Abstract

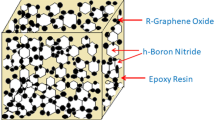

In this work, phosphomolybdic acid (PMoA) was used as a kind of eco-friendly flame retardant precursor. Then, a green intrinsic flame retardant was successfully prepared by chemically modifying PMoA with imidazolium (IM), which can be well dispersed in epoxy matrix without using any solvent. DSC results demonstrated that IM-PMoA can chemically react with epoxy monomer under heating with a moderate heat release, which greatly reduced the migration resistance of PMoA in water (1.2871% vs. 0.0439%). Meanwhile, curing kinetics indicates EP/IM-PMoA composites have higher activation energy (98.06 kJ mol−1) than pure EP (75.48 kJ mol−1). Besides, epoxy composite can pass V-0 rating with 8 mass% IM-PMoA addition. Compared to pure epoxy, the obvious decrease in the values of peak heat release rate and total smoke release were 37.78% and 31.03%, respectively. In addition, Raman spectrum indicated that the residual carbon is highly graphitized, which may be attributed to the superb catalytic carbonation ability of PMoA. The high-quality char layer can be used as physical barrier for inhibiting the heat diffusion and degradant transfer. As a result, excellent flame retardant and smoke suppression properties were achieved. This work provides a new idea to prepare a green intrinsic flame retardant for epoxy based on imidazolium.

Similar content being viewed by others

References

Park YT, Qian Y, Chan C, Suh T, Nejhad MG, Macosko CW, et al. Epoxy toughening with low graphene loading. Adv Func Mater. 2015;25(4):575–85. https://doi.org/10.1002/adfm.201402553.

Wang S, Ma S, Xu C, Liu Y, Dai J, Wang Z, et al. Vanillin-derived high-performance flame retardant epoxy resins: facile synthesis and properties. Macromolecules. 2017;50(5):1892–901. https://doi.org/10.1021/acs.macromol.7b00097.

Faye I, Decostanzi M, Ecochard Y, Caillol S. Eugenol bio-based epoxy thermosets: from cloves to applied materials. Green Chem. 2017;19(21):5236–42. https://doi.org/10.1039/c7gc02322g.

Chen C, Qiu S, Cui M, Qin S, Yan G, Zhao H, et al. Achieving high performance corrosion and wear resistant epoxy coatings via incorporation of noncovalent functionalized graphene. Carbon. 2017;114:356–66. https://doi.org/10.1016/j.carbon.2016.12.044.

Ai L, Chen S, Zeng J, Yang L, Liu P. Synergistic flame retardant effect of an intumescent flame retardant containing boron and magnesium hydroxide. ACS Omega. 2019;4(2):3314–21. https://doi.org/10.1021/acsomega.8b03333.

Kong Q, Wu T, Zhang J, Wang D-Y. Simultaneously improving flame retardancy and dynamic mechanical properties of epoxy resin nanocomposites through layered copper phenylphosphate. Compos Sci Technol. 2018;154:136–44. https://doi.org/10.1016/j.compscitech.2017.10.013.

Li Z, Zhang J, Dufosse F, Wang D-Y. Ultrafine nickel nanocatalyst-engineering of an organic layered double hydroxide towards a super-efficient fire-safe epoxy resin via interfacial catalysis. J Mater Chem A. 2018;6(18):8488–98. https://doi.org/10.1039/c8ta00910d.

Shao Z-B, Zhang M-X, Li Y, Han Y, Ren L, Deng C. A novel multi-functional polymeric curing agent: synthesis, characterization, and its epoxy resin with simultaneous excellent flame retardance and transparency. Chem Eng J. 2018;345:471–82. https://doi.org/10.1016/j.cej.2018.03.142.

Zhang L, Yang Y, Ziaee MA, Lu K, Wang R. Nanohybrid of carbon quantum dots/molybdenum phosphide nanoparticle for efficient electrochemical hydrogen evolution in alkaline medium. ACS Appl Mater Interfaces. 2018;10(11):9460–7. https://doi.org/10.1021/acsami.8b00211.

Zhang B, Asakura H, Zhang J, Zhang J, De S, Yan N. Stabilizing a platinum1 single-atom catalyst on supported phosphomolybdic acid without compromising hydrogenation activity. Angew Chem Int Ed Engl. 2016;55(29):8319–23. https://doi.org/10.1002/anie.201602801.

Li JS, Wang Y, Liu CH, Li SL, Wang YG, Dong LZ, et al. Coupled molybdenum carbide and reduced graphene oxide electrocatalysts for efficient hydrogen evolution. Nat Commun. 2016;7:11204. https://doi.org/10.1038/ncomms11204.

Song J, Luo Z, Britt DK, Furukawa H, Yaghi OM, Hardcastle KI, et al. A multiunit catalyst with synergistic stability and reactivity: a polyoxometalate-metal organic framework for aerobic decontamination. J Am Chem Soc. 2011;133(42):16839–46. https://doi.org/10.1021/ja203695h.

Ibrahim M, Lan Y, Bassil BS, Xiang Y, Suchopar A, Powell AK, et al. Hexadecacobalt(II)-containing polyoxometalate-based single-molecule magnet. Angew Chem Int Ed Engl. 2011;50(20):4708–11. https://doi.org/10.1002/anie.201100280.

Compain JD, Mialane P, Dolbecq A, Mbomekalle IM, Marrot J, Secheresse F, et al. Iron polyoxometalate single-molecule magnets. Angew Chem Int Ed Engl. 2009;48(17):3077–81. https://doi.org/10.1002/anie.200900117.

Lyu F, Zeng S, Sun Z, Qin N, Cao L, Wang Z, et al. Lamellarly stacking porous N, P Co-Doped Mo2 C/C nanosheets as high performance anode for lithium-ion batteries. Small. 2019;15(8):e1805022. https://doi.org/10.1002/smll.201805022.

Chen JJ, Symes MD, Cronin L. Highly reduced and protonated aqueous solutions of [P2W18O62](6-) for on-demand hydrogen generation and energy storage. Nat Chem. 2018;10(10):1042–7. https://doi.org/10.1038/s41557-018-0109-5.

Ji G, Wang Y, Luo Q, Han K, Xie M, Zhang L, et al. Fully coated semitransparent organic solar cells with a doctor-blade-coated composite anode buffer layer of phosphomolybdic acid and PEDOT:PSS and a spray-coated silver nanowire top electrode. ACS Appl Mater Interfaces. 2018;10(1):943–54. https://doi.org/10.1021/acsami.7b13346.

Taghavi M, Tabatabaee M, Ehrampoush MH, Ghaneian MT, Afsharnia M, Alami A, et al. Synthesis, characterization and photocatalytic activity of TiO2/ZnO-supported phosphomolybdic acid nanocomposites. J Mol Liq. 2018;249:546–53. https://doi.org/10.1016/j.molliq.2017.11.031.

Kolesov VA, Fuentes-Hernandez C, Chou WF, Aizawa N, Larrain FA, Wang M, et al. Solution-based electrical doping of semiconducting polymer films over a limited depth. Nat Mater. 2017;16(4):474–80. https://doi.org/10.1038/nmat4818.

Pu YJ, Chiba T, Ideta K, Takahashi S, Aizawa N, Hikichi T, et al. Fabrication of organic light-emitting devices comprising stacked light-emitting units by solution-based processes. Adv Mater. 2015;27(8):1327–32. https://doi.org/10.1002/adma.201403973.

Fallah Hamidabadi V, Momblona C, Perez-Del-Rey D, Bahari A, Sessolo M, Bolink HJ. Phosphomolybdic acid as an efficient hole injection material in perovskite optoelectronic devices. Dalton Trans. 2018;48(1):30–4. https://doi.org/10.1039/c8dt03680b.

Liu S, Li J, Xu S, Wang M, Zhang Y, Xue X. A modified method for enhancing adsorption capability of banana pseudostem biochar towards methylene blue at low temperature. Bioresour Technol. 2019;282:48–55. https://doi.org/10.1016/j.biortech.2019.02.092.

Chen S, Li J, Zhu Y, Guo Z, Su S. Increasing the efficiency of intumescent flame retardant polypropylene catalyzed by polyoxometalate based ionic liquid. J Mater Chem A. 2013;1(48):15242. https://doi.org/10.1039/c3ta13538a.

Xiao F, Wu K, Luo F, Yao S, Lv M, Zou H, et al. Influence of ionic liquid-based metal-organic hybrid on thermal degradation, flame retardancy, and smoke suppression properties of epoxy resin composites. J Mater Sci. 2018;53(14):10135–46. https://doi.org/10.1007/s10853-018-2318-0.

M. Aflal M. Rahmathullah AJ, † Brian Merritt,† Mark VanLandingham,‡ Steven H. McKnight,‡ and Giuseppe R. Palmese*. Room temperature ionic liquids as thermally latent initiators for polymerization of epoxy resins. Macromolecules. 2009.

Maksym P, Tarnacka M, Dzienia A, Matuszek K, Chrobok A, Kaminski K, et al. Enhanced polymerization rate and conductivity of ionic liquid-based epoxy resin. Macromolecules. 2017;50(8):3262–72. https://doi.org/10.1021/acs.macromol.6b02749.

HONORATAMAKA TS. Epoxy resin crosslinked with conventional and deep eutectic ionic liquids. POLIMERY 2012.

Xu Y-J, Wang J, Tan Y, Qi M, Chen L, Wang Y-Z. A novel and feasible approach for one-pack flame-retardant epoxy resin with long pot life and fast curing. Chem Eng J. 2018;337:30–9. https://doi.org/10.1016/j.cej.2017.12.086.

Xu Y-J, Chen L, Rao W-H, Qi M, Guo D-M, Liao W, et al. Latent curing epoxy system with excellent thermal stability, flame retardance and dielectric property. Chem Eng J. 2018;347:223–32. https://doi.org/10.1016/j.cej.2018.04.097.

Xiongwei L, Chao Chen AB, Yunsheng Y, Hongxia Z, Hao Q, Jingwei L, Xingping Z, Shijun L, Xiaolin X. Highly thermally conductive flame retardant epoxy nanocomposites with multifunctional ionic liquid flame retardant-functionalized boron nitride nanosheets. J Mater Chem A. 2018. https://doi.org/10.1039/c8ta08008a.

Ranga Rao G, Rajkumar T, Varghese B. Synthesis and characterization of 1-butyl 3-methyl imidazolium phosphomolybdate molecular salt. Solid State Sci. 2009;11(1):36–42. https://doi.org/10.1016/j.solidstatesciences.2008.05.017.

Chambreau SD, Boatz JA, Vaghjiani GL, Koh C, Kostko O, Golan A, et al. Thermal decomposition mechanism of 1-ethyl-3-methylimidazolium bromide ionic liquid. J Phys Chem A. 2012;116(24):5867–76. https://doi.org/10.1021/jp209389d.

Maka H, Spychaj T, Pilawka R. Epoxy Resin/ionic liquid systems: the influence of imidazolium cation size and anion type on reactivity and thermomechanical properties. Ind Eng Chem Res. 2012;51(14):5197–206. https://doi.org/10.1021/ie202321j.

Ham YR, Kim SH, Shin YJ, Lee DH, Yang M, Min JH, et al. A comparison of some imidazoles in the curing of epoxy resin. J Ind Eng Chem. 2010;16(4):556–9. https://doi.org/10.1016/j.jiec.2010.03.022.

Hu J, Shan J, Wen D, Liu X, Zhao J, Tong Z. Flame retardant, mechanical properties and curing kinetics of DOPO-based epoxy resins. Polym Degrad Stab. 2014;109:218–25. https://doi.org/10.1016/j.polymdegradstab.2014.07.026.

Zhao Y, Drummer D. Influence of filler content and filler size on the curing kinetics of an epoxy resin. Polymers (Basel). 2019. https://doi.org/10.3390/polym11111797.

Lu M, Liu Y, Du X, Zhang S, Chen G, Zhang Q, et al. Cure kinetics and properties of high performance cycloaliphatic epoxy resins cured with anhydride. Ind Eng Chem Res. 2019;58(16):6907–18. https://doi.org/10.1021/acs.iecr.8b06442.

Kumar S, Samal SK, Mohanty S, Nayak SK. Curing kinetics of bio-based epoxy resin-toughened DGEBA epoxy resin blend. J Therm Anal Calorim. 2019;137(5):1567–78. https://doi.org/10.1007/s10973-019-08080-4.

Morancho JM, Ramis X, Fernández-Francos X, Salla JM, Konuray O, Serra À. Curing and thermomechanical properties of off-stoichiometric anhydride–epoxy thermosets. J Therm Anal Calorim. 2019;138(4):2865–72. https://doi.org/10.1007/s10973-019-08681-z.

Liu GGC. Comparative investigation on thermal degradation of flue-cured tobacco with different particle sizes by a macro-thermogravimetric analyzer and their apparent kinetics based on distributed activation energy model. J Therm Anal Calorim. 2019;138:3375–88. https://doi.org/10.1007/s10973-019-08215-7.

Sbirrazzuoli N, Mititelu-Mija A, Vincent L, Alzina C. Isoconversional kinetic analysis of stoichiometric and off-stoichiometric epoxy-amine cures. Thermochim Acta. 2006;447(2):167–77. https://doi.org/10.1016/j.tca.2006.06.005.

Daneshmehr S, Roman F, Hutchinson JM. The surface modification of boron nitride particles. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-09160-1.

El-Thaher N, Mekonnen T, Mussone P, Bressler D, Choi P. Nonisothermal DSC study of epoxy resins cured with hydrolyzed specified risk material. Ind Eng Chem Res. 2013;52(24):8189–99. https://doi.org/10.1021/ie400803d.

Qiu S, Zhou Y, Zhou X, Zhang T, Wang C, Yuen RKK, et al. Air-stable polyphosphazene-functionalized few-layer black phosphorene for flame retardancy of epoxy resins. Small. 2019;15(10):e1805175. https://doi.org/10.1002/smll.201805175.

Zhou X, Qiu S, Cai W, Liu L, Hou Y, Wang W, et al. Construction of hierarchical MoS2@TiO2 structure for the high performance bimaleimide system with excellent fire safety and mechanical properties. Chem Eng J. 2019;369:451–62. https://doi.org/10.1016/j.cej.2019.02.181.

Acknowledgements

This work was supported by the National Key R&D Program of China (No. 2017YFD0601003) and the Zhujiang Science and Technology New-star Program of Guangzhou, China (No. 201710010084).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Jiao, E., Wu, K., Qu, Z. et al. Preparation and curing kinetics of intrinsic flame retardant epoxy resin system based on polyoxometalates. J Therm Anal Calorim 146, 1063–1076 (2021). https://doi.org/10.1007/s10973-020-10075-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10075-5