Abstract

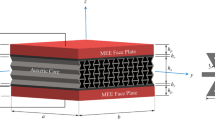

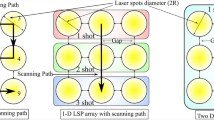

Surface modification processes of any metallic structure with the help of laser irradiation are a universal practice. The profoundly focused laser beam is to irradiate on the substrate surface to modify the surface condition for the improvement of the tribological properties in heavy and rouged engineering applications. There is a wide application of pure or raw Ti in the field of the biomedical sector specifically in implants and artificial joint prosthesis. In the viewpoint of the above, the present work determines the thermal characteristic aspect in a pure Ti physical domain by developing a two-dimensional heat transfer approach with the dual-phase-lag (DPL) model under the influence of the ultrashort pulsed laser heating. The physical domain has a Ti nanofilm of the 4 nm length, 2 nm width, and 0.02 nm thickness. A DPL model is developed for analyzing the ultrafast heating, as it is the most potential heat transfer model. The present study has modelled a hybrid analytical analysis comprising of the Duhamel’s theorem and the finite integral transform method. This work highlights the essentiality of applications of the DPL heat conduction model over the conventional Fourier’s model based on the qualitative assessment. The selection of thermal relaxation time lags was carefully chosen from the existing experimental evidence due to the requirement to reach the melting point temperature of pure Ti. The peak temperature of laser irradiation declines with the increase in the optical penetration depth and laser pulse time. Finally, the competence of the present analysis is validated with the published numerical and experimental works from the engineering accuracy standpoint.

Similar content being viewed by others

Abbreviations

- c:

-

Specific heat/J kg−1 °C−1

- C:

-

Heat capacity/J m−3 °C−1

- C1−C2 :

-

Constants for solution of differential equations, see Eq. (18)

- F:

-

Non-dimensional time, refer Eq. (5)

- Fp :

-

Non-dimensional laser pulse duration, see Eq. (5)

- i:

-

Nonnegative integers (0, 1, 2, 3….)

- I0 :

-

Laser energy density/intensity/J m−2

- \(I_{0}^{\prime \prime }\) :

-

Non-dimensional energy density/intensity, see Eq. (5)

- \(I_{0}^{\prime \prime \prime }\) :

-

Non-dimensional energy density/intensity in relation with initial condition, see Eq. (6c)

- j :

-

Nonnegative integers (0, 1, 2, 3….)

- k :

-

Thermal conductivity/W m−1ºC−1

- L:

-

Thickness of the nanofilm considered along x-direction/m, see Fig. 1b

- M1 :

-

M2, non-dimensional constants, defined in Eq. (17)

- q:

-

Rate of heat conduction/W m−2

- Q:

-

Volumetric external heat source/W m−3

- ra and rf :

-

Absorptivity and reflectivity, respectively

- rD :

-

Laser beam radius focused on substrate surface/m

- RD :

-

Non-dimensional laser beam radius focused on substrate surface, see Eq. (5)

- R:

-

Geometrical coordinates/m

- t:

-

Time for laser exposure/s

- tp :

-

Laser pulse duration/s

- T:

-

Local temperature of the nanofilm surface/°C

- Ti :

-

Initial temperature of the nanofilm/°C

- Tpeak :

-

Peak temperature, see Fig. 3/°C

- Veq and VeT :

-

Non-dimensional thermal relaxation time lag for heat flux and temperature gradient respectively, see Eq. (5)

- x :

-

X-spatial direction/m

- X:

-

Non-dimensional spatial direction, \({x \mathord{\left/ {\vphantom {x L}} \right. \kern-\nulldelimiterspace} L}\)

- y :

-

Y-spatial direction/m

- Y:

-

Non-dimensional spatial direction, \({y \mathord{\left/ {\vphantom {y L}} \right. \kern-\nulldelimiterspace} L}\)

- α :

-

Thermal diffusivity/m2s−1

- θ :

-

Non-dimensional local temperature of plate, see Eq. (5)

- δ:

-

Absorption depth/m

- Θ:

-

Anonymous transformed function of temperature based on Duhamel’s theorem, refer Eq. (9)

- \(\overline{\Theta },\overline{\overline{\Theta }}\) :

-

Transformed function of temperature based on finite integral transform, see Eqs. (13) and (15), respectively

- ρ :

-

Density/kg m−3

- Ω:

-

Non-dimensional constant, see Eq. (5)

- τ q and τ T :

-

Thermal relaxation time lag for heat flux and temperature gradient respectively

- \(\xi\) :

-

Transformed time function based on Duhamel’s theorem, see Eq. (9)

References

Shen M, Zhu S, Wang F. A general strategy for the ultrafast surface modification of metals. Nat Commun. 2016;7:13797.

Jde D. Surface modification of metals by high power lasers. Surf Coat Tech. 1998;100–101:377–82.

Aguilar-Morales AI, Alamri S, Kunze T, Lasagni AF. Influence of processing parameters on surface texture homogeneity using direct laser interference patterning. Opt Laser Tech. 2018;107:216–27.

Dunn A, Wlodarczyk KL, Carstensen JV, Hansen EB, Gabzdyl J, Harrison PM, Shephard JD, Handa DP. Laser surface texturing for high friction contacts. Appl Surf Sci. 2015;357:2313–9.

Hamilton DB, Walowit JA, Allen CM. A theory of lubrication by micro-irregularities. ASME J Basic Eng. 1996;88(1):177–85.

Kaur M, Singh K. Review on titanium and titanium based alloys as biomaterials for orthopaedic applications. Mat Sci Eng C. 2019;102:844–62.

Zhang LC, Chen LY. A review on biomedical titanium alloys: recent progress and prospect. Adv Eng Mater. 2019;21:1801215.

Niinomi M. Recent research and development in titanium alloys for biomedical applications and healthcare goods. Sci Tech Adv Mater. 2003;4:445–54.

Navarro M, Michiardi A, Castaño O, Planell JA. Biomaterials in orthopaedics. J R Soc Interface. 2008;5(27):1137–58.

Kibria G, Sen A, Tariq Aziz HM, Doloi B, Bhattacharyya B, Pulsed Nd: YAG laser surface texturing of pure titanium material, precision product-process design and optimization. Lecture Notes on Multidisciplinary Industrial Engineering 2018;361–90.

Geetha M, Singh AK, Asokamani R, Gogia AK. Ti based biomaterials, the ultimate choice for orthopaedic implants – a review. Pro Mater Sci. 2009;54:397–425.

Al-Nimr MA. Heat transfer mechanisms during short duration laser heating of thin metal films. Int J Thermophys. 1997;18(5):1257–68.

Kanavin AP, Smetanin IV, Isakov VA, Afanasiev YV, Chichkov BN, Wellegehausen B, Nolte S, Momma C, Tunnermann A. Heat transport in metals irradiated by ultrashort laser pulses. Phys Rev B. 1998;57(23):698–703.

Qiu TQ, Tien CL. Heat transfer mechanisms during short-pulse laser heating of metals. J Heat Transf. 1993;115:835–41.

Dunn A, Carstensen JV, Wlodarczyk KL, Hansen EB, Gabzdyl J, Harrison PM, Shephard JD, Hand DP. Nanosecond laser texturing for high friction applications. Opt Laser Eng. 2014;62:9–16.

Acherjee B, Misra D, Bose D, Venkadeshwaran K. Prediction of weld strength and seam width for laser transmission welding of thermoplastic using response surface methodology. Opt Laser Technol. 2009;41:956–67.

Lutey AHA, Ascari A, Fortunato A, Romoli L. Long-pulse quasi-CW laser cutting of metals. Int J Adv Manuf Technol. 2018;94(1–4):155–62.

Bouaziz MN, Boutalbi N. Laser heating of a material with time-dependent laser source. Int J Thermophys. 2011;32:1047–59.

Araya G, Gutierrez G. Analytical solution for a transient, three-dimensional temperature distribution due to a moving laser beam. Int J Heat Mass Transf. 2006;49:4124–31.

Vedavarz A, Kumar S, Moallemi MK. Significance of non-Fourier heat waves in conduction. J Heat Transf. 1994;116:221–4.

Morse PM, Feshbach H. Methods of Theoretical Physics. New York: McGraw-Hill; 1953.

Cattaneo C. A form of heat conduction equation which eliminates the paradox of instantaneous propagation. Compte Rendus. 1958;247:431–3.

Vernotte P. Les paradoxes de la theorie continue de l′equation de la chaleur. Compte Rendus. 1958;246:3154–5.

Tzou DY. Macro to Micro Scales Heat Transfer: The Lagging Behaviour. Bristol, PA: Taylor & Francis; 1996.

Yuvaraj R, Senthil KD. Numerical simulation of thermal wave propagation and collision in thin film using finite element solution. J Therm Anal Calorim. 2020;142:2351–69.

Ramadan K, Tyfour WR, Al-Nimr MA. On the analysis of short-pulse laser heating of metals using the dual phase lag heat conduction model. J Heat Transf. 2009;131:111301.

Majchrzak E, Mochnacki B, Greer AL, Suchy JS. Numerical modeling of shortpulse laser interactions with multi-layered thin metal films. Tech Sci Pres CMES. 2009;41(2):131–46.

Yang CY. Estimation of the heat source of laser pulses by a dual-phase-lag model. Int J Heat Mass Transf. 2014;73:358–64.

Kumar S, Bag S, Baruah M. Finite element model for femtosecond laser pulse heating using dual phase lag effect. J Laser Appl. 2016;28:032008.

Majchrzak E, Kałuża G. Analysis of thermal processes occurring in heated multi-layered metal films using the dual-phase lag model. Arch Mech. 2017;69(4–5):275–87.

Majchrzak E, Mochnacki B. Numerical simulation of thermal processes in a domain of thin metal film subjected to an ultrashort laser pulse. Materials. 2018;11(11):2116.

Majchrzak E, Mochnacki B. Dual-phase lag model of thermal processes in a multi-layered microdomain subjected to a strong laser pulse using the implicit scheme of FDM. Int J Therm Sci. 2018;133:240–51.

Majchrzak E, Turchan L. Modeling of laser heating of bi-layered microdomain using the general boundary element method. Eng Anal Bound Elem. 2019;108:438–46.

Majchrzak E. General Boundary Element Method for the Dual-Phase Lag Equations Describing the Heating of Two-Layered Thin Metal Films, Engineering Design Applications II. Adv. Str. Mat. 113 Springer Nature, Switzerland AG, 2020.

Majchrzak E, Mochnacki B. Second-order dual phase lag equation. Modeling of melting and resolidification of thin metal film subjected to a laser pulse. Mathematics. 2020;8:1–13.

Shanjin LV, Yang W. An investigation of pulsed laser cutting of titanium alloy sheet. Opt Laser Eng. 2006;44:1067–77.

Richter K, Behr W, Reisgen U. Low heat welding of titanium materials with a pulsed Nd:YAG laser. Mat-wiss u Werkstofftech. 2007;38(1):51–6.

Ayed Y, Germain G, Salem WB, Hamdi H. Experimental and numerical study of laser-assisted machining of Ti6Al4V titanium alloy. Finite Elem Anal Design. 2014;92:72–9.

Criales LE, Ozel T. Temperature profile and melt depth in laser powder bed fusion of Ti-6Al-4V titanium alloy. Prog Addit Manuf. 2017;2:169–77.

Junaid M, Baig MN, Shamir M, Khan FN, Rehman K, Haider J. A comparative study of pulsed laser and pulsed TIG welding of Ti-5Al-2.5Sn titanium alloy sheet. J Mater Process Tech. 2017;242:24–38.

Huang T, Lu J, Zhang X, Xiao R, Yang W, Wu Q. Femtosecond laser fabrication of anatase TiO2 micro-nanostructures with chemical oxidation and annealing. Sci Rep. 2017;7:2089.

Chatterjee S, Mahapatra SS, Bharadwaj V, Choubey A, Upadhyay BN, Bindra KS. Drilling of micro-holes on titanium alloy using pulsed Nd:YAG laser: parametric appraisal and prediction of performance characteristics. Proc IMechE Part B J Eng Manufac. 2018;233(8):1–18.

Zhechao F, Hongwei F. Study on selective laser melting and heat treatment of Ti-6Al 4V alloy. Result Phys. 2018;10:660–4.

Kumar P, Sinha AN. Effect of heat input in pulsed Nd:YAG laser welding of titanium alloy (Ti6Al4V) on microstructure and mechanical properties. Weld World. 2018;63:673–89.

Šugár P, Kováˇcik J, Šugárová J, Ludrovcová B. A Study of laser micromachining of PM processed Ti compact for dental implants applications. Materials. 2019;12(14):2246.

Tao W, Lingchao Q, Jiaqi L. Parameter analysis of thermal behavior during laser melting of Ti-6Al-4V alloy powder. Int J Adv Manu Tech. 2019;104:2875–85.

Sinha S. Thermal model based simulation of nanosecond pulsed laser irradiation of Ti6Al4V alloy. J Laser Appl. 2019;31:032008.

Fan W, Tan H, Lin X, Huang W. Thermal analysis of synchronous induction-assisted laser deposition of Ti-6Al-4V using different laser-induction interaction modes. Add Manuf. 2020;35:101267.

Schnell G, Duenow U, Seitz H. Effect of laser pulse overlap and scanning line overlap on femtosecond laser-structured Ti6Al4V Surfaces. Materials. 2020;13:969.

Orlande HRB, Özişik MN, Tzou DY. Inverse analysis for estimating the electron phonon coupling factor in thin metal films. J Appl Phys. 1995;78(3):1843–9.

Lubecki S. Duhamel’s theorem for time-dependent thermal boundary conditions. In: Hetnarski R.B. (eds) Encyclopedia of Thermal Stresses, Springer, Dordrecht. 2014.

Hahn DW, Özişik MN. Heat Conduction. John Willey Pub. 3rd Ed. 2012.

Umarov S. On fractional Duhamel’s principle and its applications. J Diff Eqns. 2012;252:5217–34.

Kast W. Solution of heat transfer problems for stochastic boundary conditions. Int J Therm Sci. 2004;43(11):1025–6.

Dubois RM, Lumer G. Formule de Duhamel abstraite. Arch Math. 1984;43:49–56.

Groulx D. Analytical solution to the unsteady one-dimensional conduction problem with two time-varying boundary conditions: Duhamel’s theorem and separation of variables. Heat Mass Transf. 2010;46:706–16.

Torabi M, Zhang K. Analytical solution for transient temperature and thermal stresses within convective multilayer disks with time-dependent internal heat generation. Part I Methodol J Therm Stress. 2016;39(4):398–413.

Li R, Zhong Y, Tian B, Liu Y. On the finite integral transform method for exact bending solutions of fully clamped orthotropic rectangular thin plates. Appl Math Letter. 2009;22(12):1821–7.

Dutta J, Kundu B. Exact analysis based on BDLTNE approach for thermal behaviour in living tissues during regional hyperthermia therapy. Acta Mech. 2019;230:2853–71.

Brorson SD, Fujimoto JG, Ippen EP. Femtosecond electronic heat-transport dynamics in thin gold films. Phys Rev Lett. 1987;59:1962–5.

Guo L, Hodson SL, Fisher TS, Xu X. Heat transfer across metal-dielectric interfaces during ultrafast-laser heating. J Heat Transf. 2012;234:042402.

ASM Handbook, ASM International, ISBN: 978–1–62708–026–2, 2019.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dutta, J., Kundu, B. & Biswas, R. Analytical model for ultrashort pulse laser heating in a titanium nanofilm by implementing dual-phase-lag theory in mathematical analysis. J Therm Anal Calorim 147, 7337–7352 (2022). https://doi.org/10.1007/s10973-021-11044-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-11044-2