Abstract

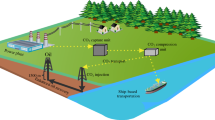

A novel hybrid system, including photovoltaic, wind turbine, diesel generator, battery, electrolyzer, gas turbine cycle, Rankine cycle, absorption chiller, and hot water line, is introduced in order to supply electricity, cooling, and heating simultaneously for a town in Istanbul. The dynamic method is employed for different parts of the system dependent on meteorological information, and the steady-state situation is considered for the other parts, such as the gas turbine cycle, Rankine cycle, absorption chiller, and hot water line. Therefore, every operational parameter of the proposed system is evaluated monthly based on the meteorological information of 2019 in Istanbul. Also, the combination of the non-dominated sorting algorithm and multi-criteria decision-making of TOPSIS is employed in order to obtain the optimum rates of monthly operational parameters. Accordingly, the maximum rates of energy and exergy efficiencies can be acquired, which belong to September, October, and November, approximately 54–60%. Furthermore, exergy destruction can be achieved at the lowest rate. The highest exergy destruction is dedicated to December, with 1925.7 MW and the combustion chamber in the gas turbine cycle has the highest contribution (48%) in the exergy destruction related to this month. At the end, the COE and NPC of the system based on the optimum operational parameters are obtained 0.05147 $kW h−1 and 579.3 M$, respectively.

Similar content being viewed by others

Abbreviations

- AB:

-

Absorption chiller

- BA:

-

Battery

- BS:

-

Biomass system

- COP:

-

Coefficient of performance

- CPV:

-

Concentration photovoltaic system

- CRF:

-

Capital recovery factor

- DG:

-

Diesel generator

- EL:

-

Electrolyzer

- ESS:

-

Efficiency of the battery storage system

- GT:

-

Gas turbine cycle

- HESS:

-

Hybrid battery storage system

- HHV:

-

High heating value

- HT:

-

Hydrogen tank

- HW:

-

Hot water line

- INV:

-

Inverter

- LHV:

-

Low heating value

- NSGA-II:

-

Non-demonstrated sorting genetic algorithm

- MAE:

-

Mean absolute error

- MRE:

-

Mean relative error

- ORC:

-

Organic Rankine cycle

- PV:

-

Photovoltaic

- RMSE:

-

Root mean square error

- SC:

-

Super capacitor

- SMES:

-

Superconducting magnetic energy storage

- SOC:

-

State of charge

- ST:

-

Steam turbine

- STC:

-

Standard test condition

- WT:

-

Wind turbine

- A :

-

Surface (m2)

- C :

-

Nominal capacity (Ah)

- C A :

-

Total annualized cost ($)

- C p :

-

Coefficient of wind turbine

- Cpair :

-

Specific heat of air (kJ kg−1 K−1)

- COE:

-

Cost of energy ($)

- Ex:

-

Exergy flow rate (kW)

- D :

-

Exergy destruction flow rate (kW)

- D :

-

Degree of deviation

- d :

-

Nominal interest rate (%)

- e :

-

Theoretical values

- FF:

-

Fill factor

- F :

-

Annual inflation rate (%)

- H :

-

Specific enthalpy (kJ kg−1)

- Ha:

-

Angle of solar elevation (°)

- I :

-

Solar irradiance (W m−2)

- I mp :

-

The current of maximum power point (A)

- I sc :

-

The current of short circuit (A)

- i :

-

Annual real interest rate

- K I :

-

Coefficient of short circuit current temperature (°C)

- K V :

-

Coefficient of open circuit voltage temperature (°C)

- Ṁ :

-

Volumetric flow rate (L h−1)

- m ´ :

-

Experimental values

- ṁ :

-

Mass flow rate (kg s−1)

- NCOT :

-

Nominal cell temperature (°C)

- n :

-

The number of days

- N :

-

Number of components

- Nc :

-

Cycle lifetime (year)

- NPC:

-

Net present cost

- P m :

-

Output power of photovoltaic (kW)

- Q̇ :

-

Heat transfer rate (kW)

- R :

-

Universal gas constant (J K−1 mol−1)

- r_ac :

-

Pressure ratio of air compressor

- r p :

-

Pump pressure ratio

- s :

-

Specific entropy (kJ kg−1 K−1)

- S p :

-

Solar radiation to the tilted panel (W m−2)

- S t :

-

Incident radiation on tilted surface (W m−2)

- T :

-

Temperature (°C)

- T i :

-

Local hour

- V :

-

Velocity (m s−1)

- V bat :

-

Nominal voltage of battery (V)

- Vmp:

-

The voltage of maximum power point (V)

- Voc:

-

The voltage of open circuit (V)

- Ẇ/P :

-

Power (kW)

- Y :

-

Number of values for comparison

- β :

-

Pv panel slop angle (°)

- γ 1 / γ 2 :

-

Fuel consumption coefficient (L kWh−1)

- Δ :

-

Solar declination (°)

- ε :

-

Effectiveness

- ƞ :

-

Efficiency

- θ :

-

Earth inclination (°)

- μ :

-

Hour angle (°)

- Ρ :

-

Density (kg m−3)

- Φ :

-

Geography of the latitude (°)

- A/0 :

-

Ambient

- a/abs:

-

Absorber

- ac:

-

Air compressor

- bat:

-

Battery

- C :

-

Cell

- CAP:

-

Capital cost

- C :

-

Cut in

- ch:

-

Chemical

- comp:

-

Compressor

- cond:

-

Condenser

- D :

-

Destruction

- DG/dgr:

-

Diesel generator

- e/eva:

-

Evaporator

- elec:

-

Electrolyzer

- ex:

-

Exergy

- F :

-

Fuel

- FUEL_DI/CO:

-

Fuel of diesel generator/combustion chamber

- f :

-

Cut off

- G-tur/Gt :

-

Gas turbine cycle

- gen/g :

-

Generator

- h :

-

Hot

- i :

-

Inlet

- LBH:

-

The mixture of lithium-bromide with water

- O&M:

-

Operation and maintenance

- o :

-

Outlet

- ph:

-

Physical

- pv:

-

Photovoltaic

- REP:

-

Replacement

- r :

-

Refrigerant

- S-tur:

-

Steam turbine

- ss:

-

Strong solution

- tot:

-

Total

- w :

-

Water

- Ws:

-

Weak solution

- wt/wg:

-

Wind turbine

- x i :

-

Mole fraction

References

Uyar TS, Beşikci D. Integration of hydrogen energy systems into renewable energy systems for better design of 100% renewable energy communities. Int J Hydrog Energy. 2017;42(4):2453–6.

Thapar S, Sharma S, Verma A. Local community as shareholders in clean energy projects: innovative strategy for accelerating renewable energy deployment in India. Renew Energy. 2017;101:873–85.

Wang R, et al. Renewable energy microgrids: Economic evaluation and decision making for government policies to contribute to affordable and clean energy. Appl Energy. 2020;274:115287.

Joshi AS, Dincer I, Reddy BV. Performance analysis of photovoltaic systems: a review. Renew Sustain Energy Rev. 2009;13(8):1884–97.

Magrassi F, et al. Hybrid solar power system versus photovoltaic plant: a comparative analysis through a life cycle approach. Renew Energy. 2019;130:290–304.

Omran KC, Mosallanejad A. SMES/battery hybrid energy storage system based on bidirectional Z-source inverter for electric vehicles. IET Electr Syst Transp. 2018;8(4):215–20.

Eltawil MA, Zhao Z. Grid-connected photovoltaic power systems: technical and potential problems—a review. Renew Sustain Energy Rev. 2010;14(1):112–29.

Hoppmann J, et al. The economic viability of battery storage for residential solar photovoltaic systems–a review and a simulation model. Renew Sustain Energy Rev. 2014;39:1101–18.

Krause MB. Zwei Wege, ein Ziel-Solon und Schüco verkaufen ab Anfang kommenden Jahres auch Speichersysteme für Solaranlagen. InPhoton 2011 (Vol. 12, p. 51f).

Li J, et al. Design and test of a new droop control algorithm for a SMES/battery hybrid energy storage system. Energy. 2017;118:1110–22.

Amikam G, Nativ P, Gendel Y. Chlorine-free alkaline seawater electrolysis for hydrogen production. Int J Hydrog Energy. 2018;43(13):6504–14.

Kumar SS, Himabindu V. Hydrogen production by PEM water electrolysis–a review. Mater Sci Energy Technol. 2019;2(3):442–54.

Chi J, Yu H. Water electrolysis based on renewable energy for hydrogen production. Chin J Catal. 2018;39(3):390–4.

Zeng K, Zhang D. Recent progress in alkaline water electrolysis for hydrogen production and applications. Prog Energy Combust Sci. 2010;36(3):307–26.

Almahdi M, Dincer I, Rosen M. A new solar based multigeneration system with hot and cold thermal storages and hydrogen production. Renew Energy. 2016;91:302–14.

Khanmohammadi S, et al. Exergoeconomic analysis and multi objective optimization of a solar based integrated energy system for hydrogen production. Int J Hydrog Energy. 2017;42(33):21443–53.

Siddiqui O, Dincer I. Analysis and performance assessment of a new solar-based multigeneration system integrated with ammonia fuel cell and solid oxide fuel cell-gas turbine combined cycle. J Power Sour. 2017;370:138–54.

Yang H, Lu L, Zhou W. A novel optimization sizing model for hybrid solar-wind power generation system. Sol Energy. 2007;81(1):76–84.

Kasaeian A, Hadavi H, Amirhaeri Y, Pourfayaz F. Thermodynamic analysis of a wood chips-based cycle integrated with solid oxide fuel cell. Renewable Energy. 2022;195:1174–1193.

Liu X, et al. A novel waste heat recovery system combing steam Rankine cycle and organic Rankine cycle for marine engine. J Clean Prod. 2020;265:121502.

Rahman, M.M., Ibrahim, T.K., Kadirgama, K., Mamat, R., Bakar, R.A., 2011. Influence of Operation Conditions and Ambient Temperature on Performance of Gas Turbine Power Plant. AMR 189–193, 3007–3013.

Khan SA, Bicer Y, Koç M. Design and analysis of a multigeneration system with concentrating photovoltaic thermal (CPV/T) and hydrogen storage. Int J Hydrog Energy. 2020;45(5):3484–98.

Bicer Y, Dincer I. Analysis and performance evaluation of a renewable energy based multigeneration system. Energy. 2016;94:623–32.

Suleman F, Dincer I, Agelin-Chaab M. Development of an integrated renewable energy system for multigeneration. Energy. 2014;78:196–204.

https://www.pveducation.org/pvcdrom/properties-of-sunlight/calculation-of-solar-insolation.

https://www.wunderground.com/history/monthly/tr/bak%C4%B1rk%C3%B6y/LTBA/date/2019-1.

Yilmaz F. Thermodynamic performance evaluation of a novel solar energy based multigeneration system. Appl Therm Eng. 2018;143:429–37.

Sonntag RE, et al. Fundamentals of thermodynamics, vol. 6. New York: Wiley; 1998.

Mehrpooya, M., Amirhaeri, Y. & Hadavi, H. Proposal and investigation of a novel small-scale natural gas liquefaction process using diffusion absorption refrigeration technology. Chem. Pap. 76, 5901–5927 (2022).

Sharafi M, El Mekkawy TY. Multi-objective optimal design of hybrid renewable energy systems using PSO-simulation based approach. Renew Energy. 2014;68:67–79.

Shi Z, Wang R, Zhang T. Multi-objective optimal design of hybrid renewable energy systems using preference-inspired coevolutionary approach. Sol Energy. 2015;118:96–106.

Sarhaddi F, et al. Exergy efficiency of a solar photovoltaic array based on exergy destructions. Proc Inst Mech Eng Part A J Power Energy. 2010;224(6):813–25.

Koutroulis E, et al. Methodology for optimal sizing of stand-alone photovoltaic/wind-generator systems using genetic algorithms. Sol Energy. 2006;80(9):1072–88.

Seyam S et al. Multi-objective optimization of hydrogen production in hybrid renewable energy systems. In: 2019 IEEE congress on evolutionary computation (CEC). 2019. IEEE.

Bilal BO, et al. Methodology to size an optimal stand-alone PV/wind/diesel/battery system minimizing the levelized cost of energy and the CO2 emissions. Energy Proc. 2012;14:1636–47.

Ming M, et al. Multi-objective optimization of hybrid renewable energy system using an enhanced multi-objective evolutionary algorithm. Energies. 2017;10(5):674.

Zhao J, Yuan X. Multi-objective optimization of stand-alone hybrid PV-wind-diesel-battery system using improved fruit fly optimization algorithm. Soft Comput. 2016;20(7):2841–53.

Saadat-Targhi M, Khanmohammadi S. Energy and exergy analysis and multi-criteria optimization of an integrated city gate station with organic Rankine flash cycle and thermoelectric generator. Appl Therm Eng. 2019;149:312–24.

Beigzadeh M, et al. Energy and exergy analyses of solid oxide fuel cell-gas turbine hybrid systems fed by different renewable biofuels: a comparative study. J Clean Prod. 2021;280:124383.

Ekrataleshian A, Pourfayaz F, Ahmadi MH. Thermodynamic and thermoeconomic analyses and energetic and exergetic optimization of a turbojet engine. J Therm Anal Calorim. 2021;145(3):909–23.

Oliveira SD. Exergy, exergy costing, and renewability analysis of energy conversion processes. InExergy 2013 (pp. 5–53). Springer, London.

Hosseini SS, et al. Introducing, evaluation and exergetic performance assessment of a novel hybrid system composed of MCFC, methanol synthesis process, and a combined power cycle. Energy Convers Manag. 2019;197:111878.

Das BK, et al. A techno-economic feasibility of a stand-alone hybrid power generation for remote area application in Bangladesh. Energy. 2017;134:775–88.

Ngan MS, Tan CW. Assessment of economic viability for PV/wind/diesel hybrid energy system in southern Peninsular Malaysia. Renew Sustain Energy Rev. 2012;16(1):634–47.

Roy D, Samanta S, Ghosh S. Thermo-economic assessment of biomass gasification-based power generation system consists of solid oxide fuel cell, supercritical carbon dioxide cycle and indirectly heated air turbine. Clean Technol Environ Policy. 2019;21(4):827–45.

Keshtkar MM, Khani AG. Exergoeconomic analysis and optimization of a hybrid system based on multi-objective generation system in Iran: a case study. Renew Energy Focus. 2018;27:1–13.

Shaofu M, et al. Exergy, economic, and optimization of a clean hydrogen production system using waste heat of a steel production factory. Int J Hydrog Energy. 2021;47:26067–81.

Zhuang Y, et al. A hierarchical optimization and design of double Kalina Cycles for waste heat recovery. Energy. 2021;219:119593.

Shamoushaki M, et al. Exergy and exergoeconomic analysis and multi-objective optimisation of gas turbine power plant by evolutionary algorithms. Case study: Aliabad Katoul power plant. Int J Exergy. 2017;22(3):279–307.

Hossain MS, et al. Techno-economic analysis of the hybrid solar PV/H/Fuel cell based supply scheme for green mobile communication. Sustainability. 2021;13(22):12508.

Baseer M, Alqahtani A, Rehman S. Techno-economic design and evaluation of hybrid energy systems for residential communities: case study of Jubail industrial city. J Clean Prod. 2019;237:117806.

Luta DN, Raji AK. Decision-making between a grid extension and a rural renewable off-grid system with hydrogen generation. Int J Hydrog Energy. 2018;43(20):9535–48.

DiOrio N, Dobos A, Janzou S. Economic analysis case studies of battery energy storage with SAM. In: 2015, National Renewable Energy Lab.(NREL), Golden, CO (United States).

Seedahmed MM, et al. A techno-economic analysis of a hybrid energy system for the electrification of a remote cluster in western Saudi Arabia. Alex Eng J. 2022;61(7):5183–202.

Pourkiaei SM, et al. Multi-objective optimization of tubular solid oxide fuel cells fed by natural gas: an energetic and exergetic simultaneous optimization. J Therm Anal Calorim. 2021;145(3):1575–83.

Khaki M, et al. Energy and exergy analysis and multi-objective optimization of an air based building integrated photovoltaic/thermal (BIPV/T) system. Sol Energy. 2017;158:380–95.

Rashidi H, Khorshidi J. Exergy analysis and multiobjective optimization of a biomass gasification based multigeneration system. Int J Hydrog Energy. 2018;43(5):2631–44.

Esfe MH, et al. Optimization, modeling and accurate prediction of thermal conductivity and dynamic viscosity of stabilized ethylene glycol and water mixture Al2O3 nanofluids by NSGA-II using ANN. Int Commun Heat Mass Transf. 2017;82:154–60.

Nădăban S, Dzitac S, Dzitac I. Fuzzy TOPSIS: a general view. Proc Comput Sci. 2016;91:823–31.

Jahangir MH, Javanshir F, Kargarzadeh A. Economic analysis and optimal design of hydrogen/diesel backup system to improve energy hubs providing the demands of sport complexes. Int J Hydrog Energy. 2021;46(27):14109–29.

Diab F, et al. An environmentally friendly factory in Egypt based on hybrid photovoltaic/wind/diesel/battery system. J Clean Prod. 2016;112:3884–94.

Rajbongshi R, Borgohain D, Mahapatra S. Optimization of PV-biomass-diesel and grid base hybrid energy systems for rural electrification by using HOMER. Energy. 2017;126:461–74.

Mandal S, Das BK, Hoque N. Optimum sizing of a stand-alone hybrid energy system for rural electrification in Bangladesh. J Clean Prod. 2018;200:12–27.

Funding

No funding was received for conducting this study. Also, the authors have no financial or proprietary interests in any material discussed in this article.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

where e, m\(^{^{\prime}}\), and y are the theoretical values, experimental values, and the number of values for comparison.

where ṁFUEL_CO and ƞcomb are the fuel mass flow of the combustion chamber and the efficiency of the combustion chamber, respectively.

where Q̇comb is the inlet heat that enters the combustion chamber.

Also, ṁ3 is the inlet mass flow rate of gas turbine.

In Eqs. (59, 60), h0 and s0 are enthalpy and entropy of the environmental conditions at atmospheric pressure and temperature, xi is the mole fraction of component in the mixed refrigerant, exch,i is the standard chemical exergy of the ith component in the mixed refrigerant. Also, R is the universal gas constant with the value of 8.314 (JKmol−1). The physical and chemical exergies of every stream are demonstrated in Table 1.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Amirhaeri, Y., Pourfayaz, F., Hadavi, H. et al. Energy and exergy analysis-based monthly co-optimization of a poly-generation system for power, heating, cooling, and hydrogen production. J Therm Anal Calorim 148, 8195–8221 (2023). https://doi.org/10.1007/s10973-022-11793-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11793-8