Abstract

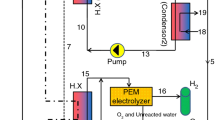

A new modified flash-binary geothermal power system with ejector-enhanced dual-pressure evaporation organic Rankine cycle (MF-EDORC) is proposed and investigated using seven pure working fluids. The exergy, exergoeconomic, and water footprint-based exergoenvironmental analyses are conducted to evaluate and compare the comprehensive performance of the new MF-EDORC and basic flash-binary system based on dual-pressure evaporation cycle (F-DORC). Non-dominated sorting genetic algorithm II and three decision-making methods are applied to ascertain the highest net power and the lowest total product cost, environmental impact (EI), and water footprint (WF) rates in MF-EDORC. Finally, an improved grey relational analysis is carried out to find the best working fluid for comprehensive performance. According to the results, the thermodynamic performance of MF-EDORC is improved compared with basic F-DORC for all selected fluids, and the maximum improvement is about 53.27% for R601. Improved grey relational analysis indicates that R600a with the highest degree of 0.834 is the best working fluid in MF-EDORC in which the net power, the energy, and exergy efficiencies reach 3430 kW, 8.8%, and 37.61%, respectively, with a 15.2% improvement compared with the basic F-DORC at the optimal point obtained through the Shannon entropy method. Moreover, the total product cost, EI, and WF rates are calculated by 4.047 $ h−1, 862.21 mPts h−1, and 18.53 kg H2O h−1, respectively, at this optimal point.

Similar content being viewed by others

Abbreviations

- CRF:

-

Capital recovery factor

- DORC:

-

Dual-pressure evaporation organic Rankine cycle

- EI:

-

Environmental impact

- F-DORC:

-

Basic flash-binary DORC cycle

- LINMAP:

-

Linear programming technique for multidimensional analysis of preference TOPSIS technique for order of preference by similarity to ideal Solution

- MF-EDORC:

-

Modified flash-ejector-enhanced DORC binary cycle

- NSGA-II:

-

Non-dominated sorting genetic algorithm II

- ORC:

-

Organic Rankine cycle

- WF:

-

Water footprint

- A :

-

Area (m2)

- \(\dot{B}\) :

-

Environmental impact rate associated with exergy (mPts s−1)

- B :

-

Environmental impact per unit of exergy (mPts kJ−1)

- \(\dot{C}\) :

-

Cost rate ($ s−1)

- c :

-

Cost per unit of exergy ($ kJ−1)

- C P :

-

Specific heat (kJ kg−1 K−1)

- d :

-

Diameter (m)

- Er:

-

Entrainment ratio

- \(\dot{E}x\) :

-

Exergy flow rate (kW)

- F :

-

Temperature difference correction factor

- \(\dot{G}\) :

-

Water footprint rate (kg H2O s−1)

- G :

-

Water consumption per exergy unit (kg H2O kJ−1)

- H :

-

Component-related water consumption (kg H2O)

- \(\dot{H}\) :

-

Component-related water consumption rate (kg H2O s−1)

- h :

-

Specific enthalpy (kJ kg−1)

- ir:

-

Interest rate (%)

- k :

-

Thermal conductivity (W m−1 K−1)

- LMTD:

-

Logarithmic mean temperature difference (K)

- M :

-

Mass (kg)

- \(\dot{m}\) :

-

Mass flow rate (kg s−1)

- P :

-

Pressure (kPa)

- Pr:

-

Prandtl number

- \(\dot{Q}\) :

-

Heat transfer rate (kW)

- Re:

-

Reynolds number

- R f :

-

Fouling resistance (m2 K W−1)

- s :

-

Specific entropy (kJ kg−1 K−1)

- SL:

-

System life (year)

- T :

-

Temperature (K)

- U :

-

Overall heat transfer coefficient (W m−2 K−1)

- V :

-

Volume (m3)

- \(\dot{W}\) :

-

Power (kW)

- x :

-

Quality

- Y :

-

Component-related environmental impact (mPts)

- \(\dot{Y}\) :

-

Component-related environmental impact rate (mPts s−1)

- Z :

-

Capital investment and operating and maintenance cost ($)

- \(\dot{Z}\) :

-

Capital investment and operating and maintenance cost rate ($ s−1)

- β :

-

Chevron angle (°)

- \(\lambda\) :

-

Convective coefficient (W m−2 K−1)

- \(\eta\) :

-

Efficiency (%)

- \(\mu\) :

-

Dynamic viscosity (Pa s)

- \(\rho\) :

-

Density (kg m−3)

- \(\upsilon\) :

-

Fluid velocity (m s−1)

- \(\omega\) :

-

Eco 99 coefficient (mPts kg−1)

- \(\delta\) :

-

Thickness (m)

- \(\varphi\) :

-

Maintenance factor

- 0:

-

Dead state

- c:

-

Cold stream

- ch:

-

Channel

- Cond:

-

Condenser

- D:

-

Destruction

- d:

-

Diffuser

- e:

-

Equivalent

- en:

-

Energy

- ex:

-

Exergy

- Exp:

-

Expander

- F:

-

Fuel

- h:

-

Hot stream

- H:

-

Hydraulic

- HPE:

-

High-pressure evaporator

- HPT:

-

High-pressure turbine

- i:

-

Inside

- in:

-

Inlet

- is:

-

Isentropic

- L:

-

Loss

- liq:

-

Liquid

- LPE:

-

Low-pressure evaporator

- LPT:

-

Low-pressure turbine

- mc:

-

Mixing chamber

- ns:

-

Nozzle section

- o:

-

Outside

- out:

-

Outlet

- P:

-

Product

- Pre:

-

Preheater

- PU:

-

Pump

- s:

-

Shell side

- SHX:

-

Self-superheating heat exchanger

- sn:

-

Suction nozzle

- t:

-

Tube side

- V:

-

Valve

- vap:

-

Vapor

- w:

-

Wall

- FS:

-

Flash separator

References

Zarrouk SJ, Purnanto MH. Geothermal steam-water separators: design overview. Geothermics. 2015;53:236–54.

Sarr J-AR, Mathieu-Potvin F. Improvement of double-flash geothermal power plant design: a comparison of six interstage heating processes. Geothermics. 2015;54:82–95.

Ozcan NY, Gokcen G. Thermodynamic assessment of gas removal systems for single-flash geothermal power plants. Appl Therm Eng. 2009;29(14–15):3246–53.

Pambudi NA, Itoi R, Jalilinasrabady S, Jaelani K. Performance improvement of a single-flash geothermal power plant in Dieng, Indonesia, upon conversion to a double-flash system using thermodynamic analysis. Renew Energy. 2015;80:424–31.

Jalilinasrabady S, Itoi R, Valdimarsson P, Saevarsdottir G, Fujii H. Flash cycle optimization of Sabalan geothermal power plant employing exergy concept. Geothermics. 2012;43:75–82.

Guzović Z, Rašković P, Blatarić Z. The comparision of a basic and a dual-pressure ORC (Organic Rankine Cycle): geothermal power plant Velika Ciglena case study. Energy. 2014;76:175–86.

Astolfi M, Romano MC, Bombarda P, Macchi E. Binary ORC (Organic Rankine Cycles) power plants for the exploitation of medium–low temperature geothermal sources–Part B: techno-economic optimization. Energy. 2014;66:435–46.

Luo C, Huang L, Gong Y, Ma W. Thermodynamic comparison of different types of geothermal power plant systems and case studies in China. Renew Energy. 2012;48:155–60.

Coskun A, Bolatturk A, Kanoglu M. Thermodynamic and economic analysis and optimization of power cycles for a medium temperature geothermal resource. Energy Convers Manag. 2014;78:39–49.

Paloso G Jr, Mohanty B. A flashing binary combined cycle for geothermal power generation. Energy. 1993;18(8):803–14.

Tchanche BF, Lambrinos G, Frangoudakis A, Papadakis G. Low-grade heat conversion into power using organic Rankine cycles–A review of various applications. Renew Sust Energ Rev. 2011;15(8):3963–79.

Vélez F, Segovia JJ, Martín MC, Antolín G, Chejne F, Quijano A. A technical, economical and market review of organic Rankine cycles for the conversion of low-grade heat for power generation. Renew Sust Energ Rev. 2012;16(6):4175–89.

Ziviani D, Beyene A, Venturini M. Advances and challenges in ORC systems modeling for low grade thermal energy recovery. Appl Energy. 2014;121:79–95.

Imran M, Haglind F, Asim M, Alvi JZ. Recent research trends in organic Rankine cycle technology: a bibliometric approach. Renew Sustain Energ Rev. 2018;81:552–62.

Kanog˘lu M, Cengel YA. Retrofitting a geothermal power plant to optimize performance: a case study. J Energy Resour Technol. 1999;121(4):295–301.

Yari M. Exergetic analysis of various types of geothermal power plants. Renew Energy. 2010;35(1):112–21.

Dagdas A. Performance optimisation of the combined single flash binary geothermal power plant. Int J Exergy. 2011;8(2):194–210.

Pasek AD, Soelaiman TF, Gunawan C. Thermodynamics study of flash–binary cycle in geothermal power plant. Renew Sustain Energ Rev. 2011;15(9):5218–23.

Zeyghami M. Performance analysis and binary working fluid selection of combined flash-binary geothermal cycle. Energy. 2015;88:765–74.

Zhao Y, Wang J. Exergoeconomic analysis and optimization of a flash-binary geothermal power system. Appl Energy. 2016;179:159–70.

Aali A, Pourmahmoud N, Zare V. Exergoeconomic analysis and multi-objective optimization of a novel combined flash-binary cycle for Sabalan geothermal power plant in Iran. Energy Convers Manag. 2017;143:377–90.

Sadeghi M, Nemati A, Yari M. Thermodynamic analysis and multi-objective optimization of various ORC (organic Rankine cycle) configurations using zeotropic mixtures. Energy. 2016;109:791–802.

Baral S, Kim D, Yun E, Kim KC. Energy, exergy and performance analysis of small-scale organic Rankine cycle systems for electrical power generation applicable in rural areas of developing countries. Energies. 2015;8(2):684–713.

Li G. Organic Rankine cycle performance evaluation and thermoeconomic assessment with various applications part I: energy and exergy performance evaluation. Renew Sust Energ Rev. 2016;53:477–99.

Heberle F, Brüggemann D. Thermo-economic evaluation of organic Rankine cycles for geothermal power generation using zeotropic mixtures. Energies. 2015;8(3):2097–124.

Liu Q, Shen A, Duan Y. Parametric optimization and performance analyses of geothermal organic Rankine cycles using R600a/R601a mixtures as working fluids. Appl Energy. 2015;148:410–20.

Liu Q, Duan Y, Yang Z. Effect of condensation temperature glide on the performance of organic Rankine cycles with zeotropic mixture working fluids. Appl Energy. 2014;115:394–404.

Kolahi M-R, Nemati A, Yari M. Performance optimization and improvement of a flash-binary geothermal power plant using zeotropic mixtures with PSO algorithm. Geothermics. 2018;74:45–56.

Chen H, Goswami DY, Stefanakos EK. A review of thermodynamic cycles and working fluids for the conversion of low-grade heat. Renew Sust Energ Rev. 2010;14(9):3059–67.

Lecompte S, Huisseune H, Van Den Broek M, Vanslambrouck B, De Paepe M. Review of organic Rankine cycle (ORC) architectures for waste heat recovery. Renew Sust Energ Rev. 2015;47:448–61.

Shengjun Z, Huaixin W, Tao G. Performance comparison and parametric optimization of subcritical Organic Rankine Cycle (ORC) and transcritical power cycle system for low-temperature geothermal power generation. Appl Energy. 2011;88(8):2740–54.

Mokarram NH, Mosaffa A. Investigation of the thermoeconomic improvement of integrating enhanced geothermal single flash with transcritical organic Rankine cycle. Energy Convers Manag. 2020;213:112831.

Larsen U, Pierobon L, Haglind F, Gabrielii C. Design and optimisation of organic Rankine cycles for waste heat recovery in marine applications using the principles of natural selection. Energy. 2013;55:803–12.

Li J, Liu Q, Ge Z, Duan Y, Yang Z. Thermodynamic performance analyses and optimization of subcritical and transcritical organic Rankine cycles using R1234ze (E) for 100–200 °C heat sources. Energy Convers Manag. 2017;149:140–54.

Zhou Y, Li S, Sun L, Zhao S, Talesh SSA. Optimization and thermodynamic performance analysis of a power generation system based on geothermal flash and dual-pressure evaporation organic Rankine cycles using zeotropic mixtures. Energy. 2020;194:116785.

Chen J, Jarall S, Havtun H, Palm B. A review on versatile ejector applications in refrigeration systems. Renew Sust Energ Rev. 2015;49:67–90.

Haghparast P, Sorin MV, Richard MA, Nesreddine H. Analysis and design optimization of an ejector integrated into an organic Rankine cycle. Appl Therm Eng. 2019;159:113979.

Li X, Li X, Zhang Q. The first and second law analysis on an organic Rankine cycle with ejector. Sol Energy. 2013;93:100–8.

Li X, Zhao C, Hu X. Thermodynamic analysis of organic Rankine cycle with ejector. Energy. 2012;42(1):342–9.

Kheiri R, Ghaebi H, Ebadollahi M, Rostamzadeh H. Thermodynamic modeling and performance analysis of four new integrated organic Rankine cycles (A comparative study). Appl Therm Eng. 2017;122:103–17.

Li X, Huang H, Zhao W. A supercritical or transcritical Rankine cycle with ejector using low-grade heat. Energy Convers Manag. 2014;78:551–8.

Stoppato A. Energetic and economic investigation of the operation management of an Organic Rankine Cycle cogeneration plant. Energy May. 2012;41(1):3–9.

Quoilin S, Declaye S, Tchanche BF, Lemort V. Thermo-economic optimization of waste heat recovery Organic Rankine Cycles. Appl Therm Eng. 2011;31(14–15):2885–93.

Liu Q, Duan Y, Yang Z. Performance analyses of geothermal organic Rankine cycles with selected hydrocarbon working fluids. Energy. 2013;63:123–32.

Feidt M, Kheiri A, Pelloux-Prayer S. Performance optimization of low-temperature power generation by supercritical ORCs (organic Rankine cycles) using low GWP (global warming potential) working fluids. Energy. 2014;67:513–26.

Hærvig J, Sørensen K, Condra TJ. Guidelines for optimal selection of working fluid for an organic Rankine cycle in relation to waste heat recovery. Energy. 2016;96:592–602.

Calm JM, Hourahan G. Refrigerant data update. Hpac Eng. 2007;79(1):50–64.

Li J, Ge Z, Duan Y, Yang Z, Liu Q. Parametric optimization and thermodynamic performance comparison of single-pressure and dual-pressure evaporation organic Rankine cycles. Appl Energy May. 2018;217:409–21.

Bao J, Zhao L. A review of working fluid and expander selections for organic Rankine cycle. Renew Sust Energ Rev. 2013;24:325–42.

Mondal S, Alam S, De S. Performance assessment of a low grade waste heat driven organic flash cycle (OFC) with ejector. Energy. 2018;163:849–62.

Chen LX, Hu P, Sheng CC, Zhang N, Xie MN, Wang FX. Thermodynamic analysis of three ejector based organic flash cycles for low grade waste heat recovery. Energy Convers Manag. 2019;185:384–95.

Sarkar J, Bhattacharyya S. Potential of organic Rankine cycle technology in India: working fluid selection and feasibility study. Energy. 2015;90:1618–25.

DiPippo R. Geothermal double-flash plant with interstage reheating: an updated and expanded thermal and exergetic analysis and optimization. Geothermics. 2013;48:121–31.

Bina SM, Jalilinasrabady S, Fujii H. Exergoeconomic analysis and optimization of single and double flash cycles for Sabalan geothermal power plant. Geothermics. 2018;72:74–82.

Meng N, Li T, Jia Y, Qin H, Liu Q, Zhao W, et al. Techno-economic performance comparison of enhanced geothermal system with typical cycle configurations for combined heating and power. Energy Convers Manag. 2020;205:112409.

Baccioli A, Antonelli M, Desideri U. Technical and economic analysis of organic flash regenerative cycles (OFRCs) for low temperature waste heat recovery. Appl Energy. 2017;199:69–87.

Wang J, Yan Z, Wang M, Li M, Dai Y. Multi-objective optimization of an organic Rankine cycle (ORC) for low grade waste heat recovery using evolutionary algorithm. Energy Convers Manag. 2013;71:146–58.

Shah RK, Sekulic DP. Fundamentals of heat exchanger design. New Jersey: Wiley; 2003.

Sinnott R. Chemical engineering design. Amsterdam: Elsevier; 2014.

Incropera FP, Lavine AS, Bergman TL, DeWitt DP. Fundamentals of heat and mass transfer. New Jersey: Wiley; 2007.

Kheiri A, Feidt M, Pelloux-Prayer S. Thermodynamic and economic optimizations of a waste heat to power plant driven by a subcritical ORC (Organic Rankine Cycle) using pure or zeotropic working fluid. Energy. 2014;78:622–38.

Barros JJC, Coira ML, de la Cruz López MP, del Caño GA. Sustainability optimisation of shell and tube heat exchanger, using a new integrated methodology. J Clean Prod. 2018;200:552–67.

Caputo AC, Pelagagge PM, Salini P. Heat exchanger design based on economic optimisation. Appl Therm Eng. 2008;28(10):1151–9.

Asadi M, Song Y, Sunden B, Xie G. Economic optimization design of shell-and-tube heat exchangers by a cuckoo-search-algorithm. Appl Therm Eng. 2014;73(1):1032–40.

Zhang C, Liu C, Xu X, Li Q, Wang S. Energetic, exergetic, economic and environmental (4E) analysis and multi-factor evaluation method of low GWP fluids in trans-critical organic Rankine cycles. Energy. 2019;168:332–45.

Kern DQ. Process heat transfer. New York: Tata McGraw-Hill Education; 1997.

Lecompte S, Huisseune H, Van den Broek M, De Schampheleire S, De Paepe M. Part load based thermo-economic optimization of the Organic Rankine Cycle (ORC) applied to a combined heat and power (CHP) system. Appl Energy. 2013;111:871–81.

García-Cascales J, Vera-García F, Corberán-Salvador J, Gonzálvez-Maciá J. Assessment of boiling and condensation heat transfer correlations in the modelling of plate heat exchangers. Int J Refrig. 2007;30(6):1029–41.

Yan Y-Y, Lio H-C, Lin T-F. Condensation heat transfer and pressure drop of refrigerant R-134a in a plate heat exchanger. Int J Heat Mass Transf. 1999;42(6):993–1006.

Bejan A, Tsatsaronis G, Moran MJ. Thermal design and optimization. New Jersey: Wiley; 1995.

Bejan A, Tsatsaronis G. Thermal design and optimization. New Jersey: Wiley; 1996.

Xin F, Ma T, Chen Y, Wang Q. Study on chemical spray etching of stainless steel for printed circuit heat exchanger channels. Nucl Eng Des. 2019;341:91–9.

Ghaebi H, Namin AS, Rostamzadeh H. Exergoeconomic optimization of a novel cascade Kalina/Kalina cycle using geothermal heat source and LNG cold energy recovery. J Clean Prod. 2018;189:279–96.

Boyaghchi FA, Chavoshi M, Sabeti V. Optimization of a novel combined cooling, heating and power cycle driven by geothermal and solar energies using the water/CuO (copper oxide) nanofluid. Energy. 2015;91:685–99.

Ebadollahi M, Rostamzadeh H, Pedram MZ, Ghaebi H, Amidpour M. Proposal and assessment of a new geothermal-based multigeneration system for cooling, heating, power, and hydrogen production, using LNG cold energy recovery. Renew Energy. 2019;135:66–87.

Meyer L, Tsatsaronis G, Buchgeister J, Schebek L. Exergoenvironmental analysis for evaluation of the environmental impact of energy conversion systems. Energy. 2009;34(1):75–89.

Liu C, He C, Gao H, Xie H, Li Y, Wu S, et al. The environmental impact of organic Rankine cycle for waste heat recovery through life-cycle assessment. Energy. 2013;56:144–54.

Sun Z, Liu C, Xu X, Li Q, Wang X, Wang S, et al. Comparative carbon and water footprint analysis and optimization of Organic Rankine Cycle. Appl Therm Eng. 2019;158:113769.

Fergani Z, Touil D, Morosuk T. Multi-criteria exergy based optimization of an Organic Rankine Cycle for waste heat recovery in the cement industry. Energy Convers Manag. 2016;112:81–90.

Ding Y, Liu C, Zhang C, Xu X, Li Q, Mao L. Exergoenvironmental model of Organic Rankine Cycle system including the manufacture and leakage of working fluid. Energy. 2018;145:52–64.

Yi Z, Luo X, Yang Z, Wang C, Chen J, Chen Y, et al. Thermo-economic-environmental optimization of a liquid separation condensation-based organic Rankine cycle driven by waste heat. J Clean Prod. 2018;184:198–210.

Ma X, Ye L, Qi C, Yang D, Shen X, Hong J. Life cycle assessment and water footprint evaluation of crude steel production: a case study in China. J Environ Manag. 2018;224:10–8.

Bayareh M, Mohammadi M. Multi-objective optimization of a triple shaft gas compressor station using Imperialist Competitive Algorithm. Appl Therm Eng. 2016;109:384–400.

Deb K, Pratap A, Agarwal S, Meyarivan T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans Evol Comput. 2002;6(2):182–97.

Ahmadi MH, Sayyaadi H, Dehghani S, Hosseinzade H. Designing a solar powered Stirling heat engine based on multiple criteria: maximized thermal efficiency and power. Energy Convers Manag. 2013;75:282–91.

Feng Y, Hung T, Zhang Y, Li B, Yang J, Shi Y. Performance comparison of low-grade ORCs (organic Rankine cycles) using R245fa, pentane and their mixtures based on the thermoeconomic multi-objective optimization and decision makings. Energy. 2015;93:2018–29.

Ahmadi MH, Ahmadi MA, Bayat R, Ashouri M, Feidt M. Thermo-economic optimization of Stirling heat pump by using non-dominated sorting genetic algorithm. Energy Convers Manag. 2015;91:315–22.

Xia XX, Wang ZQ, Zhou NJ, Hu YH, Zhang JP, Chen Y. Working fluid selection of dual-loop organic Rankine cycle using multi-objective optimization and improved grey relational analysis. Appl Therm Eng. 2020;171:115028.

Author information

Authors and Affiliations

Contributions

AS was involved in optimization. NR contributed in software. FAB contributed to supervision, investigation, conceptualization, methodology, validation, writing-original draft, writing-review, and editing.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sohbatloo, A., Rostami, N. & Ahmadi Boyaghchi, F. Exergoeconomic, water footprint-based exergoenvironmental impact and optimization of a new flash-binary geothermal power generation system using an improved grey relational method. J Therm Anal Calorim 147, 8411–8434 (2022). https://doi.org/10.1007/s10973-021-11128-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-11128-z