Abstract

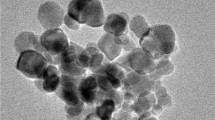

Thermal performance evaluation of TiO2-coated copper mesh wick in a cylindrical heat pipe with graphite nanofluid is experimentally analyzed at various inclinations, nanoparticle concentrations and power levels. Boiling heat transfer from the evaporator of a heat pipe depends on both thermal conductivity of the nanoparticle and suspension stability of the nanofluid. The lower the density of the nanoparticle, the better the suspension stability. Spherical graphite nanoparticles having lower density and good thermal conductivity quicken the heat transfer rate and hence the vaporization of base fluid. A hydrophilic coating of TiO2 is done on the copper wick structure to reduce the contact angle of graphite nanofluid. Results showed that the heat pipe worked well at 60° inclination compared to the other tested orientations. For this optimum condition, a reduction in 168.75% of thermal resistance is obtained compared with DI water with uncoated wick at horizontal position and also an improvement in thermal efficiency of 94.07% for 1.0 mass% particle loading. The enhancement in equivalent thermal conductivity is 90.87% for 1.0 mass% compared with DI water. Results from the repeatability test also confirm that the hydrophilic coating over the wick is stable, and results are repeatable.

Similar content being viewed by others

Abbreviations

- A :

-

Area (m2)

- C p :

-

Specific heat (J kg−1 K−1)

- d :

-

Outer diameter (mm)

- I :

-

Current (A)

- k :

-

Thermal conductivity (W m−1 K−1)

- L :

-

Length (mm)

- \(\dot{m}\) :

-

Mass flow rate (kg s−1)

- Q :

-

Input power (Heat supplied) (W)

- q :

-

Heat flux (W m−2)

- R :

-

Thermal resistance (K W−1)

- T :

-

Temperature (K)

- ΔT :

-

Temperature difference (K)

- V :

-

Voltage (V)

- Mass.:

-

Mass fraction (%)

- CW:

-

Coated wick

- UCW:

-

Uncoated wick

- av:

-

Average

- bf:

-

Base fluid

- c:

-

Condenser

- cs:

-

Cross-section

- cv:

-

Condenser vapor

- cw:

-

Condenser wall

- ec:

-

Evaporator−condenser

- Eq.:

-

Equivalent

- ev:

-

Evaporator vapor

- ew:

-

Evaporator wall

- np:

-

Nanoparticle

- o:

-

Overall

- w:

-

Water

- th:

-

Thermal

- Δ:

-

Increment

- ƞ :

-

Efficiency (%)

References

Bejan A, Kraus AD. Heat Transfer Hand Book. New York: Wiley; 2003.

Faghri Amir, Guo Zhen. Integration of heat pipe into fuel cell technology. Heat Transf Eng. 2008;29:232–8.

Guo Qing, Guo Hang, Yan XK, Ye Fang, Ma CF. Influence of inclination angle on the start-up performance of a sodium-potassium alloy heat pipe. Heat Transf Eng. 2017. https://doi.org/10.1080/01457632.2017.1370325.

Cheng Lixin, Xia Guodong, Li Qinling, Thome John R. Fundamental issues, technology development and challenges of boiling heat transfer, critical heat flux and two-phase flow phenomena with nanofluids. Heat Transf Eng. 2018. https://doi.org/10.1080/01457632.2018.1470285.

Buongiorno J, Venerus DC, Prabhat N, McKrell T, Townsend J, Christianson R, Tolmachev YV, Keblinski P, Hu LW, Alvarado JL, Bang IC, Bishnoi SW, Bonetti M, Botz F, Cecere A, Chang Y, Chen G, Chen H, Chung SJ, Chyu MK, Das SK, Paola RD, Ding Y, Dubois F, Dzido G, Eapen J, Escher W, Funfschilling D, Galand Q, Gao J, Gharagozloo PE, Goodson KE, Gutierrez JG, Hong H, Horton M, Iorio CS, Jarzêbski AB, Jiang Y, Jin LW, Kabelac S, Kamath A, Kedzierski MA, Kim C, Kim JH, Kim S, Kieng LG, Leong KC, Manna I, Michel B, Ni R, Patel HE, Philip J, Poulikakos D, Reynaud C, Savino R, Singh PK, Song P, Sundararajan T, Timofeeva E, Tritcak T, Turanov AN, Vaerenbergh SV, Wen D, Witharana S, Yang CC, Yeh WH, Zhao XZ, Zhou SQ. A benchmark study on the thermal conductivity of nanofluids. J Appl Phys. 2009;106:094312. https://doi.org/10.1063/1.3245330.

Putra N, Septiadi WN, Rahman H, Irwansyah R. Thermal performance of screen mesh wick heat pipes with nanofluids. Exp Therm Fluid Sci. 2012;40:10–7. https://doi.org/10.1016/j.expthermflusci.2012.01.007.

Moraveji MK, Razvarz S. Experimental investigation of aluminum oxide nanofluid on heat pipe thermal performance. Int Commun Heat Mass Transf. 2012;39:1444–8. https://doi.org/10.1016/j.icheatmasstransfer.2012.07.024.

Ghanbarpour M, Nikkam N, Khodabandeh R, Toprak MS, Muhammed M. Thermal performance of screen mesh heat pipe with Al2O3 nanofluid. Exp Therm Fluid Sci. 2015;66:213–20. https://doi.org/10.1016/j.expthermflusci.2015.03.024.

Kole M, Dey TK. Thermal performance of screen mesh wick heat pipes using water-based copper nanofluids. Appl Therm Eng. 2013;50:763–70. https://doi.org/10.1016/j.applthermaleng.2012.06.049.

Shukla KN, Solomon AB, Pillai BC, Ibrahim M. Thermal performance of cylindrical heat pipe using nanofluids. J Thermophys Heat Transf. 2010;24:796–802. https://doi.org/10.2514/1.48749.

Venkatachalapathy S, Kumaresan G, Suresh S. Performance analysis of cylindrical heat pipe using nanofluids—an experimental study. Int J Multiph Flow. 2015;72:188–97. https://doi.org/10.1016/j.ijmultiphaseflow.2015.02.006.

Kumaresan G, Venkatachalapathy S, Asirvatham LG. Experimental investigation on enhancement in thermal characteristics of sintered wick heat pipe using CuO nanofluids. Int J Heat Mass Transf. 2014;72:507–16. https://doi.org/10.1016/j.ijheatmasstransfer.2014.01.029.

Tsai CY, Chien HT, Ding PP, Chan B, Luh TY, Chen PH. Effect of structural character of gold nanoparticles in nanofluid on heat pipe thermal performance. Mater Lett. 2004;58:1461–5. https://doi.org/10.1016/j.matlet.2003.10.009.

Sadeghinezhad E, Mehrali M, Rosen MA, Akhiani AR, Latibari ST, Mehrali M, Metselaar HSC. Experimental investigation of the effect of graphene nanofluids on heat pipe thermal performance. Appl Therm Eng. 2016;100:775–87. https://doi.org/10.1016/j.applthermaleng.2016.02.071.

Ramachandran R, Ganesan K, Rajkumar MR, Asirvatham LG, Wongwises S. Comparative study of the effect of hybrid nanoparticle on the thermal performance of cylindrical screen mesh heat pipe. Int Commun Heat Mass Transf. 2016;76:294–300. https://doi.org/10.1016/j.icheatmasstransfer.2016.05.030.

Grab T, Gross U, Franzke U, Buschmann MH. Operation performance of thermosyphons employing titania and gold nanofluids. Int J Therm Sci. 2014;86:352–64. https://doi.org/10.1016/j.ijthermalsci.2014.06.019.

Wang PY, Chen XJ, Liu ZH, Liu YP. Application of nanofluid in an inclined mesh wicked heat pipes. Thermochim Acta. 2012;539:100–8. https://doi.org/10.1016/j.tca.2012.04.011.

Asirvatham LG, Nimmagadda R, Wongwises S. Heat transfer performance of screen mesh wick heat pipes using silver–water nanofluid. Int J Heat Mass Transf. 2013;60:201–9. https://doi.org/10.1016/j.ijheatmasstransfer.2012.11.037.

Saleh R, Putra N, Prakoso SP, Septiadi WN. Experimental investigation of thermal conductivity and heat pipe thermal performance of ZnO nanofluids. Int J Therm Sci. 2013;63:125–32. https://doi.org/10.1016/j.ijthermalsci.2012.07.011.

Mozumder AK, Akon AF, Chowdhury MSH, Banik SC. Performance of heat pipe for different working fluids and fill ratios. J Mech Eng. 2010;41:96–102.

Kumaresan G, Venkatachalapathy S. A review on heat transfer enhancement studies of heat pipes using nanofluids. Front Heat pipes. 2012. https://doi.org/10.5098/fhp.V3.4.3001.

Cacua K, Buitrago-Sierra R, Herrera B, Pabon E, Murshed SMS. Nanofluids’ stability effects on the thermal performance of heat pipes. J Therm Anal Calorim. 2019;136:1597–614. https://doi.org/10.1007/s10973-018-7787-5.

Gupta NK, Tiwari AK, Ghosh SK. Experimental study of thermal performance of nanofluid-filled and nanoparticles-coated mesh wick heat pipes. J Heat Transf. 2018. https://doi.org/10.1115/1.4040146.

Jouhara H, Chauhan A, Nannou T, Almahmoud S, Delpech B, Wrobel LC. Heat pipe based systems—advances and applications. Energy. 2017;128:729–54. https://doi.org/10.1016/j.energy.2017.04.028.

Khalid SU, Babar H, Ali HM, et al. Heat pipes: progress in thermal performance enhancement for microelectronics. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09820-7.

Jyothi Sankar PR, Venkatachalapathy S, Asirvatham LG. Thermal performance enhancement studies using graphite nanofluid for heat transfer applications. Heat Transf. 2020. https://doi.org/10.1002/htj.21758.

Nazari MA, Ghasempour R, Ahmadi MH. A review on using nanofluids in heat pipes. J Therm Anal Calorim. 2019;137:1847–55. https://doi.org/10.1007/s10973-019-08094-y.

Jyothi Sankar PR, Venkatachalapathy S, Santhosh Kumar MC. Effect of hydrophilic coating on mesh wicks used in heat pipes. Surf Eng. 2019. https://doi.org/10.1080/02670844.2019.1695370.

Kumaresan G, Vijayakumar P, Ravikumar M, Kamatchi R, Selvakumar P. Experimental study on effect of wick structures on thermal performance enhancement of cylindrical heat pipes. J Therm Anal Calorim. 2019;136:389–400. https://doi.org/10.1007/s10973-018-7842-2.

Hopkins R, Faghri A, Khrustalev D. Flat miniature heat pipes with micro capillary grooves. J Heat Transf. 1999;121:102–9. https://doi.org/10.1115/1.2825922.

Liu ZH, Zhu QZ. Application of aqueous nanofluids in a horizontal mesh heat pipe. Energy Conv Manag. 2011;52:292–300.

Acknowledgements

The authors would like to thank Advanced Thermal Sciences Laboratory, Karunya University, Coimbatore, Tamil Nadu, India, for extending the test facilities. The authors are also thankful to Mr. Jaya Seelan for his help in the fabrication of experimental setup.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jyothi Sankar, P.R., Venkatachalapathy, S., Asirvatham, L.G. et al. Effect of coated mesh wick on the performance of cylindrical heat pipe using graphite nanofluids. J Therm Anal Calorim 146, 297–309 (2021). https://doi.org/10.1007/s10973-020-09944-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09944-w