Abstract

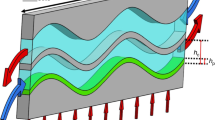

Porous structures, owning a high specific surface area, are widely employed in the industry. Microporous metal foams have high thermal performance, and their combination with nanoparticles is a genuine solution to increase heat transfer. This numerical study aims to inspect laminar flow characteristics and heat transfer of water-based nanofluids through a horizontal circular tube filled with metal foam under constant heat flux. Four nanoparticles, including NiO, Ag, SiO2 and TiO2, have been studied, and the effect of the volume fraction, Reynolds number, porosity and pores per inch on the heat transfer coefficient and pressure drop has been investigated. The highest Nusselt numbers, at 0.8% porosity, 1% concentration of nanofluid and a Reynolds number of 1000, are 16.27, 16.03, 16.47 and 16.39 for NiO, Ag, SiO22 and TiO2, respectively. The results show that, in all cases, the highest Nusselt number corresponds to the SiO2, TiO, NiO and Ag nanofluids, respectively. The pore per inch has the greatest effect on the pressure drop, and its change from 5 to 60 increases the pressure drop by about 125 times.

Similar content being viewed by others

Abbreviations

- a :

-

Specific surface area [m−2]

- C B :

-

Boltzmann's constant [1.38066 × 10–23 J K−1]

- C p :

-

Specific heat [J kg−1 K−1]

- d :

-

Particle diameter [nm]

- d f :

-

Diameter of the fiber of metal foam [mm]

- d p :

-

Pore size [mm]

- f :

-

Friction factor

- h :

-

Heat transfer coefficient [W m−2 K−1]

- k :

-

Thermal conductivity [W m−1 K−1]

- k eff :

-

Effective thermal conductivity [W m−1 K−1]

- K :

-

Permeability [m2]

- L :

-

Tube length [m]

- M :

-

Molecular weight

- n :

-

Number of samples

- N :

-

Avogadro number [6.022 × 1023 mol−1]

- Nu:

-

Nusselt number

- p :

-

Pressure [Pa]

- PPI:

-

Pore per inch

- Q w :

-

Wall heat flux [W m−2]

- Re:

-

Reynolds number

- Red :

-

Local Reynolds number

- T :

-

Temperature [K]

- U :

-

Velocity at x-axis [m s−1]

- uB:

-

Mean Brownian velocity of nanoparticle[m s−1]

- b:

-

Bulk

- bf:

-

Base fluid

- eff:

-

Effective property

- exp:

-

Experimental

- f:

-

Fluid

- in:

-

Inlet

- nf:

-

Nanofluid

- np:

-

Nanoparticle

- ref:

-

Reference state

- s:

-

Solid

- sim:

-

Simulation

- w:

-

Wall

- ε :

-

Porosity

- μ :

-

Dynamic viscosity [kg m−1 s−1]

- ρ :

-

Density [kg m−3]

- φ :

-

Volume fraction

References

Habibishandiz M, Saghir M. A critical review of heat transfer enhancement methods in the presence of porous media, nanofluids, and microorganisms. Therm Sci Eng Progress. 2022;30:101267. https://doi.org/10.1016/j.tsep.2022.101267.

Dukhan N. Forced convection of nanofluids in metal foam: an essential review. Int J Therm Sci. 2023;187:108156. https://doi.org/10.1016/j.ijthermalsci.2023.108156.

Amani M, Ameri M, Kasaeian A. The experimental study of convection heat transfer characteristics and pressure drop of magnetite nanofluid in a porous metal foam tube. Transp Porous Media. 2017;116:959–74. https://doi.org/10.1007/s11242-016-0808-6.

Amani M, Ameri M, Kasaeian A. Hydrothermal characteristics of spinel manganese ferrite nanofluid in a metal foam tube: modeling of experimental results using artificial neural network. Heat Transf Eng. 2019;40(8):627–39. https://doi.org/10.1080/01457632.2018.1436644.

Nazari M, et al. Experimental study of convective heat transfer of a nanofluid through a pipe filled with metal foam. Int J Therm Sci. 2015;88:33–9. https://doi.org/10.1016/j.ijthermalsci.2014.08.013.

Martin E, et al. Heat transfer enhancement around a finned vertical antenna by means of porous media saturated with water-copper nanofluid. Case Stud Therm Eng. 2021;28:101555. https://doi.org/10.1016/j.csite.2021.101555.

Zaaroura I, et al. Thermal performance of self-rewetting gold nanofluids: application to two-phase heat transfer devices. Int J Heat Mass Transf. 2021;174:121322. https://doi.org/10.1016/j.ijheatmasstransfer.2021.121322.

Farahani SD, et al. Effect of magnetic field on heat transfer from a channel: nanofluid flow and porous layer arrangement. Case Stud Therm Engineering. 2021;28:101675. https://doi.org/10.1016/j.csite.2021.101675.

Achard, F., James Clerk Maxwell, A treatise on electricity and magnetism, (1873), in Landmark Writings in Western Mathematics 1640–1940. 2005, Elsevier. p. 564–587. https://doi.org/10.1016/B978-044450871-3/50125-X

Choi, S.U. and J.A. Eastman, Enhancing thermal conductivity of fluids with nanoparticles. 1995, Argonne National Lab., IL (United States)

Baghban A, et al. Connectionist intelligent model estimates of convective heat transfer coefficient of nanofluids in circular cross-sectional channels. J Therm Anal Calorim. 2018;132:1213–39. https://doi.org/10.1007/s10973-017-6886-z.

Khan U, et al. A novel analysis of heat transfer in the nanofluid composed by nanodimaond and silver nanomaterials: numerical investigation. Sci Rep. 2022;12(1):1284. https://doi.org/10.1038/s41598-021-04658-x.

Baghban A, et al. Towards experimental and modeling study of heat transfer performance of water-SiO2 nanofluid in quadrangular cross-section channels. Eng Appl Comput Fluid Mech. 2019;13(1):453–69. https://doi.org/10.1080/19942060.2019.1599428.

Ekiciler R, Çetinkaya MSA. A comparative heat transfer study between monotype and hybrid nanofluid in a duct with various shapes of ribs. Therm Sci Eng Progress. 2021;23:100913. https://doi.org/10.1016/j.tsep.2021.100913.

Anitha S, Pichumani M. Numerical analysis on heat transfer performance of industrial double-tube heat exchanger using CNT: Newtonian/non-Newtonian hybrid nanofluids. J Therm Anal Calorim. 2022;147(17):9603–24. https://doi.org/10.1007/s10973-022-11249-z.

Zaboli S, Alimoradi H, Shams M. Numerical investigation on improvement in pool boiling heat transfer characteristics using different nanofluid concentrations. J Therm Anal Calorim. 2022;147(19):10659–76. https://doi.org/10.1007/s10973-022-11272-0.

Jalili B, et al. Novel usage of the curved rectangular fin on the heat transfer of a double-pipe heat exchanger with a nanofluid. Case Stud Therm Eng. 2022;35:102086. https://doi.org/10.1016/j.csite.2022.102086.

Saleh B, Sundar LS. Thermal performance, embodied energy and environmental CO2 emissions analyses for double pipe U-bend heat exchanger working with MWCNT/water nanofluid. Int J Therm Sci. 2021;169:107094. https://doi.org/10.1016/j.ijthermalsci.2021.107094.

Sundar LS, Deepanraj B, Mewada HK. ANFIS based effectiveness and number of transfer units predictions of MWCNT/water nanofluids flow in a double pipe U-bend heat exchanger. Case Stud Therm Eng. 2023;43:102645. https://doi.org/10.1016/j.csite.2022.102645.

Alklaibi A, Mouli KVC, Sundar LS. Experimental investigation of heat transfer and effectiveness of employing water and ethylene glycol mixture based Fe3O4 nanofluid in a shell and helical coil heat exchanger. Therm Sci Eng Progress. 2023;40:101739. https://doi.org/10.1016/j.csite.2022.102645.

Lotfi M, et al. An experimental study on convective heat transfer and pressure drop during the movement of TiO2/water nanofluid through a helical coiled path. J Therm Anal Calorim. 2023;148(13):6183–95. https://doi.org/10.1007/s10973-023-12080-w.

Abadeh A, et al. An experimental study on ferrofluid flow and heat transfer in a micro-fin straight circular tube. J Therm Anal Calorim. 2023. https://doi.org/10.1007/s10973-023-12024-4.

Faizan M, et al. Numerical study of nanofluid flow and heat transfer through a non-uniformly heated converging duct. Case Stud Therm Eng. 2022;40:102545. https://doi.org/10.1016/j.csite.2022.102545.

Prabakar KS, et al. Thermo-convective behavior and entropy generation studies on alumina and titania nanofluids flowing through polygonal ducts. Int J Therm Sci. 2023;186:108123. https://doi.org/10.1016/j.ijthermalsci.2022.108123.

Ambreen T, Saleem A, Park CW. Thermal efficiency of eco-friendly MXene based nanofluid for performance enhancement of a pin-fin heat sink: experimental and numerical analyses. Int J Heat Mass Transf. 2022;186:122451. https://doi.org/10.1016/j.ijheatmasstransfer.2021.122451.

Kumar R, Tiwary B, Singh PK. Thermofluidic analysis of Al2O3-water nanofluid cooled branched wavy heat sink. Appl Therm Eng. 2022;201:117787. https://doi.org/10.1016/j.applthermaleng.2021.117787.

Ali AM, Angelino M, Rona A. Numerical analysis on the thermal performance of microchannel heat sinks with Al2O3 nanofluid and various fins. Appl Therm Eng. 2021;198:117458. https://doi.org/10.1016/j.applthermaleng.2021.117458.

Xu H, et al. Analytical considerations of local thermal non-equilibrium conditions for thermal transport in metal foams. Int J Therm Sci. 2015;95:73–87. https://doi.org/10.1016/j.ijthermalsci.2015.04.007.

Buonomo B, Manca O, Lauriat G. Forced convection in micro-channels filled with porous media in local thermal non-equilibrium conditions. Int J Therm Sci. 2014;77:206–22. https://doi.org/10.1016/j.ijthermalsci.2013.11.003.

Xu H, Xing Z, Vafai K. Analytical considerations of flow/thermal coupling of nanofluids in foam metals with local thermal non-equilibrium (LTNE) phenomena and inhomogeneous nanoparticle distribution. Int J Heat Fluid Flow. 2019;77:242–55. https://doi.org/10.1016/j.ijheatfluidflow.2019.04.009.

Lu W, Zhao CY, Tassou SA. Thermal analysis on metal-foam filled heat exchangers. Part I: metal-foam filled pipes. Int J Heat Mass Transf. 2006;49(15–16):2751–61.

Calmidi VV, Mahajan RL. Forced convection in high porosity metal foams. J Heat Transf. 2000;122(3):557–65. https://doi.org/10.1115/1.1287793.

Kim S, Paek J, Kang B. Flow and heat transfer correlations for porous fin in a plate-fin heat exchanger. J Heat Transf. 2000;122(3):572–8. https://doi.org/10.1115/1.1287170.

Khanafer K, Vafai K. A critical synthesis of thermophysical characteristics of nanofluids. Int J Heat Mass Transf. 2011;54(19–20):4410–28. https://doi.org/10.1016/j.ijheatmasstransfer.2011.04.048.

Corcione M. Heat transfer features of buoyancy-driven nanofluids inside rectangular enclosures differentially heated at the sidewalls. Int J Therm Sci. 2010;49(9):1536–46. https://doi.org/10.1016/j.ijthermalsci.2010.05.005.

Bianco V, Scarpa F, Tagliafico LA. Numerical analysis of the Al2O3-water nanofluid forced laminar convection in an asymmetric heated channel for application in flat plate PV/T collector. Renew Energy. 2018;116:9–21. https://doi.org/10.1016/j.renene.2017.09.067.

Pourfayaz F, et al. An experimental comparison of SiO2/water nanofluid heat transfer in square and circular cross-sectional channels. J Therm Anal Calorim. 2018;131:1577–86. https://doi.org/10.1007/s10973-017-6500-4.

Aguilar T, et al. Investigation of enhanced thermal properties in NiO-based nanofluids for concentrating solar power applications: a molecular dynamics and experimental analysis. Appl Energy. 2018;211:677–88. https://doi.org/10.1016/j.apenergy.2017.11.069.

Sheikholeslami M, Rokni HB. Simulation of nanofluid heat transfer in presence of magnetic field: a review. Int J Heat Mass Transf. 2017;115:1203–33. https://doi.org/10.1016/j.ijheatmasstransfer.2017.08.108.

Alvariño PF, et al. A numerical investigation of laminar flow of a water/alumina nanofluid. Int J Heat Mass Transf. 2013;59:423–32. https://doi.org/10.1016/j.ijheatmasstransfer.2012.12.033.

Zhu G, et al. Heat transfer characteristics of subcooled water in a hypervapotron under high mass fluxes and high heat fluxes. Int J Heat Mass Transf. 2019;129:580–90. https://doi.org/10.1016/j.ijheatmasstransfer.2018.09.102.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fallah Barzoki, M., Rahmani, M., Shahabi Nejad, A. et al. Investigating the thermal performance of different nanofluids in a metal foam tube under laminar flow regime. J Therm Anal Calorim 148, 12947–12959 (2023). https://doi.org/10.1007/s10973-023-12553-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12553-y