Abstract

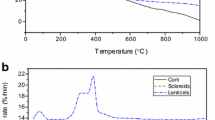

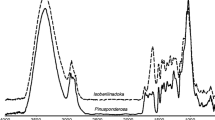

Pyrolysis is a useful technique in the characterization of the thermal behavior, kinetics and chemical composition of new materials. Alternative cork feedstocks are obtained from tree species possessing cork-enriched outer barks that are currently unused and could be used in thermal applications such as pyrolysis or gasification. An understanding of their thermal reactions is required, and this study is set to explore the pyrolysis behavior of alternative cork feedstocks from Quercus cerris, Beaucarnea recurvata and Betula pendula. Thermogravimetric analyses were carried out, and kinetics of the pyrolysis reaction were evaluated with isoconversional Vyazovkin method. The application of pyrolysis for estimation of the chemical composition of the corks of these species was also evaluated using Lorentzian multi-peak fitting. Wet chemical and FT-IR analyses were performed to determine the chemical composition of the corks and to compare the Lorentzian multi-peak fitting estimations. The results show that corks from different species have different pyrolytic degradation patterns. Pyrolysis of cork takes place in three major steps and two complementary steps. Lignin as well as suberin contents determine the thermal reactivity of cork. Desuberinised cork shows higher heat resistance at high temperatures than raw cork. Activation energy of cork varies between different species. Lorentzian multi-peak fitting could be used to estimate the chemical composition of cork as an alternative method to wet-chemical methods.

Similar content being viewed by others

References

Leite C, Pereira H. Cork-containing barks—a review. Front Mater. Frontiers; 2017;3:63.

Pereira H. Cork: biology, production and uses. Amsterdam: Elsevier; 2007.

Pereira H, Rosa ME, Fortes MA. The cellular structure of cork from Quercus suber L. IAWA J Brill. 1987;8:213–8.

Pereira H. Chemical composition and variability of cork from Quercus suber L. Wood Sci Technol. 1988;22:211–8.

Pereira H. Variability of the chemical composition of cork. BioResources. 2013;8:2246–56.

Pereira H. The rationale behind cork properties: a review of structure and chemistry. BioResources. 2015;10:6207–29.

Sen A, Miranda I, Esteves B, Pereira H. Chemical characterization, bioactive and fuel properties of waste cork and phloem fractions from Quercus cerris L. bark. Ind Crops Prod. 2020;157:112909.

Şen A, Miranda I, Santos S, Graça J, Pereira H. The chemical composition of cork and phloem in the rhytidome of Quercus cerris bark. Ind Crops Prod. 2010;31:417–22.

Şen A, Miranda I, Ferreira J, Lourenço A, Pereira H. Chemical composition and cellular structure of ponytail palm (Beaucarnea recurvata) cork. Ind Crops Prod. 2018;124:845–55.

Miranda I, Gominho J, Mirra I, Pereira H. Fractioning and chemical characterization of barks of Betula pendula and Eucalyptus globulus. Ind Crops Prod. 2013;41:299–305.

Rios P, Cabral V, Santos S, Mori F, Graça J. The chemistry of Kielmeyera coriacea outer bark: a potential source for cork. Eur J Wood Wood Prod. 2014;72:509–19.

Ferreira JPA, Miranda I, Gominho J, Pereira H. Selective fractioning of Pseudotsuga menziesii bark and chemical characterization in view of an integrated valorization. Ind Crops Prod. 2015;74:998–1007.

Ferreira JPA, Miranda I, Gominho J, Pereira H. Chemical characterization of cork and phloem from Douglas fir outer bark. Holzforschung De Gruyter. 2016;70:475–83.

Ferreira JPA, Quilhó T, Pereira H. Characterization of Betula pendula outer bark regarding cork and phloem components at chemical and structural levels in view of biorefinery integration. J wood Chem Technol. 2017;37:10–25.

Mota GS, Sartori CJ, Ferreira J, Miranda I, Quilhó T, Mori FA, et al. Cellular structure and chemical composition of cork from Plathymenia reticulata occurring in the Brazilian Cerrado. Ind Crops Prod. 2016;90:65–75.

Cardoso S, Ferreira J, Quilhó T, Pereira H. Cork of Douglas-fir bark: impact of structural and anatomical features on usage. Ind Crops Prod. 2017;99:135–41.

Şen A, De Melo MMR, Silvestre AJD, Pereira H, Silva CM. Prospective pathway for a green and enhanced friedelin production through supercritical fluid extraction of Quercus cerris cork. J Supercrit Fluids. 2015;97.

Şen A, Pereira H, Olivella MA, Villaescusa I. Heavy metals removal in aqueous environments using bark as a biosorbent. Int J Environ Sci Technol 2015; 391–404.

Şen AU, Fonseca FG, Funke A, Pereira H, Lemos F. Pyrolysis kinetics and estimation of chemical composition of Quercus cerris cork. Biomass Convers Biorefinery; 2020;1–11.

Vyazovkin S. Evaluation of activation energy of thermally stimulated solid-state reactions under arbitrary variation of temperature. J Comput Chem. 1997;18:393–402.

Joseph A, Bernardes CES, Druzhinina AI, Varushchenko RM, Nguyen TY, Emmerling F, et al. Polymorphic phase transition in 4′-hydroxyacetophenone: equilibrium temperature, kinetic barrier, and the relative stability of Z′= 1 and Z′= 2 forms. Cryst Growth Des. 2017;17:1918–32.

Saldarriaga JF, Aguado R, Pablos A, Amutio M, Olazar M, Bilbao J. Fast characterization of biomass fuels by thermogravimetric analysis (TGA). Fuel. 2015;140:744–51.

Graça J, Pereira H. Methanolysis of bark suberins: analysis of glycerol and acid monomers. Phytochem Anal An Int J Plant Chem Biochem Tech. 2000;11:45–51.

Brown RC. Thermochemical processing of biomass: conversion into fuels, chemicals and power. New York: Wiley; 2019.

Llorente MJF, García JEC. Comparing methods for predicting the sintering of biomass ash in combustion. Fuel. 2005;84:1893–900.

Niu Y, Tan H, Wang X, Liu Z, Liu H, Liu Y, et al. Study on fusion characteristics of biomass ash. Bioresour Technol. 2010;101:9373–81.

Niu Y, Lv Y, Lei Y, Liu S, Liang Y, Wang D. Biomass torrefaction: properties, applications, challenges, and economy. Renew Sustain Energy Rev. 2019;115:109395.

Miranda I, Gominho J, Mirra I, Pereira H. Chemical characterization of barks from Picea abies and Pinus sylvestris after fractioning into different particle sizes. Ind Crops Prod. 2012;36:395–400.

Pereira H. The thermochemical degradation of cork. Wood Sci Technol. 1992;26:259–69.

Şen A, Van Den Bulcke J, Defoirdt N, Van Acker J, Pereira H. Thermal behaviour of cork and cork components. Thermochim Acta. 2014;582:94–100.

Cordeiro N, Belgacem NM, Gandini A, Neto CP. Cork suberin as a new source of chemicals, 2: crystallinity, thermal and rheological properties. Bioresour Technol. 1998;63:153–8.

Fengel D, Wegener G. Wood: chemistry, ultrastructure, reactions. Walter de Gruyter; 2011.

Müller-Hagedorn M, Bockhorn H, Krebs L, Müller U. A comparative kinetic study on the pyrolysis of three different wood species. J Anal Appl Pyrolysis. 2003;68:231–49.

Sousa AF, Gandini A, Silvestre AJD, Neto CP, Cruz Pinto JJC, Eckerman C, et al. Novel suberin-based biopolyesters: from synthesis to properties. J Polym Sci Part A Polym Chem. 2011;49:2281–91.

De Oliveira H, Yoon B, Michaud V, Nam J-D, Suhr J. All natural cork composites with suberin-based polyester and lignocellulosic residue. Ind Crops Prod. 2017;109:843–9.

Cordeiro N, Belgacem MN, Gandini A, Neto CP. Urethanes and polyurethanes from suberin 2: synthesis and characterization. Ind Crops Prod. 1999;10:1–10.

Cai J, Chen S. A new iterative linear integral isoconversional method for the determination of the activation energy varying with the conversion degree. J Comput Chem. 2009;30:1986–91.

Burnham AK. Global chemical kinetics of fossil fuels: how to model matur pyrolysis. Berlin: Springer; 2017.

Shangguan W, Chen Z, Zhao J, Song X. Thermogravimetric analysis of cork and cork components from Quercus variabilis. Wood Sci Technol. 2018;52:181–92.

Cong K, Han F, Zhang Y, Li Q. The investigation of co-combustion characteristics of tobacco stalk and low rank coal using a macro-TGA. Fuel. 2019;237:126–32.

Ahmed A, Afolabi EA, Garba MU, Musa U, Alhassan M, Ishaq K. Effect of particle size on thermal decomposition and devolatilization kinetics of melon seed shell. Chem Eng Commun. 2019;206:1228–40.

Chen Z, Hu M, Zhu X, Guo D, Liu S, Hu Z, et al. Characteristics and kinetic study on pyrolysis of five lignocellulosic biomass via thermogravimetric analysis. Bioresour Technol. 2015;192:441–50.

Vyazovkin S. A time to search: finding the meaning of variable activation energy. Phys Chem Chem Phys. 2016;18:18643–56.

Conesa JA, Domene A. Biomasses pyrolysis and combustion kinetics through n-th order parallel reactions. Thermochim Acta. 2011;523:176–81.

Amutio M, Lopez G, Aguado R, Artetxe M, Bilbao J, Olazar M. Kinetic study of lignocellulosic biomass oxidative pyrolysis. Fuel. 2012;95:305–11.

Zhou H, Long Y, Meng A, Li Q, Zhang Y. The pyrolysis simulation of five biomass species by hemi-cellulose, cellulose and lignin based on thermogravimetric curves. Thermochim Acta. 2013;566:36–43.

Acknowledgements

Forest Research Centre (CEF) is a research unit funded by Fundação para a Ciência e a Tecnologia (FCT) (UIDB/00239/2020). The first author acknowledges support from FCT through a research contract (DL 57/2016). Umut Sen thanks Prof. Francisco Lemos for laboratory use.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Şen, U., Pereira, H. Pyrolysis behavior of alternative cork species. J Therm Anal Calorim 147, 4017–4025 (2022). https://doi.org/10.1007/s10973-021-10844-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10844-w