Abstract

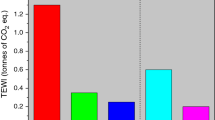

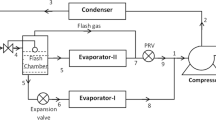

In this study, an attempt was made to extend the comfort of a passenger car cabin during the compressor off cycle using thermal energy storage (TES) in an HFO-1234yf mobile air conditioning (MAC) unit for idle stop/start vehicles. Fatty acid (OM08), as a phase change material (PCM), with 0.1–0.5 vol% of graphene nanoplatelets (GnPs) was used in this study. It was found that the inclusion of GnPs increases the thermal conductivity and dynamic viscosity of the liquid PCM nanocomposites by ~ 46% and ~ 53%, respectively, with 0.5 vol% of GnPs. During the pull-down cycle, the enhanced thermal conductivity outweighs the increased dynamic viscosity, resulting in a quicker decrease in PCM temperature. The test results revealed that the cabin temperature increases through the addition of TES, with a marginal decrease in the coefficient of performance. The addition of TES with the use of pure PCM increases the compressor power consumption of the MAC system by less than 1%. However, with the inclusion of graphene the power consumption increases with respect to the volume fraction. Without TES, the cabin comfort is extended by 78 s, 60 s, and 43 s for heating loads of 500, 1000, and 1500 W, respectively, and with the inclusion of TES, using pure PCM, the cabin comfort increased by up to 106 s, 87 s, and 63 s, respectively. The inclusion of 0.5 vol% GnPs extends the cabin comfort further by up to 189 s, 147 s, and 105 s for heating loads of 500, 1000, and 1500 W, respectively. Further, the CO2 equivalent emissions of the MAC system with TES using a pure PCM and a PCM nanocomposite are 10.54% and 5.64% lower than that of the system without TES, respectively.

Similar content being viewed by others

Abbreviations

- GHG:

-

Greenhouse gas

- GnP:

-

Graphene nanoplatelets

- GWP:

-

Global warming potential

- HFO:

-

Hydrofluoroolefin

- HVAC:

-

Heating, ventilation, and air conditioning

- IRD:

-

Integrated receiver dryer

- MAC:

-

Mobile air conditioning

- NEPCM:

-

Nano-enhanced phase change material

- RPM:

-

Revolution per minute

- RPS:

-

Regulated power supply

- SEM:

-

Scanning electron microscope

- SLHX:

-

Suction line heat exchanger

- TES:

-

Thermal energy storage

- TEWI:

-

Total equivalent warming impact

- TXV:

-

Thermostatic expansion valve

- VFD:

-

Variable frequency drive

- COP:

-

Coefficient of performance

- cp:

-

Specific heat of the air (kJ kg−1 K−1)

- DBT:

-

Dry bulb temperature (°C)

- h :

-

Enthalpy (kJ kg−1)

- h:

-

Mass flow rate (kg s−1)

- N :

-

Lifetime of the system

- L :

-

Average refrigerant leakage (%)

- M :

-

Mass of the refrigerant or mass of the fuel used (kg or lit)

- Q :

-

Heat transfer (kW)

- RH:

-

Relative humidity (%)

- T :

-

Temperature (°C)

- W :

-

Work consumption (kW)

- α :

-

Percentage of refrigerant recover (%)

- β :

-

CO2 emission factor

- comp:

-

Compressor

- ref:

-

Refrigerant

- rc:

-

Refrigerant charge

- f:

-

Fuel used

- ele:

-

Electrical power

- evap:

-

Evaporator

- in:

-

Inlet

- ini:

-

Initial

- fin:

-

Final

- inf:

-

Infiltration

- out:

-

Outlet

References

Yadav C, Sahoo RR. Exergy and energy comparison of organic phase change materials based thermal energy storage system integrated with engine exhaust. J Energy Storage. 2019;24:100773. https://doi.org/10.1016/j.est.2019.100773.

European Parliament. Setting emission performance standards for new passenger cars as part of the community’s integrated approach to reduce CO2 emissions from light-duty vehicles. Regulation (EC) No. 443/2009 of the European Parliament and of the Council of 23 April 2009. Off J Eur Union. 2009. https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2009:140:0001:0015:EN:PDF.

Johnson T. Review of diesel emissions and control. SAE Int J Fuels Lubr. 2010;3(1):16–29. https://doi.org/10.4271/2010-01-0301.

Fonseca N, Casanova J, Valdes M. Influence of the stop/start system on CO2 emissions of a diesel vehicle in urban traffic. Transp Res Part D. 2011;16:194–200. https://doi.org/10.1016/j.trd.2010.10.001.

Manski R, StraubT, Kohl T, Weinbrenner M, Heinle D. Storage evaporators: innovative AC concept for micro hybrid vehicles. SAE paper no. 2006-01-0268. https://doi.org/10.4271/2006-01-0268.

Yamada A, Nishida S, Yokoyama N, Abei J, Danjo T, Florida L, Brodie B, Nagano Y. Cold storage air conditioning system for idle stop vehicle. SAE paper no.2013-01-1287. https://doi.org/10.4271/2013-01-1287.

Morishita M, Uchida T, Mathur GD, Kato T, Matsunaga K. Evaluation of thermal environment in vehicles for occupant comfort using equivalent temperature of thermal manikin during start-stop function with energy storage evaporators. SAE paper no.2018-01-0059. https://doi.org/10.4271/2018-01-0059.

Shukla A, Dhami R, Bhargava A, Tiwari S. Development and optimization of PCM based technology for cooling applications for improvement of fuel efficiency in commercial vehicle. SAE paper no.2017-01-0150.https://doi.org/10.4271/2017-01-0150.

Oro E, Miro L, Farid MM, Martin V, Cabeza LF. Energy management and CO2 mitigation using phase change materials (PCM) for thermal energy storage (TES) in cold storage and transport. Int J Refrig. 2014;42:26–35. https://doi.org/10.1016/j.ijrefrig.2014.03.002.

Jha K, Badathala R. Low temperature thermal energy storage (TES) system for improving automotive HVAC effectiveness. SAE paper no.2015-01-0353.https://doi.org/10.4271/2015-01-0353.

Kowsky C, Wolfe E, Chowdhury S, Ghosh D, Wang M. PCM evaporator with thermosyphon. SAE paper no. 2014-01-0634.https://doi.org/10.4271/2014-01-0634.

Lee D. Numerical analysis and experimental study on the performance optimization of cold storage heat exchanger integrated with evaporator. Int J Automot Technol. 2017;18(3):377–85. https://doi.org/10.1007/s12239-017-0038-0.

Lee D. Experimental study on performance characteristics of cold storage heat exchanger for ISG vehicle. Int J Automot Technol. 2017;18(1):41–8. https://doi.org/10.1007/s12239-017-0004-x.

Zhao Y, Zhang X, Xu X, Zhang S. Development, characterization and modification study of eutectic fatty alcohol for cold energy storage application. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-10114-1.(Articleinpress).

Harish S, Orejon D, Takata Y, Kohno M. Thermal conductivity enhancement of lauric acid phase change nanocomposite in solid and liquid state with single-walled carbon nanohorn inclusions. Thermochim Acta. 2015;600:1–6. https://doi.org/10.1016/j.tca.2014.12.004.

Ranjbar S, Masoumi H, Khoshkhoo RH, Mirfendereski M. Experimental investigation of stability and thermal conductivity of phase change materials containing pristine and functionalized multi-walled carbon nanotubes. J Therm Anal Calorim. 2020;140:2505–18. https://doi.org/10.1007/s10973-019-09005-x.

Wu SY, Tong X, Nie CD, Peng DQ, Gong SG, Wang ZQ. The effects of various carbon nanofillers on the thermal properties of paraffin for energy storage applications. J Therm Anal Calorim. 2013;124:181–8. https://doi.org/10.1007/s10973-015-5153-4.

Fan L, Fang X, Wanga X, Zeng Y, Xiao Y, Yu Z, Xuc X, Hua Y, Cen K. Effects of various carbon nanofillers on the thermal conductivity and energy storage properties of paraffin-based nanocomposite phase change materials. Appl Energy. 2013;110:163–72. https://doi.org/10.1016/j.apenergy.2013.04.043.

Prabakaran R, Kumar JPN, Lal DM, Selvam C, Harish S. Constrained melting of graphene-based phase change nanocomposites inside a sphere. J Therm Anal Calorim. 2020;139(2):941–52. https://doi.org/10.1007/s10973-019-08458-4.

Prabakaran R, Sidney S, Lal DM, Selvam C, Harish S. Solidification of graphene-assisted phase change nanocomposites inside a sphere for cold storage applications. Energies. 2019;12:3473. https://doi.org/10.3390/en12183473.

Prabakaran R, Lal DM, Prabhakaran A, Kumar JK. Experimental investigations on the performance enhancement using minichannel evaporator with integrated receiver dryer condenser in an automotive air conditioning system. Heat Transf Eng. 2019;40(8):667–78. https://doi.org/10.1080/01457632.2018.1436663.

Mohanraj M, Abraham JDAP. Environment friendly refrigerant options for automobile air conditioners: a review. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-10286-w.

Lueken DJ, Waterland RT, Papasavva S. Ozone and TFA impacts in North America from degradation of 2,3,3,3-tetrafluoropropene (HFO-1234yf), a potential greenhouse gas replacement. Environ Sci Technol. 2010;44:343–8. https://doi.org/10.1021/es902481f.

Solomon KR, Velders GJ, Wilson SR, Madronich S, Longstreth J, Aucamp PJ, Bornman JF. Sources, fates, toxicity, and risks of trifluoroacetic acid and its salts: relevance to substances regulated under the Montreal and Kyoto protocols. J Toxicol Environ Health Part B. 2012;19:289–304. https://doi.org/10.1080/10937404.2016.1175981.

Kazil J, Mckeen S, Kim SW, Ahmadov R, Grell GA, Talukdar RK, Ravishankara RV. Deposition and rainwater concentrations of trifluoroacetic acid in the United States from the use of HFO-1234yf. J Geophys Res Atmos. 2014;119(24):14059–79. https://doi.org/10.1002/2014JD022058.

Russell MH, Hoogeweg G, Webster EM, Ellis DA, Waterland RL, Hoke RA. TFA from HFO-1234yf: accumulation and aquatic risk in terminal water bodies. Environ Toxicol Chem. 2012;31(9):1957–65. https://doi.org/10.1002/etc.1925.

Kim SC, Prabakaran R, Sakthivadivel D, Thangapandian N, Bhatia A, Kumar PG. Thermal transport properties of carbon-assisted phase change nanocomposite, fullerenes. Nanotub Carbon Nanostruct. 2020. https://doi.org/10.1080/1536383X.2020.1786814.(articleinpress).

Rajendran P, Dhasan ML, Narayanaswamy GR. Tuning thermostatic expansion valve for implementing suction line heat exchanger in mobile air conditioning system. J Braz Soc Mech Sci Eng. 2019;41:191. https://doi.org/10.1007/s40430-019-1680-4.

Prabakaran R, Lal DM. A novel exergy based charge optimisation for a mobile air conditioning system: an experimental study. J Therm Anal Calorim. 2018;132:1241–52. https://doi.org/10.1007/s10973-018-6998-0.

Moffat RJ. Describing the uncertainties in experimental results. Exp Therm Fluid Sci. 1988;1:3–17. https://doi.org/10.1016/0894-1777(88)90043-X.

Harish S, Orejon D, Takata Y, Kohno M. Thermal conductivity enhancement of lauric acid phase change nanocomposite with graphene nanoplatelets. Appl Therm Eng. 2015;80:205–11. https://doi.org/10.1016/j.applthermaleng.2015.01.056.

Sidney S, Dhasan ML, Selvam C, Harish S. Experimental investigation of freezing and melting characteristics of graphene-based phase change nanocomposite for cold thermal energy storage applications. Appl Sci. 2019;9:1099. https://doi.org/10.3390/app9061099.

Parameshwaran R, Deepak K, Saravanan R, Kalaiselvam S. Preparation, thermal and rheological properties of hybrid nanocomposite phase change material for thermal energy storage. Appl Energy. 2014;115:320–30. https://doi.org/10.1016/j.apenergy.2013.11.029.

ANSI/ASHRAE Standard 55.Thermal environmental conditions for human occupancy. 2010. http://arco-hvac.ir/wp-content/uploads/2015/11/ASHRAE-55-2010.pdf.

Jha K, Bhanot V, Ryali V. A simple model for calculating vehicle thermal loads. SAE Technical Paper no. 2013-01-0855. https://doi.org/10.4271/2013-01-0855.

Ingersoll J, Kalman T, Maxwell L, Niemiec R. Automobile passenger compartment thermal comfort model: part II—human thermal comfort calculation. SAE Technical Paper 1992: 920266. https://doi.org/10.4271/920266.

Prabakaran R, Lal DM, Devotta S. Effect of thermostatic expansion valve tuning on the performance enhancement and environmental impact of a mobile air conditioning system. J Therm Anal Calorim. 2021;143:335–50. https://doi.org/10.1007/s10973-019-09224-2.

Andrew Pon Abraham JD, Mohanraj M. Thermodynamic performance of automobile air conditioners working with R430A as a drop-in substitute to R134a. J Therm Anal Calorim. 2018;136(5):2071–86. https://doi.org/10.1007/s10973-018-7843-1.

Rajendran P, Sidney S, Ramakrishnan I, Dhasan ML. Experimental studies on the performance of mobile air conditioning system using environmental friendly HFO-1234yf as a refrigerant. Proc Inst Mech Eng Part E J Process Mech Eng. 2019. https://doi.org/10.1177/0954408919881236 (in press).

Acknowledgements

The authors acknowledge the Centre for Research at Anna University for providing an Anna Centenary Research Fellowship (No. CFR/ACRF/2015/4, dated January 15, 2015) and for allowing this doctoral level research to be conducted. The MAC system components for this research were provided by Mahindra Research Valley (MRV), Chennai, 603204.

Author information

Authors and Affiliations

Contributions

DML and SH were involved in conceptualization; RP and SS were involved in methodology; RP, SS, SH, and SCK were involved in formal analysis; RP was involved in writing—original draft preparation; SS, SH, DML, and SCK were involved in writing—review and editing; and DML was involved in supervision.

Corresponding author

Ethics declarations

Conflict of interest

All authors declare no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Ethical approval

We hereby confirm that all authors have participated in (a) conception and design, or analysis and interpretation of the data; (b) drafting the article or revising it critically for important intellectual content; and (c) approval of the final version. This manuscript has not been submitted to, or is under review at, another journal or other publishing venue.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Prabakaran, R., Sidney, S., Lal, D.M. et al. Experimental performance of a mobile air conditioning unit with small thermal energy storage for idle stop/start vehicles. J Therm Anal Calorim 147, 5117–5132 (2022). https://doi.org/10.1007/s10973-021-10863-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10863-7