Abstract

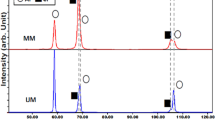

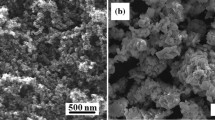

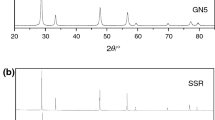

The formation of nanolaminated Cr2AlC MAX phase by using solid-state synthesis route has been investigated through thermal analysis technique. The mixture of chromium (Cr), aluminum (Al) and graphite (C) in 2:1.4:1 was subjected to differential thermal analysis in an argon atmosphere and heated up to 1250 °C, at multiple heating rates (10, 20, 30, 40 °C min−1). Two endothermic peaks (~ 666 °C and ~ 1053 °C) are observed during the synthesis of Cr2AlC MAX phase. The formation of Cr2AlC is also confirmed through XRD, FESEM, HR-TEM and SAED analysis. The kinetic triplets (activation energy, pre-exponential factor and reaction mechanism) involved during the synthesis of Cr2AlC were estimated. The activation energy and reaction mechanism were determined by using iso-conversional model-free methods (KAS, FWO and FR methods) and integral master plot method, respectively. The results indicated that F2 (second-order) reaction mechanism dominates the formation of Cr2AlC MAX phase.

Similar content being viewed by others

References

Zhong Y, Xia XH, Shi F, Zhan JY, Tu JP, Fan HJ. Transition metal carbides and nitrides in energy storage and conversion. Adv Sci. 2015;1500286:1–28.

Chen CY, Yen HW, Kao FH, Li WC, Huang CY, Yang JR, et al. Precipitation hardening of high-strength low-alloy steels by nanometer-sized carbides. Mater Sci Eng A. 2009;499:162–6.

Wuchina E, Opila E, Opeka M, Fahrenholtz W, Talmy I. UHTCs: Ultra-high temperature ceramic materials for extreme environment applications. Electrochem Soc Interface. 2007;16:30–6.

Pierson HO. The refractory carbides. In: Handbook of refractory carbides nitrides. 1st ed. Norwich: Noyes Publication; 1996. pp. 8–16.

Gogotsi YG, Andrievski RA. Materials science of carbides, Nitrides and borides. Netherlands: Springer; 2011.

Vogt U. Carbide, nitride and boride materials—synthesis and processing. J Eur Ceram Soc. 2002;18:735–6.

Griseri M, Tunca B, Lapauw T, Huang S, Popescu L, Barsoum MW, et al. Synthesis, properties and thermal decomposition of the Ta4AlC3 MAX phase. J Eur Ceram Soc. 2019;39:2973–81.

Xu B, Chen Q, Li X, Meng C, Zhang H, Xu M, et al. Synthesis of single-phase Ti3SiC2 from coarse elemental powders and the effects of excess Al. Ceram Int. 2019;45:948–53.

Guo L, Yan Z, Wang X, He Q. Ti2AlC MAX phase for resistance against CMAS attack to thermal barrier coatings. Ceram Int. 2019;45:7627–34.

Tunca B, Lapauw T, Delville R, Neuville DR, Hennet L, Thiaudière D, et al. Synthesis and characterization of double solid solution (Zr, Ti)2(Al, Sn)C MAX phase ceramics. Inorg Chem. 2019;58:6669–83.

Meshkian R, Tao Q, Dahlqvist M, Lu J, Hultman L, Rosen J. Theoretical stability and materials synthesis of a chemically ordered MAX phase, Mo2ScAlC2, and its two-dimensional derivate Mo2ScC2 MXene. Acta Mater. 2017;125:476–80.

Gonzalez-Julian J, Go T, Mack DE, Vaßen R. Environmental resistance of Cr2AlC MAX phase under thermal gradient loading using a burner rig. J Am Ceram Soc. 2018;101:1841–6.

Radovic M, Barsoum MW. MAX phases: bridging the gap between metals and ceramics. Am Ceram Soc Bull. 2013;92:20–7.

Barsoum MW. The Mn+1AXn phases: a new class of solids: thermodynamically stable nanolaminates. Prog Solid State Chem. 2000;28:201–81.

Ghidiu M, Lukatskaya MR, Zhao MQ, Gogotsi Y, Barsoum MW. Conductive two-dimensional titanium carbide “clay” with high volumetric capacitance. Nature. 2015;516:78–81.

Mashtalir O, Naguib M, Mochalin VN, Dall’Agnese Y, Heon M, Barsoum MW, et al. Intercalation and delamination of layered carbides and carbonitrides. Nat Commun. 2013;4:1716.

Naguib M, Kurtoglu M, Presser V, Lu J, Niu J, Heon M, et al. Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Adv Mater. 2011;23:4248–53.

Naguib M, Mashtalir O, Carle J, Presser V, Lu J, Hultman L, et al. Two-dimensional transition metal carbides. ACS Nano. 2012;6:1322–31.

Anasori B, Lukatskaya MR, Gogotsi Y. 2D metal carbides and nitrides (MXenes) for energy storage. Nat Rev Mater. 2017;16098:1–17.

Barsoum MW. MAX phases: properties of machinable carbides and nitrides. Singapore: Wiley-VCH; 2013.

Tallman DJ, Anasori B, Barsoum MW. A critical review of the oxidation of Ti2AlC, Ti3AlC2 and Cr2AlC in Air. Mater Res Lett. 2013;1:115–25.

Pei R, McDonald SA, Shen L, van der Zwaag S, Sloof WG, Withers PJ, et al. Crack healing behaviour of Cr2AlC MAX phase studied by X-ray tomography. J Eur Ceram Soc. 2017;37:441–50.

Li S, Xiao L, Song G, Wu X, Sloof WG, Van Der Zwaag S. Oxidation and crack healing behavior of a fine-grained Cr2AlC ceramic. J Am Ceram Soc. 2013;96:892–9.

Tian WB, Sun ZM, Du Y, Hashimoto H. Synthesis reactions of Cr2AlC from Cr–Al4C3–C by pulse discharge sintering. Mater Lett. 2008;62:3852–5.

Tian W, Wang P, Zhang G, Kan Y, Li Y, Yan D. Synthesis and thermal and electrical properties of bulk Cr2AlC. Scr Mater. 2006;54:841–6.

Tian WB, Wang PL, Zhang GJ, Kan YM, Li YX. Mechanical properties of Cr2AlC ceramics. J Am Ceram Soc. 2007;90:1663–6.

Sarwar J, Shrouf T, Srinivasa A, Gao H, Radovic M, Kakosimos K. Characterization of thermal performance, flux transmission performance and optical properties of MAX phase materials under concentrated solar irradiation. Sol Energy Mater Sol Cells. 2018;182:76–91.

Liu J, Zuo X, Wang Z, Wang L, Wu X, Ke P, et al. Fabrication and mechanical properties of high purity of Cr2AlC coatings by adjustable Al contents. J Alloys Compd. 2018;753:11–7.

Tian WB, Wang PL, Kan YM, Zhang GJ, Li YX, Yan DS. Phase formation sequence of Cr2AlC ceramics starting from Cr–Al–C powders. Mater Sci Eng A. 2007;443:229–34.

Lin Z, Zhou Y, Li M, Wang J. In-situ hot pressing/solid-liquid reaction synthesis of bulk Cr2AlC. Z für Met. 2005;96:291–6.

Yembadi R, Panigrahi BB. Thermodynamic assessments and mechanically activated synthesis of ultrafine Cr2AlC MAX phase powders. Adv Powder Technol. 2017;28:732–9.

Aksu Demirezen D, Yıldız YŞ, Demirezen Yılmaz D. Amoxicillin degradation using green synthesized iron oxide nanoparticles: kinetics and mechanism analysis. Environ Nanotechnol Monit Manag. 2019;11:100219.

Wang X, Huang Z, Wei M, Lu T, Nong D, Zhao J, et al. Catalytic effect of nanosized ZnO and TiO2 on thermal degradation of poly(lactic acid) and isoconversional kinetic analysis. Thermochim Acta. 2019;672:14–24.

Sharma P, Uniyal P. Investigating thermal and kinetic parameters of lithium titanate formation by solid-state method. J Therm Anal Calorim. 2017;51:1081–94.

Sharma P, Diwan PK, Pandey OP. Impact of environment on the kinetics involved in the solid-state synthesis of bismuth ferrite. Mater Chem Phys. 2019;233:171–9.

Hu M, Chen Z, Wang S, Guo D, Ma C, Zhou Y, et al. Thermogravimetric kinetics of lignocellulosic biomass slow pyrolysis using distributed activation energy model, Fraser-Suzuki deconvolution, and iso-conversional method. Energy Convers Manag. 2016;118:1–11.

Lysenko EN, Surzhikov AP, Nikolaev EV, Vlasov VA. Thermal analysis study of LiFeO2 formation from Li2CO3–Fe2O3 mechanically activated reagents. J Therm Anal Calorim. 2018;134:81–7.

Lysenko EN, Nikolaev EV, Surzhikov AP, Nikolaeva SA, Plotnikova IV. The influence of reagents ball milling on the lithium ferrite formation. J Therm Anal Calorim. 2019;138:2005–13.

Akahira T, Sunose T. Method of determining activation deterioration constant of electrical insulating materials. Res Rep Chiba Inst Technol (Sci Technol). 1971;16:22–31.

Starink MJ. The determination of activation energy from linear heating rate experiments: a comparison of the accuracy of isoconversion methods. Thermochim Acta. 2003;404:163–76.

Friedman HL. Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J Polym Sci Part C Polym Symp. 2007;6:183–95.

Chen J, Wang Y, Lang X, Ren X, Fan S. Evaluation of agricultural residues pyrolysis under non-isothermal conditions: thermal behaviors, kinetics, and thermodynamics. Bioresour Technol. 2017;241:340–8.

Sharma P, Pandey OP. Non-isothermal oxidation kinetics of nano-laminated Cr2AlC MAX phase. J Alloys Compd. 2019;773:872–82.

Quan C, Li A, Gao N. Thermogravimetric analysis and kinetic study on large particles of printed circuit board wastes. Waste Manag. 2009;29:2353–60.

Sharma P, Jha PK, Diwan PK, Pandey OP. Impact of CuS on the crystallization kinetics of Na2S–P2S5 glasses. J Non Cryst Solids. 2017;477:31–41.

Sharma P, Diwan PK. Study of thermal decomposition process and the reaction mechanism of the eucalyptus wood. Wood Sci Technol. 2017;128:875–82.

Flynn JH, Wall LA. A quick, direct method for the determination of activation energy from thermogravimetry data. J Polym Sci Part C Polym Lett. 1966;4:323–8.

Ozawa T. A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn. 1965;38:1881–6.

Ratcliffe C, Ratcliffe B (editors). Propagation of uncertainty an uncertainty budget example, 1st edn. Doubt-Free Uncertainty In Measurement. Switzerland: Springer International Publishing; 2015.

Sharma P, Kaur T, Pandey OP. In-situ single step reduction and silicidation of the MoO3 to form the MoSi2. J Am Ceram Soc. 2019;102:1522–34.

Sharma P, Pandey OP, Diwan PK. Non-isothermal kinetics of pseudo-components of waste biomass. Fuel. 2019;253:1149–61.

Dueramae I, Jubsilp C, Takeichi T, Rimdusit S. Thermal degradation mechanism of highly filled nano-SiO2 and polybenzoxazine. J Therm Anal Calorim. 2014;116:435–46.

Zhu F, Xu Y, Feng Q, Yang Q. Thermal kinetics study and flammability evaluation of polyimide fiber material. J Therm Anal Calorim. 2018;131:2579–87.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sharma, P., Pandey, O.P. Thermal kinetics involved during the solid-state synthesis of Cr2AlC MAX phase. J Therm Anal Calorim 143, 3997–4008 (2021). https://doi.org/10.1007/s10973-020-09390-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09390-8