Abstract

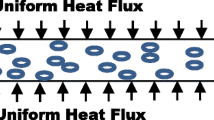

In the case of flow boiling, the prediction of vapour fraction in the horizontal microchannel is a severe issue using the numerical technique. Two-dimensional numerical simulation was carried out for the flow boiling in microchannels with different boiling models (VOF, MM and EM). This study is one of the first studies that report a numerical assessment of these three models. Numerical simulations have done with water as a working fluid. The different mass flow rates (1.586 × 10−6 kg−1, 2.541 × 10−6 kg s−1, 3.112 × 10−6 kg s−1) and different heat fluxes (300 kW m−2, 400 kW m−2, 500 kW m−2) with different flow boiling models are used. The vapour fraction estimation was done by image processing in MATLAB program and compared with various mass flow rate and heat flux. It well validated with the published literature. An onset of nucleate boiling point position is estimated with same time step, and uncertainties of the numerical simulation were less than 2.5% at the lowest mass flow rate. The result shows that the vapour fraction in the microchannel increases with an increase in mass flow rate and heat flux. Similarly, the model’s heat transfer rate compared with the same mass flow rate and heat flux. The mixture model is best to estimate of vapour fraction compared to other models. The estimated vapour fraction values are 0.2950, 0.1848 and 0.1726 for MM, VOF and EM respectively. The heat transfer coefficient value for the mixture model is 20.381 kW m−2. Its value was very higher compared to other models because of the increase in fluid temperature difference at constant heat flux. This comparison can be used to provide design guidelines by selecting proper model for simulation work and minimize the complexity and wastage time.

Graphic abstract

Similar content being viewed by others

Abbreviations

- VOF:

-

Volume of fluid

- MM:

-

Mixture model

- EM:

-

Eulerian model

- PISO:

-

Pressure implicit with splitting operations

- PRESTO:

-

Pressure staggering options

- QUICK:

-

Quadratic upstream interpolation for convective kinematics

- RPI:

-

Rensselaer Polytechnical Institute (RPI) wall boiling model

- ONB:

-

Onset of nucleate boiling

- CHF:

-

Critical heat flux

- M qp :

-

Mass transfer from phase q to phase p (kg s−1)

- M pq :

-

Mass transfer from phase p to phase q (kg s−1)

- E q :

-

Energy of the phase (J s−1)

- K eff :

-

Effective thermal conductivity (W m−1 K−1)

- V m :

-

Mass averaged velocity (m s−1)

- F :

-

Body force (N)

- h k :

-

Sensible enthalpy for phase (kJ kg−1)

- E :

-

Energy (J s−1)

- V dr :

-

Drift velocity for secondary phase k (m s−1)

- F lift :

-

Lift force (N)

- S q :

-

Sources of enthalpy (J kg−1)

- Q pq :

-

Intensity heat phase p to phase q (J s−1)

- C pl :

-

Liquid specific heat (J kg−1 K−1)

- C pv :

-

Vapour specific heat (J kg−1 K−1)

- C ps :

-

Specific heat (J kg−1 K−1)

- h lv :

-

Enthalpy (kJ kg−1)

- k l :

-

Liquid thermal conductivity (W m−1 K−1)

- k v :

-

Vapour thermal conductivity (W m−1 K−1)

- k s :

-

Solid thermal conductivity (W m−1 K−1)

- α q :

-

Phase volume fraction (–)

- α k :

-

Volume fraction of phase K (–)

- μ :

-

Dynamics viscosity of phase (N s m−2)

- μ l :

-

Liquid dynamics viscosity (N s m−2)

- μ V :

-

Vapour dynamics viscosity (N s m−2)

- µ m :

-

Viscosity of the mixture (N s m−2)

- ρ :

-

Density of phases (kg m−3)

- ρ m :

-

Mixture density (kg m−3)

- ρ l :

-

Liquid density (kg m−3)

- ρ v :

-

Vapour density (kg m−3)

- ρ s :

-

Solid density (kg m−3)

- σ :

-

Surface tension (N m−1)

- ρ r :

-

ρl/ρv (–)

- x :

-

Vapour quality (–)

- α :

-

Void fraction (–)

- μ r :

-

μl/μv (–)

- X r :

-

(1 − x)/x (–)

- X tt :

-

Lockhart–Martinelli correlating parameter (–)

- ϕ :

-

Diameter (m)

References

Deb UK, Chayantrakom K, Lenbury Y. Comparison of single phase and two phase flow dynamics in the HLTP for microalgae culture. Int J Math Comput Simul. 2012;6:496–502.

Shkarah AJ, Sulaiman MY, Bin MR, Ayob HJ. A 2D numerical simulation for nucleation in flow boiling in microchannel heat sink. Sci Int. 2015;27:365–9.

Harirchian T, Garimella SV. Effects of channel dimension, heat flux, and mass flux on flow boiling regimes in microchannels. Int J Multiph Flow. 2009;35:349–62. https://doi.org/10.1016/j.ijmultiphaseflow.2009.01.003.

Sharma JP, Sharma A, Jilte RD, Kumar R, Ahmadi MH. A study on thermo hydraulic characteristics of fluid flow through microchannels. J Therm Anal Calorim. 2019;1:1–32. https://doi.org/10.1007/s10973-019-08741-4.

Prajapati YK, Bhandari P. Flow boiling instabilities in microchannels and their promising solutions—a review. Exp Therm Fluid Sci. 2017;88:576–93. https://doi.org/10.1016/j.expthermflusci.2017.07.014.

Kumar P. Numerical investigation of fluid flow and heat transfer in trapezoidal microchannel with groove structure. Int J Therm Sci. 2019;136:33–43. https://doi.org/10.1016/j.ijthermalsci.2018.10.006.

Narendran G, Natarajan G, Perumal DA. A review on recent advances in microchannel heat sink configurations. Recent Pat Mech Eng. 2018;11:190–215.

Abdel Aziz O, Aute V, Radermacher R. Effect of void fraction model on the dynamic performance of moving boundary heat exchanger. Int Refrig Air Cond. 2008;1:1–8.

Colombo M, Thakrar R, Fairweather M, Walker SP. Assessment of semi-mechanistic bubble departure diameter modelling for the CFD simulation of boiling flows. Nucl Eng Des. 2019;344:15–27. https://doi.org/10.1016/j.nucengdes.2019.01.014.

Xin RC, Awwad A, Dong ZF, Ebadian MA. An experimental study of single-phase and two-phase flow pressure drop in annular helicoidal pipes. Int J Heat Fluid Flow. 1997;18:482–8.

Lu C, Kong R, Qiao S, Larimer J, Kim S, Bajork S, Tien K. Frictional pressure drop analysis for horizontal and vertical air-water two phase flows in different pipe sizes. Nucl Eng Des. 2018;332:147–61. https://doi.org/10.1016/j.nucengdes.2018.03.036.

Choi K, Pamitrana AS, Young C, Taek J. Boiling heat transfer of R-22, R-134a, and CO2 in horizontal smooth mini channels. Int J Refrig. 2007;30:1336–46. https://doi.org/10.1016/j.ijrefrig.2007.04.007.

Chen S, Liu D, Xiao Y, Gu H. Experimental study on onset of nucleate boiling and flow boiling heat transfer in a 5 × 5 rod bundle at low flow rate. Int J Heat Mass Transf. 2019;137:727–39. https://doi.org/10.1016/j.ijheatmasstransfer.2019.03.156.

Talley JD, Worosz T, Kim S. Characterization of horizontal air-water two phase flow in a round pipe part II: measurement of local two phase parameters in bubbly flow. Int J Multiph Flow. 2015;76:223–36. https://doi.org/10.1016/j.ijmultiphaseflow.2015.06.012.

Kneer A, Wirtz M, Laufer T, Nestler B, Barbe S. Experimental investigations on pressure loss and heat transfer of two phase carbon dioxide flow in a horizontal circular pipe of 0.4 mm diameter. Int J Heat Mass Transf. 2018;119:828–40. https://doi.org/10.1016/j.ijheatmasstransfer.2017.11.146.

Zhang X, ChunLi R, Zheng Q. Analysis and simulation of high-power LED array with microchannel heat sink. Berlin: Springer; 2013. p. 191–5. https://doi.org/10.1007/s40436-013-0027-0.

Soh GY, Yeoh GH, Timchenko V. Improved volume of fluid (VOF) model for predictions of velocity fields and droplet lengths in microchannels. Flow Meas Inst. 2016;51:105–15. https://doi.org/10.1016/j.flowmeasinst.2016.09.004.

Xie X, Liu H, He C, Zhang B, Chen Q, Pan M. Deciphering the heat and mass transfer behaviors of staggered tube bundles in a closed wet cooling tower using a 3-D VOF model. Appl Therm Eng. 2019;161:1–17. https://doi.org/10.1016/j.applthermaleng.2019.114202.

Setyawan A, Indarto I, Aan D. Experimental investigations of the circumferential liquid film distribution of air-water annular two phase flow in a horizontal pipe. Exp Therm Fluid Sci. 2017;85:95–118. https://doi.org/10.1016/j.expthermflusci.2017.02.026.

Alugoju UK, Manmode R, Dubey SK, Javed A. Numerical modelling of flow boiling in expanding micro channel with non-uniform heat flux. J Phys: Conf Ser. 2019;1:1–9. https://doi.org/10.1088/1742-6596/1276/1/012045.

Lorbek L, Kuhelj A, Dular M, Kitanovski A. Two phase flow patterns in adiabatic refrigerant flow through capillary tubes. Int J Refrig. 2020;1:1–19. https://doi.org/10.1016/j.ijrefrig.2020.02.030.

Liu B, Liu X, Lu C, Godbole A, Michal G, Tieu AK. A CFD decompression model for CO2 mixture and the influence of non-equilibrium phase transition. Appl Energy. 2018;2018(227):516–24. https://doi.org/10.1016/j.apenergy.2017.09.016.

Braz Filho FA, Ribeiro GB, Caldeira AD. Prediction of sub cooled flow boiling characteristics using two-fluid Eulerian CFD model. Nucl Eng Des. 2016;308:30–7. https://doi.org/10.1016/j.nucengdes.2016.08.016.

Li H, Unekar H, Vasquez SA, Muralikrishnan R. Prediction of boiling and critical heat flux using an Eulerian multiphase boiling model. IMECE. 2011;2011:1–14.

Mimouni S, Benguigui W, Lavieville J, Merigoux N, Guingo M, Baudry C, Marfaing O. New nucleation boiling model devoted to high pressure flows. In: ICMF 2016—9th international conference on multiphase flow; 2016. p. 1–6.

Qiu JT, Yang CJ, Dong XQ, Wang ZL, Li W, Noblesse F. Numerical simulation and uncertainty analysis of an axial-flow water jet pump. J Mar Sci Eng. 2018;2018(6):71. https://doi.org/10.3390/jmse6020071.

Ramalingam K, Kandasamy A, Balasubramanian D, Palani M, Subramanian T, Varuvel EG, Viswanathan K. Forecasting of an ANN model for predicting behaviour of diesel engine energised by a combination of two low viscous biofuels. Environ Sci Pollut Res. 2020;27:24702–22. https://doi.org/10.1007/s11356-019-06222-7.

Thiyagarajan S, Sonthalia A, Geoa VE, Prakash T, Karthickeyan V, Ashokd B, Nanthagopal K, Dhinesh B. Effect of manifold injection of methanol/n-pentanol in safflower biodiesel fuelled CI engine. Fuel. 2020;261:1–9. https://doi.org/10.1016/j.fuel.2019.116378.

Acknowledgements

The author would like to acknowledge CFD Centre, SRMIST Kattankulathur for numerical simulations provides the simulation facility. Besides, the authors would like to thank the Management, SRMIST Kattankulathur for their continued support.

Funding

This study was supported by CFD Center, Department of mechanical engineering, Kattankulathur, Chengalpattu District - 603 203, Tamil Nadu, India.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jeyaraj, T., Pankaj, K. Numerical investigation of flow boiling characteristics of water in a rectangular microchannel. J Therm Anal Calorim 147, 579–598 (2022). https://doi.org/10.1007/s10973-020-10231-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10231-x