Abstract

Phosphogypsum (PG) is a solid waste generated in the phosphate fertilizer industry and decomposing PG to recover calcium and sulfur is an appropriate way to reuse PG. The present work aims to enrich the basic theory of coal decomposition PG process, focusing on the effect of coal ash on the reduction roasting of PG and CaS oxidation process. Firstly, typical substances in coal ash such as SiO2, Fe2O3 and Al2O3 are investigated using fixed-bed experiments, TG-DSC combined with FactSage simulations. Finally, coal ash is used for experimental verification. It is found that SiO2, Fe2O3 and Al2O3 reduce the CaS yield in the reduction process and CaO yield in the roasting process. The results obtained from the addition of coal ash are consistent with those obtained from typical substances. The addition of coal ash reduce the temperature of the PG reduction and roasting processes, while it has little effect on the CaS oxidation process. For example, the addition of 20% coal ash reduce the CaS yield from 68.32 to 57.32% and reduce the CaO yield from 87.23 to 51.87%. In addition, the addition of 20% coal ash reduce the melting temperature of PG-CaS system from 1556.15 to 1490.15 K. The experimental results are consistent with FactSage simulations.

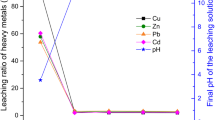

Graphical abstract

Similar content being viewed by others

References

Xu P, Li H, Chen Y. Experimental study on optimization of phosphogypsum suspension decomposition conditions under double catalysis. Materials. 2021;14(5):1120. https://doi.org/10.3390/ma14051120.

Suslikov AV, Zhirnov BS, Murtazin FR. A study of the kinetics of the reaction of petroleum coke with phosphogypsum to give calcium sulfide. Chem Technol Fuels Oils. 2021;57(3):461–6. https://doi.org/10.1007/s10553-021-01266-3.

Yang J, Zhu B, Ma LP, Liu HP. Investigation of Al2O3 and Fe2O3 transmission and transformation during the decomposition of phosphogypsum. Chin J Chem Eng. 2019;27(5):1125–31. https://doi.org/10.1016/j.cjche.2018.09.023.

Zheng SC, Ning P, Ma LP, Niu XK, Zhang W, Chen YH. Reductive decomposition of phosphogypsum with high-sulfur-concentration coal to SO2 in an inert atmosphere. Chem Eng Res Des. 2011;89(12A):2736–41. https://doi.org/10.1016/j.cherd.2011.03.016.

Zheng D, Lu HL, Sun XY, Liu XD, Han WQ, Wang LJ. Reaction mechanism of reductive decomposition of FGD gypsum with anthracite. Thermochim Acta. 2013;559:23–31. https://doi.org/10.1016/j.tca.2013.02.026.

Antar K, Jemal M. A thermogravimetric study into the effects of additives and water vapor on the reduction of gypsum and Tunisian phosphogypsum with graphite or coke in a nitrogen atmosphere. J Therm Anal Calorim. 2018;132(1):113–25. https://doi.org/10.1007/s10973-017-6871-6.

Zi Z, Ma L, Ma J, Chen J, Zhou L, Zhang H. Effect of impurities on the reductive decomposition of phosphogypsum by powdered carbon. Bull Chin Ceram Soc. 2014;33(11):2772–7. https://doi.org/10.16552/j.cnki.issn1001-1625.2014.11.007.

Mihara N, Kuchar D, Kojima Y, Matsuda H. Reductive decomposition of waste gypsum with SiO2, Al2O3, and Fe2O3 additives. J Mater Cycles Waste Manage. 2007;9(1):21–6. https://doi.org/10.1007/s10163-006-0167-4.

Shi T, Wan T, Zhang Z, Yang X, Yang L, Zhong B. Effect of SiO2 on the melting characteristics of reaction between phosphogypsum and calcium sulfide. J Therm Anal Calorim. 2016;123(2):1601–9. https://doi.org/10.1007/s10973-015-5032-z.

Zhao L, Wan T, Yang X, Yang L, Kong X, Zhang Z. Effects of kaolinite addition on the melting characteristics of the reaction between phosphogypsum and CaS. J Therm Anal Calorim. 2015;119(3):2119–26. https://doi.org/10.1007/s10973-015-4400-z.

Wang Y, Wan T, Zhong Y, Ma X, Chen Z, Wang X. Environmental sustainability of renewable phosphogypsum by CaS. J Therm Anal Calorim. 2020;139(6):3457–71. https://doi.org/10.1007/s10973-019-08718-3.

Wan T, Zhang Z, Wang X, Yang X, Zhong B. Research on the melting characteristics during the reaction process of phosphogypsum and calcium sulfide. Mod Chem Ind. 2011;31(12):63–7. https://doi.org/10.16606/j.cnki.issn0253-4320.2011.12.010.

Zhang L, Huang Z, Shen M, Wang Z, Zhou J. Effect of different regulative methods on coal ash fusion characteristics. J Fuel Chem Technol. 2015;43(2):145–52.

Liang W, Wang GW, Ning XJ, Zhang JL, Li YJ, Jiang CH. Effect of CaO mineral change on coal ash melting characteristics. J Energy Inst. 2020;93(2):642–8. https://doi.org/10.1016/j.joei.2019.06.001.

Lin D, Liu L, Zhao Y, Zhao Y, Qiu P, Xie X. Influence of pyrolysis pressure on structure and combustion reactivity of Zhundong demineralized coal char. J Energy Inst. 2020;93(5):1798–808. https://doi.org/10.1016/j.joei.2020.03.011.

Yan B, Ma L, Xie L, Ma J, Zi Z, Yan X. Reaction mechanism for iron catalyst in the process of phosphogypsum decomposition. Ind Eng Chem Res. 2013;52(49):17383–9. https://doi.org/10.1021/ie402321w.

Wang Y, Wang JZ, Zhang ZY, Yang L, Yang XS, Zhong BH. Investigation of the fusion characteristics of ash in the reduction of pyrite and phosphogypsum. J Sustain Metall. 2017;3(4):737–52. https://doi.org/10.1007/s40831-017-0138-0.

He HW, Hao LF, Fan CG, Li SG, Lin WG. A two-step approach to phosphogypsum decomposition: oxidation of CaS with CO2. Thermochim Acta. 2022. https://doi.org/10.1016/j.tca.2021.179122.

Davies NH, Hayhurst AN. On the formation of liquid melts of CaS and CaSO4 and their importance in the absorption of SO2 by CaO. Combust Flame. 1996;106(3):359–62. https://doi.org/10.1016/0010-2180(96)00003-X.

Bi YX, Xu L, Yang M, Chen QL. Study on the effect of the activity of anthracite on the decomposition of phosphogypsum. Ind Eng Chem Res. 2022;61(19):6311–21. https://doi.org/10.1021/acs.iecr.2c00081.

Fang R, Tan HB, Mao WJ, Ma XL, Feng Y, Jiang Q. Influence of carbon and additives on the high-temperature decomposition behavior of phosphogypsum. Mater Tehnol. 2020;54(6):861–5. https://doi.org/10.17222/mit.2020.083.

Zhang ZF, Wang YF, Zhu LC, Li JL, Wang FC, Yu GS. Performance of Fe2O3/Al2O3 oxygen carrier modified by CaCO3 and CaSO4 in chemical looping combustion. Appl Therm Eng. 2019;160:113813. https://doi.org/10.1016/j.applthermaleng.2019.113813.

Saleh HI. Synthesis and formation mechanisms of calcium ferrite compounds. J Mater Sci Technol. 2004;20(5):530–4.

Li W, Han X, Chen H, Li B. Kinetics and model of oxidation of CaS under pressure. J Chem Ind Eng (China, Chin Ed). 2003;54(5):625–32.

Xiao H, Zhou J, Liu J, Cao X, Fan H, Cen K. Research on oxidation of CaS under high temperature. J Chem Eng Chin Univ. 2006;20(3):494–8.

Zhao P, Pei X, Wang W, Peng S, Shao W. Analysis of alumina clinker as by-product through coal powder burning process. Light Met. 2010;2:16–9. https://doi.org/10.13662/j.cnki.qjs.2010.02.015.

Li XR, Zhang Y, Shen XD, Wang QQ, Pan ZG. Kinetics of calcium sulfoaluminate formation from tricalcium aluminate, calcium sulfate and calcium oxide. Cem Concr Res. 2014;55:79–87. https://doi.org/10.1016/j.cemconres.2013.10.006.

Liu Q, Ao XQ, Chen QL, Xie Y, Cao Y. Reaction characteristics and kinetics of phosphogypsum decomposition via synergistic reduction effect of composite reducing agent. J Mater Cycles Waste Manage. 2022;24(2):595–605. https://doi.org/10.1007/s10163-021-01344-y.

Lu DH, Chen QL, Li CQ, Gong S. Effect of potassium feldspar on the decomposition rate of phosphogypsum. J Chem Technol Biotechnol. 2021;96(2):374–83. https://doi.org/10.1002/jctb.6549.

Chen FH, Wen GH, Tang P, Yu L, Han FN. The role of carbonaceous materials in mold powder and influence on melting behavior. J Therm Anal Calorim. 2022;147(20):10965–75. https://doi.org/10.1007/s10973-022-11361-0.

Tan JX, He Y, Yuan Y, Zhou ZJ, Liu JZ, Wang ZH. Reactions and transformations of mineral matters during entrained flow coal gasification using oxygen-enriched air. J Energy Inst. 2022;102:229–39. https://doi.org/10.1016/j.joei.2022.03.006.

Acknowledgements

This work is supported by the Cooperation Project between Zhejiang University and Yuntianhua Company (2019-KYY-508101-0078).

Author information

Authors and Affiliations

Contributions

DM contributed to experiment, formal analysis, data curation, investigation and writing—original draft. QW contributed to methodology, conceptualization, resources, review and editing and supervision.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ma, D., Wang, Q. Effect of coal ash on the reduction and roasting processes of phosphogypsum. J Therm Anal Calorim 148, 3671–3688 (2023). https://doi.org/10.1007/s10973-023-11954-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-11954-3