Abstract

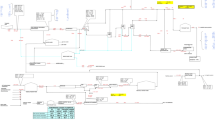

Zero liquid discharge (ZLD) has shown to be a promising technology to recycle water with good quality. The ZLD objective is to purify the water from all the liquid waste. The ZLD approach is concentrated on reducing wastewater for possible reuse. In conventional ZLD systems, thermal processes are fundamental. The biggest challenge to implement thermal ZLD systems widely is its intensive energy consumption. As a solution, thermal ZLD systems are integrated with membrane-based reverse osmosis (RO) technology to reduce both capital and operational costs. This study, therefore, focuses on the optimizing a RO/thermal ZLD system based on one of the most important parameters of design—the salinity of the reject brine of evaporator. To give more practical aspect to the results, solution is based realistic design data of a petrochemical complex as the producer of ammonia (2050 ton day−1) and urea (3250 ton day−1). Results show that increasing the salinity of brine stream in evaporator reduces the total required heating surface area of the ZLD plant as well as its required power. This decrease is evident at lower amounts of Xb, but the rate is lowered with increasing of this parameter. So, further increase in Xb does not have much effect on reducing the total heating surface area and power consumption. It means that there is an optimum amount of Xb which can be selected for different applications.

Similar content being viewed by others

Abbreviations

- \(B\) :

-

Brine mass flow (t h−1)

- \(C_{\text{fw}}\) :

-

Feed concentration (kg kg−1)

- \(M_{\text{TP}}\) :

-

Product slurry concentration (kg m−3)

- \(\rho_{\text{SL}}\) :

-

Density of slurry (kg m−3)

- \(C_{\text{Pf}}\) :

-

Specific heat of feed (kJ kg−1 k−1)

- \(\bar{T}\) :

-

Evaporator entry temperature (°C)

- \(T_{\text{f}}\) :

-

Feed temperature (°C)

- \(V\) :

-

Recovered water mass flow (t h−1)

- \(\lambda\) :

-

Latent heat for vaporization (kJ kg−1)

- \(C_{\text{PSL}}\) :

-

Specific heat of slurry (kJ kg−1 k−1)

- \(\rho_{\text{v}}\) :

-

Vapor density (kg m−3)

- \(u_{\text{v}}\) :

-

Vapor velocity (m s−1)

- \(D_{\text{v}}\) :

-

Diameter of cylinder (m)

- \(\mu_{\text{SL}}\) :

-

Dynamic viscosity of Slurry (Ns m−2)

- \(h\) :

-

Required hydrostatic head (m)

- \(\Delta T_{\text{LMTD}}\) :

-

Logarithmic mean temperature difference

- \(M_{\text{d}}\) :

-

Mass flow rate of distillate (kg s−1)

- \(M_{\text{f}}\) :

-

Mass flow rate of feed (kg s−1)

- \(T_{\text{b}}\) :

-

Brine boiling temperature (°C)

- \(T_{\text{d}}\) :

-

Condensed vapor temperature (°C)

- \(T_{\text{s}}\) :

-

Range of compressed vapor temperature (°C)

- \(\lambda_{\text{b}}\) :

-

Latent heat for brine (kJ kg−1)

- \(\lambda_{\text{d}}\) :

-

Latent heat for distillate (kJ kg−1)

- \(C_{\text{p}}\) :

-

Heat capacity (kJ kg−1 k−1)

- \(C_{\text{pv}}\) :

-

Heat capacity of the vapor (kJ kg−1 k−1)

- \(U_{\text{b}}\) :

-

Overall heat transfer coefficient of brine HE (kW m−2 k)

- \(U_{\text{d}}\) :

-

Overall heat transfer coefficient of distillate HE (kW m−2 k)

- \(\gamma\) :

-

Compressibility factor

- \(X_{\text{b}}\) :

-

Salinity of reject brine (ppm)

- \(X_{\text{f}}\) :

-

Feed stream salinity (ppm)

- \(\lambda_{\text{c}}\) :

-

Latent heat for compressor (kJ kg−1)

- \(M_{\text{c}}\) :

-

Mass flow rate in compressor (kg s−1)

- \(U_{\text{c}}\) :

-

Overall heat transfer coefficient in compressor (kW m−2 k)

- \(U_{\text{e}}\) :

-

Overall heat transfer coefficient in evaporator (kW m−2 k)

- \(\eta\) :

-

Efficiency of the vapor compressor

References

Ghorbani B, Shirmohammadi R, Amidpour M, Inzoli F, Rocco M. Design and thermoeconomic analysis of a multi-effect desalination unit equipped with a cryogenic refrigeration system. Energy Convers Manag. 2019;202:112208. https://doi.org/10.1016/j.enconman.2019.112208.

Ghorbani B, Miansari M, Zendehboudi S, Hamedi M-H. Exergetic and economic evaluation of carbon dioxide liquefaction process in a hybridized system of water desalination, power generation, and liquefied natural gas regasification. Energy Convers Manag. 2020;205:112374. https://doi.org/10.1016/j.enconman.2019.112374.

Ghorbani B, Ebadi SM. Economic evaluation of saline water desalination system in Qeshm Island using using flat plate solar collectors and phase change material. Iran J Ecohydrol. 2020;7:891–906. https://doi.org/10.22059/ije.2020.306023.1352.

Wang Y, Kamari ML, Haghighat S, et al. Electrical and thermal analyses of solar PV module by considering realistic working conditions. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09752-2.

Ghorbani B, Mehrpooya M, Sadeghzadeh M. Developing a tri-generation system of power, heating, and freshwater (for an industrial town) by using solar flat plate collectors, multi-stage desalination unit, and Kalina power generation cycle. Energy Convers Manag. 2018;165:113–26. https://doi.org/10.1016/J.ENCONMAN.2018.03.040.

Naeimi A, Ahmadi MH, Sadeghzadeh M, Kasaeian A. Optimum arrangement of two-stage plug and concentrate recycling RO systems using thermodynamic and exergy analysis. Int J Numer Methods Heat Fluid Flow. 2019. https://doi.org/10.1108/HFF-12-2018-0766.

Grant SB, Saphores JD, Feldman DL, Hamilton AJ, Fletcher TD, Cook PLM, et al. Taking the “waste” out of “wastewater” for human water security and ecosystem sustainability. Science (80-). 2012;337:681–6. https://doi.org/10.1126/science.121685210.1126/science.1216852.

Pramanik BK, Shu L, Jegatheesan V. A review of the management and treatment of brine solutions. Environ Sci Water Res Technol. 2017;3:625–58. https://doi.org/10.1039/C6EW00339G.

Schwarzenbach RP, Egli T, Hofstetter TB, von Gunten U, Wehrli B. Global water pollution and human health. Annu Rev Environ Resour. 2010;35:109–36. https://doi.org/10.1146/annurev-environ-100809-125342.

Ebrahimi A, Ghorbani B, Ziabasharhagh M, Rahimi MJ. Biomass gasification process integration with Stirling engine, solid oxide fuel cell, and multi-effect distillation. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-10314-9.

GWI. From Zero to Hero—The Rise of ZLD n.d. https://www.globalwaterintel.com/global-water-intelligence-agazine/10/12/marketinsight/from-zero-to-hero-the-rise-of-zld. Accessed 15 Oct 2018.

Loucks DP. Sustainable water resources management. Water Int. 2000;25:3–10. https://doi.org/10.1080/02508060008686793.

van Linden N, Shang R, Stockinger G, Heijman B, Spanjers H. Separation of natural organic matter and sodium chloride for salt recovery purposes in zero liquid discharge. Water Resour Ind. 2020;23:100117. https://doi.org/10.1016/j.wri.2019.100117.

Byers B. Zero discharge. I: a systematic approach to water reuse. Chem Eng. 1995;102:96–100.

Tong T, Elimelech M. The global rise of zero liquid discharge for wastewater management: drivers, technologies, and future directions. Environ Sci Technol. 2016;50:6846–55. https://doi.org/10.1021/acs.est.6b01000.

Kariman H, Hoseinzadeh S, Shirkhani A, Heyns PS, Wannenburg J. Energy and economic analysis of evaporative vacuum easy desalination system with brine tank. J Therm Anal Calorim. 2020;140:1935–44. https://doi.org/10.1007/s10973-019-08945-8.

Ghaffour N, Missimer TM, Amy GL. Technical review and evaluation of the economics of water desalination: current and future challenges for better water supply sustainability. Desalination. 2013;309:197–207. https://doi.org/10.1016/j.desal.2012.10.015.

Mickley M. Survey of high-recovery and zero liquid discharge technologies for water utilities. Surv High-Recovery Zero Liq Disch Technol Water Util 2008.

Shaffer D, Chavez L, Ben-Sasson M, Romero-Vargas Castrillón S, Yip N, Elimelech M. Desalination and reuse of high-salinity shale gas produced water: drivers, technologies, and future directions. Environ Sci Technol. 2013;47:9569–83. https://doi.org/10.1021/es401966e.

Brandhuber PJ. Pilot testing of membrane zero liquid discharge for drinking water systems. Water Intell Online. 2014. https://doi.org/10.2166/9781780406688.

Yaqub Muhammad, Lee W. Zero-liquid discharge (ZLD) technology for resource recovery from wastewater: a review. Sci Total Environ. 2019;681:551–63. https://doi.org/10.1016/j.scitotenv.2019.05.062.

Akbari Vakilabadi M, Bidi M, Najafi AF, Ahmadi MH. Energy, exergy analysis and performance evaluation of a vacuum evaporator for solar thermal power plant zero liquid discharge systems. J Therm Anal Calorim. 2020;139:1275–90. https://doi.org/10.1007/s10973-019-08463-7.

Oren Y, Korngold E, Daltrophe N, Messalem R, Volkman Y, Aronov L, et al. Pilot studies on high recovery BWRO-EDR for near zero liquid discharge approach. Desalination. 2010;261:321–30. https://doi.org/10.1016/j.desal.2010.06.010.

Elimelech M, Phillip W. The future of seawater desalination: energy, technology, and the environment. Science. 2011;333:712–7. https://doi.org/10.1126/science.1200488.

Bond R, Veerapaneni S. Zeroing in on ZLD technologies for inland desalination. J AWWA. 2008;100:76–89. https://doi.org/10.1002/j.1551-8833.2008.tb09722.x.

Maleki A, Pourfayaz F, Ahmadi MH. Design of a cost-effective wind/photovoltaic/hydrogen energy system for supplying a desalination unit by a heuristic approach. Sol Energy. 2016;139:666–75. https://doi.org/10.1016/j.solener.2016.09.028.

Wu B, Maleki A, Pourfayaz F, Rosen MA. Optimal design of stand-alone reverse osmosis desalination driven by a photovoltaic and diesel generator hybrid system. Sol Energy. 2018;163:91–103. https://doi.org/10.1016/j.solener.2018.01.016.

Peng W, Maleki A, Rosen MA, Azarikhah P. Optimization of a hybrid system for solar-wind-based water desalination by reverse osmosis: comparison of approaches. Desalination. 2018;442:16–31. https://doi.org/10.1016/j.desal.2018.03.021.

Benaissa M, Menni Y, Chamkha A, Lorenzini G, Noureddine K, Bibi-Triki N, et al. Effect of various physical parameters on the productivity of the hybrid distiller—in the time of distillation extension at night. Eur J Electr Eng. 2019;21:265–71.

Ettouney H. Design of single-effect mechanical vapor compression. Desalination. 2006;190:1–15. https://doi.org/10.1016/j.desal.2005.08.003.

Tavare N. Industrial crystallization : process simulation analysis and design. Berlin: Springer; 1995.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mohammadi, S., Ahmadi, M.H. & Ehsani, R. Optimization of combined Reverse Osmosis: thermal Zero Liquid Discharge system parameters for an Ammonia and Urea production complex. J Therm Anal Calorim 144, 1863–1871 (2021). https://doi.org/10.1007/s10973-020-10523-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10523-2