry is the trans-critical carbon dioxide cycle. The fundamental trans-critical carbon dioxide refrigeration cycle performs poorly, which inspired researchers to develop innovative technologies to increase its energy efficiency. One of the most appealing ways to improve cycle performance is to employ a porous internal heat exchanger. For this, a porous internal heat exchanger, compressor, gas cooler, expansion valve, evaporator and experimental test rig are constructed. For the internal heat exchanger’s porous material, sea sand with porosities of 35%, 42% and 51% is used. It is also taken into account when the internal heat exchanger’s tube is empty (porosity = 100%). Investigations were conducted on the cycle refrigeration capacity, coefficient of performance, pressure drop, internal heat exchanger effectiveness, relative refrigeration capacity index and compressor power consumption per kW of refrigeration in relation to changes in the gas cooler discharge temperature, gas cooler working pressure, evaporation temperature, internal heat exchanger porosity and degree of subcooling. When the gas cooler discharge temperature was lowered from 53 to 34 °C and the porosity was reduced from 100 to 35%, the cycle refrigeration capacity and coefficient of performance were raised by 49.7% and 93%, respectively. An increase in refrigeration capacity of 46% and increase in coefficient of performance of 87.5% were the consequence of raising the degree of subcooling from 2 to 12 °C and lowering porosity from 100 to 35%. By reducing the internal heat exchanger’s porosity from 100 to 35%, the compressor’s power consumption per kW of refrigeration is reduced by around 29.6%.

Similar content being viewed by others

Abbreviations

- C:

-

Celsius

- COP:

-

Coefficient of performance

- \({e}_{\mathrm{PIHX}}\) :

-

Effectiveness of porous internal heat exchanger (%)

- GCDT:

-

Gas cooler discharge temperature in (°C)

- GCP:

-

Gas cooler pressure (kPa)

- GWP:

-

Global warming potential

- H:

-

Enthalpy (kJ kg−1)

- IHX:

-

Internal heat exchanger

- \(\dot{m}{ }_{{\mathrm{CO}}_{2}}\) :

-

Mass flow rate of carbon dioxide (kg s−1)

- ODP:

-

Ozone depletion potential

- P:

-

Pressure

- PC:

-

Power consumption in (kW)

- Pe:

-

Evaporation pressure

- PCPkWR:

-

Power consumption per kW of refrigeration (kW kW−1)

- PIHX:

-

Porous internal heat exchanger

- \({\dot{Q}}_{\mathrm{H}}\) :

-

Heat rejection rate (kW)

- \({\dot{Q}}_{\mathrm{R}}\) :

-

Refrigeration capacity (kW)

- \({\dot{Q}}_{\mathrm{Rn}}\) :

-

Refrigeration capacity (kW) with no internal heat exchanger

- R:

-

Refrigerant

- RRCI:

-

Relative refrigeration capacity index (%)

- TC:

-

Thermocouple reading

- Te:

-

Evaporation temperature in (°C)

- TXV:

-

Thermal expansion valve

- W:

-

Watt

- \(\dot{{W}_{\mathrm{C}}}\) :

-

Compressor power (kW)

- ε :

-

Porosity (%)

- ΔP :

-

Pressure drop (kPa)

- ΔT (sub):

-

Degree of subcooling in (°C)

- e:

-

Evaporation

- os:

-

Out side

- n:

-

No internal heat exchanger

- sub:

-

Subcooling

- °:

-

Degree

References

Zhang Z, Tian L, Chen Y, Tong L. Effect of an internal heat exchanger on performance of the trans-critical carbon dioxide refrigeration cycle with an expander. Entropy. 2014;16(11):5919–34.

Elbel SW, Hrnjak PS. Effect of internal heat exchanger on performance of transcritical CO2 systems with ejector. International refrigeration and air conditioning conference. Purdue University. 2004. Paper 708.

Tarawneh M. Effect of using a porous gas cooler on the performance of trans-critical carbon dioxide refrigeration cycle. Heat Transfer. 2022;51(2):2306–17.

Liopis R, Sanz-Kock C, Cabello R, Sánchez D, Nebot-Andrés L, Catalán-Gi J. Effects caused by the internal heat exchanger at the low temperature cycle in a cascade refrigeration plan. Appl Therm Eng. 2016;103(1):1077–86.

Wang D, Binbin Yu, Shi J, Chen J. Experimental and theoretical study on the cooling performance of a co2 mobile air conditioning system. Energies. 2018;11(8):1–13.

Casi A, Aranguren P, Araiz M, Sanchez D, Cabello R, Astrain D. Experimental evaluation of a trans-critical co2 refrigeration facility working with an internal heat exchanger and a thermoelectric sub-cooler: performance assessment and comparative. Int J Refrig. 2022;2022(141):66–75.

Tarawneh M. Experimental investigation of the effect of using porous internal sub-cooler on the performance of refrigeration system: R422A case study. Int J Heat Technol. 2019;37(4):1127–32.

Tarawneh M, Alshqirate AbedAlrzaq, Khasawneh K, Hammad M. Experimental study on the effect of porous medium on performance of a single tube heat exchanger: a CO2 case study. Heat Transfer-Asian Res. 2013;42(6):473–84.

Tao YB, He YL, Tao WQ, Wu ZG. Experimental study on the performance of co2 residential air-conditioning system with an internal heat exchanger. Energy Convers Manag. 2010;51:64–70.

Tarawneh M. Experimental study on the performance of trans-critical carbon dioxide refrigeration system using porous evaporator. J Adv Res Fluid Mech Therm Sci. 2020;74(1):57–67.

Tesfamichael BA, Suhaimi H, Reduan Allya Radzihan B, Woldeyohannes Abraham D. Performance investigation of trans-critical carbon dioxide refrigeration cycle. Proced CRIP. 2015;26:482–5.

Ahmed Okasha, Norbert Müller. Simulation and performance correlation for trans-critical CO2 heat pump cycle. International refrigeration and airconditioning conference. Purdue University. 2018. Paper 2056.

Feng F, Zhang Z, Liu X, Liu C, Hou Y. The influence of internal heat exchanger on the performance of trans-critical CO2 water source heat pump water heater. Energies. 2020;13(7):1787.

Sarkar J. Trans-critical CO2 refrigeration systems: comparison with conventional solutions and applications. Int J Air Cond Refrig. 2012;20(4):1–11.

Li W, Yu Z. Heat exchangers for cooling supercritical carbon dioxide and heat transfer enhancement: a review and assessment. Energy Rep. 2021;7(1):4085–105.

Rony RU, Yang H, Krishnan S, Song J. Recent advances in trans-critical CO2 (R744) heat pump system: a review. Energies. 2019;12(3):457.

Rosle ND, Saat FA, Raja Othman RN, Sukri MF, Saechan P. The effect of porous materials on temperature drop in a standing wave thermoacoustic cooler. Int J Nanoelectron Mater. 2022;2:15.

Nebot-Andrés L, Duca MGD, CiroAprea AŽ, JakaTušek RodrigoLlopis, Maiorino A. Improving efficiency of trans-critical co2 cycles through a magnetic refrigeration subcooling system. Energy Convers Manag. 2022;265:115766.

Nebot-Andr´es L, Calleja-Anta D, Sanchez D, Cabello R, Llopis R. Experimental assessment of dedicated and integrated mechanical subcooling systems vs parallel compression in trans-critical CO2 refrigeration plants. Energy Convers Manag. 2022;252:115051.

Bellos E, Tzivanidis C. CO2 Trans-critical refrigeration cycle with dedicated subcooling: mechanical compression vs Absorption Chiller. Appl Sci. 2019;9(8):1–27.

Homon P, Chantawong P, Khedari J. Experimental investigation of using liquid suction heat exchanger with condensed cold-water on the performance of air conditioning system. Int J Heat Technol. 2022;40(2):390–6.

Li G, Tang Z, Zou H, Zhang R. Experimental investigation of cooling performance of a CO2 heat pump system with an integrated accumulator heat exchanger for electric vehicles: impact of refrigerant charge and valve opening. Appl Therm Eng. 2023;224:120077.

Kwan TH, Shen Y, Zhen Wu, Yao Q. Performance analysis of the thermoelectric device as the internal heat exchanger of the trans-critical carbon dioxide cycle. Energy Convers Manag. 2020;208:112585.

ASHRAE fact sheet: ASHRAE Standard 34. 2020. https://www.ashrae.org/file%20library/technical%20resources/refrigeration/factsheet_ashrae_english_20200424.pdf.

BITZER Report 21:https://www.bitzer-refrigerantreport.com/fileadmin/Content/01_Startseite/A-501-21_EN.pdf.

Acknowledgements

Great thanks to Engineering Geniuses Company for their great technical support during all stages of this experimental work. (www.egeniuses.net)- Jordan/Amman.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tarawneh, M. Performance evaluation of trans-critical carbon dioxide refrigeration system integrated with porous internal heat exchange. J Therm Anal Calorim 148, 5777–5786 (2023). https://doi.org/10.1007/s10973-023-12058-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12058-8