Abstract

This work aims to determine the antioxidants activity of individual antioxidants and natural extracts by isothermal calorimetry. The proposed method is an adaptation of the “inhibited autoxidation method”. It consists of the monitoring of the heat-flow signal evolved during the autoxidation of styrene, in the presence of 2,2′-azobis(isobutyronitrile) as radical initiator, with individual antioxidants or plant extracts as inhibitors, and under isothermal conditions (303 K). The resulting calorimetric traces were transformed in conversion fractions over time. The antioxidant activity was expressed with the initial slope of the inhibited period of styrene autoxidation. Also, the induction period observed at the onset of the uninhibited styrene autoxidation leaded the stoichiometry number of the reaction between antioxidants and free radicals. The approach was very simple, and it allowed to rank individual antioxidants (α-tocopherol > > gallic acid = quercetin > syringic acid > > synaptic acid > 4-hydroxybenzoic acid) and plant extracts (Olea europea > Melissa officinalis > Fraxinus excelsior > > Papaver rhoeas), based on their ability to decrease the conversion rate of styrene autoxidation. The results on plant extracts were critically compared with those from the DPPH assay. Differently to the many antioxidant assays widely used nowadays, the proposed approach has the merit to test the activity of micromolar quantities of antioxidants to inhibit the autoxidation of a large excess of an oxidizable substrate, whose oxidation is induced by a constant rate of free radicals formation under well controlled and reproducible experimental conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Most processed foods, feeds or cosmetics contain a certain amount of antioxidants. Their use is essential to protect such products from degradative oxidation processes [1]. Recently, there is a growing trend, especially in the food sector, to replace synthetic antioxidants (i.e., butylated hydroxytolune (BHT), butylated hydroxyanisole (BHA)) with natural extracts (i.e., extracts from vegetables, botanical herbs, spices and food by-products) [2,3,4]. However, the development of formulations with the use of natural extracts is often limited by the lack of methodologies available for their testing and validation. The final decision on which antioxidant systems must be used in a formulation is generally based on very long shelf-life studies (which may take months or years), or alternatively, with complex accelerated stress testing studies, whose validity could be debated. Moreover, because of the importance of antioxidants in the protection of foods, feeds and cosmetics, a large variety of quick tests have been also proposed in recent years, although their capacity to predict the behavior of natural extracts in complex systems (like foods) seems quite limited [5].

One of the most comprehensive methods to determine the antioxidant activity is the “inhibited autoxidation method” [6]. This method is based on quantitative kinetic studies that measure the ability of antioxidants to inhibit the rate of an autoxidation process of a reference substrate [7]. The choice of the substrate is based on the effectiveness of the antioxidants under investigation. For instance, fast antioxidants, like tocopherols, require very fast oxidizable substrates, like linoleic acid (having rate constant of chain propagation kp of 62 M−1 s−1 at 30 °C) or styrene (kp = 41 M−1 s−1). Instead, less effective antioxidants may be studied with cumene (kp = 0.34 M−1 s−1) [8]. To study quantitatively the kinetics of antioxidants, it is essential to control the rate of free radical initiation. This is generally achieved by using azo initiators, like α,α-azo-bis-isobutyronitrile (AIBN), which can generate radicals at a reproducible and constant rate [6].

Inhibited autoxidation methods may be classified based on their detection principle. The extent of the autoxidation can be followed by monitoring the consumption of oxygen in the headspace [8], the oxidation of the substrate [9], or through the hydroperoxides formation [10]. However, regardless to the detection principle, the resulting transient signal is characterized, generally, by two characteristic periods. The first is when autoxidation is inhibited by antioxidants (this phase is called inhibited). The second is when antioxidants are consumed, and autoxidation can proceed uninhibited (this phase is called uninhibited). The rate of styrene oxidation during the inhibited period is used to characterize the antioxidant activity of pure molecules [11] and raw extracts [4, 12, 13]. Furthermore, the time at which the breakpoint or induction period occurs can be used to determine the stoichiometry factor of the reaction between antioxidants and radicals.

Although inhibited autoxidation methods have the advantage to test antioxidants in highly controlled experimental conditions, the complexity of the setup has often limited their widespread use. For this reason, during the last decades, antioxidant properties have been often studied with fast and simple in vitro assays, like the ferric reducing antioxidant power (FRAP), the total radical-trapping antioxidant potential (TRAP), the 2,2-diphenyl-1-picrylhydrazyl (DPPH) and the oxygen radical absorbing capacity (ORAC) assays [11,12,13,14]. With only a few exceptions [15], such rapid in vitro assays are generally designed to measure merely a change in color before and after an arbitrary reaction time. The payback for such oversimplified procedures is that they are rarely useful to express an antioxidant activity. Also, such assays investigate the performance of an antioxidants without the presence of an oxidizable substrate. This impedes to predict the performance of an antioxidants when applied to food or biological systems. Finally, such assays are designed to express the capacity of antioxidants (e.g., how many?), rather than their activity (e.g., how fast?). For these reasons, the use of such in vitro assays has been often debated [10].

In this work, a calorimetric adaptation of the classical “inhibited autoxidation methods” was proposed to determine the activity of individual antioxidants (4-hydroxybenzoic acid, synaptic acid, syringic acid, quercetin, gallic acid and α-tocopherol) or natural extracts (Papaver rhoeas, Olea europea, Melissa officinalis, Fraxinus excelsior). The results have been compared with those based on the bleaching of radical probes (DPPH) [16]. Overall, this work investigated the possibility to use isothermal calorimetry to test the activity of antioxidants (in micromolar concentration) to inhibit the autoxidation of an oxidizable substrate (in large excess), induced by a constant flux of free radicals, under well controlled and reproducible conditions of temperature. This effort was intended to promote the development of a standardized method for testing the antioxidant activity of plant extracts.

Materials and methods

Reagents

Styrene, azo-bis-isobutyronitrile (AIBN), antioxidants (α-tocopherol, gallic acid, syringic acid, 4-hydroxybenzoic acid, quercetin, synaptic acid), acetonitrile, Folin–Ciocalteu’s reagent, 2,2-diphenyl-1-picrylhydrazyl (DPPH) and sodium carbonate were purchased from Sigma-Aldrich (Milano, Italy).

Solutions

Known concentrations (0–50 µM) of α-tocopherol, gallic acid, hydroxybenzoic acid, quercetin, synapic acid and syringic acid were prepared in acetonitrile and mixed with styrene (3.96 M). AIBN (4, 10, 30 mM) was added as a radical initiator. Antioxidant solutions and AIBN stock solutions were prepared daily. Each mixture was thoroughly vortex for 10 s to obtain a homogeneous clear solution, which was then used for the analysis.

Kinetic model of the inhibited autoxidation of styrene

The autoxidation of styrene in aprotic solvents was described by a simplified kinetic model based on Scheme 1.

Where AIBN is the azo-initiator, RH is styrene, ROOH are polyperoxides, AH is the antioxidant and \(n\) is the stoichiometric factor. The latter expresses the number of radicals trapped by one molecule of antioxidant. Finally, \(k_{{\text{p}}}\), \(k_{{\text{t}}}\), and \(k_{{{\text{inh}}}}\) are, respectively, the rate constant of propagation, termination, and inhibition. ko is the rate constant of oxygen association with alkyl radicals, and it is generally very fast and not rate limiting [17]. Also, \(k_{{\text{d}}}\) is the rate constant of AIBN decomposition, which can be predicted by Eq. 6 [18]:

where \(R\) is expressed as 8.314 J mol−1 K−1.

Isothermal calorimetry measurements

Experiments were performed by a twin-type calorimeter (Thermal Activity Monitor, Model 421 TAM III, TA Instruments) consisting of a sample cell, which is placed over a reference. The sample cell holds a glass ampoule (\(4.0 \cdot 10^{ - 3} \;{\text{ L}}\)), which is filled with the sample (\(2.0 \cdot 10^{ - 4} {\text{ L}}\)) and sealed with a silicone septum. The reference cell consists of a sealed empty ampoule. The sample and reference cells are surrounded by a thermostat, which assure long-term stability better than ± 10–4 K/24 h. Each run requires a first equilibration step, in which the sample ampoule is lowered at mid height inside the microcalorimeter and held for at least 15 min. In such period, the temperature of the sample is equilibrated with that of the thermostat. When the glass ampoule is lowered into the measurement position, the recording of the heat-flow signal is collected every 10 s [19].

Phenolic extracts from herbs

Samples of Melissa officinalis, Fraxinus excelsior, Olea europea leaves and Papaver rhoeas flowers were kindly provided by Naturalsalus®. The freeze-dried herbs were grounded into fine powders using a laboratory hammer mill (Perten Instruments, Hagersten Sweden). A porous cellulose thimble containing 10 g of each dried sample was set into a Soxhlet apparatus. The extraction was carried out for 6 h using 150 mL of ethanol placed in a round bottom flask. At the end of the process, the solvent was removed using a rotary evaporator (Laborota 4000, Heidolph, Schwabach, Germany) and further dried overnight at 40 °C.

Total phenolic content

The total phenolic content of plant extracts was obtained by the Folin–Ciocalteu method proposed by Singleton and Rossi [20] with slight modifications. A blue color was developed by the reaction between the phenolic compounds and phosphomolybdic/phosphotungstic acid complexes. The absorbance was measured with a spectrophotometer (Cary 100 Series UV–Vis Spectrophotometer, Agilent Technologies, Italy) at 765 nm and compared with a calibration curve of gallic acid. Methanolic plant extracts were incubated for 2 h in the dark before measuring the absorbance. The results were expressed as mol of gallic acid equivalent (GAE) per mg of extract.

DPPH assay

The antioxidant activity of plant extracts was estimated the classical DPPH assay, as described by Brand-Williams [21] with small modifications [22]. DPPH solution was characterized by a violet color, which was reduced in the presence of an antioxidant. For this purpose, 10 mg of DPPH were dissolved in 250 mL of methanol and sonicated for 1 min. Trolox (6-hydroxy-2, 5, 7, 8-tetramethylchroman-2-carboxylic acid) was used as reference. Different concentrations of Trolox (0–800 µM) were prepared to build the calibration curve. To perform the measurements, 1.9 mL of DPPH solution were transferred into cuvettes and 100 µL of the Trolox solutions or the methanolic plant extracts were added. The samples were kept in dark for 30 min at room temperature and the absorbance was recorded at 515 nm with a spectrophotometer (Cary 100 Series UV–Vis Spectrophotometer, Agilent Technologies, Italy). The antioxidant capacity of the extracts was determined using the standard Trolox calibration curve and all results were expressed as mol of Trolox equivalent (TEA) per mg of extract.

Statistical analysis

The results are expressed as mean and standard deviation. The propagation of the uncertainty of symbolic expressions composed by variables with mean and standard deviation was calculated by first- or second-order Taylor expansion with the software R [23] and the package “propagate” [24].

Results and discussion

Styrene oxidation

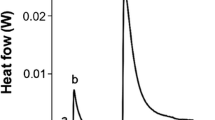

Figure 1A (line a) shows the isothermal calorimetry traces observed during the autoxidation of styrene initiated by 10 mM of AIBN at 303 K. The reason for using styrene as oxidizable substrate have been previously reported by Burton and Ingold [25]. Briefly, styrene has been widely used in previous quantitative kinetic studies of phenol-inhibited autoxidation [4,5,6,7,8]. Second, its propagation rate constant is relatively large (\(k_{{\text{p}}} = 41 \;{\text{M}}^{ - 1} {\text{s}}^{ - 1}\) at 303 K). This means, in practice, that styrene oxidation occurs fast enough to allow the testing of very efficient antioxidants. Also, as styrene contains no readily abstracted hydrogen atom, its oxidation forms polyperoxides rather than hydroperoxides [26]. This is a further advantage as it prevents the complication of backward reactions, which are typically observed when hydroperoxides give back a hydrogen atom to the antioxidant radicals (A*) generated in Eq. 5 [27].

Calorimetric trace A resulting from the oxidation of styrene (3.96 M) induced by AIBN at 303 K in the presence of increasing concentrations of α-tocopherol [from (a) 0 to (f) 50 µM]. Exo signal is positive. Also shown B the conversion fraction over time, and C, inset the induction time vs concentration of α-tocopherol

The autoxidation of styrene was induced by the addition of an artificial radical initiator, which was able to generate radicals at a reproducible and constant rate. At this purpose, 2,2′-azobis(isobutyronitrile) (AIBN) (\(1.0 \cdot 10^{ - 2} \;{\text{M}}\)) was chosen because of its well-established use in the radical reactions of styrene [8]. Also, AIBN decomposes with the formation of a pairs of carbon-centered radicals (e.g., alkyl radicals, \(R^{ * }\)), which react very rapidly with oxygen to form peroxyl radicals (\({\text{ROO}}^{ * }\)). During its decomposition, AIBN continuously supplies initiating radicals, even at moderate temperatures, following a first order rate law regardless of the solvent or initiator concentration [28].

Without antioxidants, the area of the calorimetric trace resulted in an overall exothermic heat \(Q_{{{\text{tot}}}}\) of (6.31 ± 0.22) J (n = 5). The \(Q_{{{\text{tot}}}}\) value reflected the sum of the heats associated with several simultaneous reactions, at least, initiation, propagation, and many kinds of terminations. The process was even more complicated by the fact that, toward the end of the autoxidation process, the oxygen present in the ampoule headspace became rate limiting. However, at point a1, the consumption of oxygen was completed. This was verified with independent autoxidation experiments performed with different substrates (e.g., AIBN dissolved in vegetable oils) with the extent of oxygen consumption monitored over time by an optical oxygen measurement system. The complete oxygen consumption was possible thanks to the use of the azo-initiator AIBN. This consistently generated free radicals (R*), which reacted very rapidly with all the remaining oxygen (see Eq. 2). This explains the sudden decrease of the heat-flow signal as well in the immediate vicinity prior to point a1. Based on such finding, the heat generated following point a1 was not associated with the autoxidation of styrene and, therefore, was neglected.

Thus, assuming that the main exothermic event observed in Fig. 1 was attributed to the heat released during the autoxidation of styrene, then, the cumulative integration of the heat flow signal (\({\int }_{0}^{t}\dot{q}\cdot dt\)) and the overall integral of the heat-flow rate \({Q}_{\text{tot}}\) can be used to calculate the conversion fraction of the process (Eq. 7):

The conversion fraction \(\alpha \left( t \right)\) is a value that changes from 0 to 1 during the conversion of reactants to products. Figure 1B (line a) shows its evolution over time during the uninhibited autoxidation of styrene. It should be noted that the autoxidation process did not start immediately. This was because the bulk styrene reagent contained a stabilizer (4-tert-butylcatechol, < 15 mg/kg). Until the stabilizer was present, the conversion fraction remained negligible. Accidentally, the presence of this stabilizer was desired because it allowed the preliminary operations of the experiment, such as the addition of the sample in the ampoule and its loading into the calorimetric cell, to be performed without the occurrence of autoxidation. Only when all the stabilizer was consumed, the autoxidation process could start [29]. Indeed, from that point on, the heat flow value, and the conversion fraction increased linearly and steady. The slope of the styrene conversion (line a) during the uninhibited period resulted in an apparent rate (\({\rm d}\alpha_{{{\text{uni}}}} /dt\)) of \(3.98 \pm 0.08\cdot10^{ - 6} \;{\text{s}}^{ - 1}\). Such rate was very important because it was used later as reference value to express the percentage of inhibition exerted by antioxidants.

Rate of free radical initiation

Subsequent experiments aimed to determine the rate of initiation (\(R_{i}\)). This rate was defined as the amount of free radicals (\(R^{*}\)) generated during the decomposition of AIBN [30]. Such rate was experimentally determined by the “induction period method” [5]. The method consists of measuring the induction period (\(\tau\)) (i.e., the onset time of the uninhibited oxidation of styrene) in the presence of different concentrations of an efficient antioxidant, like α-tocopherol. The resulting \(R_{{\text{i}}}\) was calculated by Eq. 8 [16]:

where \(n\) is the stoichiometric factor, which expresses the number of radicals trapped by one antioxidant molecule. For α-tocopherol \(n\) was assumed equal to \(2.0\).

Accordingly, Fig. 1A (from b to f) shows some typical calorimetric traces recorded during the inhibited autoxidation of styrene by α-tocopherol (10–50 µM). Figure 1B shows the corresponding styrene conversion fractions over time, based on Eq. 9. All the conversions broke when α-tocopherol was consumed. Such breakpoints were sharp because α-tocopherol is one of the most efficient antioxidants, and because the heat generated during the following uninhibited styrene oxidation was largely exothermic. Notably, the times at which such breakpoints occurred were proportional to the concentration of α-tocopherol. Thus, they were considered a reliable measure of the induction periods (τ), provided that their value was corrected by the induction time required to consume the stabilizer (which was initially present in the styrene bulk reagent, vide supra). After τ, the conversion of styrene increased suddenly and linearly, with a slope matching the one observed in the absence of antioxidants (line a) [25, 31]. Thus, after τ, the reaction proceeded uninhibited, regardless to the concentration of α-tocopherol (or stabilizers eventually present). By plotting the τ (corrected by the presence of stabilizers) as a function of α-tocopherol concentration (inset C), a linear relationship was obtained (R2 = 0.999), with slope equal to \(n/R_{{\text{i}}} = \left( {1.55 \pm 0.02} \right) \cdot 10^{9} \;{\text{s}}\;{\text{M}}^{ - 1}\). This led to a rate of initiation \(R_{{\text{i}}}\) of (1.29 ± 0.06)·10−9 M s−1.

It should be highlighted that, when α-tocopherol was higher than 10 µM, the resulting heat-flow signal was slightly endothermic for most of the inhibited period. This happened because, at higher concentrations of α-tocopherol, the rate of the inhibited period (\({R}_{\text{inh}}\)) approached the rate of radical initiation (\(R_{{\text{i}}}\)). When this happened, the radical chain length was close to 1. This means that styrene autoxidation was completely inhibited and that the observed process was no longer a radical chain. Also, since no sign of styrene oxidation could be measured in such periods, any small endothermic contribution to the overall heat, like the AIBN decomposition process or the interactions between \(R^{*}\) and \({\text{ROO}}^{*}\) radicals with α-tocopherol, may prevail. Accordingly, when the recorded heat flow was endothermic, the conversion fraction was considered equal to zero. Overall, because of the lack of a radical chain process, the results achievable from the induction period method were used uniquely to determine \(R_{{\text{i}}}\), as suggested also by many Authors [32, 33].

Given \(R_{{\text{i}}}\), the corresponding rate constant (\(k_{{\text{i}}}\)) of the radical initiation process could be estimated. The rate law follows a first order (\(R_{i} = k_{i} \cdot \left[ {{\text{AIBN}}} \right]\)) [25]. This was verified with different concentrations of AIBN. Consistently, when AIBN concentration triplicated (3.0.10−2 M), the resulting \(R_{{\text{i}}}\) increased of three times (3.8·10−9 M s−1), whereas, when AIBN was reduced of 2.5 times (4.0ꞏ10−3 M), the resulting \(R_{{\text{i}}}\) decreased proportionally to 5.1·10−10 M s−1. Thus, regardless of the initial AIBN concentration, the resulting rate constant \(k_{{\text{i}}}\) was (1.29 ± 0.06)·10−7 s−1.

Moreover, the value of \(k_{{\text{i}}}\) was related to the rate constant of AIBN decomposition (\(k_{\rm d}\)) by Eq. 9:

where \(\varepsilon\) is the cage factor, a number between 0 and 1 that expresses the capacity of the solvent to cage or hinder the reactivity of the pairs of free radicals generated during the thermal decomposition of AIBN. In other words, such cage represents an overall effectiveness of the initiator to generate free radicals. Given \({R}_{\rm i}\), and with \({k}_{\rm d}\) predicted by Eq. 6, (\(1.05 \cdot 10^{ - 7} \;{\text{M}}^{ - 1} {\text{s}}^{ - 1}\), 20% error), [18], the cage value resulted equal to 0.62 ± 0.12. This value was consistent with those previously reported [32,33,34].

Antioxidant activity of synthetic antioxidants

Figure 2 shows the conversion fractions of styrene autoxidation inhibited by equimolar concentrations of different antioxidants (\(2.5 \cdot 10^{ - 5} \;{\text{M}}\)). The antioxidants were ranked based on the conversion rates observed during the inhibited period of styrene autoxidation. Accordingly, salicylic and hydroxybenzoic acid (traces 2 and trace 3 of Fig. 2) were defined as inefficient antioxidants since no distinctive inhibition period was observed. Their effect was only to slightly decrease the rate of styrene autoxidation (trace 1), from 5 to 8% relative to the rate of the uninhibited process. Instead, trace 4 reflected the strong radical scavenging activity of syringic acid, whose activity was able to decrease the rate of styrene oxidation of 74%. Syringic acid showed an induction period of \(4.5 \cdot 10^{4} \;{\text{s}}\). This corresponded to a stoichiometry factor of 2.2. This value reflected the presence of one free hydroxyl group (at position 5), which was supported by two adjacent methoxyl groups at positions 4 and 6 of the aromatic ring. Then, trace 5–7 refer to BHT, gallic acid and quercetin, respectively. All these antioxidants greatly reduced the rate of styrene oxidation of about 80–95%. In particular, gallic acid and quercetin showed similar capacity to inhibit styrene autoxidation (92–95% reduction). However, they differed for their induction periods, respectively, of \(4.6 \cdot 10^{4} \;{\text{s}}\) and \(5.5 \cdot 10^{4} \;{\text{s}}\). This resulted in stoichiometric factors of about 2.3 and 3.0. Finally, trace (8) refers to α-tocopherol, which was by far the most efficient antioxidant, able to inhibit almost completely the styrene autoxidation.

A Calorimetric traces (exo signal is positive) and B conversion fraction resulting from the oxidation of (1) styrene (3.96 M), induced by AIBN initiator (10 mM), and inhibited by 25 µM of (2) 4-hydroxybenzoic acid; (3) synaptic acid; (4) syringic acid; (5) BHT; (6) gallic acid; (7) quercetin; (8) α-tocopherol

Antioxidant activity of botanical plants extracts

The determination of the antioxidant activity is of great importance for revealing the value of plant species as a source of new antioxidant compounds. Since plant extracts contain several antioxidant compounds, an apparent antioxidant activity could be estimated only if the total antioxidant content was known. Accordingly, the total phenolic content of (1) Papaver rhoeas leaves, (2) Olea europea leaves, (3) Melissa officinalis leaves and (4) Fraxinus excelsior leaves was determined by the Folin–Ciocalteu assay and reported in Table 1. Then, a fixed volume of each plant extract was mixed with styrene and AIBN. Figure 3 shows the resulting calorimetric traces, together with the corresponding conversion fractions. As for the individual antioxidants, each plant extract showed a distinctive ability to inhibit styrene autoxidation. In details, extracts from Papaver rhoeas leaves (trace 1) did not show a distinctive induction period, but only a modest decrement of the styrene autoxidation rate. Instead, the extracts from Olea europea leaves (trace 2), Melissa officinalis leaves (trace 3) and Fraxinus excelsior leaves (trace 4) resulted in clear inhibited periods, decreasing the conversion rate of styrene oxidation, respectively, of 91, 95 and 98%. Finally, based on the induction period (τ) and the total phenol content ([AH]0), the extracts of Olea europea leaves and Melissa officinalis leaves were characterized by an equivalent stoichiometry factor of 2.0, whereas it was close to 1.0 for Fraxinus excelsior leaves. The results of conversion rate are only weakly correlated with the results of the antioxidant activity measured by the classical DPPH assay. This is likely because the classical DPPH assays fails to estimate the kinetic behavior of antioxidants, while it provides an apparent antioxidant capacity.

A Calorimetric traces (exo signal is positive) resulting from the oxidation of styrene (3.96 M) initiated by AIBN (10 mM) in the presence of: (1) Papaver rhoeas flowers (diluted 1:10 in acetonitrile), (2) Olea europea leaves (diluted 1:10 in acetonitrile), (3) Melissa officinalis leaves (diluted 1:10 in acetonitrile) and (4) Fraxinus excelsior leaves (pure extract)

Conclusions

This study has shown how isothermal calorimetry can be used to characterize the activity of individual antioxidants and complex plant extracts to inhibit the autoxidation of styrene, in the presence of the radical initiator AIBN. The proposed approach allowed to derive the rate of radical initiation (\({R}_{i}\)), and the conversion rates of the inhibited and uninhibited period of styrene oxidation. Furthermore, based on the induction period, the stoichiometry factor was also assessed. Overall, the proposed approach is very simple and requires little experimental effort. Also, the results are superior to those achievable with the bleaching of radical probes (i.e., the classical DPPH assay), whose results fail to determine the antioxidant activity, but can provide only an apparent antioxidant capacity.

References

Valgimigli L, Pratt DA. Antioxidants in chemistry and biology. In: Chatgilialoglu C, Studer A, editors. Encyclopedia of radicals in chemistry biology and materials. Chichester: Wiley; 2012. https://doi.org/10.1002/9781119953678.rad055.

Shahidi F. Antioxidants in food and food antioxidants. Food Nahrung. 2000;44:158–63.

Cardoso-Ugarte GA, Sosa-Morales ME. Essential oils from herbs and spices as natural antioxidants: diversity of promising food applications in the past decade. Food Rev Int. 2021. https://doi.org/10.1080/87559129.2021.1872084.

Amorati R, Foti MC, Valgimigli L. Antioxidant activity of essential oils. J Agric Food Chem. 2013;61:10835–47. https://doi.org/10.1021/jf403496k.

Amorati R, Valgimigli L. Advantages and limitations of common testing methods for antioxidants. Free Radical Res. 2015;49:633–49.

Amorati R, Valgimigli L. Methods to measure the antioxidant activity of phytochemicals and plant extracts. J Agric Food Chem. 2018;66:3324–9.

Baschieri A, Amorati R. Methods to determine chain-breaking antioxidant activity of nanomaterials beyond DPPH. A review. Antioxidants. 2021;10:1551.

Amorati R, Baschieri A, Valgimigli L. Measuring antioxidant activity in bioorganic samples by the differential oxygen uptake apparatus: recent advances. J Chem. 2017. https://doi.org/10.1155/2017/6369358.

Haidasz EA, van Kessel ATM, Pratt DA. A continuous visible light spectrophotometric approach to accurately determine the reactivity of radical-trapping antioxidants. J Org Chem. 2016;81:737–44.

Foti MC. Use and abuse of the DPPH radical. J Agric Food Chem. 2015;63:8765–76.

Ou B, Huang D, Hampsch-Woodill M, Flanagan JA, Deemer EK. Analysis of antioxidant activities of common vegetables employing oxygen radical absorbance capacity (ORAC) and ferric reducing antioxidant power (FRAP) assays: a comparative study. J Agric Food Chem. 2002;50:3122–8. https://doi.org/10.1021/jf0116606.

Zulueta A, Esteve MJ, Frígola A. ORAC and TEAC assays comparison to measure the antioxidant capacity of food products. Food Chem. 2009;114:310–6. https://doi.org/10.1016/j.foodchem.2008.09.033.

Di Majo D, Giammanco M, La Guardia M, Tripoli E, Giammanco S, Finotti E. Flavanones in citrus fruit: structure–antioxidant activity relationships. Food Res Int. 2005;38:1161–6. https://doi.org/10.1016/j.foodres.2005.05.001.

Cheung LM, Cheung PC, Ooi VE. Antioxidant activity and total phenolics of edible mushroom extracts. Food Chem. 2003;81:249–55. https://doi.org/10.1016/S0308-8146(02)00419-3.

Angeli L, Imperiale S, Ding Y, Scampicchio M, Morozova K. A novel stoichio-kinetic model for the DPPH assay: the importance of the side reaction and application to complex mixtures. Antioxidants (Basel). 2021. https://doi.org/10.3390/antiox10071019.

Howard JA, Ingold KU. Absolute rate constants for hydrocarbon autoxidation: I. Styrene. Can J Chem. 1965;43:2729–36. https://doi.org/10.1139/v65-383.

Maillard B, Ingold KU, Scaiano JC. Rate constants for the reactions of free radicals with oxygen in solution. J Am Chem Soc. 1983;105:5095–9.

Denisov ET, Afanas’ev IB. Oxidation and antioxidants in organic chemistry and biology. 14200308. 2005.

Bera O, Radic̆ević R, Stoiljković D, Jovic̆ić M, Pavlic̆ević J. A new approach for the kinetic modeling of free radical bulk polymerization of styrene. Polym J. 2011;43:826–31.

Singleton VL, Rossi JA. Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am J Enol Vitic. 1965;16:144–58.

Brand-Williams W, Cuvelier ME, Berset C. Use of a free radical method to evaluate antioxidant activity. LWT Food Sci Technol. 1995;28:25–30. https://doi.org/10.1016/S0023-6438(95)80008-5.

Koleva II, van Beek TA, Linssen JPH, de Groot A, Evstatieva LN. Screening of plant extracts for antioxidant activity: a comparative study on three testing methods. Phytochem Anal. 2002;13:8–17. https://doi.org/10.1002/pca.611.

Team RC. R: A language and environment for statistical computing. 2013.

Spiess A-N. propagate: Propagation of Uncertainty. R package version 1.0-6 2018.

Burton G, Ingold KU. Autoxidation of biological molecules. 1. Antioxidant activity of vitamin E and related chain-breaking phenolic antioxidants in vitro. J Am Chem Soc. 1981;103:6472–7.

Miller AA, Mayo FR. Oxidation of unsaturated compounds. I. The oxidation of styrene1. J Am Chem Soc. 1956;78:1017–23.

Mahoney LR, Ferris FC. Evidence for chain transfer in the autoxidation of hydrocarbons retarded by phenol. J Am Chem Soc. 1963;85:2345–6.

Lucarini M, Pedulli GF. Free radical intermediates in the inhibition of the autoxidation reaction. Chem Soc Rev. 2010;39:2106–19.

Chatgilialoglu C, Studer A, editors. Encyclopedia of radicals in chemistry, biology and materials. Chichester, UK: Wiley; 2012.

Ingold KU. Inhibition of the autoxidation of organic substances in the liquid phase. Chem Rev. 1961;61:563–89.

Burton GW, Hughes L, Ingold KU. Antioxidant activity of phenols related to vitamin E. Are there chain-breaking antioxidants better than.alpha.-tocopherol? J Am Chem Soc. 1983;105:5950–1. https://doi.org/10.1021/ja00356a057.

Bevington JC, Bradbury JH, Burnett GM. A new method for the determination of the rate of initiation in radical polymerizations. J Polym Sci. 1954;12:469–80.

Henrici-Olivé VG, Olive S. Lösungsmitteleffekte bei der radikalpolymerisation I Beeinflussung der startgeschwindigkeit bei der polymerisation von styrol mit AIBN als initiator. Die Makromolekulare Chemie Macromol Chem Phys. 1962;58:188–94.

Howard JA, Ingold KU. The inhibited autoxidation of styren: Part IV. Solvent effects. Can J Chem. 1964;42:1044–56.

Funding

Open access funding provided by Libera Università di Bolzano within the CRUI-CARE Agreement. No funding was received for conducting this study.

Author information

Authors and Affiliations

Contributions

MS contributed to conceptualization, methodology, visualization, writing—original draft, and writing—review and editing. OMK contributed to investigation, methodology, formal analysis, and writing—original draft. GF contributed to data curation, formal analysis, validation, and writing—original draft.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no financial or proprietary interests in any material discussed in this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mosibo, O.K., Scampicchio, M. & Ferrentino, G. Calorimetric adaptation of the inhibited autoxidation method to determine the activity of individual antioxidants and natural extracts. J Therm Anal Calorim 147, 12829–12836 (2022). https://doi.org/10.1007/s10973-022-11399-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11399-0