Abstract

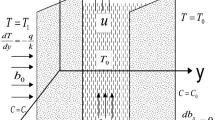

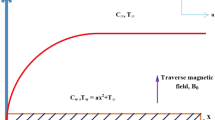

This paper examined the problem associated with incompressible viscous nanofluid flow inside shrinking and stretching walls. Flow is contemplated from a sink or source through channel. MHD, radiation, heat source/sink, chemical reaction and cross-diffusion consequences are considered to find out about the nature of various profiles like: velocity, mass as well as temperature. Later on by using non-dimensional parameters, we obtain PDE from governing equations after which these are figure out by using OHAM. A valuable agreement is obtained on comparing the results with previous research studies. Ranges for various non-dimensional parameters are considered during present work, which are likewise: opening angle \(\left( {{ - 9}^{ \circ } \le \alpha \le {9}^{ \circ } } \right)\), Reynolds number \(\left( {40 \le {\text{Re}} \le 60} \right)\), nanoparticles volume fraction \(\left( {0 \le {\varphi } \le 0.15} \right)\), magnetic parameter \(\left( {{0 \le { M} \le 110}} \right)\), radiation parameter \(\left( {0 \le Rd \le 0.1} \right)\), Prandtl number \(\left( {1 \le \Pr \le 6.2} \right)\), heat source/sink parameter \(\left( {0 \le Hs \le 0.8} \right)\), Eckert number \(\left( {0 \le Ec \le 0.01} \right)\), Dufour number \(\left( {0 \le D_{\text{f}} \le 2.4} \right)\), Schmidt number \(\left( {0 \le Sc \le 1.39} \right)\), chemical reaction parameter \(\left( {0 \le K \le 1.6} \right)\), Soret number \(\left( {0 \le Sr \le 0.57} \right)\) and stretching/shrinking parameter \(\left( { - 2.8 \le C^{*} \le 2.8} \right)\). It is predicted that for divergent channel the velocity function reduces, whereas it shows contrast nature for convergent channel with an enhancement in the volume fraction of nanoparticles. With rise in Soret as well as Dufour number, there is rise in temperature and fall down in concentration function.

Similar content being viewed by others

Abbreviations

- \(A,B\) :

-

Constant parameters (–)

- \(B_{0}\) :

-

Magnetic field (N m−1 A−1)

- \(B_{1}\) :

-

Constant parameter (–)

- \(c_{\text{p}}\) :

-

Specific heat (J kg−1 K−1)

- \(c_{\text{s}}\) :

-

Concentration susceptibility (mol m−3)

- \(C\) :

-

Concentration (mol m−3)

- \(C_{\text{f}}\) :

-

Skin friction coefficient (–)

- \(C_{\text{w}}\) :

-

Concentration at the plate (mol m−3)

- \(C^{*}\) :

-

Stretching/shrinking parameter (–)

- \(D\) :

-

Mass diffusion coefficient (m2 s−1)

- \(D_{\text{f}}\) :

-

Dufour number (–)

- \(Ec\) :

-

Eckert number (–)

- \(f\) :

-

Dimensionless velocity (–)

- \(Hs\) :

-

Heat source/sink parameter (–)

- \(k\) :

-

Thermal conductivity (W m2 K−1)

- \(k_{1}\) :

-

Chemical reaction rate (mol m−3 s−1)

- \(k^{*}\) :

-

Mean absorption coefficient (–)

- \(K\) :

-

Chemical reaction parameter (–)

- \(K_{\text{T}}\) :

-

Thermal diffusion ratio (m−2 s−1)

- \(M\) :

-

Magnetic parameter (–)

- \(Nu\) :

-

Nusselt number (–)

- \(p\) :

-

Pressure (N m−2)

- \(\Pr\) :

-

Prandtl number (–)

- \(q_{\text{m}}\) :

-

Surface mass flux (kg s −1 m−2)

- \(q_{\text{rad}}\) :

-

Radiative heat flux (kg s −3)

- \(q_{\text{w}}\) :

-

Surface heat flux (W m−2)

- \(Q_{0}\) :

-

Heat source/sink (J)

- \(r\) :

-

Cylindrical coordinate (–)

- \(Rd\) :

-

Radiation parameter (–)

- \({\text{Re}}\) :

-

Reynolds number (–)

- \(s\) :

-

Stretching/shrinking rate (m2 s−1)

- \(Sc\) :

-

Schmidt number (–)

- \(Sh\) :

-

Sherwood number (–)

- \(Sr\) :

-

Soret number (–)

- \(T\) :

-

Temperature (K)

- \(T_{\text{w}}\) :

-

Surface temperature of channel (K)

- \(T_{0}\) :

-

Free stream temperature (K)

- \(u\) :

-

Velocity component in the radial direction (m s−1)

- \(u_{\text{c}}\) :

-

Rate of movement in the radial direction (m2 s−1)

- \(u_{\text{w}}\) :

-

Wall velocity component in the radial direction (m s−1)

- \(\alpha\) :

-

Angle of the channel (–)

- \(\phi\) :

-

Dimensionless concentration (–)

- \(\varphi\) :

-

Nanoparticles volume fraction (–)

- \(\eta\) :

-

Dimensionless angle (–)

- \(\mu\) :

-

Dynamic viscosity (kg m−1 s−1)

- \(\theta\) :

-

Cylindrical coordinate (–)

- \(\Theta\) :

-

Dimensionless temperature (–)

- \(\rho\) :

-

Density (kg m−3)

- \(\sigma\) :

-

Electrical conductivity (s m−1)

- \(\sigma^{*}\) :

-

Stefan–Boltzmann constant (–)

- \(\tau_{\text{w}}\) :

-

Shear stress on the wall (N m−2)

- \(f\) :

-

Base fluid

- \(nf\) :

-

Nanofluid

- \(s\) :

-

Nanoparticle

References

Choi SUS, Eastman JA. Enhancing thermal conductivity of fluids with nanoparticles. ASME Int Mech Eng Congress Expo. 1995;1–8.

Mohyud-Din ST, Khan U, Hassan SM. Numerical investigation of magnetohydrodynamic flow and heat transfer of copper–water nanofluid in a channel with non-parallel walls considering different shapes of nanoparticles. Adv Mech Eng. 2016;8:1–9. https://doi.org/10.1177/1687814016637318.

Arifuzzaman SM, Mehedi MFU, Al-Mamun A, Biswas P, Islam MR, Khan MS. Magnetohydrodynamic micropolar fluid flow in presence of nanoparticles through porous plate: A numerical study. Int J Heat Tech. 2018;36:936–48. https://doi.org/10.18280/ijht.360321.

Li Z, Khan I, Shafee A, Tlili I, Asifa T. Energy transfer of Jeffery-Hamel nanofluid flow between non-parallel walls using Maxwell-Garnetts (MG) and Brinkman models. Energy Rep. 2018;4:393–9. https://doi.org/10.1016/j.egyr.2018.05.003.

Waini I, Ishak A, Pop I. Unsteady flow and heat transfer past a stretching/shrinking sheet in a hybrid nanofluid. Int J Heat Mass Transf. 2019;136:288–97. https://doi.org/10.1016/j.ijheatmasstransfer.2019.02.101.

Rana P, Shukla N, Gupta Y, Pop I. Analytical prediction of multiple solutions for MHD Jeffery-Hamel flow and heat transfer utilizing KKL nanofluid model. Phys Lett. 2019;383:176–85. https://doi.org/10.1016/j.physleta.2018.10.026.

Jeffery GB. The two-dimensional steady motion of a viscous fluid. Philos Mag. 1915;29:455–65. https://doi.org/10.1080/14786440408635327.

Hamel G. Spiralförmige Bewegungen zäher Flüssigkeiten. Dtsch Math Ver. 1917;25:34–60.

Hosseini R, Poozesh S, Dinarvand S. MHD flow of an incompressible viscous fluid through convergent or divergent channels in presence of a high magnetic field. J Appl Math. 2012;2012:1–12. https://doi.org/10.1155/2012/157067.

Turkyilmazoglu M. Extending the traditional Jeffery-Hamel flow to stretchable convergent/divergent channel. Comput Fluids. 2014;100:196–203. https://doi.org/10.1016/j.compfluid.2014.05.016.

Mohyud-Din ST, Khan U, Ahmed N, Hassan SM. Magnetohydrodynamic flow and heat transfer of nanofluids in stretchable convergent/divergent channels. Appl Sci. 2015;5:1639–64. https://doi.org/10.3390/app5041639.

Dogonchi AS, Ganji DD. Investigation of MHD nanofluid flow and heat transfer in a stretching/shrinking convergent/divergent channel considering thermal radiation. J Mol Liq. 2016;220:592–603. https://doi.org/10.1016/j.molliq.2016.05.022.

Dogonchi AS, Ganji DD. Study of nanofluid flow and heat transfer between non-parallel stretching walls considering Brownian motion. J Taiwan Inst Chem Eng. 2016;69:1–13. https://doi.org/10.1016/j.jtice.2016.09.029.

Mohyud-Din ST, Khan U, Ahmed N, Bin-Mohsin B. Heat and mass transfer analysis for MHD flow of nanofluid inconvergent/divergent channels with stretchable walls using Buongiorno’s model. Neural Comput Appl. 2017;28:4079–92. https://doi.org/10.1007/s00521-016-2289-5.

Pandey AK, Kumar M. MHD flow inside a stretching/shrinking convergent/divergent channel with heat generation/absorption and viscous-Ohmic dissipation utilizing Cu− water nanofluid. Comput Therm Sci. 2018;10:457–71. https://doi.org/10.1615/ComputThermalScien.2018020807.

Karami F, Sabzpooshani M. Analytical investigation of MHD nanofluid flow between non-parallel stretching/shrinking walls with considering Joule heating effect. Modares Mech Eng. 2019;19:697–708.

Kumar KG, Chamkha AJ. Darcy-Forchheimer flow and heat transfer of water-based Cu nanoparticles in convergent/divergent channel subjected to particle shape effect. Eur Phys J Plus. 2019;134:1–12. https://doi.org/10.1140/epjp/i2019-12447-y.

Qadeer M, Khan U, Ahmad S. Irreversibility analysis for flow of nanofluids with aggregation in converging and diverging channel. Sci Rep. 2022;12:1–23. https://doi.org/10.1038/s41598-022-14529-8.

Jaafar A, Waini I, Jamaludin A, Nazar R, Pop I. MHD flow and heat transfer of a hybrid nanofluid past a nonlinear surface stretching/shrinking with effects of thermal radiation and suction. Chin J Phys. 2022. https://doi.org/10.1016/j.cjph.2022.06.026.

Venkateswarlu B, Narayana PVS. Chemical reaction and radiation absorption effects on the flow and heat transfer of a nanofluid in a rotating system. Appl Nanosci. 2015;5:351–60. https://doi.org/10.1007/s13204-014-0324-3.

Singh K, Kumar M. Influence of chemical reaction on heat and mass transfer flow of a micropolar fluid over a permeable channel with radiation and heat generation. J Thermodyn. 2016;2016:1–10. https://doi.org/10.1155/2016/8307980.

Khan U, Ahmed N, Mohyud-Din ST. Thermo-diffusion, diffusion-thermo and chemical reaction effects on MHD flow of viscous fluid in divergent and convergent channels. Chem Eng Sci. 2016;141:17–27. https://doi.org/10.1016/j.ces.2015.10.032.

Khan U, Adnan, Ahmed N, Mohyud-Din ST. Soret and Dufour effects on Jeffery-Hamel flow of second-grade fluid between convergent/divergent channel with stretchable walls. Results Phys. 2017;7:361–72. http://doi.org/https://doi.org/10.1016/j.rinp.2016.12.020.

Akinshilo AT. Mixed convective heat transfer analysis of MHD fluid flowing through an electrically conducting and non-conducting walls of a vertical micro-channel considering radiation effect. Appl Therm Eng. 2019;156:506–13. https://doi.org/10.1016/j.applthermaleng.2019.04.100.

Patel HR. Effects of cross diffusion and heat generation on mixed convective MHD flow of Casson fluid through porous medium with non-linear thermal radiation. Heliyon. 2019;5:1–26. https://doi.org/10.1016/j.heliyon.2019.e01555.

Ahmad S, Ashraf M, Ali K. Simulation of thermal radiation in a micropolar fluid flow through a porous medium between channel walls. J Therm Anal Calorim. 2021;144:941–53. https://doi.org/10.1007/s10973-020-09542-w.

Mahabaleshwar US, Aly EH, Anusha T. MHD slip flow of a Casson hybrid nanofluid over a stretching/shrinking sheet with thermal radiation. Chin J Phys. 2022. https://doi.org/10.1016/j.cjph.2022.06.008.

Biswas R, Hossain MdS, Islam R, Ahmmed SF, Mishra SR, Afikuzzaman M. Computational treatment of MHD Maxwell nanofluid flow across a stretching sheet considering higher-order chemical reaction and thermal radiation. J Comput Math Data Sci. 2022;4:1–13. https://doi.org/10.1016/j.jcmds.2022.100048.

Arulmozhi S, Sukkiramathi K, Santra SS, Edwan R, Fernandez-Gamiz U, Noeiaghdam S. Heat and mass transfer analysis of radiative and chemical reactive effects on MHD nanofluid over an infinite moving vertical plate. Result Eng. 2022;14:1–9. https://doi.org/10.1016/j.rineng.2022.100394.

Hossain R, Hasan MdJ, Azad AK, Rahman MM. Numerical study of low Reynolds number effect on MHD mixed convection using CNT-oil nanofluid with radiation. Result Eng. 2022;14:1–14. https://doi.org/10.1016/j.rineng.2022.100446.

Author information

Authors and Affiliations

Contributions

All authors contributed equally to this work. And all the authors have read and approved the final version manuscript.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bhaskar, K., Sharma, K. & Bhaskar, K. Cross-diffusion and chemical reaction effects of a MHD nanofluid flow inside a divergent/convergent channel with heat source/sink. J Therm Anal Calorim 148, 573–588 (2023). https://doi.org/10.1007/s10973-022-11525-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11525-y