Abstract

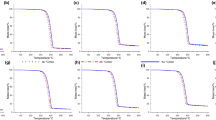

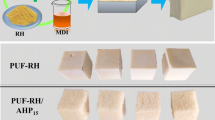

This work presents biochemical, physical and thermal properties of K85 and K98 rice husks species from Uganda before and after modification with sodium hydroxide (NaOH) and magnesium hydroxide (Mg(OH)2). Modified and unmodified rice husks were analysed by SEM, TGA, Bomb calorimetry, XRF, Ultimate analysis, Bulk density, FTIR and Van Soest approach. SEM analysis disclosed that alkali pre-treatment of rice husks improves micro-structure. Generally, the husks had higher cellulose compositions than hemicellulose and lignin. High cellulose contents in reinforcement material decrease composites’ oxygen permeability and improve their mechanical properties. Physical properties confirmed that rice husks were characterized by more volatiles than ash, followed by fixed carbon and low moisture. XRF results indicate that the silica was the most dominant mineral in the unmodified K98 and K85 rice husk ashes. Peak temperatures of modified husks generally increased with increasing alkali concentrations, signalling increased thermal stability of PLA composites developed with these husks. The results suggest that modified rice husks are more preferred as reinforcement in flame retardant fiber-reinforced PLA composites to unmodified rice husks. FTIR revealed that the main functional groups were –COOH, signalling enhanced flame retardancy abilities in the rice husks.

Similar content being viewed by others

References

Ridzuan MJM, Majid MA, Afendi M, Kanafiah SA, Zahri JM, Gibson AG. Characterisation of natural cellulosic fibre from Pennisetum purpureum stem as potential reinforcement of polymer composites. Mater Des. 2016;89:839–47. https://doi.org/10.1016/j.matdes.2015.10.052.

Chougan M, Ghaffar SH, Al-Kheetan MJ, Gecevicius M. Wheat straw pre-treatments using eco-friendly strategies for enhancing the tensile properties of bio-based polylactic acid composites. Ind Crops Prod. 2020;155: 112836. https://doi.org/10.1016/j.indcrop.2020.112836.

Singh T, Gangil B, Patnaik A, Biswas D, Fekete G. Agriculture waste reinforced corn starch-based biocomposites: effect of rice husk/walnut shell on physicomechanical, biodegradable and thermal properties. Mater Res Express. 2019;6(4): 045702. https://doi.org/10.1088/2053-1591/aafe45.

Yu T, Jiang N, Li Y. Study on short ramie fiber/poly (lactic acid) composites compatibilized by maleic anhydride. Compos A Appl Sci Manuf. 2014;64:139–46. https://doi.org/10.1016/j.compositesa.2014.05.008.

Yiga VA, Pagel S, Lubwama M, Epple S, Olupot PW, Bonten C. Development of fiber-reinforced polypropylene with NaOH pretreated rice and coffee husks as fillers: mechanical and thermal properties. J Thermoplast Compos Mater. 2020;33(9):1269–91. https://doi.org/10.1177/2F0892705718823255.

Guna V, Ilangovan M, Hu C, Venkatesh K, Reddy N. Valorization of sugarcane bagasse by developing completely biodegradable composites for industrial applications. Ind Crops Prod. 2019;131:25–31. https://doi.org/10.1016/j.indcrop.2019.01.011.

Hegyesi N, Zhang Y, Kohári A, Polyák P, Sui X, Pukánszky B. Enzymatic degradation of PLA/cellulose nanocrystal composites. Ind Crops Prod. 2019;141: 111799. https://doi.org/10.1016/j.indcrop.2019.111799.

Singh T, Gangil B, Patnaik A, Kumar S, Rishiraj A, Fekete G. Physico-mechanical, thermal and dynamic mechanical behaviour of natural-synthetic fiber reinforced vinylester based homogenous and functionally graded composites. Mater Res Express. 2018;6(2): 025704. https://doi.org/10.1088/2053-1591/aaee30.

Sullins T, Pillay S, Komus A, Ning H. Hemp fiber reinforced polypropylene composites: the effects of material treatments. Compos B Eng. 2017;114:15–22. https://doi.org/10.1016/j.compositesb.2017.02.001.

Lubwama M, Yiga VA. Characteristics of briquettes developed from rice and coffee husks for domestic cooking applications in Uganda. Renew Energy. 2018;118:43–55. https://doi.org/10.1016/j.renene.2017.11.003.

Pedroso GB, Silva LO, Araujo RB, Saldanha LF, Denardi L, Martins AF. An innovative approach for the biotechnological production of succinoglycan from rice husks. Ind Crops Prod. 2019;137:615–27. https://doi.org/10.1016/j.indcrop.2019.05.052.

Anggono J, Budiarto BILY, Sugondo S, Purwaningsih H. The strength of polylactic acid composites reinforced with sugarcane bagasse and rice husk. In: Whitley BM, editor. Materials Science Forum, vol. 1000. Zurich: Trans Tech Publications Ltd; 2020. p. 193–9. https://doi.org/10.4028/www.scientific.net/MSF.1000.193.

Qi Y, Zhu S, Zhang J. The incorporation of modified Sb2O3 and DBDPE: a new member of high solar-reflective particles and their simultaneous application in next-generation multifunctional cool material with improved flame retardancy and lower wetting behaviour. Energy Build. 2018;172:47–56. https://doi.org/10.1016/j.enbuild.2018.04.050.

Běhálek L, Borůvka M, Brdlík P, Habr J, Lenfeld P, Kroisová D, Novák J, et al. Thermal properties and non-isothermal crystallization kinetics of biocomposites based on poly (lactic acid), rice husks and cellulose fibres. J Therm Anal Calorim. 2020;142(2):629–49. https://doi.org/10.1007/s10973-020-09894-3.

Santmartí A, Lee KY. Crystallinity and thermal stability of nanocellulose. Nanocellulose Sustain. 2018. https://doi.org/10.1201/9781351262927-5.

Hamdan MHM, Siregar JP, Rejab MRM, Bachtiar D, Jamiluddin J, Tezara C. Effect of maleated anhydride on mechanical properties of rice husk filler reinforced PLA matrix polymer composite. Int J Precis Eng Manuf-Green Technol. 2019;6(1):113–24. https://doi.org/10.1007/s40684-019-00017-4.

Tsou CH, Yao WH, Wu CS, Tsou CY, Hung WS, Chen JC, Sunn MC, et al. Preparation and characterization of renewable composites from polylactide and Rice husk for 3D printing applications. J Polym Res. 2019;26(9):227. https://doi.org/10.1007/s10965-019-1882-6.

Adeosun SO, Aworinde AK, Diwe IV, Olaleye SA. Mechanical and microstructural characteristics of rice husk reinforced polylactide nano composite. West Indian J Eng 2016;39(1):63–71. http://sta.uwi.edu/eng/wije/

Low JH, Ghanbari T, Wan Abdul Rahman WA, Majid RA. Preparation and characterization of kenaf papers reinforced with tapioca starch: physicomechanical and morphological properties. J Natural Fibers. 2018;15(2):191–203. https://doi.org/10.1080/15440478.2017.1321518.

Tabasi RY, Najarzadeh Z, Ajji A. Development of high performance sealable films based on biodegradable/compostable blends. Ind Crops Prod. 2015;72:206–13. https://doi.org/10.1016/j.indcrop.2014.11.021.

Cai M, Takagi H, Nakagaito AN, Li Y, Waterhouse GI. Effect of alkali treatment on interfacial bonding in abaca fiber-reinforced composites. Compos A Appl Sci Manuf. 2016;90:589–97. https://doi.org/10.1016/j.compositesa.2016.08.025.

Ahad NA, Parimin N, Mahmed N, Ibrahim SS, Nizzam K, Ho YM. Effect of chemical treatment on the surface of natural fiber. J Nuclear Relat Technol. 2009;6(1):155–8.

Siakeng R, Jawaid M, Asim M, Saba N, Sanjay MR, Siengchin S, Fouad H. Alkali treated coir/pineapple leaf fibres reinforced PLA hybrid composites: Evaluation of mechanical, morphological, thermal and physical properties. EXPRESS Polym Lett. 2020;14:8. https://doi.org/10.3144/expresspolymlett.2020.59.

Debeli DK, Qin Z, Guo J. Study on the pre-treatment, physical and chemical properties of ramie fibers reinforced poly (Lactic Acid)(PLA) biocomposite. J Natural Fibers. 2018;15(4):596–610. https://doi.org/10.1080/15440478.2017.1349711.

Lin J, Yang Z, Hu X, Hong G, Zhang S, Song W. The effect of alkali treatment on properties of dopamine modification of bamboo fiber/polylactic acid composites. Polymers. 2018;10(4):403. https://doi.org/10.3390/polym10040403.

Orue A, Jauregi A, Unsuain U, Labidi J, Eceiza A, Arbelaiz A. The effect of alkaline and silane treatments on mechanical properties and breakage of sisal fibers and poly (lactic acid)/sisal fiber composites. Compos A Appl Sci Manuf. 2016;84:186–95. https://doi.org/10.1016/j.compositesa.2016.01.021.

Xia X, Liu W, Zhou L, Hua Z, Liu H, He S. Modification of flax fiber surface and its compatibilization in polylactic acid/flax composites. Iran Polym J. 2016;25(1):25–35. https://doi.org/10.1007/s13726-015-0395-3.

Karsli NG, Aytac A. Properties of alkali treated short flax fiber reinforced poly (lactic acid)/polycarbonate composites. Fibers Polym. 2014;15(12):2607–12. https://doi.org/10.1007/s12221-014-2607-4.

Oza S, Ning H, Ferguson I, Lu N. Effect of surface treatment on thermal stability of the hemp-PLA composites: correlation of activation energy with thermal degradation. Compos B Eng. 2014;67:227–32. https://doi.org/10.1016/j.compositesb.2014.06.033.

Shukor F, Hassan A, Islam MS, Mokhtar M, Hasan M. Effect of ammonium polyphosphate on flame retardancy, thermal stability and mechanical properties of alkali treated kenaf fiber filled PLA biocomposites. Mater Des. 2014;1980–2015(54):425–9. https://doi.org/10.1016/j.matdes.2013.07.095.

Islam MS, Ahmed-Haras MR, Kao N, Gupta R, Bhattacharya S, Islam MN. Physico-mechanical properties of bio-composites fabricated from polylactic acid and rice husk treated with alkali and ionic liquid. Res Commun Eng Sci Technol. 2019;2:28–41. https://doi.org/10.22597/rcest.v2.63.

Tran TPT, Bénézet JC, Bergeret A. Rice and Einkorn wheat husks reinforced poly (lactic acid)(PLA) biocomposites: effects of alkaline and silane surface treatments of husks. Ind Crops Prod. 2014;58:111–24. https://doi.org/10.1016/j.indcrop.2014.04.012.

Farah Dina A, Zaleha S, Noor Najmi B, Nor Azowa I. The influence of alkaline treatment on mechanical properties and morphology of rice husk fibre reinforced polylactic acid. In: Advanced Materials Research, vol. 911. Zurich: Trans Tech Publications Ltd.; 2014. p. 13–7. https://doi.org/10.4028/www.scientific.net/AMR.911.13.

Johar N, Ahmad I, Dufresne A. Extraction, preparation and characterization of cellulose fibres and nanocrystals from rice husk. Ind Crops Prod. 2012;37(1):93–9. https://doi.org/10.1016/j.indcrop.2011.12.016.

Menya E, Olupot PW, Storz H, Lubwama M, Kiros Y. Characterization and alkaline pretreatment of rice husk varieties in Uganda for potential utilization as precursors in the production of activated carbon and other value-added products. Waste Manag. 2018;81:104–16. https://doi.org/10.1016/j.wasman.2018.09.050.

Yiga VA, Lubwama M, Olupot PW. Effect of alkaline surface modification and carbonization on biochemical properties of rice and coffee husks for use in briquettes and fiber-reinforced plastics. J Natural Fibers. 2021;18(4):620–9. https://doi.org/10.1080/15440478.2019.1642824.

Yiga VA, Lubwama M, Olupot PW. Investigation on char residues and mean reactivity of compression molded rice and coffee husks bio-char reinforced polypropylene. In ASTFE Digital Library. Begel House Inc., 2020b.

Malucelli LC, Silvestre GF, Carneiro J, Vasconcelos EC, Guiotoku M, Maia CMBF, Carvalho Filho MAS. Biochar higher heating value estimative using thermogravimetric analysis. J Therm Anal Calorim. 2020;139(3):2215–20. https://doi.org/10.1007/s10973-019-09061-3.

Van Soest PV, Robertson JB, Lewis BA. Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J Dairy Sci. 1991;74(10):3583–97. https://doi.org/10.3168/jds.S0022-0302(91)78551-2.

Olupot PW, Candia A, Menya E, Walozi R. Characterization of rice husk varieties in Uganda for biofuels and their techno-economic feasibility in gasification. Chem Eng Res Des. 2016;107:63–72. https://doi.org/10.1016/j.cherd.2015.11.010.

Lubwama M, Yiga VA. Development of groundnut shells and bagasse briquettes as sustainable fuel sources for domestic cooking applications in Uganda. Renew Energy. 2017;111:532–42. https://doi.org/10.1016/j.renene.2017.04.041.

Yilmaz-Turan S, Jiménez-Quero A, Menzel C, de Carvalho DM, Lindström ME, Sevastyanova O, Vilaplana F, et al. Bio-based films from wheat bran feruloylated arabinoxylan: effect of extraction technique, acetylation and feruloylation. Carbohyd Polym. 2020;250: 116916. https://doi.org/10.1016/j.carbpol.2020.116916.

Yeh SK, Hsieh CC, Chang HC, Yen CC, Chang YC. Synergistic effect of coupling agents and fiber treatments on mechanical properties and moisture absorption of polypropylene–rice husk composites and their foam. Compos A Appl Sci Manuf. 2015;68:313–22. https://doi.org/10.1016/j.compositesa.2014.10.019.

Monte LS, Escócio VA, de Sousa AMF, Furtado CRG, Leite MCAM, Visconte LLY, Pacheco EBAV. Study of time reaction on alkaline pretreatment applied to rice husk on biomass component extraction. Biomass Convers Biorefinery. 2018;8(1):189–97. https://doi.org/10.1007/s13399-017-0271-9.

Wang Z, Yao Z, Zhou J, Zhang Y. Reuse of waste cotton cloth for the extraction of cellulose nanocrystals. Carbohyd Polym. 2017;157:945–52. https://doi.org/10.1016/j.carbpol.2016.10.044.

Rashid S, Dutta H. Characterization of nanocellulose extracted from short, medium and long grain rice husks. Ind Crops Prod. 2020;154: 112627. https://doi.org/10.1016/j.indcrop.2020.112627.

Ramesh P, Prasad BD, Narayana KL. Effect of MMT Clay on mechanical, thermal and barrier properties of treated aloevera fiber/PLA-hybrid biocomposites. SILICON. 2019. https://doi.org/10.1007/s12633-019-00275-6.

Tun SZ, Win N, Beisl S, Friedl A. Physicomechanical properties of rice husk pellets for domestic combustion in Myanmar. J Mech Eng Autom. 2020;10:66–72. https://doi.org/10.17265/2159-5275/2020.02.005.

Meng QK, Hetzer M, De Kee D. PLA/clay/wood nanocomposites: nanoclay effects on mechanical and thermal properties. J Compos Mater. 2011;45(10):1145–58. https://doi.org/10.1177/0021998310381541.

Chen RS, Ahmad S. Mechanical performance and flame retardancy of rice husk/organoclay-reinforced blend of recycled plastics. Mater Chem Phys. 2017;198:57–65. https://doi.org/10.1016/j.matchemphys.2017.05.054.

Tripathi M, Sahu JN, Ganesan P. Effect of process parameters on production of biochar from biomass waste through pyrolysis: a review. Renew Sustain Energy Rev. 2016;55:467–81. https://doi.org/10.1016/j.rser.2015.10.122.

Wang B, Sheng H, Shi Y, Hu W, Hong N, Zeng W, Hu Y, et al. Recent advances for microencapsulation of flame retardant. Polym Degrad Stab. 2015;113:96–109. https://doi.org/10.1016/j.polymdegradstab.2015.01.008.

Williams CL, Westover TL, Emerson RM, Tumuluru JS, Li C. Sources of biomass feedstock variability and the potential impact on biofuels production. BioEnergy Res. 2016;9(1):1–14. https://doi.org/10.1007/s12155-015-9694-y.

Huerta-Cardoso O, Durazo-Cardenas I, Longhurst P, Simms NJ, Encinas-Oropesa A. Fabrication of agave tequilana bagasse/PLA composite and preliminary mechanical properties assessment. Ind Crops Prod. 2020;152: 112523. https://doi.org/10.1016/j.indcrop.2020.112523.

Wu CS, Tsou CH. Fabrication, characterization, and application of biocomposites from poly (lactic acid) with renewable rice husk as reinforcement. J Polym Res. 2019;26(2):44. https://doi.org/10.1007/s10965-019-1710-z.

Grotto CGL, Colares CJG, Lima DR, Pereira DH, do Vale AT. Energy potential of biomass from two types of genetically improved rice husks in Brazil: a theoretical-experimental study. Biomass Bioenerg. 2020;142: 105816. https://doi.org/10.1016/j.biombioe.2020.105816.

Schirp A, Barrio A. Fire retardancy of polypropylene composites reinforced with rice husks: from oxygen index measurements and cone calorimetry to large-scale single-burning-item tests. J Appl Polym Sci. 2018;135(37):46654. https://doi.org/10.1002/app.46654.

Yiga VA, Lubwama M, Pagel S, Benz J, Olupot PW, Bonten C. Flame retardancy and thermal stability of agricultural residue fiber-reinforced polylactic acid: a review. Polym Compos. 2021;24:15–44. https://doi.org/10.1002/pc.25835.

Nizamuddin S, Siddiqui MTH, Baloch HA, Mubarak NM, Griffin G, Madapusi S, Tanksale A. Upgradation of chemical, fuel, thermal, and structural properties of rice husk through microwave-assisted hydrothermal carbonization. Environ Sci Pollut Res. 2018;25(18):17529–39. https://doi.org/10.1007/s11356-018-1876-7.

Morais MR, Seye O, Freitas KTD. Obtenção de briquetes de carvão vegetal de cascas de arroz utilizando baixa pressão de compactação. Proceedings of the 6. Encontro de Energia no Meio Rural, 2006.

Yiga VA, Lubwama M. Thermogravimetric analysis of agricultural residue carbonized briquettes for domestic and industrial applications. MRS Adv. 2020;5(20):1039–48. https://doi.org/10.1557/adv.2019.485.

Yussuf AA, Massoumi I, Hassan A. Comparison of polylactic acid/kenaf and polylactic acid/rise husk composites: the influence of the natural fibers on the mechanical, thermal and biodegradability properties. J Polym Environ. 2010;18(3):422–9. https://doi.org/10.1007/s10924-010-0185-0.

Zhang H, Wang H, Wang H. Flame retardant mechanism and surface modification of magnesium hydroxide flame retardant. IOP Conf Ser. 2018. https://doi.org/10.1088/1755-1315/170/3/032028.

Das O, Hedenqvist MS, Prakash C, Lin RJ. Nanoindentation and flammability characterisation of five rice husk biomasses for biocomposites applications. Compos A Appl Sci Manuf. 2019;125: 105566. https://doi.org/10.1016/j.compositesa.2019.105566.

Ferreira IT, Schirmer WN, de Oliveira Machado G, Gueri MVD. Estimativa do potencial energético de resíduos celulósicos de fabricação de papel através de análise imediata. Rev Brasil Energias Renov. 2014;3:4. https://doi.org/10.5380/rber.v3i4.38618.

Menya E, Olupot PW, Storz H, Lubwama M, Kiros Y. Production and performance of activated carbon from rice husks for removal of natural organic matter from water: a review. Chem Eng Res Des. 2018;129:271–96. https://doi.org/10.1016/j.cherd.2017.11.008.

Le Guen MJ, Hill S, Smith D, Theobald B, Gaugler E, Barakat A, Mayer-Laigle C. Influence of rice husk and wood biomass on the manufacture of filaments for fused deposition modelling. Front Chem. 2019;7:735. https://doi.org/10.3389/fchem.2019.00735.

Umasabor RI, Okovido JO. Fire resistance evaluation of rice husk ash concrete. Heliyon. 2018;4(12): e01035. https://doi.org/10.1016/j.heliyon.2018.e01035.

Lim ACR, Chin BLF, Jawad ZA, Hii KL. Kinetic analysis of rice husk pyrolysis using Kissinger-Akahira-Sunose (KAS) method. Procedia Eng. 2016;148:1247–51. https://doi.org/10.1016/j.proeng.2016.06.486.

Pereira CMC, Martins MSS. Flame retardancy of fiber-reinforced polymer composites based on nanoclays and carbon nanotubes. In: Pereira CMC, editor. Polymer Green Flame Retardants. New York: Elsevier; 2014. p. 551–95. https://doi.org/10.1016/B978-0-444-53808-6.00017-2.

Menya E, Olupot PW, Storz H, Lubwama M, Kiros Y, John MJ. Effect of alkaline pretreatment on the thermal behavior and chemical properties of rice husk varieties in relation to activated carbon production. J Therm Anal Calorim. 2020;139(3):1681–91. https://doi.org/10.1007/s10973-019-08553-6.

Wang Y, Zhao J. Comparative study on flame retardancy of silica fume-based geopolymer activated by different activators. J Alloy Compd. 2018;743:108–14. https://doi.org/10.1016/j.jallcom.2018.01.302.

Ilyas RA, Sapuan SM, Ishak MR, Zainudin ES. Development and characterization of sugar palm nanocrystalline cellulose reinforced sugar palm starch bionanocomposites. Carbohyd Polym. 2018;202:186–202. https://doi.org/10.1016/j.carbpol.2018.09.002.

Chen WH, Lu KM, Tsai CM. An experimental analysis on property and structure variations of agricultural wastes undergoing torrefaction. Appl Energy. 2012;100:318–25. https://doi.org/10.1016/j.apenergy.2012.05.056.

Ghaffar SH, Fan M. Differential behaviour of nodes and internodes of wheat straw with various pre-treatments. Biomass Bioenerg. 2015;83:373–82. https://doi.org/10.1016/j.biombioe.2015.10.020.

Cho D, Kim JM, Song IS, Hong I. Effect of alkali pre-treatment of jute on the formation of jute-based carbon fibers. Mater Lett. 2011;65(10):1492–4. https://doi.org/10.1016/j.matlet.2011.02.050.

Lubwama M, Yiga VA, Muhairwe F, Kihedu J. Physical and combustion properties of agricultural residue bio-char bio-composite briquettes as sustainable domestic energy sources. Renew Energy. 2020;148:1002–16. https://doi.org/10.1016/j.renene.2019.10.085.

Jiang D, Pan M, Cai X, Zhao Y. Flame retardancy of rice straw-polyethylene composites affected by in situ polymerization of ammonium polyphosphate/silica. Compos A Appl Sci Manuf. 2018;109:1–9. https://doi.org/10.1016/j.compositesa.2018.02.023.

Das O, Sarmah AK, Bhattacharyya D. Biocomposites from waste derived biochars: mechanical, thermal, chemical, and morphological properties. Waste Manag. 2016;49:560–70. https://doi.org/10.1016/j.wasman.2015.12.007.

Balakrishnan H, Hassan A, Isitman NA, Kaynak C. On the use of magnesium hydroxide towards halogen-free flame-retarded polyamide-6/polypropylene blends. Polym Degrad Stab. 2012;97(8):1447–57. https://doi.org/10.1016/j.polymdegradstab.2012.05.011.

Senthamaraikannan P, Kathiresan M. Characterization of raw and alkali treated new natural cellulosic fiber from Coccinia grandis L. Carbohydr Polym. 2018;186:332–43. https://doi.org/10.1016/j.carbpol.2018.01.072.

Xu T, Huang X, Zhao Y. Investigation into the properties of asphalt mixtures containing magnesium hydroxide flame retardant. Fire Saf J. 2011;46(6):330–4. https://doi.org/10.1016/j.firesaf.2011.05.001.

Chungcharoen T, Srisang N. Preparation and characterization of fuel briquettes made from dual agricultural waste: cashew nut shells and areca nuts. J Clean Prod. 2020;256: 120434. https://doi.org/10.1016/j.jclepro.2020.120434.

Liu T, Wang F, Li G, Liu P, Gao C, Ding Y, Yang M, et al. Magnesium hydroxide nanoparticles grafted by DOPO and its flame retardancy in ethylene-vinyl acetate copolymers. J Appl Polym Sci. 2020. https://doi.org/10.1002/app.49607.

Kabir MM, Wang H, Lau KT, Cardona F. Chemical treatments on plant-based natural fibre reinforced polymer composites: an overview. Compos B Eng. 2012;43(7):2883–92. https://doi.org/10.1016/j.compositesb.2012.04.053.

Zhang L, Sun Z, Liang D, Lin J, Xiao W. Preparation and performance evaluation of PLA/coir fibre biocomposites. BioResources. 2017;12(4):7349–62.

Sharmin E, Zafar F. Flame retardants. In flame retardants. Singapore: IntechOpen; 2019.

Fernandes EM, Mano JF, Reis RL. Hybrid cork–polymer composites containing sisal fibre: morphology, effect of the fibre treatment on the mechanical properties and tensile failure prediction. Compos Struct. 2013;105:153–62. https://doi.org/10.1016/j.compstruct.2013.05.012.

Bali G, Meng X, Deneff JI, Sun Q, Ragauskas AJ. The effect of alkaline pretreatment methods on cellulose structure and accessibility. Chemsuschem. 2015;8(2):275–9. https://doi.org/10.1002/cssc.201402752.

Sun Z, Zhang L, Liang D, Xiao W, Lin J. Mechanical and thermal properties of PLA biocomposites reinforced by coir fibers. Int J Polym Sci. 2017. https://doi.org/10.1155/2017/2178329.

Jandas PJ, Mohanty S, Nayak SK. Surface treated banana fiber reinforced poly (lactic acid) nanocomposites for disposable applications. J Clean Prod. 2013;52:392–401. https://doi.org/10.1016/j.jclepro.2013.03.033.

Li DF, Zhao X, Jia YW, He L, Wang XL, Wang YZ. Simultaneously enhance both the flame retardancy and toughness of polylactic acid by the cooperation of intumescent flame retardant and bio-based unsaturated polyester. Polym Degrad Stab. 2019;168: 108961. https://doi.org/10.1016/j.polymdegradstab.2019.108961.

Ghetti P, Ricca L, Angelini L. Thermal analysis of biomass and corresponding pyrolysis products. Fuel. 1996;75(5):565–73. https://doi.org/10.1016/0016-2361(95)00296-0.

Sanchez-Olivares G, Rabe S, Perez-Chavez R, Calderas F, Schartel B. Industrial-waste agave fibres in flame-retarded thermoplastic starch biocomposites. Compos B Eng. 2019;177: 107370. https://doi.org/10.1016/j.compositesb.2019.107370.

Zhu S, Gong W, Luo J, Meng X, Xin Z, Wu J, Jiang Z. Flame retardancy and mechanism of novel phosphorus-silicon flame retardant based on polysilsesquioxane. Polymers. 2019;11(8):1304. https://doi.org/10.3390/polym11081304.

Norkhairunnisa M, Majid DL. A review on thermal performance of hybrid natural fiber/nanoclay polymer composites. In: Jawaid M, editor. Nanoclay Reinforced Polymer Composites. Singapore: Springer; 2016. p. 151–74. https://doi.org/10.1007/2F978-981-10-0950-1_7.

Ferreira MVF, Neves ACC, de Oliveira CG, Lopes FPD, Margem FM, Vieira CMF, Monteiro SN. Thermogravimetric characterization of polyester matrix composites reinforced with eucalyptus fibers. J Market Res. 2017;6(4):396–400. https://doi.org/10.1016/j.jmrt.2017.09.002.

Ogwang G, Olupot PW, Kasedde H, Menya E, Storz H, Kiros Y. Experimental evaluation of rice husk ash for applications in geopolymer mortars. J Bioresources Bioproducts. 2021. https://doi.org/10.1016/j.jobab.2021.02.008.

Hossain SS, Mathur L, Roy PK. Rice husk/rice husk ash as an alternative source of silica in ceramics: a review. J Asian Ceramic Soc. 2018;6(4):299–313. https://doi.org/10.1080/21870764.2018.1539210.

Bugaris DE, zur Loye, H. C. Materials discovery by flux crystal growth: quaternary and higher order oxides. Angew Chem Int Ed. 2012;51(16):3780–811. https://doi.org/10.1002/anie.201102676.

Ahmetli G, Kocaman S, Ozaytekin I, Bozkurt P. Epoxy composites based on inexpensive char filler obtained from plastic waste and natural resources. Polym Compos. 2013;34(4):500–9. https://doi.org/10.1002/pc.22452.

Battegazzore D, Bocchini S, Alongi J, Frache A, Marino F. Cellulose extracted from rice husk as filler for poly (lactic acid): preparation and characterization. Cellulose. 2014;21(3):1813–21. https://doi.org/10.1007/s10570-014-0207-5.

Liu Z, Quek A, Balasubramanian R. Preparation and characterization of fuel pellets from woody biomass, agro-residues and their corresponding hydrochars. Appl Energy. 2014;113:1315–22. https://doi.org/10.1016/j.apenergy.2013.08.087.

Bergeret A, Benezet JC, Tran TPT, Papanicolaou GC, Koutsomitopoulou A. Valorization of agricultural by-products in poly(lactic acid) to develop biocomposites. In: Thakur VK, editor. Green Composites from Natural Resources. Boca Raton: CRC Press; 2013.

Zhao, J. Enhancement of methane production from solid-state anaerobic digestion of yard trimmings by biological pretreatment (Doctoral dissertation, The Ohio State University) 2013. http://rave.ohiolink.edu/etdc/view?acc_num=osu1374240087

Zheng Y, Zhao J, Xu F, Li Y. Pretreatment of lignocellulosic biomass for enhanced biogas production. Prog Energy Combust Sci. 2014;42:35–53. https://doi.org/10.1016/j.pecs.2014.01.001.

Gilbert P, Ryu P, Sharifi V, Swithenbank J. Effect of process parameters on pelletisation of herbaceous crops. Fuel. 2009;88:1491–7. https://doi.org/10.1016/j.fuel.2009.03.015.

Yadav K, Tyagi M, Kumari S, Jagadevan S. Influence of process parameters on optimization of biochar fuel characteristics derived from rice husk: a promising alternative solid fuel. BioEnergy Res. 2019;12(4):1052–65. https://doi.org/10.1007/s12155-019-10027-4.

Abdulkareem SA, Amosa MK, Adeniyi AG, Adeoye SA, Ajayi AK. Development of natural fibre reinforced polystyrene (NFRP) composites: Impact resistance study. IOP Conf Ser. 2019;640(1):012059. https://doi.org/10.1088/1757-899X/640/1/012059.

Yu G, Song M, Jiao S, Jia X, Li Y. Flame retardancy of thermoplastic polyurethane using phosphorus-containing flame retardants. IOP Conf Ser. 2019;585(1):1012038. https://doi.org/10.1088/1757-899X/585/1/012038.

Mutuku, K. Characterization of physical properties of biomass waste materials in kenya for gasification: rice husks and coffee husks.

Zhang Y, Wang Q, Li B, Li H, Zhao W. Is there a general relationship between the exergy and HHV for rice residues? Renew Energy. 2018;117:37–45. https://doi.org/10.1016/j.renene.2017.10.022.

Wang Y, Li X, Wendt JO. Ash aerosol and deposition formation mechanisms during air/oxy-combustion of rice husks in a 100 kW combustor. Energy Fuels. 2018;32(4):4391–8. https://doi.org/10.1021/acs.energyfuels.7b03127.

Shah AUR, Prabhakar MN, Song JI. Current advances in the fire retardancy of natural fiber and bio-based composites—a review. Int J Precis Eng Manuf-Green Technol. 2017;4(2):247–62. https://doi.org/10.1007/s40684-017-0030-1.

Xue Y, Guo Y, Rafailovich MH. Flame retardant polymer nanocomposites and interfaces. In Flame Retardants. Singapore: IntechOpen; 2019.

Zhang Z, Wang Q, Li L, Xu G. Pyrolysis characteristics, kinetics and evolved volatiles determination of rice-husk-based distiller’s grains. Biomass Bioenerg. 2020;135: 105525. https://doi.org/10.1016/j.biombioe.2020.105525.

Qiao Y, Wang B, Zong P, Tian Y, Xu F, Li D, Tian Y, et al. Thermal behavior, kinetics and fast pyrolysis characteristics of palm oil: analytical TG-FTIR and Py-GC/MS study. Energy Convers Manag. 2019;199: 111964. https://doi.org/10.1016/j.enconman.2019.111964.

Zhang Z, Xu G, Wang Q, Cui Z, Wang L. Pyrolysis characteristics, kinetics, and evolved gas determination of chrome-tanned sludge by thermogravimetry–Fourier-transform infrared spectroscopy and pyrolysis gas chromatography-mass spectrometry. Waste Manag. 2019;93:130–7. https://doi.org/10.1016/j.wasman.2019.05.034.

Wang L, He C, Yang X. Effects of pretreatment on the soil aging behavior of rice husk fibers/polyvinyl chloride composites. BioResources. 2019;14(1):59–69. https://doi.org/10.15376/biores.14.1.59-69.

Chen D, Wang Y, Liu Y, Cen K, Cao X, Ma Z, Li Y. Comparative study on the pyrolysis behaviors of rice straw under different washing pretreatments of water, acid solution, and aqueous phase bio-oil by using TG-FTIR and Py-GC/MS. Fuel. 2019;252:1–9. https://doi.org/10.1016/j.fuel.2019.04.086.

Wang C, Bi H, Lin Q, Jiang X, Jiang C. Co-pyrolysis of sewage sludge and rice husk by TG–FTIR–MS: pyrolysis behavior, kinetics, and condensable/non-condensable gases characteristics. Renew Energy. 2020;160:1048–66. https://doi.org/10.1016/j.renene.2020.07.046.

Magdaleno-López C, Pérez-Bueno JDJ, Flores-Segura JC, Reyes-Araiza JL, Mendoza-López ML, Arés O, Manzano-Ramírez A. A geopolymeric composite of non-calcined rice husks made of metakaolin/sol–gel silica. J Compos Mater. 2019;53(5):603–11. https://doi.org/10.1177/0021998318788145.

Şımşek Y. Preparation and characterization of high purity silica obtained from rice husks. Acta Phys Polonica A. 2017;132(3):1002–5. https://doi.org/10.12693/APhysPolA.132.1002.

Bardalai M, Mahanta DK. Characterization of rice huskthrough x-ray diffraction, scanning electron microscope and fourier transform infrared analysis. Inter J Innov Res Sci Eng. 2016;2:472–9.

Qin L, Qiu J, Liu M, Ding S, Shao L, Lü S, Fu X, et al. Mechanical and thermal properties of poly (lactic acid) composites with rice straw fiber modified by poly (butyl acrylate). Chem Eng J. 2011;166(2):772–8. https://doi.org/10.1016/j.cej.2010.11.039.

Cheedarala RK, IL Song J. Thermally exfoliated π-π stacked blustered graphene oxide as an efficient flame retardant soft nano-bundles for vinyl ester resin composites. Mater Adv. 2020. https://doi.org/10.1039/D0MA00813C.

Subhedar PB, Gogate PR. Alkaline and ultrasound assisted alkaline pretreatment for intensification of delignification process from sustainable raw-material. Ultrason Sonochem. 2014;21(1):216–25. https://doi.org/10.1016/j.ultsonch.2013.08.001.

Herlina Sari N, Wardana ING, Irawan YS, Siswanto E. Characterization of the chemical, physical, and mechanical properties of NaOH-treated natural cellulosic fibers from corn husks. J Natural Fibers. 2018;15(4):545–58. https://doi.org/10.1080/15440478.2017.1349707.

Acknowledgements

This work was supported by the Volkswagen Foundation under Grant No. 96655 entitled “Enhanced flame retardancy of bio-composite plastics developed with rice husks and clay fillers”. The authors would like to gratefully acknowledge Sinja Pagel, Dr.-Ing. Johannes Benz and Prof. Dr.-Ing. Christian Bonten from Institut für Kunststofftechnik, University of Stuttgart, Germany, for generous efforts in reviewing and proof-reading this manuscript. Technical support from the Materials and Metallurgy Lab at Busitema University Tororo, Uganda is also acknowledged.

Author information

Authors and Affiliations

Contributions

VAY: Conceptualization, Experimental design; Experimentation; Writing-original draft; Writing-review and editing. ML: Conceptualization, Writing-original draft, Writing-review and editing; Supervision, Fund acquisition. PWO: Methodology; Writing-review and editing; Investigation; Supervision.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yiga, V.A., Lubwama, M. & Olupot, P.W. Thermal stability of unmodified and alkali-modified rice husks for flame retardant fiber-reinforced PLA composites. J Therm Anal Calorim 147, 11049–11075 (2022). https://doi.org/10.1007/s10973-022-11311-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11311-w