Abstract

By differential thermal analysis, a concentration field suitable for the growth of Zr, Mg co-doped strontium hexagallate crystals was observed that corresponds well with known experimental results. It was shown that the melting point of doped crystal is ca. 60 K higher than that of undoped crystals. This higher melting points indicate hexagallate phase stabilization by Zr, Mg co-doping and increase the growth window of (Mg,Zr):SrGa12O19, compared to undoped SrGa12O19 that grows from SrO–Ga2O3 melts.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Among the many pseudobinary compounds in the system SrO–Ga2O3, the composition of SrGa12O19 is closest to the component GaO1.5 = ½ Ga2O3, with a molar fraction of GaO1.5, x = 0.9231 (Table 1). SrGa12O19 is isostructural to the mineral magnetoplumbite, (Pb,Mn2+,Mg2+)(Fe3+,Mn3+)12O19, space group P63/mmc, which again belongs to the larger group of hexagonal ferrites, or “hexaferrites” [1]. Many of these materials possess strong and highly anisotropic persistent magnetic and electric moments, which make them interesting as permanent magnets or even multiferroics. Crystal growth of Fe3+ based hexaferrites is a challenge, because at the high melting points beyond 1500 °C of these materials, partial reduction to Fe2+ occurs; typically, liquidus temperatures are reduced by foreign solvents like Na2O to stabilize iron valency [2]. Resulting from the structural similarity, SrGa12O19 is a good substrate crystal for the epitaxial deposition of other hexaferrites [3]. Moreover, the chemical versatility of the magnetoplumbite structure allows doping of SrGa12O19 with luminescent ions such as Mn2+ and Cr3+ [4, 5].

The first publication of a phase diagram for the system SrO–Ga2O3 [6] showed that SrGa2O4 is the only intermediate compound with a congruent melting point. In more recent studies, this system was redetermined and partially thermodynamically assessed [7, 8], with mainly similar results like the previous study [6] – but with the difference that the peritectic melting of SrGa12O19 was reported there at significantly higher temperature (Table 1). However, all studies agree with the observation that it melts peritectically with the formation of β-Ga2O3. A somewhat lower peritectic melting temperature 1540 °C for SrGa12O19 and 1530 °C for BaGa12O19 was reported elsewhere; both compounds form an isomorph solid solution series [9, 10]. For the SrO–Ga2O3 system, minor differences are reported mainly on the SrO side, the reader is referred to the PhD theses of Solak [11] and Richter [12].

As a result of peritectic melting, crystal growth of SrGa12O19 is only possible from melts with an excess of SrO, compared to the stoichiometry of the compound. According to the assessment of Zinkevich [8], this phase with a Ga2O3 molar fraction x = 0.9231 is in equilibrium with the melt only between the peritectic points of SrGa12O19 (xper = 0.8002, Tper = 1553 °C) and the neighboring phase SrGa4O7 (xper = 0.7723, Tper = 1492 °C). (The concentration data from [8] that are based on the components SrO and Ga2O3 were converted to SrO and GaO1.5 which are used here.) With the lever rule, from these data a maximum yield Y = (0.8002 − 0.7723)/(0.9231 − 0.7723) ≈ 18% for the growth of SrGa12O19 crystals from melts with excess SrO can be calculated.

First SrGa12O19 crystals with size up to 3 mm were grown by Haberey et al. [13] from fluxes with x = 0.830, which means a slightly higher GaO1.5 concentration than the peritectic point given by Zinkevich [8], xper = 0.8002. This difference indicates that supercooling of the melt might avoid the primary crystallization of β-Ga2O3. Later, the same authors performed growth experiments with the addition of alkali molybdates or bismuth oxide. From melt solutions with Bi2O3 as flux, SrGa12O19 crystals up to 15 mm diameter (useful area up to 30 mm2) could be obtained. However, these crystals incorporated ca. 0.5 mol% Bi [14].

Significantly better and larger crystals were obtained by Mateika and Laurien [15]. They stated that the small concentration region in the pseudobinary system where SrGa12O19 crystallizes first (in their paper 0.7730 ≤ x(GaO1.5) ≤ 0.8095, very similar to the data given above) can be increased, if Ga3+ is substituted partially by small equimolar additions of Mg2+ and Zr4+. The partitioning coefficients of both ions was found to be k ≈ 1.05 > 1, which suggest that the hexaferrite structure is stabilized. The possibility to substitute Ga3+ by equimolar amounts of Mg2+ and Zr4+ was already earlier demonstrated for Gd3Ga5O12 [16].

Experimental

Differential thermal analysis (DTA) with simultaneous thermogravimetry (TG) was performed using NETZSCH STA 449C “Jupiter” and STA 409CD thermal analyzers. DTA/TG sample holders with Pt/Pt90Rh10 thermocouples and lidded platinum crucibles allowed measurements up to 1650 °C in a flowing mixture of 20 mL min-1 Ar + 20 mL min-1 O2. (Ga2O3 evaporates mainly under dissociation as Ga2O, and SrO mainly as metallic Sr; and both reactions can be suppressed by adding O2 to the atmosphere.) Usually the DTA samples were molten twice to ensure good mixing, and the second heating curves were used for further analysis. Unfortunately, under these experimental conditions the liquidus temperatures of mixtures close to the high melting components SrO and Ga2O3 (cf. Table 1) cannot be accessed, which prohibits good mixing and equilibration of DTA samples. Alternative DTA setups with higher maximum temperature cannot be used, because sample holder and/or furnaces contain parts that are sensitive with respect to oxygen (e.g., from tungsten or graphite). Under reducing conditions, however, both components are prone to decomposition to metallic Sr or Ga, or Ga2O suboxide, respectively, and subsequent evaporation. Ca. 50 different compositions spanning the whole range from pure SrO to pure Ga2O3 were prepared by melting together appropriate quantities of SrCO3 and Ga2O3 powders (Alfa, 99.99% purity) in the DTA crucibles.

Prior to charging the samples into the DTA crucibles, the starting materials were checked for mass losses by emanating CO2 (from carbonate calcination) or adsorbed volatiles such as traces of water. The samples themselves, with masses of at least 50 mg, were prepared on a balance with 0.01 mg resolution. This high accuracy ensures that concentration errors are insignificant.

In a second series MgO, ZrO2, and an equimolar mixture of MgO + ZrO2 was added to a (1 − x) SrO + x GaO1.5 mixture with x = 0.857, that is close to the growth window of SrGa12O19. Only MgO + ZrO2 co-doping proved to be useful. It was the aim of this series to reveal the influence of these dopants on the growth window.

Results and discussion

As mentioned in the previous section, the liquidus temperatures close to pure strontium or gallium oxide, respectively, are so high that evaporation from the sample prevents reliable thermal analysis. Not so in the center of the system where a low eutectic (1326 °C, x = 0.49) between Sr10Ga6O19 and Sr3Ga4O9 results in low liquidus temperatures without significant evaporation (cf. Fig. 2). Nevertheless, another peculiarity made interpretation of DTA signals not straightforward there: It turned out that DTA curves were often not well reproducible, especially for compositions from the central region of the phase diagram. This is demonstrated for (1 − x) SrO + x GaO1.5 mixtures with x = 0.5549 (two subsequent heatings of one sample) and x = 0.5855 (three heatings) in Fig. 1.

It is obvious that the curve (1) for sample x = 0.5549, and curves (2) and (3) for sample x = 0.5855 show exothermal peaks during these heating runs, which is untypical. All melting processes are endothermal events, but exothermal effects may occur if a sample is not in thermodynamic equilibrium and returns to equilibrium during heating.

For the x = 0.5549 sample, the peaks with onsets at 1241 °C and 1326 °C appear for both heating runs, because there equilibrium is obviously obtained, also for the upper curve. Not so the peak with onset at 1182 °C which results from a non-equilibrium situation. From Fig. 2 it can be seen that this could be possible, e.g., if Sr3Ga4O9 as well as Sr3Ga2O6 are not formed. This can occur as a result of strong supercooling of both phases, which results in the non-equilibrium crystallization of their neighbors SrGa2O4 and Sr10Ga6O19. Then, however, it is normal that these neighbor phases form together a lower eutectic (indicated by the dashed isotherm at 1182 °C and the non-equilibrium prolongations of the liquidus lines in Fig. 2).

Experimental phase diagram Ga2O3–SrO with seven intermediate compounds. Only a part of the experimental points is shown. Dashed liquidus lines indicate strong evaporation resulting from high temperatures close to the end members, or metastability near x = 0.5, respectively. Besides, one metastable eutectic at 1182 °C is drawn

Curve (1) for the x = 0.5855 sample shows the same non-equilibrium eutectic. No other effects appear until 1416 °C, which is the peritectic melting temperature of Sr3Ga4O9. This melting temperature was found here higher than reported in recent studies [6, 12], but we assume that these authors mixed up the eutectic at 1326 °C with the peritectic melting of Sr3Ga4O9. It should be noted that the composition of this sample is just 1.4% right from Sr3Ga4O9, and hence this phase should be predominating there under equilibrium conditions. Only in curve (2) of this sample, Sr3Ga2O6 is formed as a non-equilibrium phase first, which decomposes soon at 1241 °C to Sr3Ga4O9 and Sr10Ga6O19, which then melt eutectically at 1326 °C. The last heating curve (3) for this sample is similar to the previous one–with the difference that the exothermal jump into equilibrium occurs slightly later, and consequently the decomposition peak of Sr3Ga2O6 cannot be observed.

After passing all DTA peaks, the x = 0.5855 curves show an upward bend near 1490 °C. This indicates the liquidus temperature at this composition, because all melting processes are completed and the DTA curves return to their basis line. For the x = 0.5549 sample an analogous (but weaker) bend occurs near 1400 °C because this composition is closer to the eutectic point. However, for this experimental point, drawn slightly below the left termination of the 1416 °C peritectic in Fig. 2, this peritectic and the liquidus of Sr3Ga4O9 as well as SrGa2O4, cannot be resolved experimentally.

A tentative phase diagram of the system ½ Ga2O3–SrO is shown in Fig. 2 which is partially based on the references [6, 7, 10,11,12], but complemented and corrected with experimental DTA points from this study. It is obvious that not all experimental points can be explained by the liquidus and isothermal lines in the diagram. However, additional non-equilibrium events can be expected to occur, e.g., if one or two of the equilibrium eutectic phases at 1326 °C are absent. Other effects, like the peaks on the 1410 °C level right from x = 0.8, result from the initial crystallization of the hexagallate SrGa12O19, which shifts the concentration of the rest melt to the left. The remaining melt is depleted by Ga2O3 and its composition moves along the liquidus toward the eutectic point near x = 0.76, which produces then the corresponding peak also for compositions right from SrGa4O7. The occurrence of metastable non-equilibrium near the eutectic composition agrees with X-ray measurements and optical microscopy by Batti & Sloccari [6] who observed repeatedly Sr4Ga2O7 for such samples–which contradicts thermodynamic equilibrium. The large endothermal effect at 1182 °C (cf. also Fig. 1) is interpreted in Fig. 2 as metastable eutectic between Sr4Ga2O7 and SrGa2O4. However, this interpretation is not assured, because the inclusion of other phases (e.g., Sr3Ga2O6) cannot be ruled out.

In agreement with the Mateika & Laurien paper [15], Fig. 2 shows that the SrGa12O19 liquidus, and hence its crystallization window, is extremely narrow. Moreover, crystal growth is hampered there by the non-equilibrium crystallization of the neighbor phase SrGa4O7 [15]. As pointed out before, the occasional crystallization of non-equilibrium phases seems to be a general issue of the Ga2O3–SrO system.

In the magnetoplumbite crystal structure, the Ga3+ ions reside in octahedral, bipyramidal, and tetragonal environments, and the fivefold coordinated Ga3+ is randomly displaced from the center of its trigonal bipyramidal coordination polyhedron along positive and negative directions of the c-axis [1, 21, 22]. Mateika & Laurien [15] succeeded to increase the growth window of SrGa12O19 by partial substitution of Ga3+ (ionic radius r [6] = 76; r [4] = 61 pm [23]) by simultaneous substitution with identical amounts of Mg2+ (r [6] = 86; r [4] = 71 pm) and Zr4+ ions (r [6] = 86; r [4] = 73 pm), and crystals > 1 cm3 could be grown from a Sr1.56Ga10.40Mg0.52Zr0.52O18.72 melt [15].

It was the purpose of further DTA measurements in this study to investigate how Mg2+ and/or Zr4+ doping influences relevant phase equilibria in the ½ Ga2O3–SrO system. From Fig. 2 it is evident that crystal growth of SrGa12O19 should be possible along its liquidus between the peritectic lines at 1469 °C and 1434 °C, which is a very narrow growth window. In three series of DTA measurements, to a SrO/Ga2O3 mixture with x = 0.8571 (where both peritectic peaks are strong) growing amounts of MgO only, ZrO2 only, and of an equimolar MgO/ZrO2 mixture were added.

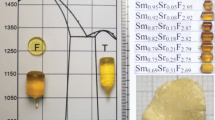

Doping by exclusively MgO or ZrO2 was not useful: In both cases the 1434 °C peak (SrGa4O7 peritectic) is lowered by 10 K, but the 1469 °C peak (SrGa12O19 peritectic) disappeared for additive levels around 4%–indicating instability of the hexagallate phase. Not so for equimolar MgO/ZrO2 doping, which is shown in Fig. 3. It turns out that again the lower peritectic moves downward, here by 20 K. Even more impressing is that the higher peritectic, which is the upper stability range of the hexagallate phase, shifts by > 60 K upward. As already pointed out by Mateika & Laurien [15], obviously the co-doping with Mg2+/Zr4+ increases the stability range. One can see from Fig. 3 that an upper useful co-doping level, is of the order y = 0.1, where y is the mole fraction of (MgO + ZrO2) per 1 mol of SrGa12O19. This means each 10% of MgO and ZrO2 can be added. One can assume that the highly versatile coordinations [4,5,6] of Ga3+ in the hexaferrite structure support the partial replacement of this ion by the Mg2+/Zr4+ dopant. Besides, the high number of four components leads at liquidus temperatures around 1500 °C to a significant entropic stabilization of the (Mg, Zr):SrGa12O19 mixture phase.

Starting from a (1 − x) SrO + x GaO1.5 mixture with x = 0.857 (cf. Fig. 2), growing molar concentrations y of a MgO:ZrO2 = 1:1 mixture were added. This increases the difference between the lower SrGa4O7 and the higher SrGa12O19 peritectic decomposition significantly

The graphical representation of this co-doping is not straightforward, because quaternary systems cannot be drawn without constrains in two dimensions. Mateika & Laurien [15] used a simplified concentration triangle with (MgO·ZrO2)–Ga2O3–SrO as pseudocomponents or components, respectively. This is reasonable, because MgO and ZrO2 are used only in the 1:1 molar ratio, and it is justified, because only the rim systems SrO–Ga2O3, SrO–ZrO2, and MgO–Ga2O3 are relevant for the discussion. Figure 4 a) is a similar presentation of this concentration triangle, with the difference that ½Ga2O3 and ½(MgO·ZrO2) are defined as components. This has the benefit that all corners represent one single cation.

a Concentration triangle SrO–½ Ga2O3–½ (MgO·ZrO2). Compounds with congruent melting points are marked by circles •, with peritectic melting by asterisks ⋆. Blue tie lines SrZrO3–Ga2O3 and MgGa2O4–SrGa2O4 separate independent partial systems. Data of Mateika & Laurien [15] and from this study added. b Ga2O3 rich corner of the triangle

The further discussion may neglect the potential rim system MgO–SrO because this is simple eutectic without intermediate compounds, and hence no other phases that could crystallize first [24]. The other potential rim system ZrO2–Ga2O3 is not known from the literature. However, simple Ga-Zr oxides do not exist and Ga–O–Zr bonds can be stabilized only with organic ligands [25]. Hence, one can assume that also the ZrO2–Ga2O3 system is eutectic, like ZrO2–Al2O3 [26]. Indeed, from Ga2O3 rich ternary melts with high MgO/ZrO2 doping only MgGa2O4 crystallized in addition to SrGa12O19 and β-Ga2O3, and no Ga-Zr oxide phase was found [15]. Consequently, also the potential rim system ZrO2–Ga2O3 can be neglected.

Both remaining rim systems that include MgO·ZrO2 contain one intermediate compound with congruent melting behavior: SrZrO3 (Tf = 2671 °C, [27]) and MgGa2O4 (Tf ≈ 1930…1950 °C, [28, 29]). If intermediate compounds in ternary systems can coexist in equilibrium, tie lines can be drawn between them and the concentration triangle can be divided to partial systems. It is very common that such tie lines can be drawn between congruently melting phases, although exceptions are possible, e.g., near ternary peritectic points [30]. In such cases, however, three solid phases should coexist, which was not reported in the literature [15, 31] so far.

Figure 4 a shows the concentration triangle with these tie lines that separate independent partial systems. The considerations given above allow to conclude that for melts inside the shaded area, the whole crystallization path remains within this triangle, because this is a partial system. The triangle is enlarged in Fig. 4 b. The experiments by Mateika & Laurien resulted in the red corner as upper useful limits for the Ga2O3 and dopant concentrations (in reference [15] Fig. 1 a. In this publication, the chemical composition of melts was compared with the composition of (Mg,Zr):SrGa12O19 crystals that were grown, and enrichment of the dopants in the crystal was found. Besides, the peritectic melting behavior of SrGa12O19 requires melts with a smaller Ga2O3 concentration than the crystal. As a consequence, an upward right shift of the crystal compositions compared to the melts was observed [15].

Unfortunately, there is a contradiction: Fig. 1 in [15] shows that (Mg,Zr):SrGa12O19 crystallizes only from melts inside the “red corner” in Fig. 4 of this article; but the melt composition Sr1.56Ga10.40Mg0.52Zr0.52O18.72 that is given in Tab. 2 of the Mateika & Laurien paper corresponds to the left red square in Fig. 4, and the resulting crystal to the right square. We assume that concentration data were mixed up and can only guess that dopant concentration have to be doubled. Then the melt concentration lies almost exactly in the corner, and the result is (within the typical experimental error) almost exactly on the blue rim of the partial triangle. One can conclude that by trial and error Mateika & Laurien found a melt composition that is almost optimum for crystal growth in this system.

The DTA measurements that are shown in Fig. 3 are a confirmation: The growth window for (Mg,Zr):SrGa12O19 could be increased mainly by an increased stability of hexagallate phase. This works well up to the y = 0.0937 doping level. The starting composition of this doping series, x = 0.857, and the useful upper doping level are marked by green circles in Fig. 4. Higher doping along the green dashed line is detrimental because the partial system is left.

Conclusions

Mateika & Laurien [15] identified a concentration field in the quaternary system SrO–Ga2O3–MgO–ZrO2 were the growth of bulk (Mg,Zr):SrGa12O19 crystals is possible. With DTA measurements, this concentration field was confirmed to be optimum, and a further optimization with respect to starting composition seems not possible. One technical error concerning concentration data in Tab. 2 of [15] was identified.

References

Delacotte C, Whitehead GFS, Pitcher MJ, Robertson CM, Sharp PM, Dyer MS, Alaria J, Claridge JB, Darling GR, Allan DR, Winter G, Rosseinsky MJ. Structure determination and crystal chemistry of large repeat mixed-layer hexaferrites. IUCrJ. 2018;5:681–98. https://doi.org/10.1107/S2052252518011351.

Gambino R, Leonhard F. Growth of barium ferrite single crystals. J Amer Ceram Soc. 1961;44(5):221–4. https://doi.org/10.1111/j.1151-2916.1961.tb15364.x.

Kamzin AS, Lutsev LV, Petrov VA. Epitaxial films of Ba–M type hexagonal ferrites. Phys Solid State. 2001;43(12):2253–6. https://doi.org/10.1134/1.1427952.

Verstegen JMPJ. Luminescence of Mn2+ in SrGa12O19, LaMgGa11O19, and BaGa12O19. J Solid State Chem. 1973;7:468–73. https://doi.org/10.1016/0022-4596(73)90176-X.

Xu J, Chen D, Yu Y, Zhu W, Zhou J, Wang Y. Cr3+:SrGa12O19: a broadband near-infrared long-persistent phosphor. Chem Asian J. 2014;9:1020–5.

Batti P, Sloccari G. Diagramma di stato del sistema SrO–Ga2O3. Anal Chim. 1969;59:155–62.

Kobzareva VP, Kovba LM, Lopato LM, Lykova LN, Shevchenko AV. Phase diagram of the system SrO–Ga2O3. Zh Neorg Chim. 1976;21:1651–4.

Zinkevich M. Calorimetric study and thermodynamic assessment of the SrO–Ga2O3 system. Internat J Mat Res. 2007;98:574–9. https://doi.org/10.3139/146.101513.

Kovba LM, Lykova LN, Kobzareva VP, Lopato LM, Shevchenko AV. Phase diagram of the system BaO–Ga2O3. Neorg Mater. 1975;20:1970–3.

Kadyrova ZR, Sirazhiddinov NA, Tuganova SK. Investigation of the systems SrAl12O19–Ca(Ba)Al12O19 and SrGa12O19–BaGa12O19. Neorg Mater. 1997;33:360–3.

Solak N. Interface stability in solid oxide fuel cells for intermediate temperature applications, Ph.D. thesis, Universität Stuttgart (2007). doi:https://doi.org/10.18419/opus-872.

Richter AN, Stabilität, Kristallchemie, Strukturen und optische Eigenschaften von Hexaphasen in CaO/SrO/BaO–Al2O3/Ga2O3–MgO/MnOx Systemen, Ph.D. thesis, Friedrich-Alexander-Universität, Erlangen-Nürnberg (2012).

Haberey F, Leckebusch R, Sahl K, Rosenberg M. Zur Züchtung von SrGa12019-Einkristallen. Naturwissenschaften. 1979;66:617.

Haberey F, Leckebusch R, Rosenberg M, Sahl K. Flux growth of SrGa12O19 crystals. J Cryst Growth. 1983;61:284–8. https://doi.org/10.1016/0022-0248(83)90364-0.

Mateika D, Laurien R. Czochralski growth of solid solutions of strontium hexagallate with magnesium and zirconium as dopants. J Cryst Growth. 1981;52:566–72. https://doi.org/10.1016/0022-0248(81)90341-9.

Mateika D, Rusche C. Coupled substitution of gallium by magnesium and zirconium in single crystals of gadolinium gallium garnet. J Cryst Growth. 1977;42:440–4. https://doi.org/10.1016/0022-0248(77)90229-9.

Ropp R.C. editor. Ch. Group 13 (B, Al, Ga, In and Tl) alkaline earth compounds. In: Encyclopedia of the alkaline earth compounds. Amsterdam: Elsevier;2013. pp. 481–635. https://doi.org/10.1016/B978-0-444-59550-8.00006-5

www.factsage.com, FactSage 7.3, GTT Technologies, Kaiserstr. 100, 52134 Herzogenrath, Germany;2019.

Kahlenberg V. The crystal structures of the strontium gallates Sr10Ga6O19 and Sr3Ga2O6. J Solid State Chem. 2001;160:421–9. https://doi.org/10.1006/jssc.2001.9259.

Krüger H, Lazić B, Arroyabe E, Kahlenberg V. Modulated structure and phase transitions of Sr10Ga6O19. Acta Cryst B: Struct Sci. 2009;65:587–92. https://doi.org/10.1107/S0108768109026974.

Pullar RC. Hexagonal ferrites: a review of the synthesis, properties and applications of hexaferrite ceramics. Prog Mat Sci. 2012;57(7):1191-310 1334. https://doi.org/10.1016/j.pmatsci.2012.04.00.

Graetsch H, Gebert W. Positional and thermal disorder in the trigonal bipyramid of magnetoplumbite structure type SrGa12O19. Z Krist Crystal Mater. 1994;209(4):338–42. https://doi.org/10.1524/zkri.1994.209.4.338.

Shannon RD. Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Cryst A. 1976;32:751–67. https://doi.org/10.1107/S0567739476001551.

van der Kemp WJM, Blok JG, van der Linde PR, Oonk HAJ, Schuijff A, Verdonk ML. Binary alkaline earth oxide mixtures: estimation of the excess thermodynamic properties and calculation of the phase diagrams. Calphad. 1994;18:255–67. https://doi.org/10.1016/0364-5916(94)90032-9.

Singh S, Jancik V, Roesky HW, Herbst-Irmer R. Synthesis, characterization, and X-ray crystal structure of a gallium monohydroxide and a hetero-bimetallic gallium zirconium oxide. Inorg Chem. 2006;45:949–51. https://doi.org/10.1021/ic051769l.

Lakiza SM, Lopato LM. Stable and metastable phase relations in the system alumina–zirconia–yttria. J Amer Ceram Soc. 1997;80:893–902. https://doi.org/10.1111/j.1151-2916.1997.tb02919.x.

ACerS and NIST, Phase Equilibria Diagrams, V. 4.0, entry Zr-082 (2013). https://ceramics.org/publications-resources/phaseequilibrium-diagrams.

Zinkevich M, Geupel S, Aldinger F. Thermodynamic assessment of the ternary systems Ga–Mg–O, Ga–Ni–O, Mg–Ni–O and extrapolation to the Ga–Mg–Ni–O phase diagram. J Alloy Compd. 2005;393:154–66. https://doi.org/10.1016/j.jallcom.2004.09.069.

Galazka Z, Klimm D, Irmscher K, Uecker R, Pietsch M, Bertram R, Naumann M, Albrecht M, Kwasniewski A, Schewski R, Bickermann M. MgGa2O4 as a new wide bandgap transparent semiconducting oxide: growth and properties of bulk single crystals. Phys Stat Sol (a). 2015;212:1455–60.

Paufler P. Phasendiagramme. Berlin: Akademie-Verlag; 1981.

Majewski PJ, Rozumek M, Schluckwerder H, Aldinger F. Phase diagram studies in the systems La2O3–SrO–Ga2O3, La2O3–MgO–La2O3, and SrO–MgO–Ga2O3 at 1400°C in air. J Amer Ceram Soc. 2001;84:1093–6. https://doi.org/10.1111/jace.2001.84.issue-5.

Acknowledgements

The authors thank Christo Guguschev for helpful discussions on this topic, and Steffen Ganschow for hints improving the manuscript. B.S. acknowledges support from the EU in the framework of the Erasmus+ program.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by BS. The first draft of the manuscript was written by DK and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Klimm, D., Szczefanowicz, B., Wolff, N. et al. Phase diagram studies for the growth of (Mg,Zr):SrGa12O19 crystals. J Therm Anal Calorim 147, 7133–7139 (2022). https://doi.org/10.1007/s10973-021-11050-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-11050-4