Abstract

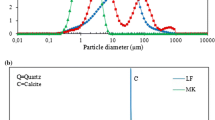

The effects of ordinary limestone powder (OLP) and ultrafine limestone powder (UFLP) on the fluidity, setting time, compressive strength, hydration heat and microstructure of calcium sulfoaluminate cement (CSA) were investigated. The results show that finer limestone powder reduces the fluidity and setting time of CSA. Increasing fineness of limestone powder improves the growth rates of strength and chemical bound water content, and higher compressive strength and chemical bound water content are obtained. The hydration of CSA is dramatically promoted by adding UFLP, and the promoting effect increases with increasing dosage, but cumulative hydration heat is reduced. The higher content and finer limestone powder result in larger amount of hemicarbonate and minor amount of monosulfate phase (AFm). The microstructure of hardened CSA paste is densified by adding UFLP. Owing to the poor bond between limestone powder and surrounding hydrates, the compressive strength of CSA mortar containing larger amount of limestone powder is low.

Similar content being viewed by others

References

García-Maté M, Torre AGD, León-Reina L, Losilla ER, Aranda MAG, Santacruz I. Effect of calcium sulfate source on the hydration of calcium sulfoaluminate eco-cement. Cem Concr Compos. 2015;55:53–61.

Sirtoli D, Wyrzykowski M, Riva P, Tortelli S, Marchi M, Lura P. Shrinkage and creep of high-performance concrete based on calcium sulfoaluminate cement. Cem Concr Compos. 2019;98:61–73.

Cao R, Yang J, Li G, Liu F, Niu M, Wang W. Resistance of the composite cementitious system of ordinary Portland/calcium sulfoaluminate cement to sulfuric acid attack. Constr Build Mater. 2022;329: 127171.

Li P, Gao X, Wang K, Tam VWY, Li W. Hydration mechanism and early frost resistance of calcium sulfoaluminate cement concrete. Cem Concr Compos. 2020;239:117862.

Afroughsabet V, Biolzi L, Monteiro PJM, Gastaldi MM. Investigation of the mechanical and durability properties of sustainable high performance concrete based on calcium sulfoaluminate cement. J Build Eng. 2021;43:1–14.

Qin L, Gao X, Zhang A. Potential application of Portland cement-calcium sulfoaluminate cement blends to avoid early age frost damage. Constr Build Mater. 2018;190:363–72.

Huang G, Pudasainee D, Gupta R, Liu WV. The performance of calcium sulfoaluminate cement for preventing early-age frost damage. Constr Build Mater. 2020;254: 119322.

Ge Z, Yuan H, Sun R, Zhang H, Wang W, Qi H. Use of green calcium sulphoaluminate cement to prepare foamed concrete for road embankment: A feasibility study. Constr Build Mater. 2020;237:117791.

Li T, Huang F, Li L, Zhu J, Jiang X, Huang Y. Preparation and properties of sulphoaluminate cement-based foamed concrete with high performance. Constr Build Mater. 2020;263:120945.

Lippiatt N, Ling TC, Pan SY. Towards carbon-neutral construction materials: carbonation of cement-based materials and the future perspective. J Build Eng. 2020;28:101062.

Gartner E, Hirao H. A review of alternative approaches to the reduction of CO2 emissions associated with the manufacture of the binder phase in concrete. Cem Concr Res. 2015;78:126–42.

Scrivener KL, John VM, Gartner EM. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem Concr Res. 2018;114:2–26.

Shi C, Jiménez AF, Palomo A. New cements for the twenty-first century: the pursuit of an alternative to Portland cement. Cem Concr Res. 2011;41:750–63.

Sun Z, Nie S, Zhou J, Li H, Chen Z, Xu M, Mu R, Wang Y. Hydration mechanism of calcium sulfoaluminate-activated supersulfated cement. J Clean Prod. 2022;333:130094.

Ke G, Zhang J, Xie S, Pei T. Rheological behavior of calcium sulfoaluminate cement paste with supplementary cementitious materials. Constr Build Mater. 2020;243:118234.

Gao D, Meng Y, Yang L, Tang J, Lv M. Effect of ground granulated blast furnace slag on the properties of calcium sulfoaluminate cement. Constr Build Mater. 2019;227:116665.

Ke G, Zhang J, Liu Y, Xie S. Pore characteristics of calcium sulfoaluminate cement paste with impact of supplementary cementitious materials and water to binder ratio. Powder Technol. 2021;387:146–55.

Kleib J, Aouad G, Benzerzour M, Zakhour M, Abriak NE. Effect of calcium sulfoaluminate cements composition on their durability. Constr Build Mater. 2021;307:124952.

Afroughsabet V, Biolzi L, Monteiro PJM, Gastaldi MM. Investigation of the mechanical and durability properties of sustainable high performance concrete based on calcium sulfoaluminate cement. J Build Eng. 2021;43: 102656.

Winnefeld F, Barlag S. Calorimetric and thermogravimetric study on the influence of calcium sulfate on the hydration of ye’elimite. J Therm Anal Calorim. 2010;101:949–57.

Pichler C, Perfler L, Kaufmann K, Bidner T, Lackner R. Thermo-chemo-mechanical characterization, modeling, and analysis of hydration of calcium-sulfoaluminate cement paste. Constr Build Mater. 2022;319:125747.

Li N, Xu L, Wang R, Li L, Wang P. Experimental study of calcium sulfoaluminate cement-based self-leveling compound exposed to various temperatures and moisture conditions: Hydration mechanism and mortar properties. Cem Concr Res. 2018;108:103–15.

Wang S, Chen C, Lu L, Cheng X. Effects of slag and limestone powder on the hydration and hardening process of alite-barium calcium sulphoaluminate cement. Constr Build Mater. 2012;35:227–31.

Cui K, Lau D, Zhang Y, Chang J. Mechanical properties and mechanism of nano-CaCO3 enhanced sulphoaluminate cement-based reactive powder concrete. Constr Build Mater. 2021;309:125099.

Pelletier-Chaignat L, Winnefeld F, Lothenbach B, Müller CJ. Beneficial use of limestone filler with calcium sulphoaluminate cement. Constr Build Mater. 2012;26:619–27.

Ma J, Yu Z, Ni C, Shi H, Shen X. Effects of limestone powder on the hydration and microstructure development of calcium sulphoaluminate cement under long-term curing. Constr Build Mater. 2019;199:688–95.

Martin LHJ, Winnefeld F, Tschopp E, Müller CJ, Lothenbach B. Influence of fly ash on the hydration of calcium sulfoaluminate cement. Cem Concr Res. 2017;95:152–63.

Yoon HN, Seo J, Kim S, Lee HK, Park S. Hydration of calcium sulfoaluminate cement blended with blast-furnace slag. Constr Build Mater. 2021;268:121214.

Seo J, Kim S, Park S, Yoon HN, Lee HK. Carbonation of calcium sulfoaluminate cement blended with blast furnace slag. Cem Concr Compos. 2021;118:103918.

Gao D, Che Q, Meng Y, Yang L, Xie X. Properties evolution of calcium sulfoaluminate cement blended with ground granulated blast furnace slag suffered from sulfate attack. J Mater Res Technol. 2022;17:1642–51.

Liao Y, Jiang G, Wang K, Qunaynah SA, Yuan W. Effect of steel slag on the hydration and strength development of calcium sulfoaluminate cement. Constr Build Mater. 2020;265:120301.

Tan H, Li M, He X, Su Y, Yang J, Zhao H. Effect of wet grinded lithium slag on compressive strength and hydration of sulphoaluminate cement system. Constr Build Mater. 2021;267:120465.

Jeong Y, Hargis CW, Chun S, Moon J. Effect of calcium carbonate fineness on calcium culfoaluminate-belite cement. Mater. 2017;10(8):900–900.

Aqel M, Panesar DK. Hydration kinetics and compressive strength of steam-cured cement pastes and mortars containing limestone filler. Constr Build Mater. 2016;113:359–68.

Wang D, Shi C, Farzadnia N, Shi Z, Jia H, Ou Z. A review on use of limestone powder in cement-based materials: mechanism, hydration and microstructure. Constr Build Mater. 2018;181:659–72.

Costa EBC, Cardoso FA, John VM. Influence of high contents of limestone fines on rheological behaviour and bond strength of cement-based mortars. Constr Build Mater. 2017;156:1114–26.

Moon GD, Oh S, Jung SH, Choi YC. Effects of the fineness of limestone powder and cement on the hydration and strength development of PLC concrete. Constr Build Mater. 2017;135:129–36.

Martin LHJ, Winnefeld F, Müller CJ, Lothenbach B. Contribution of limestone to the hydration of calcium sulfoaluminate cement. Cem Concr Compos. 2015;62:204–11.

Briki Y, Zajac M, Haha MB, Scrivener K. Impact of limestone fineness on cement hydration at early age. Cem Concr Res. 2021;147: 106515.

Júnior LUDT, Matos PRD, Lima GS, Silvestro L, Rocha JC, Campos CEM, Gleize PJP. Effect of the nanosilica source on the rheology and early-age hydration of calcium sulfoaluminate cement pastes. Constr Build Mater. 2022;327:126942.

Thongsanitgarn P, Wongkeo W, Chaipanich A, Poon CS. Heat of hydration of Portland high-calcium fly ash cement incorporating limestone powder: effect of limestone particle size. Constr Build Mater. 2014;66:410–7.

Wang D, Shi C, Farzadnia N, Jia H, Zeng R, Wu Y, Lao L. A quantitative study on physical and chemical effects of limestone powder on properties of cement pastes. Constr Build Mater. 2019;204:58–69.

Winnefeld F, Martin LHJ, Müller CJ, Lothenbach B. Using gypsum to control hydration kinetics of CSA cements. Constr Build Mater. 2017;155:154–63.

Xu L, Wu K, Li N, Zhou X, Wang P. Utilization of flue gas desulfurization gypsum for producing calcium sulfoaluminate cement. J Clean Prod. 2017;161:803–11.

Shenbagam VK, Chaunsali P. Influence of calcium hydroxide and calcium sulfate on early-age properties of non-expansive calcium sulfoaluminate belite cement. Cem Concr Compos. 2022;128:104444.

Zhang Y, Zhao Q, Gao Z, Chang J. Nanostructural evolution of Al(OH)3 gel formed by the cubic and orthorhombic ye’elimite clinkers of calcium sulfoaluminate cements in an ultra-wide hydration temperature range. Cem Concr Res. 2021;150:106607.

Hargis CW, Kirchheim AP, Monteiro PJM, Gartner EM. Early age hydration of calcium sulfoaluminate (synthetic ye’elimite, C4A3S) in the presence of gypsum and varying amounts of calcium hydroxide. Cem Concr Res. 2013;48:105–15.

Acknowledgements

The authors would like to acknowledge the National Natural Science Foundation of China (No. 51908033).

Author information

Authors and Affiliations

Contributions

Fanghui Han: Conceptualization, Formal analysis, Methodology, Funding acquisition, Supervision, Writing-original draft. Hongbo Zhang: Formal analysis, Investigation, Writing-review & editing, Data curation. Ziyi Li: Formal analysis, Writing-review & editing, Data curation. Zhiming Pang: Investigation, Data curation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Han, F., Zhang, H., Li, Z. et al. Effect of the fineness of limestone powder on the properties of calcium sulfoaluminate cement. J Therm Anal Calorim 148, 4033–4047 (2023). https://doi.org/10.1007/s10973-023-12040-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12040-4