Abstract

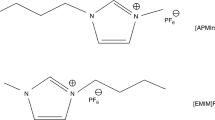

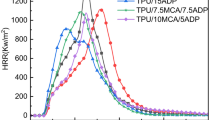

The flame retardancy of polyurethane (PU) elastomer based on aluminum monomethylphosphinate (MeP-Al) was investigated. Thermal analysis, evolved gas analysis (TG-FTIR), flammability tests (LOI, UL 94), heat release rate (HRR) (microcombustion calorimeter), and chemical analysis of residues (SEM–EDX and FTIR) were used to investigate the flame-retardant performance and mechanism of the PU/MeP-Al. Results show that adding MeP-Al endows PU desired flame retardancy and anti-dripping property. The sample containing 20 mass% of MeP-Al passes the UL 94 V0 rating with LOI value of 29.6% and no dripping during combustion. Moreover, the heat release during combustion and the amount of organic volatile from PU decomposition are significantly reduced. The good flame retardancy, anti-dripping property, dramatically a reduction in release of heat and organic compounds are attributed to the efficient action of the MeP-Al in both the gas and condensed phase. In the gas phase, the MeP-Al decomposes into monomethylphosphinic acid to inhibit flame and reduces the heat release. In the condensed phase, MeP-Al turns into the tough aluminum pyrophosphonate and promotes PU to form stable carbonaceous char by interacting with PU.

Similar content being viewed by others

References

Zia KM, Bhatti HN, Bhatti IA. Methods for polyurethane and polyurethane composites, recycling and recovery: a review. React Funct Polym. 2007;67:675–92.

Chattopadhyay DK, Webster DC. Thermal stability and flame retardancy of polyurethanes. Prog Polym Sci. 2009;34:1068–133.

Khobragade PS, Hansora DP, Naik JB, Chatterjee A. Flame retarding performance of elastomeric nanocomposites: a review. Polym Degrad Stab. 2016;130:194–244.

Berta M, Lindsay C, Pans G, Camino G. Effect of chemical structure on combustion and thermal behaviour of polyurethane elastomer layered silicate nanocomposites. Polym Degrad Stab. 2006;91:1179–91.

Ding H, Xia C, Wang J, Chu F. Inherently flame-retardant flexible bio-based polyurethane sealant with phosphorus and nitrogen-containing polyurethane prepolymer. J Mater Sci. 2016;51:5008–18.

Liu Y, He J, Yang R. Effects of dimethyl methylphosphonate, aluminum hydroxide, ammonium polyphosphate, and expandable graphite on the flame retardancy and thermal properties of polyisocyanurate–polyurethane foams. Ind Eng Chem Res. 2015;54:5876–84.

Muralidharan B, Laya S, Vigneswari S. Asian J Tex. 2011;1:114–29.

Chen X, Jiang Y, Liu J, Jiao C, Qian S, Li X. Smoke suppression properties of fumed silica on flame-retardant thermoplastic polyurethane based on ammonium polyphosphate. J Therm Anal Calorim. 2015;120:1493–501.

Duquesne S, Le Bras M, Bourbigot S, Camino G. Mechanism of fire retardancy of polyurethanes using ammonium polyphosphate. J Appl Polym Sci. 2001;82:3262–74.

Lubczak JM, Lubczak R. Melamine polyphosphate—the reactive and additive flame retardant for polyurethane foams. Acta Chim Slov. 2016;63:77–87.

Weferling N, Zhang SM, Chiang CH. Commercial organophosphorus chemicals: status and new developments. Proc Eng. 2016;138:291–301.

Xu W, Xu B, Wang G, Wang X, Liu L. Synergistic effect of expandable graphite and α-type zirconium phosphate on flame retardancy of polyurethane elastomer. J Appl Polym Sci. 2017;134:45188.

Cao Z, Dong X, Fu T, Deng B, Liao W, Wang Y. Coated vs. naked red phosphorus: a comparative study on their fire retardancy and smoke suppression for rigid polyurethane foams. Polym Degrad Stab. 2017;136:103–11.

Benin V, Gardelle B, Morgan AB. Heat release of polyurethanes containing potential flame retardants based on boron and phosphorus chemistries. Polym Degrad Stab. 2014;106:108–21.

Buszard D, Phillips MD, Rose RS, Fallon SB. Blends of tetrahalophthalate esters and phosphorus-containing flame retardants for polyurethane compositions. US Patent 7,423,069. 2008.

Youssef B, Mortaigne B, Soulard M, Saiter JM. Fireproofing of polyurethane by organophosphonates: study of degradation by simultaneously TG/DSC. J Therm Anal Calorim. 2007;90:489–94.

Döring M, Diederichs J. Non-reactive-fillers. In: Innovative flame retardants in E&E applications, 2nd edn. Belgium: pinfa; 2009. p. 25–26.

Tilliette V, Schmidt LE, Ghoul C, Schaal S. Environmentally friendly flame retardant epoxy for electrical insulation. In: The 2008 IEEE international symposium on electrical insulation. Vancouver; 2008. p. 492–6.

Brehme S, Köppl T, Schartel B, Altstädt V. Competition in aluminium phosphinate-based halogen-free flame retardancy of poly (butylene terephthalate) and its glass-fibre composites. E-Polymer. 2014;14:193–208.

Isitman NA, Dogan M, Bayramli E, Kaynakab C. The role of nanoparticle geometry in flame retardancy of polylactide nanocomposites containing aluminium phosphinate. Polym Degrad Stab. 2012;97:1285–96.

Ramani A, Dahoe AE. On flame retardancy in polycaprolactam composites by aluminium diethylphosphinate and melamine polyphosphate in conjunction with organically modified montmorillonite nanoclay. Polym Degrad Stab. 2014;105:1–11.

Doğan M, Bayraml E. The flame retardant effect of aluminum phosphinate in combination with zinc borate, borophosphate, and nanoclay in polyamide-6. Fire Mater. 2014;38:92–9.

Naik AD, Fontaine G, Samyn F, Delva X, Bourgeois Y. Melamine integrated metal phosphates as non-halogenated flame retardants: synergism with aluminium phosphinate for flame retardancy in glass fiber reinforced polyamide 66. Polym Degrad Stab. 2013;98:2653–62.

Levchik SV, Weil ED. Thermal decomposition, combustion and flame-retardancy of epoxy resins: a review of the recent literature. Polym Int. 2004;53:1901–29.

Orhan T, Isitman NA, Hacaloglu J, Kaynak C. Thermal degradation mechanisms of aluminium phosphinate, melamine polyphosphate and zinc borate in poly (methyl methacrylate). Polym Degrad Stab. 2011;96:1780–7.

Yang W, Jiang Z, Yang J, Yang B, Lu H. Preparation of thermoplastic polyester elastomer/cerium carbonate hydroxide composites containing aluminum phosphinate with improved flame-retardant and mechanical properties. Ind Eng Chem Res. 2015;54:11048–55.

Aslzadeh MM, Abdouss M, Sadeghi GMM. Preparation and characterization of new flame retardant polyurethane composite and nanocomposite. J Appl Polym Sci. 2013;127:1683–90.

Bauer H, Hoerold S, Sicken M. Mixtures of aluminum hydrogenphosphites with aluminum salts, process for the production thereof and the use thereof. US Patent 9,505,904. 2016.

Braun U, Schartel B, Fichera MA, Jäger C. Flame retardancy mechanisms of aluminium phosphinate in combination with melamine polyphosphate and zinc borate in glass-fibre reinforced polyamide 6, 6. Polym Degrad Stab. 2007;92:1528–45.

Braun U, Schartel B. Flame retardancy mechanisms of aluminium phosphinate in combination with melamine cyanurate in glass-fiber-reinforced poly (1,4-butylene terephthalate). Macromol Mater Eng. 2008;293:206–17.

Braun U, Bahr H, Sturm H, Schartel B. Flame retardancy mechanisms of metal phosphinates and metal phosphinates in combination with melamine cyanurate in glass-fiber reinforced poly (1, 4-butylene terephthalate): the influence of metal cation. Polym Adv Technol. 2008;19:680–92.

Li H, Ning N, Zhang L, Wang Y, Liang W. Different flame retardancy effects and mechanisms of aluminium phosphinate in PPO, TPU and PP. Polym Degrad Stab. 2014;105:86–95.

Liu X, Liu J, Sun S, Chen J, Cai S. Novel flame-retardant epoxy based on zinc methylethyl phosphinate. Fire Mater. 2014;38:599–608.

Liu X, Liu J, Chen J, Cai S, Hu C. Novel flame-retardant epoxy composites containing aluminium β-carboxylethylmethylphosphinate. Polym Eng Sci. 2015;55:657–63.

Bartels G. Process for the preparation of α-aminoalkylphosphonic acids and of α-amino- alkylphosphinic acids. US Patent 4,960,920. 1990.

Hong S, Ku J, Bae, SH, Choi JH, Kim JH. Salt of carboxyethyl phosphinate ester and flame retardant thermoplastic resin composition containing the same. US Patent 7,939,588. 2011.

Hu Q, Peng P, Peng S, Liu J, Liu X. Flame-retardant epoxy resin based on aluminum monomethylphosphinate. J Therm Anal Calorim. 2017;128:201–10.

Ionkin AS, Marshall WJ, Fish BM. Divalent germanium and tin compounds stabilized by sterically bulky P∧O, PO∧O, PS∧O, and PN∧O ligands: synthesis and first insights into catalytic application to polyurethane systems. Organometallics. 2006;25:4170–8.

Levchik SV, Weil ED. Thermal decomposition, combustion and fire-retardancy of polyurethanes—a review of the recent literature. Polym Int. 2004;53:1585–610.

Bilbao R, Mastral JF, Ceamanos J, Aldea ME. Kinetics of the thermal decomposition of polyurethane foams in nitrogen and air atmospheres. J Anal Appl Pyrol. 1996;37:69–82.

Gjurova K, Bechev C, Troev K, et al. Thermal decomposition of polyurethane elastomers containing antipyrene. J Therm Anal Calorim. 1983;27:367–77.

Liang S, Neisius M, Mispreuve H, Naescher R, Gaan S. Flame retardancy and thermal decomposition of flexible polyurethane foams: structural influence of organophosphorus compounds. Polym Degrad Stab. 2012;97:2428–40.

Berlin KD, Morgan JG, Peterson ME, Pivonka WC. Mechanism of decomposition of alkyl diphenylphosphinates. J Org Chem. 1969;34:1266–71.

Nodera A, Kanai T. Thermal decomposition behavior and flame retardancy of polycarbonate containing organic metal salts: effect of salt composition. J Appl Polym Sci. 2004;94:2131–9.

Acknowledgements

This work is supported by the national high-tech R&D program of China (863 program) (2016YFB0401505).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Hu, Q., Zou, L., Liu, Z. et al. Flame-retardant polyurethane elastomer based on aluminum salt of monomethylphosphinate. J Therm Anal Calorim 143, 2953–2961 (2021). https://doi.org/10.1007/s10973-020-09480-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09480-7