Abstract

The combustible features of wheat dust easily induce a potential hazard in its processing and application. To clearly reveal the effects of porous mesh parameters on the flame propagation of wheat dust, a vertical combustion pipeline together with the data collecting by the high-speed photography and fine thermocouple was built. Results indicate that with the increase in the mesh scale, the dust combustion and peak temperature are intensified first and then decreased with a darker luminescence. The increasing mesh number shows an inhibition effect on both peak temperature and combustion pressure, but an accelerating first and then weakening effect on flame velocity. A smaller particle size contributes to a more complete combustion, causing a higher peak temperature and flame velocity. At the particle mass of 2.5 g, the maximum value of peak temperature, flame velocity and combustion pressure were obtained during the flame propagation.

Similar content being viewed by others

References

Eckhoff RK. Dust explosions in the process industries. J Hazard Mater. 1991;54(3):266–7.

Benedetto D, Russo P, Amyotte P, et al. Studies on accidental gas and dust explosions. Chem Eng Sci. 2010;65(2):772–9.

Dobashi R, Senda K. Detailed analysis of flame propagation during dust explosions by UV band observations. J Loss Prev Process Ind. 2006;19(2–3):149–53.

Sun J, Dobashi R, Hirano T. Temperature profile across the combustion zone propagating through an iron particle cloud. J Loss Prev Process Ind. 2001;14(6):463–7.

Sun J, Dobashi R, Hirano T. Structure of flames propagating through aluminum particles cloud and combustion process of particles. J Loss Prev Process Ind. 2006;19(6):769–73.

Gao W, Mogi T, Sun J, et al. Effects of particle thermal characteristics on flame structures during dust explosions of three long-chain monobasic alcohols in an open-space chamber. Fuel. 2013;113:86–96.

Proust C. A few fundamental aspects about ignition and flame propagation in dust clouds. J Loss Prev Process Ind. 2006;19(2–3):104–20.

Han OS, Yashima M, Matsuda T, et al. Behavior of flames propagating through lycopodium dust clouds in a vertical duct. J Loss Prev Process Ind. 2000;13(6):449–57.

Bidabadi M, Rahbari A. Novel analytical model for predicting the combustion characteristics of premixed flame propagation in lycopodium dust particles. J Mech Sci Technol. 2009;23(9):2417–23.

Li H, Rosebrock CD, Riefler N. Experimental investigation on micro explosion of single isolated burning droplets containing titanium tetraisopropoxide for nanoparticle production. Proc Combust Inst. 2017;36(1):1011–8.

Gan B, Gao W, Jiang H, et al. Flame propagation behaviors and temperature characteristics in polyethylene dust explosions. Powder Technol. 2018;328:345–57.

Ying H, Risha GA, Yang V, et al. Combustion of bimodal nano/micron-sized aluminum particle dust in air. Proc Combust Inst. 2007;31(2):2001–9.

Bozorg MV, Bidabadi M, Bordbar V. Numerical investigation of flame behavior and quenching distance in randomly distributed poly-dispersed iron dust cloud combustion within a narrow channel. J Hazard Mater. 2019;367(5):482–91.

Benedetto AD, Russo P, Amyotte P, et al. Modelling the effect of particle size on dust explosions. Chem Eng Sci. 2010;65(2):772–9.

Yu J, Zhang X, Zhang Q, et al. Combustion behaviors and flame microstructures of micro- and nano-titanium dust explosions. Fuel. 2016;181:785–92.

Zhang H, Chen X, Zhang Y, et al. Effects of particle size on flame structures through corn starch dust explosions. J Loss Prev Process Ind. 2017;50:7–14.

Gao W, Mogi T, Sun J, et al. Effects of particle size distributions on flame propagation mechanism during octadecanol dust explosions. Powder Technol. 2013;249:168–74.

Zhang X, Yu J, Yan X. Flame propagation behaviors of nano- and micro-scale PMMA dust explosions. J Loss Prev Process Ind. 2016;40:101–11.

Gao W, Yu J, Li J, et al. Experimental investigation on micro- and nano-PMMA dust explosion venting at elevated static activation overpressures. Powder Technol. 2016;301:713–22.

Sun Y, Sun R, Zhu B, et al. Thermal reaction mechanisms of nano- and micro-scale aluminum powders in carbon dioxide at low heating rate. J Therm Anal Calorim. 2016;124(3):1727–34.

Mostashari SM, Fayyaz F. TG of a cotton fabric impregnated by sodium borate decahydrate (Na2B4O7·10H2O) as a flame-retardant. J Therm Anal Calorim. 2008;93(3):933–6.

Li Y, Bi M, Huang L, et al. Hydrogen cloud explosion evaluation under inert gas atmosphere. Fuel Process Technol. 2018;180:96–104.

Li J, Zhou F, Li S. Experimental study on the dust filtration performance with participation of water mist. Process Saf Environ Prot. 2017;109:357–64.

Song Y, Nassim B, Zhang Q. Explosion energy of methane/deposited coal dust and inert effects of rock dust. Fuel. 2018;228:112–22.

Amyotte PR. Solid inertants and their use in dust explosion prevention and mitigation. J Loss Prev Process Ind. 2006;19(2–3):161–73.

Jiang H, Bi M, Li B, et al. Inhibition evaluation of ABC powder in aluminum dust explosion. J Hazard Mater. 2019;361:273–82.

Chen X, Zhang H, Chen X, et al. Effect of dust explosion suppression by sodium bicarbonate with different granulometric distribution. J Loss Prev Process Ind. 2017;49:905–11.

Jiang H, Bi M, Gao W, et al. Inhibition of aluminum dust explosion by NaHCO3 with different particle size distributions. J Hazard Mater. 2019;200:97–114.

Yuan C, Amyotte PR, Hossain MN, et al. Minimum ignition energy of nano and micro Ti powder in the presence of inert nano TiO2 powder. J Hazard Mater. 2014;274:322–30.

Yuan C, Cai J, Amyotte P, et al. Fire hazard of titanium powder layers mixed with inert nano TiO2 powder. J Hazard Mater. 2017;346:19–26.

Masri AR, Ibrahim SS, Nehzat N, et al. Experimental study of premixed flame propagation over various solid obstructions. Exp Thermal Fluid Sci. 2000;21(1):109–16.

Li P, Duan Q, Gong L, et al. Effects of obstacles inside the tube on the shock wave propagation and spontaneous ignition of high-pressure hydrogen. Fuel. 2019;236:1586–94.

Li Q, Ciccarelli G, Sun X, et al. Flame propagation across a flexible obstacle in a square cross-section channel. Int J Hydrogen Energy. 2018;43(36):17480–91.

Zhang D, Nie B, Wang C, et al. Preliminary research on porous foam ceramics against gas explosions in goaf. Procedia Eng. 2011;26(4):1330–6.

Nie B, He X, Zhang R, et al. The roles of foam ceramics in suppression of gas explosion overpressure and quenching of flame propagation. J Hazard Mater. 2011;192(2):741–7.

Wang Y, Jiang S, Wu Z, et al. Study on the inhibition influence on gas explosions by metal foam based on its density and coal dust. J Loss Prev Process Ind. 2018;56:451–7.

Chen P, Huang F, Sun Y, et al. Effects of metal foam meshes on premixed methane-air flame propagation in the closed duct. J Loss Prev Process Ind. 2017;47:22–8.

Zhang K, Wang Z, Yan C, et al. Effect of size on methane-air mixture explosions and explosion suppression in spherical vessels connected with pipes. J Loss Prev Process Ind. 2017;49:785–90.

Zhang S, Wang Z, Zuo Q, et al. Suppression effect of explosion in linked spherical vessels and pipelines impacted by wire-mesh structure. Process Saf Prog. 2016;35(1):68–75.

Chen X, Zhao Q, Dai H, et al. Effect of metal mesh on the flame propagation characteristics of wheat starch dust. J Loss Prev Process Ind. 2018;55:107–12.

Jin K, Duan Q, Chen J, et al. Experimental study on the influence of multi-layer wire mesh on dynamics of premixed hydrogen-air flame propagation in a closed duct. Int J Hydrogen Energy. 2017;42(21):14809–20.

Ballantyne A, Moss JB. Fine wire thermocouple measurements of fluctuating temperature. Combust Sci Technol. 1977;17(1–2):63–72.

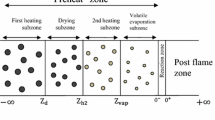

Gao W, Mogi T, Yu J, et al. Flame propagation mechanisms in dust explosions. J Loss Prev Process Ind. 2015;36:186–94.

Bidabadi M, Biouki SA, Afzalabadi A, et al. Modeling propagation and extinction of aluminum dust particles in a reaction medium with spatially uniform distribution of particles. J Therm Anal Calorim. 2017;129(3):1855–64.

Zhang H, Chen X, Xie T, et al. Effects of reduced oxygen levels on flame propagation behaviors of starch dust deflagration. J Loss Prev Process Ind. 2018;54:146–52.

Li X, Choi M, Kim K, et al. Effects of pulverized coal particle size on flame structure in a methane-assisted swirl burner. Fuel. 2019;242:68–76.

Zhang X, Yu J, Gao W, et al. Effects of particle size distributions on PMMA dust flame propagation behaviors. Powder Technol. 2017;317(15):197–208.

Bidabadi M, Haghiri A, Rahbari A. The effect of Lewis and Damköhler numbers on the flame propagation through micro-organic dust particles. Int J Therm Sci. 2009;49(3):534–42.

Acknowledgements

The authors wish to acknowledge the support to this work by the National Key Research and Development Program of China (No. 2018YFC0808500), the National Natural Science Foundation of China (No. 51804237), the Natural Science Foundation of Hubei Province of China (No. 2018CFB207) and the Fundamental Research Funds for the Central Universities (WUT: 2019IVB035).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nan, X., Dai, H., Chen, X. et al. Scale effect of porous mesh on the inhibition mechanism of wheat dust flame. J Therm Anal Calorim 146, 2291–2302 (2021). https://doi.org/10.1007/s10973-021-10745-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10745-y