Abstract

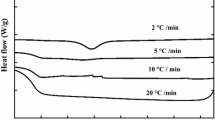

A model is proposed to fit differential scanning calorimetry (DSC) isothermal crystallization curves obtained from the molten state at different temperatures. A commercial 3D printing polylactic acid (PLA) sample is used to test the method. All DSC curves are fitted by a mixture of two simultaneous functions, one of them being a time derivative generalized logistic accounting for the exothermic effect and the other, a generalized logistic, accounting for the baseline. There is a rate parameter, which is allowed to vary across different temperatures. The rate parameter values obtained at different temperatures were jointly explained as a result of three crystallization processes, each one defined by a characteristic crystallization time, a characteristic temperature, and a dispersion or width factor. Apart from the very good fittings obtained at all temperatures, the results agree with the existence of a few crystal forms of PLA, which were demonstrated by other authors. Thus, the main significance of this work consists in providing a new approach in order to mathematically describe the isothermal crystallization kinetics of a polymer from the melt. Such a kinetic description is needed in order to predict the extent of a crystallization process as a function of time at any isothermal temperature. The approach used here allows to understand the overall crystallization of the PLA used in this work as the sum of three crystallization processes, each of them corresponding to a different crystal form. Each experimental crystallization exotherm, which may include more than one crystal form, can be reproduced by a generalized logistic function. The overall rate factor at a given temperature is the weighted sum of the rate factors of the different crystal structures at that temperature. The rate factor of each of these three processes is described by a Gaussian function whose parameters are a crystallization time, a characteristic temperature and a temperature dispersion factor. Therefore, the crystallization rate for each crystal form can be interpreted as a relative likelihood to crystallize at a given temperature. On the other hand, the characteristic crystallization time parameter refers to the time needed for a given crystal structure to be formed at the temperature at which the relative likelihood to crystallize of that form is highest.

Similar content being viewed by others

References

Gracia-Fernández CA, Gómez-Barreiro S, Álvarez-García A, López-Beceiro J, Álvarez-García B, Zaragoza-Fernández S, et al. Thermal characterization of poly-l-lactide by dielectric analysis and modulated DSC. J Therm Anal Calorim. 2014;116:1273–8.

Gracia-Fernández CA, Gómez-Barreiro S, López-Beceiro J, Naya S, Artiaga R. New approach to the double melting peak of poly(l-lactic acid) observed by DSC. J Mater Res. 2012;27:1379–82.

Wei Z, Song P, Zhou C, Chen G, Chang Y, Li J, et al. Insight into the annealing peak and microstructural changes of poly(l-lactic acid) by annealing at elevated temperatures. Polymer. 2013;54:3377–84.

López-Beceiro J, Gracia-Fernández C, Artiaga R. A kinetic model that fits nicely isothermal and non-isothermal bulk crystallizations of polymers from the melt. Eur Polym J. http://linkinghub.elsevier.com/retrieve/pii/S0014305713002140.

Supaphol P. Crystallization and melting behavior in syndiotactic polypropylene: origin of multiple melting phenomenon. J Appl Polym Sci. 2001;82:1083–97.

Janković B. The pyrolysis process of wood biomass samples under isothermal experimental conditions-energy density considerations: application of the distributed apparent activation energy model with a mixture of distribution functions. Cellulose. 2014;21:2285–314.

Janković B, Adnađević B, Jovanović J. Application of model-fitting and model-free kinetics to the study of non-isothermal dehydration of equilibrium swollen poly (acrylic acid) hydrogel: thermogravimetric analysis. Thermochim Acta. 2007;452:106–15.

Li Y, Duan L, Cheng L, Yang Y, Li Y, Cheng Y, et al. Thermal analysis and crystallization kinetics of polyurethane. J Therm Anal Calorim. 2019;135:2843–8.

Vyazovkin S. Chapter 13 isoconversional kinetics. Elsevier; 2008. p. 503–38. http://linkinghub.elsevier.com/retrieve/pii/S1573437408800167.

Friedman HL. Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J Polym Sci Part C Polym Symp. 1964;6:183–95.

Starink MJ. The determination of activation energy from linear heating rate experiments: a comparison of the accuracy of isoconversion methods. Thermochim Acta. 2003;404:163–76.

Dubaj T, Cibulková Z, Šimon P. An incremental isoconversional method for kinetic analysis based on the orthogonal distance regression. J Comput Chem. 2015;36:392–8.

Šimon P. Isoconversional methods. J Therm Anal Calorim. 2004;76:123–32.

Hou F, Martin JD, Dill ED, Folmer JCW, Josey AA. Transition zone theory of crystal growth and viscosity. Chem Mater. 2015;27:3526–32.

Dill ED, Josey AA, Folmer JCW, Hou F, Martin JD. Experimental determination of the crystallization phase-boundary velocity in the halozeotype CZX-1. Chem Mater. 2013;25:3932–40.

Dill ED, Folmer JCW, Martin JD. Crystal growth simulations to establish physically relevant kinetic parameters from the empirical Kolmogorov–Johnson–Mehl–Avrami model. Chem Mater. 2013;25:3941–51.

Hillis B, Losey B, Weng J, Ghaleb N, Hou F, Martin J. From rate measurements to mechanistic data for condensed matter reactions: a case study using the crystallization of [Zn(OH2)6][ZnCl4]. Crystals. 2016;7:11.

Kowalczyk M, Piorkowska E, Kulpinski P, Pracella M. Mechanical and thermal properties of PLA composites with cellulose nanofibers and standard size fibers. Compos Part Appl Sci Manuf. 2011;42:1509–14.

Supaphol P, Spruiell JE. Isothermal melt- and cold-crystallization kinetics and subsequent melting behavior in syndiotactic polypropylene: a differential scanning calorimetry study. Polymer. 2001;42:699–712.

Refaa Z, Boutaous M, Xin S, Siginer DA. Thermophysical analysis and modeling of the crystallization and melting behavior of PLA with talc: kinetics and crystalline structures. J Therm Anal Calorim. 2017;128:687–98.

Kalish JP, Aou K, Yang X, Hsu SL. Spectroscopic and thermal analyses of α′ and α crystalline forms of poly(l-lactic acid). Polymer. 2011;52:814–21.

Nelder JA, Mead R. A simplex method for function minimization. Comput J. 1965;7:308–13.

Wojdyr M. Fityk: a general-purpose peak fitting program. J Appl Crystallogr. 2010;43:1126–8.

Liao Y, Liu C, Coppola B, Barra G, Di Maio L, Incarnato L, et al. Effect of porosity and crystallinity on 3D printed PLA properties. Polymers. 2019;11:1487.

Müller AJ, Ávila M, Saenz G, Salazar J. CHAPTER 3. Crystallization of PLA-based materials. In: Jiménez A, Peltzer M, Ruseckaite R, editors. Polymer science, series. Cambridge: Royal Society of Chemistry; 2014, p. 66–98. http://ebook.rsc.org/?DOI=10.1039/9781782624806-00066.

Supaphol P, Spruiell JE, Lin J-S. Isothermal melt crystallization and melting behaviour of syndiotactic polypropylene. Polym Int. 2000;49:1473–82.

Acknowledgements

This research has been supported by the Spanish Ministry of Science and Innovation, MINECO Grant MTM2017–82724-R.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Díaz-Díaz, A.M., López-Beceiro, J., Li, Y. et al. Crystallization kinetics of a commercial poly(lactic acid) based on characteristic crystallization time and optimal crystallization temperature. J Therm Anal Calorim 145, 3125–3132 (2021). https://doi.org/10.1007/s10973-020-10081-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10081-7