Abstract

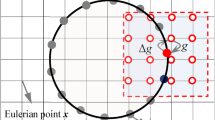

In this study investigated the deposition of micro-scaled particles using the lattice Boltzmann (LBM) and finite volume (FVM). A real-time data transfer is used to transfer data between LBM and FVM, while a special grid generation algorithm is used to generate a boundary grid around the micro-particles. In order to track particle information such as velocity, direction, and concentration over time, an adaptive interface is developed between FVM and LBM zones. The pore-scale porous media approach is assumed to further improve the results’ quality and reliability. Pores have an average diameter of two mm, while micro-particles have an average diameter of 0.2 mm. The results showed that the deposition layer’s formation directly affected the fluid’s flux rate at the inlet. Heat transfer coefficients of the fluid change in response to the density of the fluid as the deposition layer thickness increases. The thermal conductivity coefficient of the wall decreases as the deposition layer increases, which is variable over time and along the path. Furthermore, we found that heat transfer and pressure drop are affected by the deposition process in the porous medium. Porous media with an increasing pressure drop are also subject to an increasing pressure drop due to the deposition process. In addition, the particles’ thermal conductivity can affect the porous medium’s net heat transfer rate. The heat transfer coefficient has been evaluated, and the results showed that 8.43% exists between the numerical analysis and the results of the empirical test at the highest error value. Existing particles’ density bank in the porous medium beats, such particles exhibit little change due to their extremely small size, resulting in a 0.4 percent and 0.5 percent increase in pressure drop due to deposition at 100. It showed that the suggested method of grid generation based on the cell birth–death algorithm, which serves as the foundation for the particle’s transfer tracking algorithm, the porous medium abled track 70 million particles.

Similar content being viewed by others

Abbreviations

- \(\widehat{\mathrm{f}}\mathrm{i}\) :

-

Dimensionless function

- \({\mathrm{U}}^{\mathrm{m}}\) :

-

Mixture velocity (x direction), [m.s−1]

- \({\mathrm{e}}_{\mathrm{i}}\) :

-

Collision velocity

- \({\mathrm{T}}_{\mathrm{particle}}\) :

-

Particle temperature [k]

- f:

-

Lattice distribution function

- \({\mathrm{k}}_{\mathrm{s}}\) :

-

\(conduction \, coefficient\) For solid [W.m−1.K−1]

- \(\widehat{\mathrm{x}}\) :

-

Dimensionless point

- \(\mathrm{x},\mathrm{y},\mathrm{z}\) :

-

Coordinates

- \({\widehat{\mathrm{c}}}_{\mathrm{i}}\) :

-

Dimensionless discrete particle of speed

- \(\widehat{\mathrm{f}}\) :

-

Dimensionless of function

- \({\Omega }_{\mathrm{i}}\) :

-

The collision operator

- \(\widehat{\mathrm{t}}\) :

-

Dimensionless of time

- \(\widehat{\Delta }\mathrm{t}\) :

-

Dimensionless of time

- \({\mathrm{f}}_{\mathrm{i}}\) :

-

Fluid velocity distribution function

- \({\upomega }_{\mathrm{i}}\) :

-

Equilibrium distribution function facto

- \({\mathrm{f}}_{\mathrm{i}}^{\left(\mathrm{eq}\right)}\) :

-

Equilibrium distribution function

- \({\uptau }^{{\mathrm{m}}^{*}}\) :

-

Stress of mth phase, [n.m−2]

- \({\mathrm{C}}_{\mathrm{x}}={\mathrm{C}}_{\mathrm{y}}={\mathrm{C}}_{\mathrm{z}}\) :

-

Volume fraction [kg.m−1]

- \(\upzeta\) :

-

Friction coefficient

- \({\mathrm{c}}_{\mathrm{i}}\) :

-

Yields of results

- \({\Delta \mathrm{T}}^{\mathrm{m}}\) :

-

Temperature gradient, [K]

- \({\mathrm{T}}_{\mathrm{fliud}}\) :

-

Fluid temperature [k]

- \({\nabla \mathrm{T}}_{\mathrm{solid}}\) :

-

Temperature gradient for solid

- \({\mathrm{h}}_{\mathrm{nf}}\) :

-

Convection coefficient for nanofluid [W.m−1.K−1]

- \({\uplambda }_{\mathrm{sediment \, layer}}\) :

-

Ratio of the dynamic viscosity for sediment

- \({\mathrm{U}}_{\mathrm{x}}\cdot {\mathrm{U}}_{\mathrm{y}}\cdot {\mathrm{U}}_{\mathrm{z}}\) :

-

Velocity in xyz-direction for liquid phase, [m.s−1]

- \({\uplambda }_{\mathrm{particle}}\) :

-

Ratio of the dynamic viscosity for particle

- \({\mathrm{v}}^{{\mathrm{m}}^{*}}\) :

-

Velocity of mth phase, [m.s−1]

- \({\mathrm{\alpha }}^{{\mathrm{m}}^{*}}\) :

-

Volume fraction for mth fluid phase

- \({\mathrm{x}}^{{\mathrm{m}}^{*}}\) :

-

Passion of mth phase, [\(\mathrm{m}]\)

- \(\upmu\) :

-

Dynamic viscosity, [kg.m−1.s−1]

- \({\mathrm{H}}^{\mathrm{m}}\) :

-

Multiphase energy, [w]

- \({\uplambda }^{\mathrm{m}}\) :

-

Mixture thermal conductivity, [W.m−1.K−1]

- \(\mathrm{p}\) :

-

Total pressure, [Pa]

- \(\uprho\) :

-

Density, [kg.m−3]

- \({\mathrm{q}}_{\mathrm{H}}^{\mathrm{m}}\) :

-

Heat flux for mth fluid, [W.m−2]

- \({\uprho }^{{\mathrm{m}}^{*}}\) :

-

Density of mth phase, [kg.m−3]

- \({\mathrm{U}}^{{\mathrm{drm}}^{*}}\) :

-

Mixture velocity, [m.s−1]

- \({\uprho }^{\mathrm{m}}\) :

-

Mixture density, [kg.m−3]

- \({\mathrm{H}}^{{\mathrm{m}}^{*}}\) :

-

Energy of mth phase, \([w]\)

- \({\uplambda }^{{\mathrm{m}}^{*}}\) :

-

Thermal conductivity for mth fluid phase, [W.m−2.K−1]

- \({\mathrm{q}}_{\mathrm{f}}^{\mathrm{^{\prime}}\mathrm{^{\prime}}}\) :

-

Heat flux for fluid, [W.m−2]

- \({\Delta }_{\mathrm{t}}\) :

-

Time step, [s]

- \(\mathrm{T}\) :

-

Temperature, [K]

- \({\Delta }_{\mathrm{x}}\) :

-

Lattice spacing, [m]

- t:

-

Times, [s]

- \({\uplambda }_{\mathrm{tube}}\) :

-

Ratio of the dynamic viscosity for tube

- m:

-

Mixture

- eq:

-

Equilibrium

- ^:

-

Dimensionless

- m*:

-

Mth

- “:

-

Flux

- LBM:

-

Lattice Boltzmann method

- FVM:

-

Finite volume method

- DEM:

-

distinct element method

References

Yousefzadeh S, et al. Numerical investigation of mixed convection heat transfer behavior of nanofluid in a cavity with different heat transfer areas. J Therm Anal Calorim. 2020;140(6):2779–803.

Oh D-W, et al. Thermal conductivity measurement and sedimentation detection of aluminum oxide nanofluids by using the 3ω method. Int J Heat Fluid Flow. 2008;29(5):1456–61.

Maleki A, et al. Thermal conductivity modeling of nanofluids with ZnO particles by using approaches based on artificial neural network and MARS. J Thermal Anal Calorim. 2020;143:4261–72.

Lin C-Y, Wang J-C, Chen T-C. Analysis of suspension and heat transfer characteristics of Al2O3 nanofluids prepared through ultrasonic vibration. Appl Energy. 2011;88(12):4527–33.

Niu X, Yu J, Wang S. Experimental study on low-temperature waste heat thermoelectric generator. J Power Sources. 2009;188(2):621–6.

Yang Y, et al. Pore-scale simulation of remaining oil distribution in 3D porous media affected by wettability and capillarity based on Volume of Fluid method. Int J Multiph Flow. 2021;143: 103746.

Pinder GF, Gray WG. Essentials of multiphase flow and transport in porous media. New Jersey: Wiley; 2008. p. B05.

Meakin P, Tartakovsky AM. Modeling and simulation of pore-scale multiphase fluid flow and reactive transport in fractured and porous media. Rev Geophys. 2009;47(3):1045.

Lin C, Videla A, Miller JD. Advanced three-dimensional multiphase flow simulation in porous media reconstructed from X-ray Microtomography using the He–Chen–Zhang Lattice Boltzmann Model. Flow Meas Instrum. 2010;21(3):255–61.

Yang X et al. Comparison of LBM and FVM for simulation of solid-liquid phase change problem with natural convection. In: IOP conference series: earth and environmental science. 2021. IOP Publishing

Wen M, Li W, Zhao Z. A hybrid scheme coupling lattice Boltzmann method and finite-volume lattice Boltzmann method for steady incompressible flows. Phys Fluids. 2022;34(3):037114.

Mellouli S, et al. Hydrogen storage in metal hydride tanks equipped with metal foam heat exchanger. Int J Hydrogen Energy. 2009;34(23):9393–401.

Miri Joibary SM, Siavashi M. Effect of Reynolds asymmetry and use of porous media in the Counterflow double-pipe heat exchanger for passive heat transfer enhancement. J Thermal Analy Calorim. 2020;140(3):1079–93.

Moradi A, et al. An experimental study on MWCNT–water nanofluids flow and heat transfer in double-pipe heat exchanger using porous media. J Therm Anal Calorim. 2019;137(5):1797–807.

Zhao CY, Lu W, Tassou SA. Thermal analysis on metal-foam filled heat exchangers. Part II: Tube heat exchangers. Int J Heat Mass Transfer. 2006;49(15–16):2762–70.

Dai Z, et al. A comparison of metal-foam heat exchangers to compact multilouver designs for air-side heat transfer applications. Heat Transfer Eng. 2012;33(1):21–30.

Boutt DF, et al. Direct simulation of fluid-solid mechanics in porous media using the discrete element and lattice-Boltzmann methods. J Geophys Res: Solid Earth. 2007;112(B10):201.

Dan H-C, et al. DEM-aided method for predicting the hydraulic properties with particle-size distribution of porous media. Eng Computat. 2019;20:18.

Su J, et al. Pore-scale direct numerical simulation of particle transport in porous media. Chem Eng Sci. 2019;199:613–27.

Zheng N, et al. A review on single-phase convective heat transfer enhancement based on multi-longitudinal vortices in heat exchanger tubes. Appl Therm Eng. 2020;164:114475.

Zhou K, et al. Study on the flow resistance of the dispersion system of deformable preformed particle gel in porous media using LBM-DEM-IMB method. J Dispers Sci Technol. 2019;40(10):1523–30.

Zhou K, Yang S. Understanding household energy consumption behavior: The contribution of energy big data analytics. Renew Sustain Energy Rev. 2016;56:810–9.

Habib R, et al. A pore-scale assessment of the dynamic response of forced convection in porous media to inlet flow modulations. Int J Heat Mass Transf. 2020;153:119657.

Kaviany M. Principles of heat transfer in porous media. New York: Springer-Verlag; 1991. p. 1024.

Kaviany M. Principles of heat transfer in porous media. London: Springer; 2012. p. 24.

Mesgarpour M, et al. Predicting the effects of environmental parameters on the spatio-temporal distribution of the droplets carrying coronavirus in public transport–A machine learning approach. Chem Eng J. 2022;430:132761.

Yeoh GH, Tu J. Computational techniques for multiphase flows. Oxford: Butterworth-Heinemann; 2019. p. 102.

Crowe CT. Multiphase flow handbook. New York: CRC Press; 2005. p. 59.

Ross-Jones J, et al. Pore-scale conjugate heat transfer simulations using lattice Boltzmann methods for industrial applications. Appl Therm Eng. 2021;182:116073.

Qin J, Xu Z, Ma X. Pore-Scale Simulation on Pool Boiling Heat Transfer and Bubble Dynamics in Open-Cell Metal Foam by Lattice Boltzmann Method. J Heat Transfer. 2021;143(1):011602.

Abbassi MA, et al. LBM simulation of free convection in a nanofluid filled incinerator containing a hot block. Int J Mech Sci. 2018;144:172–85.

Peng C, et al. Implementation issues and benchmarking of lattice Boltzmann method for moving rigid particle simulations in a viscous flow. Comput Math Appl. 2016;72(2):349–74.

McCullough J, et al. Lattice Boltzmann methods for the simulation of heat transfer in particle suspensions. Int J Heat Fluid Flow. 2016;62:150–65.

Mino Y, et al. Lattice-Boltzmann flow simulation of an oil-in-water emulsion through a coalescing filter: effects of filter structure. Chem Eng Sci. 2018;177:210–7.

Karimnejad S, et al. Sedimentation of elliptical particles using immersed boundary-lattice Boltzmann method: a complementary repulsive force model. J Mol Liq. 2018;262:180–93.

Baghsaz S, Rezanejad S, Moghimi M. Numerical investigation of transient natural convection and entropy generation analysis in a porous cavity filled with nanofluid considering nanoparticles sedimentation. J Mol Liq. 2019;279:327–41.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ashouri, H., Mohammadiun, H., Mohammadiun, M. et al. An innovative method for calculating the deposition of micro-scale particles in pore-scale porous media. J Therm Anal Calorim 148, 8627–8640 (2023). https://doi.org/10.1007/s10973-023-12043-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12043-1