Abstract

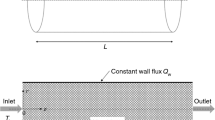

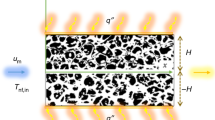

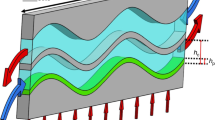

The following study aimed to determine the effect of nanofluid concentration and the inclusion of porously filled channels on the thermal performance of highly porous open-cell foam metals. The study considered variable heat flux, nanofluid concentration and considered porously filled channels and bulk porous media. The nanofluid used in the experimental and numerical work was γ-Al2O3 nanoparticles suspended in water. The foam metal used was composed of 6061-T6 aluminum with a porosity of 0.91 and a permeability of 3.36e − 8 m2. The nanofluid concentrations used for the study were 0.1%, 0.3%, and 0.6% by volume. The experimental and numerical work showed good agreement with a maximum relative error between numerical and experimental temperature of 4.8% and an average error of 3.0%. The thermal performance of the system was evaluated based on Nusselt number and an index of performance including pressure effects. The results indicate that the optimal conditions for system operation are 0.6% with porously filled channels when pumping power is not considered of importance. However, should the pumping power be considered as an essential operating parameter then the optimal system conditions are 0.3% with bulk porous media.

Similar content being viewed by others

References

Dukhan N, Bagci O, Ozdemir M. Metal foam hydrodynamics: flow regimes from pre-Darcy to turbulent. Int J Heat Mass Transf. 2014;77:114–23.

Xu C, Mao Y, Hu Z. Numerical study of pore-scale flow and noise of an open cell metal foam. Aerosp Sci Technol. 2018;82–83:185–98.

Andrea D, Bodla KK, Rossetto L, Garimella SV. Numerical investigation of pressure drop and heat transfer through reconstructed metal foams and comparison against experiments. Int J Heat Mass Transf. 2015;88:508–15.

Etaig S, Hasan R, Perera N. A new effective viscosity model for nanofluids. Int J Numer Methods Heat Fluid Flow. 2018;28(3):571–83.

Moldoveanu GM, Minea AA, Iacob M, Ibanescu C, Danu M. Experimental study on viscosity of stabilized Al2O3, TiO2 nanofluids and their hybrid. Thermochim Acta. 2018;659:203–12.

Hsu CT, Cheng P, Wong KW. Modified Zehner–Schlunder models for stagnant thermal conductivity of porous media. Int J Heat Mass Transf. 1994;37(17):2751–9.

Bhattacharya A, Calmidi VV, Mahajan RL. Thermophysical properties of high porosity metal foams. Int J Heat Mass Transf. 2002;45:1017–31.

Boomsma K, Poulikakos D. On the effective thermal conductivity of a three- dimensionally structured fluid-saturated metal foam. Int J Heat Mass Transf. 2001;44:827–36.

Dai Z, Nawaz K, Park YG, Bock J, Jacobi AM. Correcting and extending the boomsma-poulikakos effective thermal conductivity model for three-dimensional fluid-saturated metal foams. Int Commun Heat Mass Transf. 2010;37:575–80.

Boomsma K, Poulikakos D. Corrigendum for the paper: K. Boomsma, D. Poulikakos, ‘‘On the effective thermal conductivity of a three-dimensionally structured fluid-saturated metal foam’’. Int J Heat Mass Transf. 2001;44:827–36.

Boomsma K, Poulikakos D. Corrigendum for the paper: K. Boomsma, D. Poulikakos, ‘‘On the effective thermal conductivity of a three-dimensionally structured fluid-saturated metal foam’’. Int J Heat Mass Transf. 2011;54:746–8.

Bhattacharya A, Mahajan RL. Finned metal foam heat sinks for electronics cooling in forced convection. J Electron Packag. 2002;124(3):155–63.

Zhao CY, Kim T, Lu TJ, Hodson HP. Thermal transport in high porosity cellular metal foams. J Thermophys Heat Transf. 2004;18(3):309–18.

Xu H, Gong L, Huang S, Xu M. Flow and heat transfer characteristics of nanofluid flowing through metal foams. Int J Heat Mass Transf. 2015;83:399–407.

Vijay D, Goetze P, Wulf R, Gross U. Homogenized and pore-scale analyses of forced convection through open cell foams. Int J Heat Mass Transf. 2018;123:787–804.

Gong L, Li Y, Bai Z, Xu M. Thermal performance of micro-channel heat sink with metallic porous/solid compound fin design. J Appl Therm Eng. 2018;137:288–95.

Buschmann MH, Azizian R, Kempe T, Julia JE, Martinez-Cuenca R, Sunden B, Wu Z, Seppala A, Ala-Nissila T. Correct interpretation of nanofluid convective heat transfer. Int J Therm Sci. 2018;129:504–31.

Ho C, Chen M, Li Z. Numerical simulation of natural convection of nanofluid in a square enclosure: effects due to uncertainties of viscosity and thermal conductivity. Int J Heat Mass Transf. 2008;51(17–18):4506–16. https://doi.org/10.1016/j.ijheatmasstransfer.2007.12.019.

Ho C, Liu W, Chang Y, Lin C. Natural convection heat transfer of alumina-water nanofluid in vertical square enclosures: an experimental study. Int J Therm Sci. 2010;49(8):1345–53. https://doi.org/10.1016/j.ijthermalsci.2010.02.013.

Ho C, Wei L, Li Z. An experimental investigation of forced convective cooling performance of a microchannel heat sink with Al2O3/water nanofluid. Appl Therm Eng. 2010;30(2–3):96–103. https://doi.org/10.1016/j.applthermaleng.2009.07.003.

Ho C, Chen W. An experimental study on thermal performance of Al2O3/water nanofluid in a minichannel heat sink. Appl Therm Eng. 2013;50(1):516–22. https://doi.org/10.1016/j.applthermaleng.2012.07.037.

Bayomy A, Saghir M, Yousefi T. Electronic cooling using water flow in aluminum metal foam heat sink: Experimental and numerical approach. Int J Therm Sci. 2016;109:182–200. https://doi.org/10.1016/j.ijthermalsci.2016.06.007.

Bayomy A, Saghir M. Experimental study of using γ-Al2O3—water nanofluid flow through aluminum foam heat sink: comparison with numerical approach. Int J Heat Mass Transf. 2017;107:181–203. https://doi.org/10.1016/j.ijheatmasstransfer.2016.11.037.

Jouybari H, Saedodin S, Zamzamian A, Nimvari M, Wongwises S. Effects of porous material and nanoparticles on the thermal performance of a flat plate solar collector: an experimental study. Renew Energy. 2017;114:1407–18. https://doi.org/10.1016/j.renene.2017.07.008.

Jouybari H, Nimvari M, Saedodin S. Thermal performance evaluation of a nanofluid- based flat- plate solar collector. J Therm Anal Calorim. 2019;137(5):1757–74. https://doi.org/10.1007/s10973-019-08077-z.

B. Battleson, “Duocel® Aluminum Foam”, ERG Aerospace, 2019. [Online]. Available: http://ergaerospace.com/materials/duocel-aluminum-foam/. Accessed 10 Jun 2019.

“Buy Al2O3-monodisperse spherical nanoparticles in Aqueous media | Al2O3-monodisperse spherical nanoparticles in Aqueous media Online: MKNano.com”, Mknano.com, 2019. [Online]. Available: https://www.mknano.com/Nanoparticles/Single-Element-Oxides/Aluminum-Oxide-Nanopowder/Al2O3-monodisperse-spherical-nanoparticles-in-Aqueous-media. Accessed 10 Jun 2019.

Bayomy A, Saghir M. Experimental and numerical study of the heat transfer characteristics of aluminum metal foam (with/without channels) subjected to steady water flow. J Sci Technol. 2017;25(1):221–46.

“COMSOL Multiphysics® Modeling Software”, Comsol.com, 2019. [Online]. Available: https://www.comsol.com/. Accessed 10 Jun 2019.

Acknowledgements

The authors would like to thank Ryerson University for their continued support and funding of their research and study into thermal science. As well the authors would like to thank the National Science and Engineering Research Council of Canada for their funding and support which made the successful completion of this research possible.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Welsford, C.A., Delisle, C.S., Plant, R.D. et al. Effects of nanofluid concentration and channeling on the thermal effectiveness of highly porous open-cell foam metals: a numerical and experimental study. J Therm Anal Calorim 140, 1507–1517 (2020). https://doi.org/10.1007/s10973-019-09166-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-09166-9