Abstract

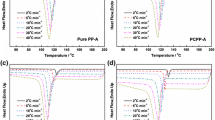

The Non-isothermal crystallization behavior of isotactic polypropylene (iPP)/copper nanocomposites with four different mass percentages (0.5, 1.0, 2.0 and 4.0 mass%) of copper nanoparticles (nCu) were study by means of differential scanning calorimeter (DSC) at 2.5, 5, 10 and 20 °C min−1. The nanostructure of PP/nCu nanocomposites was also studied by WAXD, SEM and optical microscopy, while their hierarchical crystalline morphologies (e.g., spherulites, lamellas and unit cell) were studied during the crystallization progress through polarized optical microscopy and in situ X-ray scattering at small and wide angle, observing that the spherulite size was not influenced by the nCu’s, although the lamellas size and X-ray diffraction intensity increased with the incorporation of nanoparticles. The PP/nCu nanocomposites presented a mixture morphology with well-dispersed oxidized nanoparticles and some agglomerates, which were larger at higher concentration of particles. The crystallization results obtained by DSC indicated a displacement in the peak crystallization temperature at higher values. These results in combination with the kinetic of crystallization analyzed by the Jeziorny method clearly indicated an acceleration in the crystallization process. Additionally, the crystallization activation energy decreases for all nanoparticle’s concentration, indicating a possible nucleating effect. However, the nucleation activity analyzed by the Dobreva and Gutzow’s method showed that nCu could not be considered such as conventional heterogeneous nucleating agent of iPP. Conversely, the incorporation of nCu in the iPP matrix increased significantly the thermal conductivity of nanocomposites helping to the thermal dissipation from the melted macromolecules to the nCu’s, accelerating the non-isothermal crystallization process.

Similar content being viewed by others

References

Móczó J, Pukánszky B. Polymer micro and nanocomposites: structure, interactions, properties. J Ind Eng Chem. 2008;14:535–63.

Zhang S, Cao XY, Ma YM, Ke YC, Zhang JK, Wang FS. The effects of particle size and content on the thermal conductivity and mechanical properties of Al2O3/high density polyethylene (HDPE) composites. Express Polym Lett. 2011;5:581–90.

Kratochvíla J, Boudenne A, Krupa I. Effect of filler size on thermophysical and electrical behavior of nanocomposites based on expanded graphite nanoparticles filled in low-density polyethylene matrix. Polym Compos. 2013;34:149–55.

Masirek R, Szkudlarek E, Piorkowska E, Slouf M, Kratochvil J, Baldrian J. Nucleation of isotactic polypropylene crystallization by gold nanoparticles. J Polym Sci Part B Polym Phys. 2010;48:469–78.

Isayev AI, Kumar R, Lewis TM. Ultrasound assisted twin screw extrusion of polymer–nanocomposites containing carbon nanotubes. Polymer. 2009;50:250–60.

Yang L, Zhang Z, Wang X, Chen J, Li H. Effect of ultrasonic irradiation on the microstructure and the electric property of PP/CPP/MWNT composites. J Appl Polym Sci. 2012;128:1510–20.

Ávila-Orta CA, Martínez-Colunga JG, Bueno-Baqués D, Raudry-López CE, Cruz-Delgado VJ, González-Morones P, Valdéz-Garza JA, Esparza-Juárez ME, Espinoza-González CJ, Rodríguez-González JA. Proceso continuo asistido por ultrasonido de frecuencia y amplitud variable, para la preparación de nanocompuestos a base de polímeros y nanopartículas. Mx. Patent MX/a/2009/003842, 19 September 2014.

Mata-Padilla JM, Ávila-Orta CA, Medellín-Rodríguez FJ, Hernández-Hernández E, Jiménez-Barrera RM, Crúz-Delgado VJ, et al. Structural and morphological studies on the deformation behavior of polypropylene/multi-walled carbon nanotubes nanocomposites prepared through ultrasound-assisted melt extrusion process. J Polym Sci Part B Polym Phys. 2015;53:475–91.

Ávila-Orta C, Quiñones-Jurado Z, Waldo-Mendoza M, Rivera-Paz E, Cruz-Delgado V, Mata-Padilla J, et al. Ultrasound-assist extrusion methods for the fabrication of polymer nanocomposites based on polypropylene/multi-wall carbon nanotubes. Materials (Basel). 2015;8:7900–12.

Suktha P, Lekpet K, Siwayaprahm P, Sawangphruk M. Enhanced mechanical properties and bactericidal activity of polypropylene nanocomposite with dual-function silica-silver core–shell nanoparticles. J Appl Polym Sci. 2013;128:4339–45.

Tjong SC, Bao S. Structure and mechanical behavior of isotactic polypropylene composites filled with silver nanoparticles. E-Polymers. 2007. https://doi.org/10.1515/epoly.2007.7.1.1618.

Dehnavi MH, Asghar A, Jeddi A, Gharehaghaji AA, Yazdanshenas ME. Thermal properties of conductive nanocomposite core–shell filament yarns. Indian J Fibre Text Res. 2013;38:380–6.

Fredin L, Li Z, Lanagan MT, Ratner M, Marks TJ. Substantial recoverable energy storage in percolative metallic aluminum-polypropylene nanocomposites. Adv Funct Mater. 2013;23:3560–9.

Delgado K, Quijada R, Palma R, Palza H. Polypropylene with embedded copper metal or copper oxide nanoparticles as a novel plastic antimicrobial agent. Lett Appl Microbiol. 2011;53:50–4.

España-Sánchez BL, Ávila-Orta CA, Padilla-Vaca F, Neira-Velázquez MG, González-Morones P, Rodríguez-González JA, et al. Enhanced antibacterial activity of melt processed poly(propylene) Ag and Cu nanocomposites by argon plasma treatment. Plasma Process Polym. 2014;11:353–65.

Gawish SM, Avci H, Ramadan AM, Mosleh S, Monticello R, Breidt F, et al. Properties of antibacterial polypropylene/nanometal composite fibers. J Biomater Sci Polym. 2012;23:43–61.

Arranz-Andrés J, Pérez E, Cerrada M. Nanocomposites based on isotactic polypropylene–copper nanoparticles as electromagnetic shields. Sci Adv Mater. 2013;5:1524–32.

Cruz-Delgado VJ, Ávila-Orta CA, Espinoza-Martínez AB, Mata-Padilla JM, Solis-Rosales SG, Jalbout AF, et al. Carbon nanotube surface-induced crystallization of polyethylene terephthalate (PET). Polymer. 2014;55:642–50.

Mikešová J, Šlouf M, Gohs U, Popelková D, Vacková T, Vu NH, et al. Nanocomposites of polypropylene/titanate nanotubes: morphology, nucleation effects of nanoparticles and properties. Polym Bull. 2014;71:795–818.

Espinoza-Martínez AB, Ávila-Orta CA, Cruz-Delgado VJ, Medellín-Rodríguez FJ, Bueno-Baqués D, Mata-Padilla JM. Effect of MWNTs concentration and cooling rate on the morphological, structural, and electrical properties of non-isothermally crystallized PEN/MWNT nanocomposites. J Appl Polym Sci. 2015;132:1–8.

Espinoza-Martinez AB, Avalos-Belmontes F, De Valle LFR, Espinoza-Martinez PA, Avila-Orta CA, Soriano-Corral F, et al. Morphological study and dielectric behavior of nonisothermally crystallized poly(ethylene naphthalate) nanocomposites as a function of graphene content. J Nanomater. 2016;2016:9846102.

Jeziorny A. Parameters characterizing the kinetics of the non-isothermal crystallization of poly(ethylene terephthalate) determined by DSC. Polymer. 1978;19:1142–4.

Medellín-Rodríguez FJ, Mata-Padilla JM, Hsiao BS, Waldo-Mendoza MA, Ramírez-Vargas E, Sánchez-Valdes S. The effect of nanoclays on the nucleation, crystallization, and melting mechanisms of isotactic polypropylene. Polym Eng Sci. 2007;47:1889–97.

Chae DW, Kim BC. Physical properties of isotactic poly(propylene)/silver nanocomposites: dynamic crystallization behavior and resultant morphology. Macromol Mater Eng. 2005;290:1149–56.

Du M, Guo B, Wan J, Zou Q, Jia D. Effects of halloysite nanotubes on kinetics and activation energy of non-isothermal crystallization of polypropylene. J Polym Res. 2010;17:109–18.

Hao W, Li W, Yang W, Shen L. Effect of silicon nitride nanoparticles on the crystallization behavior of polypropylene. Polym Test. 2011;30:527–33.

Alvarez VA, Perez CJ. Effect of different inorganic filler over isothermal and non-isothermal crystallization of polypropylene homopolymer. J Therm Anal Calorim. 2012;107:633–43.

Ferreira CI, Dal Castel C, Oviedo MAS, Mauler RS. Isothermal and non-isothermal crystallization kinetics of polypropylene/exfoliated graphite nanocomposites. Thermochim Acta. 2013;553:40–8.

Radhakrishnan S, Sonawane PS. Role of heat transfer and thermal conductivity in the crystallization behavior of polypropylene-containing additives: a phenomenological model. J Appl Polym Sci. 2003;89:2994–9.

Radhakrishnan S, Sonawane P, Pawaskar N. Effect of thermal conductivity and heat transfer on crystallization, structure, and morphology of polypropylene containing different fillers. J Appl Polym Sci. 2004;93:615–23.

Hwang H, Lee KY, Yeo T, Choi W. Investigation of structural and chemical transitions in copper oxide microstructures produced by combustion waves in a mixture of CuO–Cu2O–Cu and fuel. Appl Surf Sci. 2015;359:931–8.

Hybiak D, Garbarczyk J. Silver nanoparticles in isotactic polypropylene (iPP)* Part I. Silver nanoparticles as metallic nucleating agents for β-iPP polymorph. Polymers. 2014;59:585–91.

Slouf M, Vacková T, Zhigunov A, Sikora A, Piorkowska E. Nucleation of polypropylene crystallization with gold nanoparticles. Part 2: relation between particle morphology and nucleation activity. J Macromol Sci Part B. 2016;55:393–410.

Fanegas N, Gámez MA, Marco C, Jiménez I, Ellis G. Influence of a nucleating agent on the crystallization behaviour of isotactic polypropylene and elastomer blends. Polymer. 2007;48:5324–31.

Medellín-Rodríguez FJ, Mata-Padilla M, Sánchez-Valdes S, Vega-Díaz S, Dávalos-Montoya O. Step-like melting mechanisms of isothermally crystallized isotactic polypropylene. J Polym Sci Part B Polym Phys. 2008;46:2188–200.

Coburn N, Douglas P, Kaya D, Gupta J, McNally T. Isothermal and non-isothermal crystallization kinetics of composites of poly(propylene) and MWCNTs. Adv Ind Eng Polym Res. 2018;1:99–110.

Lu Y, Tang Y, Xia X. Non-isothermal crystallization of copper-containing composite based on polymer alloy of poly(ethylene oxide) and polyethylene. Thermochim Acta. 2018;670:61–70.

Chen Y, Yin Q, Zhang X, Xue X, Jia H. The crystallization behaviors and rheological properties of polypropylene/graphene nanocomposites: the role of surface structure of reduced graphene oxide. Thermochim Acta. 2018;661:124–36.

Rasana N, Jayanarayanan K, Pegoretti A. Non-isothermal crystallization kinetics of polypropylene/short glass fibre/multiwalled carbon nanotube composites. RSC Adv. 2018;8:39127–39.

Layachi A, Makhlouf A, Frihi D, Satha H, Belaadi A, Seguela R. Non-isothermal crystallization kinetics and nucleation behavior of isotactic polypropylene composites with micro-talc. J Therm Anal Calorim. 2019;138:1081–95.

Wu Z, Zhang Z, Mai K. Non-isothermal crystallization kinetics of UHMWPE composites filled by oligomer modified CaCO3. J Therm Anal Calorim. 2020;139:1111–20.

Ardanuy M, Velasco JI, Realinho V, Arencón D, Martínez AB. Non-isothermal crystallization kinetics and activity of filler in polypropylene/Mg–Al layered double hydroxide nanocomposites. Thermochim Acta. 2008;479:45–52.

Ozawa T. Kinetics of non-isothermal crystallization. Polymer. 1971;12:150–8.

Kissinger HE. Variation of peak temperature with heating rate in differential thermal analysis. J Res Natl Bur Stand. 1934;1956(57):217.

Blaine RL, Kissinger HE. Homer Kissinger and the Kissinger equation. Thermochim Acta. 2012;540:1–6.

Vyazovkin S. Is the Kissinger equation applicable to the processes that occur on cooling? Macromol Rapid Commun. 2002;23:771–5.

Friedman HL. Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J Polym Sci Part C Polym Symp. 2007;6:183–95.

Gonzalez-Calderon J, Castrejon-Gonzalez EO, Medellin-Rodriguez FJ, Stribeck N, Almendarez-Camarillo A. Functionalization of multi-walled carbon nanotubes (MWCNTs) with pimelic acid molecules: effect of linkage on β-crystal formation in an isotactic polypropylene (iPP) matrix. J Mater Sci. 2015;50:1457–68.

Ma W, Wang X, Zhang J. Crystallization kinetics of poly (vinylidene fluoride)/MMT, SiO2, CaCO3, or PTFE nanocomposite by differential scanning calorimeter. J Therm Anal Calorim. 2011;103:319–27.

Dobreva A, Gutzow I. Activity of substrates in the catalyzed nucleation of glass-forming melts. II. Experimental evidence. J Non Cryst Solids. 1993;162:13–25.

Han Z, Fina A. Thermal conductivity of carbon nanotubes and their polymer nanocomposites: a review. Prog Polym Sci. 2011;36:914–44.

Acknowledgements

The authors gratefully acknowledge the financial support of CONACYT Grant 127151/EU 7th FP Grant 26396 (CuVito Project), the Project 207450/12 SENER/CONACyT/CEMIE-Sol program (Project 12 “Desarrollo de Captadores, Sistemas Solares y Sistemas de Baja Temperatura con Materiales Novedosos para México”) and through Grant 294030 (LANIAUTO). Also, we are grateful to Janett Valdez, Myriam Lozano, María Guadalupe Méndez, and Ana Izabal for their technical assistance in the nanocomposites characterization.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mata-Padilla, J.M., Ávila-Orta, C.A., Almendárez-Camarillo, A. et al. Non-isothermal crystallization behavior of isotactic polypropylene/copper nanocomposites. J Therm Anal Calorim 143, 2919–2932 (2021). https://doi.org/10.1007/s10973-020-09512-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09512-2