Abstract

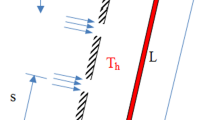

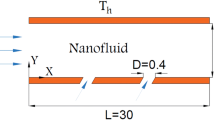

In this work, the nanofluid flow inside a microchannel with serrated injection jet on the upper wall of microchannel and using magnetic field with intensity of 0–40 Hartman were surveyed. The lower microchannel wall with jet injection racks has a constant temperature, but the upper microchannel wall is insulated among injection jets. Applying dented mode for injection jets was performed to enhance heat transfer. This research was performed for Reynolds numbers 10–50 and B = 0.01, 0.05, and 0.1 and for volume fraction of 0–6% water/Al2O3. The results indicated that the higher the height of dents was, the higher the heat transfer occurred.

Similar content being viewed by others

Abbreviations

- A:

-

Area, m2

- Cf :

-

Friction factor

- Cp :

-

Heat capacity, J kg−1 K−1

- d:

-

Diameter, m

- g:

-

Gravity acceleration, m s-2

- H,L:

-

Microchannel height and length, m

- X = x/H, Y = y/H:

-

Dimensionless microchannel height and length

- k:

-

Thermal conductivity coefficient, W m−1 K−1

- n:

-

Range of numbers in the equation placed or counter

- Nu:

-

Nusselt number

- p:

-

Fluid pressure, Pa

- Pe = (usds/αf):

-

Peclet number

- Pr=υf /αf :

-

Prandtl number

- Re=ρf uc h /μf :

-

Reynolds number

- T:

-

Temperature, K

- u, v:

-

Velocity components in x, y directions, m s−1

- uc :

-

Inlet flow velocity, m s−1

- us :

-

Brownian motion velocity, m s−1

- (U, V) = (u/ U0, v/ U0):

-

Dimensionless flow velocity in x–y direction

- x, y:

-

Cartesian coordinates, m

- (X, Y) = (x/h, y/h):

-

Dimensionless coordinates

- α:

-

Thermal diffusivity, m2 s−1

- β:

-

Rib height coefficient

- φ:

-

Nanoparticles volume fraction

- Kb :

-

Boltzmann constant, J K−1

- μ:

-

Dynamic viscosity, Pa s

- θ = (T–TC)/(TH –TC):

-

Dimensionless temperature

- ρ:

-

Density, kg m−3

- υ:

-

Kinematics viscosity, m2 s−1

- c:

-

Cold

- f:

-

Effective

- h:

-

Base fluid (pure water)

- M:

-

Hot mean

- nf:

-

Nanofluid

- s:

-

Solid nanoparticles

References

Yang L, Du K. Numerical simulation of nanofluid flow and heat transfer in a microchannel: the effect of changing the injection layout arrangement. Int J Mech Sci. 2020;172:105415.

Karimipour A, Hossein Nezhad A, D’Orazio A, Shirani E. Investigation of the gravity effects on the mixed convection heat transfer in a microchannel using lattice Boltzmann method. Int J Therm Sci. 2012;54:142–52.

Karimipour A. New correlation for Nusselt number of nanofluid with Ag/Al2O3/Cu nanoparticles in amicrochannel considering slip velocity and temperature jump by using lattice Boltzmann method. Int J Therm Sci. 2015;91:146–56.

Karimipour A, Nezhad AH, D’Orazio A, Esfe MH, Safaei MR, Shirani E. Simulation of copper-water nanofluid in a microchannel in slip flow regime using the lattice Boltzmann method. Eur J Mech B Fluids. 2015;49:89–99.

Bahrami D, Abbasian-Naghneh S, Karimipour A, Karimipour A. Efficacy of injectable rib height on the heat transfer and entropy generation in the microchannel by affecting slip flow. Math Methods Appl Sci. 2020. https://doi.org/10.1002/mma.6728.

Esfe MH, Arani AAA, Niroumand AH, Yan W-M, Karimipour A. Mixed convection heat transfer from surface-mounted block heat sources in a horizontal channel with nanofluids. Int J Heat Mass Transfer. 2015;89:783–91.

Bagherzadeh SA, Jalali E, Sarafraz MM, Akbari OA, Karimipour A, Goodarzi M, Bach QV. Effects of magnetic field on micro cross jet injection of dispersed nanoparticles in a microchannel. Int J Numer Meth Heat Fluid Flow. 2019;30(5):2683–704.

Alipour H, Karimipour A, Safaei MR, Semiromi DT, Akbari OA. Influence of T-semi attached rib on turbulent flow and heat transfer parameters of a silver-water nanofluid with different volume fractions in a three-dimensional trapezoidal microchannel. Physica E. 2017;88:60–76.

Dehkordi RB, Toghraie D, Hashemian M, Aghadavoudi F, Akbari M. Molecular dynamics simulation of ferro-nanofluid flow in a microchannel in the presence of external electric field: Effects of Fe3O4 nanoparticles. Int Commun Heat Mass Transfer. 2020;116(104):653.

Choi Z, Zhang Y. Numerical simulation of laminar forced convection heat transfer Al2O3–water nanofluid in a pipe with return bend. Int J Therm Sci. 2012;55:90–102.

Akbarinia A, Laur R. Investigating the diameter of solid particles effects on a laminar nanofluid flow in a curved tube using a two phase approach. Int J Heat Fluid Flow. 2011;30:706–18.

Jalali E, Karimipour A. Simulation the effects of cross-flow injection on the slip velocity and temperature domain of a nanofluid flow inside a microchannel. Int J Numerical Methods Heat Fluid Flow. 2019;29(5):1546–62.

L. Wei, H. Arasteh, A. Parsian, M. Taghipour, R. Mashayekhi, I. Tlili (2020), Locally weighted moving regression: Anon-parametric method for modeling nanofluid features of dynamic viscosity, Phys A Stat Mech its Appl. 124124

Zhuang Y, Ma CF, Qin M. Experimental study on local heat transfer with liquid impingement flow in two-dimensional micro-channels. Int J Heat Mass Transf. 1997;40(97):4055–9.

Jang SP, Kim SJ, Paik KW. Experimental investigation of thermal characteristics for a microchannel heat sink subject to an impinging jet, using a micro-thermal sensor array. Sensors Actuators A. 2003;105:211–24.

Yousefzadeh S, Rajabi H, Ghajari N, Sarafraz MM, Akbari OA, Goodarzi M. Numerical investigation of mixed convection heat transfer behavior of nanofluid in a cavity with different heat transfer areas. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-09018-6.

Karimipour A, Taghipour A, Malvandi A. Developing the laminar MHD forced convection flow of water/FMWNT carbon nanotubes in a microchannel imposed the uniform heat flux. J Magn Magn Mater. 2016;419:420–8.

Li F, Ma Q, Xin G, Zhang J, Wang X. Heat transfer and flow characteristics of microchannels with solid and porous ribs. Appl Therm Eng. 2020;178:115639.

Arjmandfard A, Toghraie D, Mehmandoust B, Hashemian M, Karimipour A. The study of atomic porosity effect on water/Fe nanofluid flow in a microchannel with a molecular dynamics method. J Mol Liq. 2020;317:114291.

Tahir S, Mital M. Numerical investigation of laminar nanofluid developing flow and heat transfer in a circular channel. Appl Therm Eng. 2012;39:8–14.

Eastman JA, Choi SUS, Li S, Yu W, Thompson LJ. Anomalously increased effective thermal conductivities of ethylene glycol-based nanofluids containing copper nanoparticles. Appl Phys Lett. 2001;78:718–20.

Halelfadl S, Adham AM, Mohd-Ghazali N, Maré T, Estellé P, Ahmad R. Optimization of thermal performances and pressure drop of rectangular microchannel heat sink using aqueous carbon nanotubes based nanofluid. Appl Therm Eng. 2014;62:492–9.

Behnampour A, Akbari OA, Safaei MR, Ghavami M, Marzban A, Sheikh Shabani GA, Zarringhalam M, Mashayekhi R. Analysis of heat transfer and nanofluid fluid flow in microchannels with trapezoidal, rectangular and triangular shaped ribs. Phys E Low-Dimens Syst Nanostruct. 2017;91:15–31.

Ahmadi MH, Mirlohi A, Alhuyi Nazari M, Ghasempour R. A review of thermal conductivity of various nanofluids. J Mol Liq. 2018;265:181–8.

Safaei MR, Togun H, Vafai K, Kazi SN, Badarudin A. Investigation of heat transfer enhancement in a forward-facing contracting channel using FMWCNT nanofluids. Numer Heat Transf Part A Appl. 2014;66:1321–40.

Sajadifar SA, Karimipour A, Toghraie D. Fluid flow and heat transfer of non-Newtonian nanofluid in a microtube considering slip velocity and temperature jump boundary conditions. Eur J Mech-B/Fluids. 2017;61:25–32.

Jalali E, Akbari OA, Sarafraz MM, Abbas T, Safaei MR. Heat transfer of oil/MWCNT nanofluid jet injection inside a rectangular microchannel. Symmetry. 2019;11:757.

Aminossadati SM, Raisi A, Ghasemi B. Effects of magnetic field on nanofluid forced convection in a partially heated microchannel. Int J Non-Linear Mecha. 2011;46:1373–82.

Raisi A, Ghasemi B, Aminossadati SM. A numerical study on the forced convection of laminar nanofluid in a microchannel with both slip and no-slip conditions. Numer Heat Transfer, Part A. 2011;59:114–29.

Hoseinzadeh S, Sohani A, Shahverdian MH, Shirkhani A, Heyns S. Acquiring an analytical solution and performing a comparative sensitivity analysis for flowing Maxwell upper-convected fluid on a horizontal surface. Thermal Sci Eng Progress. 2021;23:100901.

Hoseinzadeh S, Sahebi SAR, Ghasemiasl R, Majidian AR. Experimental analysis to improving thermosyphon (TPCT) thermal efficiency using nanoparticles/based fluids (water). Eur Phys J Plus. 2017;132(5):1–8.

Hoseinzadeh, S., Heyns, P.S. and Kariman, H., 2019. Numerical investigation of heat transfer of laminar and turbulent pulsating Al2O3/water nanofluid flow. Intl J Numerical Methods Heat Fluid Flow

Hoseinzadeh, S., Sohani, A. and Ashrafi, T.G., 2021. An artificial intelligence-based prediction way to describe flowing a Newtonian liquid/gas on a permeable flat surface. J Thermal Analys Calorimetry, pp.1–7

Hoseinzadeh S, Heyns PS, Chamkha AJ, Shirkhani A. Thermal analysis of porous fins enclosure with the comparison of analytical and numerical methods. J Therm Anal Calorim. 2019;138(1):727–35.

Sohani, A., Hoseinzadeh, S., Samiezadeh, S. and Verhaert, I., 2021. Machine learning prediction approach for dynamic performance modeling of an enhanced solar still desalination system. J Thermal Analy Calorimetry, pp.1–12

Kariman H, Hoseinzadeh S, Shirkhani A, Heyns PS, Wannenburg J. Energy and economic analysis of evaporative vacuum easy desalination system with brine tank. J Therm Anal Calorim. 2020;140(4):1935–44.

Javadi MA, Hoseinzadeh S, Ghasemiasl R, Heyns PS, Chamkha AJ. Sensitivity analysis of combined cycle parameters on exergy, economic, and environmental of a power plant. J Therm Anal Calorim. 2020;139(1):519–25.

Alayi R, Zishan F, Mohkam M, Hoseinzadeh S, Memon S, Garcia DA. A sustainable energy distribution configuration for microgrids integrated to the national grid using back-to-back converters in a renewable power system. Electronics. 2021;10(15):1826.

Hoseinzadeh S, Sohani A, Heyns S. Comprehensive analysis of the effect of air injection on the wake development of an airfoil. Ocean Eng. 2021;220:108455.

Sarafraz MM, Safaei MR, Goodarzi M, Arjomandi M. Reforming of methanol with steam in a micro-reactor with Cu–SiO2 porous catalyst. Int J Hydrogen Energy. 2019;44(36):19628–39.

Sarafraz MM, Hormozi F. Application of thermodynamic models to estimating the convective flow boiling heat transfer coefficient of mixtures. Exp Thermal Fluid Sci. 2014;53:70–85.

Salari, E., Peyghambarzadeh, M., Sarafraz, M. and Hormozi, F., 2016. Boiling heat transfer of alumina nano-fluids: role of nanoparticle deposition on the boiling heat transfer coefficient

Sarafraz MM, Hormozi F, Peyghambarzadeh SM. Pool boiling heat transfer to aqueous alumina nano-fluids on the plain and concentric circular micro-structured (CCM) surfaces. Exp Thermal Fluid Sci. 2016;72:125–39.

Sarafraz MM, Hormozi F. Experimental study on the thermal performance and efficiency of a copper made thermosyphon heat pipe charged with alumina–glycol based nanofluids. Powder Technol. 2014;266:378–87.

Sarafraz MM, Hormozi F. Forced convective and nucleate flow boiling heat transfer to alumnia nanofluids. Periodica Polytech, Chem Eng. 2014;58(1):37–46.

Nazari S, Ellahi R, Sarafraz MM, Safaei MR, Asgari A, Akbari OA. Numerical study on mixed convection of a non-Newtonian nanofluid with porous media in a two lid-driven square cavity. J Therm Anal Calorim. 2020;140(3):1121–45.

Sarafraz MM, Safaei MR. Diurnal thermal evaluation of an evacuated tube solar collector (ETSC) charged with graphene nanoplatelets-methanol nano-suspension. Renew Energy. 2019;142:364–72.

Goodarzi M, Amiri A, Goodarzi MS, Safaei MR, Karimipour A, Languri EM, Dahari M. Investigation of heat transfer and pressure drop of a counter flow corrugated plate heat exchanger using MWCNT based nanofluids. Int Commun Heat Mass Transfer. 2015;66:172–9.

Esfahani JA, Safaei MR, Goharimanesh M, De Oliveira LR, Goodarzi M, Shamshirband S, Bandarra Filho EP. Comparison of experimental data, modelling and non-linear regression on transport properties of mineral oil based nanofluids. Powder Technol. 2017;317:458–70.

Akbari OA, Safaei MR, Goodarzi M, Akbar NS, Zarringhalam M, Shabani GAS, Dahari M. A modified two-phase mixture model of nanofluid flow and heat transfer in a 3-D curved microtube. Adv Powder Technol. 2016;27(5):2175–85.

Bagherzadeh SA, D’Orazio A, Karimipour A, Goodarzi M, Bach QV. A novel sensitivity analysis model of EANN for F-MWCNTs–Fe3O4/EG nanofluid thermal conductivity: outputs predicted analytically instead of numerically to more accuracy and less costs. Physica A. 2019;521:406–15.

Tian Z, Abdollahi A, Shariati M, Amindoust A, Arasteh H, Karimipour A, Goodarzi M, Bach QV. Turbulent flows in a spiral double-pipe heat exchanger: optimal performance conditions using an enhanced genetic algorithm. Int J Numer Meth Heat Fluid Flow. 2019;30(1):39–53.

Ahmadi MH, Mohseni-Gharyehsafa B, Ghazvini M, Goodarzi M, Jilte RD, Kumar R. Comparing various machine learning approaches in modeling the dynamic viscosity of CuO/water nanofluid. J Therm Anal Calorim. 2020;139(4):2585–99.

Bahiraei M, Jamshidmofid M, Goodarzi M. Efficacy of a hybrid nanofluid in a new microchannel heat sink equipped with both secondary channels and ribs. J Mol Liq. 2019;273:88–98.

Bahmani MH, Sheikhzadeh G, Zarringhalam M, Akbari OA, Alrashed AA, Shabani GAS, Goodarzi M. Investigation of turbulent heat transfer and nanofluid flow in a double pipe heat exchanger. Adv Powder Technol. 2018;29(2):273–82.

Giwa SO, Sharifpur M, Goodarzi M, Alsulami H, Meyer JP. Influence of base fluid, temperature, and concentration on the thermophysical properties of hybrid nanofluids of alumina–ferrofluid: experimental data, modeling through enhanced ANN, ANFIS, and curve fitting. J Therm Anal Calorim. 2021;143(6):4149–67.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

jalali, E., Sajadi, S.M., Ghaemi, F. et al. Numerical analysis of the effect of hot dent infusion jet on the fluid flow and heat transfer rate through the microchannel in the presence of external magnetic field. J Therm Anal Calorim 147, 8397–8409 (2022). https://doi.org/10.1007/s10973-021-11095-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-11095-5