Abstract

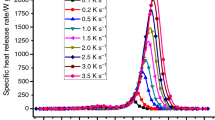

Prediction of flammability characteristics of materials is possible via molar group contribution calculations. However, in most industries raw material composition is unknown and micro combustion calorimeter (MCC) is applied for measuring heat release rate (HRR) and calculates flammability characteristics. This work predicts HRR and flammability characteristics for complex formulations based on HRR from a reduced number of the individual constituents, all with unknown chemical composition. Water-based paints (> 15 components) with and without chemical interaction during thermal decomposition were predicted via linear combinations of component HRR and validated against experimental MCC data. Prediction of HRR and flammability characteristics was successful, and the obvious breakdown for reactive mixtures was confirmed. These results can be utilized as screening tool for flammability characteristics and identity component interaction in mixtures—which considerably enhances the strength of MCC in development of new materials.

Similar content being viewed by others

References

Lyon RE, Walters RN. A microscale combustion calorimeter. DOT/FAA/AR-01/117. Federal Aviation Administration Washington DC Office of Aviation Research; 2002.

Lyon RE, Walters RN. Pyrolysis combustion flow calorimetry. JAAP. 2004;71(1):27–46.

Walters RN, Lyon RE. Microscale combustion calorimeter: interlaboratory study of precision and bias. DOT/FAA/TC-12/39. Federal Aviation Administration William J. Hughes Technical Center Fire Safety Branch; 2012.

Lyon RE, Walters RN, Stoliarov SI, Safronava N. Principles and practice of microscale combustion calorimetry. DOT/FAA/TC-12/53, R1. Federal Aviation Administration: Atlantic City International Airport, NJ, USA; 2013.

Lin TS, Cogen JM, Lyon RE. Correlations between microscale combustion calorimetry and conventional flammability tests for flame retardant wire and cable compounds. In: Proceedings of the 56th IWCS. 2007; pp. 176–85.

Cogen JM, Lin TS, Lyon RE. Correlations between pyrolysis combustion flow calorimetry and conventional flammability tests with halogen-free flame retardant polyolefin compounds. Fire Mater. 2009;33(1):33–50.

Xu Q, Jiang L, Majlingova A, Ulbrikova N, Mensah RA, Das O, Berto F. Wood dust flammability analysis by microscale combustion calorimetry. Polymers. 2022;14(1):45.

Lowden LA, Hull TR. Flammability behaviour of wood and a review of the methods for its reduction. Fire Sci Rev. 2013;2(1):1–19.

Yang CQ, He Q. Textile heat release properties measured by microscale combustion calorimetry: experimental repeatability. Fire Mater. 2012;36(2):127–37.

Yang CQ, He Q, Lyon RE, Hu Y. Investigation of the flammability of different textile fabrics using micro-scale combustion calorimetry. Polym Degrad Stab. 2010;95(2):108–15.

Merk V, Chanana M, Keplinger T, Gaan S, Burgert I. Hybrid wood materials with improved fire retardance by bio-inspired mineralisation on the nano-and submicron level. Green Chem. 2015;17(3):1423–8.

McKenna ST, Jones N, Peck G, Dickens K, Pawelec W, Oradei S, Harris S, Stec AA, Hull TR. Fire behaviour of modern façade materials–understanding the Grenfell Tower fire. J Hazard Mater. 2019;368:115–23.

Mihăilă A, Danu M, Ibănescu C, Anghel I, Şofran IE, Balanescu LV, Lisa G, et al. Thermal characterization and rheological behavior of some varnishes and paints used for wood protection. Int J Environ Sci Technol. 2022; 19(7): 6299–6314.

Lyon RE, Walters RN, Stoliarov SI. Screening flame retardants for plastics using microscale combustion calorimetry. Polym Eng Sci. 2007;47(10):1501–10.

Sonnier R, Negrell-Guirao C, Vahabi H, Otazaghine B, David G, Lopez-Cuesta JM. Relationships between the molecular structure and the flammability of polymers: study of phosphonate functions using microscale combustion calorimeter. Polymer. 2012;53(6):1258–66.

Clayton H. Estimation of rate of heat release by means of oxygen consumption measurements. Fire Mater. 1980;4(2):61–5.

Parker WJ. Calculations of the heat release rate by oxygen consumption for various applications. J Fire Sci. 1984;2(5):380–95.

ASTM D7309–13 Standard Test Method For Determining Flammability Characteristics Of Plastics And Other Solid Materials Using Microscale Combustion Calorimetry

Walters RN, Lyon RE. Molar group contributions to polymer flammability. J Appl Polym Sci. 2003;87(3):548–63.

Lyon RE, Takemori MT, Safronava N, Stoliarov SI, Walters RN. A molecular basis for polymer flammability. Polymer. 2009;50(12):2608–17.

Lyon RE, Safronava N, Crowley S, Walters RN. A molecular-level fire growth parameter. Polym Degrad Stab. 2021;186:109478.

Swann JD, Stoliarov SI. Determination of pyrolysis and combustion properties of poly (vinylidene fluoride) using comprehensive modelling: relating heat transfer to the intumescent char’s porous structure. Fire Saf J. 2021;120:103086.

Mensah RA, Jiang L, Asante-Okyere S, Xu Q, Jin C. Comparative evaluation of the predictability of neural network methods on the flammability characteristics of extruded polystyrene from microscale combustion calorimetry. J Therm Anal Calorim. 2019;138(5):3055–64.

Rimez B, Rahier H, Van Assche G, Artoos T, Biesemans M, Van Mele B. The thermal degradation of poly (vinyl acetate) and poly (ethylene-co-vinyl acetate), Part I: experimental study of the degradation mechanism. Polym Degrad Stab. 2008;93(4):800–10.

Barrales-Rienda JM, Chaves MS, Arechederra JM, Martin FF. Polymer precursors of polyacetylene. Thermal degradation of poly (vinyl esters). Part 1—molecular weight dependence of the autocatalytic thermal degradation of poly (vinyl acetate)(PVAc). Polym Degrad Stab. 1988;21(1):55–72.

Šimon P, Rybár M. Kinetics of polymer degradation involving the splitting off of small molecules: Part 8. Thermal degradation of polyvinyl esters. Polym Degrad Stab. 1992;38(3):255–9.

Wang Z, Han E, Ke W. Effect of acrylic polymer and nanocomposite with nano-SiO2 on thermal degradation and fire resistance of APP–DPER–MEL coating. Polym Degrad Stab. 2006;91(9):1937–47.

Lattimer RP. Pyrolysis mass spectrometry of acrylic acid polymers”. JAAP. 2003;68:3–14.

Pimenta JT, Gonçalves C, Hiliou L, Coelho JF, Magalhaes FD. Effect of binder on performance of intumescent coatings. J Coat Technol Res. 2016;13(2):227–38.

Cardoso AP, de Sá SC, Beraldo CH, Hidalgo GE, Ferreira CA. Intumescent coatings using epoxy, alkyd, acrylic, silicone, and silicone–epoxy hybrid resins for steel fire protection. J Coat Technol Res. 2020;17(6):1471–88.

Snegirev AY, Handawy MK, Stepanov VV, Talalov VA. Pyrolysis and combustion of polymer mixtures: exploring additivity of the heat release rate. Polym Degrad Stab. 2019;161:245–59.

Camino G, Costa L, Martinasso G. Intumescent fire-retardant systems”. Polym Degrad Stab. 1989;23(4):359–76.

Bourbigot S, Le Bras M, Delobel R, Bréant P, Trémillon JM. Carbonization mechanisms resulting from intumescence-part II. Association with an ethylene terpolymer and the ammonium polyphosphate-pentaerythritol fire retardant system. Carbon. 1995;33(3):283–94.

Bourbigot S, Le Bras M, Delobel R. Carbonization mechanisms resulting from intumescence association with the ammonium polyphosphate-pentaerythritol fire retardant system. Carbon. 1993;31(8):1219–30.

Zhang H. Fire-Safe polymers and polymer composites. DOT/FAA/AR-04/11. Federal Aviation Administration William J. Hughes Technical Center Fire Safety Branch; 2003

Dutta J, Naskar K. Investigation of morphology, mechanical, dynamic mechanical and thermal behaviour of blends based on ethylene vinyl acetate (EVA) and thermoplastic polyurethane (TPU). RSC Adv. 2014;4(105):60831–41.

Andres B, Livkiss K, Bhargava A, van Hees P. Using micro-scale and solid material data for modelling heat transfer in stone wool composites under heat exposures. Fire Technol. 2021;57(4):1541–67.

Acknowledgements

The authors thank Kim Mathisen for insights on paint formulation. This work is partly funded by Innovation Fund Denmark (Grant No: 9065-00233B).

Author information

Authors and Affiliations

Contributions

IH-B involved in conceptualization, formal analysis, investigation, methodology, software, validation, writing—original draft, writing—review and editing. KJ took part in formal analysis, investigation, validation. JR involved in funding, resources, supervision, writing—review and editing. MH involved in conceptualization, methodology, software, supervision, funding, project administration, resources, writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

As a paint producer of fire-retardant products, Teknos (i.e. Iben Hansen-Bruhn, Kirsten Jensen, and Jens B. Ravnsbæk) declares interest in commercial exploitation of the work reported in this paper. Mogens Hinge declares to have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hansen-Bruhn, I., Jensen, K., Ravnsbæk, J.B. et al. Micro combustion calorimeter for development of fire protective paints. J Therm Anal Calorim 148, 3993–4000 (2023). https://doi.org/10.1007/s10973-023-12018-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12018-2