Abstract

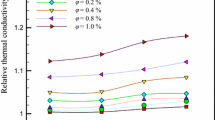

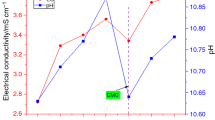

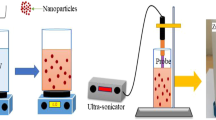

In this paper, 0.5–5 mass/% of Al2O3 and CuO nano-additives were dispersed in the base water by the two stage method (with a magnetic stirrer and ultra-sonication bath) to prepare different nanofluids with enhanced thermophysical properties. These nanofluids are considered to be utilized, as the bath fluid in the shell side of an indirect water bath heater to improve the thermal performance and reduce the power consumption of the heater. The effects of ultra-sonication time, surfactants, and nanoparticle size on the well formation of nanofluids, and their stabilities were probed. Densities, shear stresses, and apparent viscosities of the nanofluids were also measured to investigate the non-Newtonian behavior of samples. In addition, effects of the temperature, PH, nanoparticle type and concentration, and nanoparticle sizes on the thermal conductivities of nanofluids were investigated. Finally, nanofluids were utilized in a large-scale indirect water bath heater and its power consumption reduction compared to that of using water, as the bath fluid was measured and reported. 5 mass/% of CuO/water nanofluid at 80 °C was found the best nanofluids with the thermal conductivity enhancement of 43.28% and heater power consumption reduction of 17.1%.

Similar content being viewed by others

References

Jannatabadi M, Farzaneh-Gord M, Rahbari HR, Nersi A. Energy and exergy analysis of reciprocating natural gas expansion engine based on valve configurations. Energy. 2018;158:986–1000.

Liu Y, Hou J, Zhao H, Liu X, Xia Z. A method to recover natural gas hydrates with geothermal energy conveyed by CO2. Energy. 2018;144:265–78.

Soleimani P, Khoshvaght-Aliabadi M, Rashidi H, Bahmanpour H. Performance enhancement of water bath heater at natural gas city gate station using twisted tubes. Chinese J Chem Eng. 2019;28:165–79.

Qiu L, Ouyang Y, Feng Y, Zhang X. Review on micro/nano phase change materials for solar thermal applications. Renew Energy. 2019;140:513–38.

Mehling H, Cabeza LF. Phase change materials and their basic properties. In: Paksoy HÖ, editor. Thermal energy storage for sustainable energy consumption. Dordrecht: Springer; 2007. p. 257–77. https://doi.org/10.1007/978-1-4020-5290-3_17.

Olfati M, Bahiraei M, Veysi F. A novel modification on preheating process of natural gas in pressure reduction stations to improve energy consumption, exergy destruction and CO2 emission: preheating based on real demand. Energy. 2019;173:598–609.

Rashidmardani A, Hamzehei M. Effect of various parameters on indirect fired water bath heaters’ efficiency to reduce energy losses. Int J Sci Eng Investig. 2013;2:17–24.

Farzaneh-Gord M, Arabkoohsar A, Deymi Dasht-bayaz M, Machado L, Koury RNN. Energy and exergy analysis of natural gas pressure reduction points equipped with solar heat and controllable heaters. Renew Energy. 2014;72:258–70.

Akhlaghi K, Eftekhari H, Farzaneh-Gord M, Khatib M. Solar heat utilization in birjand natural gas pressure reduction, a thermo-economic analysis. Int J Chem Environ Eng. 2011;2:267.

Arabkoohsar A, Ismail KAR, Machado L, Koury RNN. Energy consumption minimization in an innovative hybrid power production station by employing PV and evacuated tube collector solar thermal systems. Renew Energy. 2016;93:424–41.

Borelli D, Devia F, Lo Cascio E, Schenone C. Energy recovery from natural gas pressure reduction stations: integration with low temperature heat sources. Energy Convers Manag. 2018;159:274–83.

Xiong Y, An S, Xu P, Ding Y, Li C, Zhang Q, et al. A novel expander-depending natural gas pressure regulation configuration: performance analysis. Appl Energy. 2018;220:21–35.

Yang S, Zhang L, Xu H. Experimental study on convective heat transfer and flow resistance characteristics of water flow in twisted elliptical tubes. Appl Therm Eng. 2011;31:2981–91.

Khoshvaght-Aliabadi M, Arani Z, Rahimpour F. Influence of Al2O3–H2O nanofluid on performance of twisted minichannels. Adv Powder Technol. 2016;27:1514–25.

Khoshvaght-Aliabadi M, Arani-Lahtari Z. Proposing new configurations for twisted square channel (TSC): nanofluid as working fluid. Appl Therm Eng. 2016;108:709–19.

Feizabadi A, Khoshvaght-Aliabadi M, Rahimi AB. Numerical investigation on Al2O3/water nanofluid flow through twisted-serpentine tube with empirical validation. Appl Therm Eng. 2018;137:296–309.

Eiamsa-ard S, Promthaisong P, Thianpong C, Pimsarn M, Chuwattanakul V. Influence of three-start spirally twisted tube combined with triple-channel twisted tape insert on heat transfer enhancement. Chem Eng Process Process Intensif. 2016;102:117–29.

Farzaneh-Gord M, Ghezelbash R, Sadi M, Moghadam AJ. Integration of vertical ground-coupled heat pump into a conventional natural gas pressure drop station: Energy, economic and CO2 emission assessment. Energy. 2016;112:998–1014.

Angelo W, Mantelli MH, Milanez FH. Design of a heater for natural gas stations assisted by two-phase loop thermosyphon. In: 14th international heat pipe conference 2007

Dabiri E, Bahrami F, Mohammadzadeh S. Experimental investigation on turbulent convection heat transfer of SiC/W and MgO/W nanofluids in a circular tube under constant heat flux boundary condition. J Therm Anal Calorim. 2018;131:2243–59. https://doi.org/10.1007/s10973-017-6791-5.

Sadeghalvaad M, Dabiri E, Afsharimoghadam P. Lithium lubricating greases containing carbon base nano-additives: preparation and comprehensive properties evaluation. SN Appl Sci. 2019;1:264. https://doi.org/10.1007/s42452-019-0289-7.

Sadeghalvaad M, Dabiri E, Zahmatkesh S, Afsharimoghadam P. Preparation and properties evaluation of nitrile rubber nanocomposites reinforced with organo-clay, CaCO3, and SiO2 nanofillers. Polym Bull. 2018. https://doi.org/10.1007/s00289-018-2583-8.

Sadeghalvaad M, Dabiri E, Zahmatkesh SAP. Improved curing conditions and mechanical/chemical properties of nitrile butadiene rubber composites reinforced with carbon based nanofillers. Nanostructures. 2019;9:453–67.

Khorramdel H, Dabiri E, Tabrizi FF, Galehdari M. Synthesis and characterization of graphene acid membrane with ultrafast and selective water transport channels. Sep Purif Technol. 2019;212:497–504.

Zahmatkesh S, Zebarjad SM, Bahrololoom ME, Dabiri E, Arab SM. Synthesis of ZnO/In2O3 composite nanofibers by co-electrospinning: a comprehensive parametric investigating the process. Int: Ceram; 2018.

Dabiri E, Noori M, Zahmatkesh S. Modeling and CFD simulation of volatile organic compounds removal from wastewater by membrane gas stripping using an electro-spun nanofiber membrane. J Water Process Eng. 2018;30:100635.

Sadeghalvaad M, Sabbaghi S. The effect of the TiO2/polyacrylamide nanocomposite on water-based drilling fluid properties. Powder Technol. 2015;272:113–9.

Qiu L, Zhu N, Zou H, Feng Y, Zhang X, Tang D. Advances in thermal transport properties at nanoscale in China. Int J Heat Mass Transf. 2018;125:413–33.

Chol SUS. Enhancing thermal conductivity of fluids with nanoparticles. ASME J. 1995;231:99–106.

Khoshvaght-Aliabadi M, Pazdar S, Sartipzadeh O. Experimental investigation of water based nanofluid containing copper nanoparticles across helical microtubes. Int Commun Heat Mass Transf. 2016;70:84–92. https://doi.org/10.1016/j.icheatmasstransfer.2015.12.006.

Patel HE, Das SK, Sundararajan T, Sreekumaran Nair A, George B, Pradeep T. Thermal conductivities of naked and monolayer protected metal nanoparticle based nanofluids: Manifestation of anomalous enhancement and chemical effects. Appl Phys Lett. 2003;83:2931.

Xing M, Yu J, Wang R. Experimental study on the thermal conductivity enhancement of water based nanofluids using different types of carbon nanotubes. Int J Heat Mass Transf. 2015;88:609–16. https://doi.org/10.1016/j.ijheatmasstransfer.2015.05.005.

Ahammed N, Asirvatham LG, Titus J, Bose JR, Wongwises S. Measurement of thermal conductivity of graphene-water nanofluid at below and above ambient temperatures. Int Commun Heat Mass Transf. 2016;70:66–74. https://doi.org/10.1016/j.icheatmasstransfer.2015.11.002.

Li X, Zou C, Zhou L, Qi A. Experimental study on the thermo-physical properties of diathermic oil based SiC nanofluids for high temperature applications. Int J Heat Mass Transf. 2016;97:631–7. https://doi.org/10.1016/j.ijheatmasstransfer.2016.02.056.

Shahrul IM, Mahbubul IM, Saidur R, Sabri MFM. Experimental investigation on Al2O3–W, SiO2–W and ZnO–W nanofluids and their application in a shell and tube heat exchanger. Int J Heat Mass Transf. 2016;97:547–58. https://doi.org/10.1016/j.ijheatmasstransfer.2016.02.016.

Guo S-Z, Li Y, Jiang J-S, Xie H-Q. Nanofluids containing γ-Fe2O3 nanoparticles and their heat transfer enhancements. Nanoscale Res Lett. 2010;5:1222–7.

Nemade K, Waghuley S. A novel approach for enhancement of thermal conductivity of CuO/H2O based nanofluids. Appl Therm Eng. 2016;95:271–4.

Chen J, Zhai F, Liu M, Hou X, Chou KC. SiC nanowires with tunable hydrophobicity/hydrophilicity and their application as nanofluids. Langmuir. 2016;32:5909–16.

Noghrehabadi A, Ghalambaz M, Ghanbarzadeh A. Effects of variable viscosity and thermal conductivity on natural-convection of nanofluids past a vertical plate in porous media. J Mech. 2014;30:265–75.

Qiu L, Zheng XH, Su GP, Tang DW. Design and application of a freestanding sensor based on 3ω technique for thermal-conductivity measurement of solids, liquids, and nanopowders. Int J Thermophys. 2013;34:2261–75. https://doi.org/10.1007/s10765-011-1075-y.

Kole M, Dey TK. Role of interfacial layer and clustering on the effective thermal conductivity of CuO–gear oil nanofluids. Exp Therm Fluid Sci. 2011;35:1490–5.

Yiamsawasd T, Dalkilic AS, Wongwises S. Measurement of the thermal conductivity of titania and alumina nanofluids. Thermochim Acta. 2012;545:48–56.

Heris SZ, Etemad SG, Esfahany MN. Experimental investigation of oxide nanofluids laminar flow convective heat transfer. Int Commun Heat Mass Transf. 2006;33:529–35.

Pak BC, Cho YI. Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp Heat Transf. 1998;11:151–70.

He Y, Jin Y, Chen H, Ding Y, Cang D, Lu H. Heat transfer and flow behaviour of aqueous suspensions of TiO2 nanoparticles (nanofluids) flowing upward through a vertical pipe. Int J Heat Mass Transf. 2007;50:2272–81.

Rahmati AR, Reiszadeh M. An experimental study on the effects of the use of multi-walled carbon nanotubes in ethylene glycol/water-based fluid with indirect heaters in gas pressure reducing stations. Appl Therm Eng. 2018;134:107–17.

Qiu L, Zou H, Wang X, Feng Y, Zhang X, Zhao J, et al. Enhancing the interfacial interaction of carbon nanotubes fibers by Au nanoparticles with improved performance of the electrical and thermal conductivity. Carbon. 2019;141:497–505.

Qiu L, Guo P, Zou H, Feng Y, Zhang X, Pervaiz S, et al. Extremely low thermal conductivity of graphene nanoplatelets using nanoparticle decoration. ES Energy Environ. 2018;2:66–72.

Kumar PM, Kumar J, Tamilarasan R, Sendhilnathan S, Suresh S. Review on nanofluids theoretical thermal conductivity models. Eng J. 2015;19:67–83.

Acknowledgements

Authors are grateful to the Fars Science and Technology Park for providing its equipped laboratories for them to successfully complete this work.

Funding

This research received grant from Fars Science and Technology Park by the Contract Number of 720-3654-58352.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding authors state that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Razavi, S.R., Sadeghalvaad, M. & Sabbaghi, S. Experimental investigation on the stability and thermophysical properties of Al2O3/DW and CuO/DW nanofluids to be utilized in an indirect water bath heater. J Therm Anal Calorim 142, 2303–2318 (2020). https://doi.org/10.1007/s10973-020-09592-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09592-0