Abstract

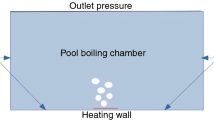

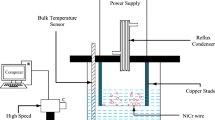

Recently, increasing the heat transfer rate in boiling systems using nanofluids has attracted great attention. Researchers use nanofluids to escalate the heat transfer in boiling. Nanofluids, due to their hydrophilicity and hydrophobicity, can affect heat transfer boiling positively or oppositely. In the present study, the application of various silica nanofluid concentrations on the pool boiling was investigated using the Eulerian–Eulerian approach. In this approach, liquid water was denoted as the continuous flow. Additionally, vapor was considered as the dispersed flow. To simulate such a multiphase flow phenomenon, a single-phase mixture model was utilized for silica nanoparticles and liquid water, and the simulation is done by considering the Eulerian–Eulerian approach for silica nanofluid. Furthermore, numerical correlations are proposed based on the results to calculate three different parameters, namely heat transfer coefficient (HTC), bubble departure diameter, and nucleation site density. The finite volume method (FVM) is applied to solve equations. Furthermore, the RPI model is developed to investigate heat transfer. Various nanofluid concentrations and heat fluxes are studied to understand how they affect heat transfer coefficient, nanofluid velocity, and vapor volume fraction. The results showed that the modifications caused by silica nanofluid on the surface could improve the numerical results. Besides, the heat transfer coefficient rose by 49.35% with a nanofluid volumetric concentration of 0.1%. The increasing effect of nanofluid concentration is so dominant at high heat fluxes.

Similar content being viewed by others

References

Kamel MS, Lezsovits F, Hussein AK. Experimental studies of flow boiling heat transfer by using nanofluids: a critical recent review. J Therm Anal Calorim. 2019;138(6):4019–43.

Sutharshan B, Mutyala M, Vijuk R, Mishra A. The AP1000TM reactor: passive safety and modular design. Energy Procedia. 2011;7:293–302.

Gorgy E, Eckels S. Local heat transfer coefficient for pool boiling of R-134a and R-123 on smooth and enhanced tubes. Int J Heat Mass Transf. 2012;55:3021–8.

A Fasquelle, J Pellé, S Harmand, and IV Shevchuk numerical study of convective heat transfer enhancement in a pipe rotating around a parallel axis. J. Heat Transfer, 136(5): 2014.

Alimoradi H, Shams M. Numerical simulation of the effects of surface roughness on nucleation site density of nanofluid boiling. Modares Mech Eng. 2019;19(7):1613–22.

Siddique W, El-Gabry L, Shevchuk IV, Fransson TH. Validation and Analysis of Numerical Results for a Two-Pass Trapezoidal Channel With Different Cooling Configurations of Trailing Edge. J Turbomach. 2012;135(1):011027.

Alimoradi H, Shams M, Ashgriz N, Bozorgnezhad A. A novel scheme for simulating the effect of microstructure surface roughness on the heat transfer characteristics of subcooled flow boiling. Case Stud Therm Eng. 2021;24:100829.

Zolfagharnasab MH, Salimi M, Zolfagharnasab H, Alimoradi H, Shams M, Aghanajafi C. A novel numerical investigation of erosion wear over various 90-degree elbow duct sections. Powder Technol. 2021;380:1–17.

Alimoradi H, Shams M, Valizadeh Z. The effects of nanoparticles in the subcooled boiling flow in the channels with different cross-sectional area and same hydraulic diameter. Modares Mech Eng. 2017;16(12):545–54.

Kim HY, Kim YG, Kang BH. Enhancement of natural convection and pool boiling heat transfer via ultrasonic vibration. Int J Heat Mass Transf. 2004;47(12–13):2831–40.

Alangar S. Effect of boiling surface vibration on heat transfer. Heat Mass Transf und Stoffuebertragung. 2017;53(1):73–9.

Mohammadi N, Fadda D, Choi CK, Lee J, You SM. Effects of surface wettability on pool boiling of water using super-polished silicon surfaces. Int J Heat Mass Transf. 2018;127:1128–37.

Yin X, Hu C, Bai M, Lv J. Effects of depositional nanoparticle wettability on explosive boiling heat transfer: a molecular dynamics study. Int Commun Heat Mass Transf. 2019;109:104390.

Sharma PO, Barewar SD, Chougule SS. Experimental investigation of heat transfer enhancement in pool boiling using novel Ag/ZnO hybrid nanofluids. J Therm Anal Calorim. 2021;143(2):1051–61.

Dadhich M, Prajapati OS, Rohatgi N. Flow boiling heat transfer analysis of Al2O3 and TiO2 nanofluids in horizontal tube using artificial neural network (ANN). J Therm Anal Calorim. 2020;139(5):3197–217.

Trisaksri V, Wongwises S. Nucleate pool boiling heat transfer of TiO2-R141b nanofluids. Int J Heat Mass Transf. 2009;52(5–6):1582–8.

V Sajith, MR Madhusoodanan, and CB Sobhan, An Experimental Investigation of the Boiling Performance of Water-Based Nanofluids, ASME 2008 , pp. 555–561.

Bang IC, Heung Chang S. Boiling heat transfer performance and phenomena of Al2O 3-water nano-fluids from a plain surface in a pool. Int J Heat Mass Transf. 2005;48(12):2407–19.

Wen D, Ding Y. Experimental investigation into the pool boiling heat transfer of aqueous based γ-alumina nanofluids. J Nanoparticle Res. 2005;7(2–3):265–74.

MH Shi, et al. “Experimental study of pool boiling heat transfer for nanoparticle suspensions on plate surface,” 2006.

Narayan GP, et al. Effect of surface orientation on pool boiling heat transfer of nanoparticle suspensions. Int J Multiph Flow. 2008;34(2):145–60.

Norouzipour A, Abdollahi A, Afrand M. Experimental study of the optimum size of silica nanoparticles on the pool boiling heat transfer coefficient of silicon oxide/deionized water nanofluid. Powder Technol. 2019;345:728–38.

Gong S, Cheng P. Numerical simulation of pool boiling heat transfer on smooth surfaces with mixed wettability by lattice Boltzmann method. Int J Heat Mass Transf. 2015;80:206–16.

Dehghan M, Vajedi H, Daneshipour M, Pourrajabian A, Rahgozar S, Ilis GG. Pumping power and heat transfer rate of converging microchannel heat sinks: errors associated with the temperature dependency of nanofluids. J Therm Anal Calorim. 2020;140(3):1267–75.

Alimoradi H, Shams M. Optimization of subcooled flow boiling in a vertical pipe by using artificial neural network and multi objective genetic algorithm. Appl Therm Eng. 2017;111:1039–51.

Li J, Hu H, Wang H. Numerical investigation on flow pattern transformation and heat transfer characteristics of two-phase flow boiling in the shell side of LNG spiral wound heat exchanger. Int J Therm Sci. 2019;152:106289.

Valizadeh Z, Shams M. Numerical investigation of water-based nanofluid subcooled flow boiling by three-phase Euler-Euler, Euler-Lagrange approach. Heat Mass Transf und Stoffuebertragung. 2016;52(8):1501–14.

Aminfar H, Mohammadpourfard M, Sahraro M. Numerical simulation of nucleate pool boiling on the horizontal surface for nano-fluid using wall heat flux partitioning method. Comput Fluids. 2012;66:29–38.

MS Kamel, MS Al-agha, F Lezsovits, and O Mahian Simulation of pool boiling of nanofluids by using Eulerian multiphase model,” J Therm Anal Calorim, no. 0123456789, 2019.

Shevchuk IV, Jenkins SC, Weigand B, von Wolfersdorf J, Neumann SO, Schnieder M. Validation and Analysis of Numerical Results for a Varying Aspect Ratio Two-Pass Internal Cooling Channel. J Heat Transfer. 2011;133(5):051701

Cheung SCP, Vahaji S, Yeoh GH, Tu JY. Modeling subcooled flow boiling in vertical channels at low pressures—Part 1: Assessment of empirical correlations. Int J Heat Mass Transf. 2014;75:736–53.

Li X, Yuan Y, Tu J. A parametric study of the heat flux partitioning model for nucleate boiling of nanofluids. Int J Therm Sci. 2015;98:42–50.

Mohammadpourfard M, Aminfar H, Sahraro M. Numerical simulation of nucleate pool boiling on the horizontal surface for ferrofluid under the effect of non-uniform magnetic field. Heat Mass Transf und Stoffuebertragung. 2014;50(8):1167–76.

Hamilton RL, Crosser OK. Thermal conductivity of heterogeneous two-component systems. Ind Eng Chem Fundam. 1962;1(3):187–91.

Brinkman HC. The viscosity of concentrated suspensions and solutions. J Chem Phys. 1952;20(4):571.

M Ishii Two-fluid model for two-phase flow. In: 2nd international workshop on two-phase flow fundamentals. RPI, Troy, NY, 1979.

WR Ranz, WE and Marshall, Evaporation from drops, vol. 48. Chemical Engineering Progress, 1952.

Lopez de Bertodano M, Turbulent bubbly flow in a triangular duct. Ph.D. Thesis, Troy, New York: Rensselaer Polytechnic Institute, 1991.

PM Kurul N, “On the modeling of multidimensional effects in boiling channels ANS. In: 1991.

P. M. Kurul N Multidimensional effects in forced convection subcooled boiling. In: Proc. ninth Int. heat Transf. Conf., vol. 2, 1990.

H Salehi and F Hormozi 2017 Numerical study of silica-water based nanofluid nucleate pool boiling by two-phase Eulerian scheme. Heat Mass Transf vol. 54, 2017.

Krepper E, Končar B, Egorov Y. CFD modelling of subcooled boiling-Concept, validation and application to fuel assembly design. Nucl Eng Des. 2007;237(7):716–31.

Lemmert M, Chawla JM. Influence of flow velocity on surface boiling heat transfer coefficient. Heat Transf Boil. 1977;237–47.

Kostanchuk DM and Tolubinsky, VI Vapour bubbles growth rate and heat transfer intensity at subcooled water boiling. In: Proc. 4th Int. heat Transf. Conf., vol. 5, 1970.

Gerardi C, Buongiorno J, Hu L, Mckrell T. Infrared thermometry study of nanofluid pool boiling phenomena. Nanoscale Res Lett. 2011;6:1–7.

Alimoradi H, Zaboli S, Shams M. Numerical simulation of surface vibration effects on improvement of pool boiling heat transfer characteristics of nanofluid. Korean J Chem Eng. 2022;39(1):69–85.

Akbari A, Alavi Fazel SA, Maghsoodi S, Kootenaei AS. Pool boiling heat transfer characteristics of graphene-based aqueous nanofluids. J Therm Anal Calorim. 2019;135(1):697–711.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zaboli, S., Alimoradi, H. & Shams, M. Numerical investigation on improvement in pool boiling heat transfer characteristics using different nanofluid concentrations. J Therm Anal Calorim 147, 10659–10676 (2022). https://doi.org/10.1007/s10973-022-11272-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11272-0