Abstract

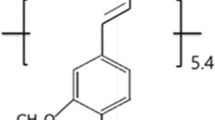

Lignin-based polycaprolactone (PCL) graft copolymers with various graft ratios were prepared by ring-opening reaction in order to design new lignin derivatives. Molecular length of PCL side chain was varied in a wide range, i.e. caprolactone/hydroxyl group (CL/OH) ratio was varied from 3 to 100 mol mol−1. The effect of lignin on thermal properties of PCL was examined by differential scanning calorimetry (DSC) and thermogravimetry. In DSC heating curves of lignin-based PCL, glass transition, pre-melt crystallization and melting were observed. From DSC results, the phase diagram of lignin-based PCL was established. It was found that glass transition temperature (Tg) decreased until CL/OH ratio reached 20, and then, Tg was maintained at around 200 K. Tg slightly increased when CL/OH ratio became higher than 20. The above facts suggest that the random structure of lignin affects the molecular motion of copolymers in a limited length of PCL chains, and that with increasing PCL chain length, free molecular motion is restricted by crystallization. The amorphous region of lignin–PCL was reorganized at pre-melt crystallization, and crystallinity increased. When CL/OH ratio increased more than 20, two melting peaks were observed; the low-temperature side is PCL crystallite affected by lignin and the high-temperature side melting peak is attributed to melting PCL crystal. The effect of lignin on thermal decomposition is apparently observed for lignin-based PCL when CL/OH ratio is smaller than 20. The above results suggest that lignin-based PCL graft copolymers have the potential of an applicant of novel nature-friendly polymers.

Similar content being viewed by others

References

Labe M, Thielemans W. Synthesis of polycaprolactone: a review. Chem Soc Rev. 2009;38:3484–504.

Woodruff MA, Hutmacher DW. The return of a forgotten polymer-Polycaprolactone in the 21st century. Prog Polym Sci. 2010;35:1195–216.

Pitt CC, Chasalow FI, Hibionada YM, Klimas DM, Schindler A. Aliphatic polyesters. I. The degradation of poly(ε‐caprolactone) in vivo. J Appl Polym Sci. 1981;81:3779–87.

De Kesel C, Vander C, Wauven DC. Biodegradation of polycaprolactone and its blends with poly(vinylalcohol) by micro-organisms from a compost of house-hold refuse. Polym Degrad Stabil. 1997;55:107–13.

Wu C-S. Physical properties and biodegradability of maleated-polycaprolactone/starch composite. Polym Deg Stab. 2003;80:127–34.

Coleman MM, Zarian J. Fourier-transform infrared studies of polymer blends. II. Poly(ε-caprolactone)-poly(vinyl chloride) system. J Polym Sci Polym Phys. 1979;17:837–50.

Chun YS, Kyung YJ, Jung HC, Kim WN. Thermal and rheological properties of poly(e-caprolactone) and polystyrene blends. Polymer. 2000;41:8729–33.

Hatakeyama H, Hatakeyama T. Lignin structure, properties and application. Adv Polym Sci. 2010;232:1–63.

Hatakeyama T, Hatakeyama H. Thermal properties of green polymers and biocomposites. Dordrecht: Kluwer Academic; 2004.

Hatakeyama H, Hatakeyama T. Green polyurethanes: molecular design and application. New York: Nova Science Publishers, Inc.; 2016.

Hatakeyama H, Hirogaki A, Matsumura H, Hatakeyama T. Glass transition temperature of polyurethane foams derived from lignin by controlled reaction rate. J Therm Anal Calorim. 2013;14:1075–82.

Hatakeyama H, Hatakeyama T. Thermal properties of freezing bound water restrained by sodium lignosulfonate-based polyurethane hydrogels. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7337-1.

Hatakeyama H, Ohsuga T, Hatakeyama T. Thermogravimetry on wood powder-filled polyurethane composites derived from lignin. J Therm Anal Calorim. 2014;118:23–30.

Hatakeyama H, Hirose S. Biodegradable polymeric material and preparation method (Title: translated from Japanese), JP-3291523, registered 2002-3-29; 2002.

Hatakeyama H, Izuta Y, Kobashigawa K, Hirose S, Hatakeyama T. Synthesis and physical properties of polyurethanes from saccharide-based polycaprolactones. Macromol Symp. 1998;130:127–38.

Honma T, Senda T, Inoue Y. Thermal properties and crystallization behavior of blends of poly(ε-caprolactone) with chitin and chitosan. Polym J. 2003;52:1839–46.

Chen B, Sun K, Ren T. Mechanical and viscoelastic properties of chitin fiber reinforced poly(ε-caprolactone). Eur Polym J. 2005;41:453–7.

Salgado CL, Sanchez EMS, Mano JF, Moraes AM. Characterization of chitosan and polycaprolactone membranes designed for wound repair application. J Mater Sci. 2012;47:659–67.

Hatakeyama H, Yoshida T, Hatakeyama T. The effect of side chain association on thermal and viscoelastic properties Cellulose acetate based polycaprolactones. J Thermal Anal Calorim. 2000;59:157–68.

Hirose S, Hatakeyama T, Izuta Y, Hatakeyama H. TG-FTIR studies on lignin-based polycaprolactones. J Therm Anal Calorim. 2002;70:853–60.

Persenaire O, Alexandre M, Degée P, Dubois P. Mechanisms and kinetics of thermal degradation of poly(ε-caprolactone). Biomacromolecules. 2001;2:288–94.

Murphy SH, Leeke GA, Jenkins MJ. A Comparison of the use of FTIR spectroscopy with DSC in the characterisation of melting and crystallisation in polycaprolactone. J Therm Anal Calorim. 2012;107:669–74.

Lai ZY, Sarkanen KV. Isolation and structural studies. In: Sarkanen KV, Ludwig CH, editors. Lignins, occurrence, formation, structure and reactions. New York: Wiley; 1971. p. 165–240.

Lebo SE, Braten SM, Fredheim GE, Lutnaes BF, Lauten RA, Myrvold BO, McNally TJ. Recent advances in the characterization of lignosulfonate. In: Hu TQ, editor. Characterization of lignocellulosic materials. Oxford: Blackwell; 2008. p. 188–205.

Huarng JC, Min K, White JL. Phase equilibrium in the binary and ternary blend system: Polycaprolactone-polyvinyl chloride-styrene acrylonitrile copolymer. Polym Eng Sci. 1988;24:1590–9.

Hatakeyama H, Tsujimoto Y, Zarubin Ja M, Krutov SM, Hatakeyama T. Thermal decomposition and glass transition of industrial hydrolysis lignin. J Therm Anal Calorim. 2010;101:289–95.

Hatakeyama T, Izuta Y, Hirose S, Hatakeyama H. Phase transitions of lignin-based polycaprolactones and their polyurethane derivatives. Polymer. 2002;43:177–1182.

Hatakeyama H, Yoshida T, Hirose S, Hatakeyama T. Thermal and viscoelastic properties of cellulose-and lignin-based polycaprolactones. In: Kennedy JF, Phillips GO, Williams PA, Lönnberg B, editors. Cellulosic pulps, fibres and materials. Cambridge: Woodhead Pub Ltd; 2000. p. 327–36.

Hatakeyama T, Hatakeyama H. Effect of chemical structure of amorphous polymers on heat capacity difference at glass transition temperature. Thermochim Acta. 1995;267:249–57.

Acknowledgements

We wish to express our thanks to Professor Clive S. Langham for his help with the preparation of the manuscript for this article.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hatakeyama, T., Yamashita, S. & Hatakeyama, H. Thermal properties of lignin-based polycaprolactones. J Therm Anal Calorim 143, 203–211 (2021). https://doi.org/10.1007/s10973-019-09161-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-09161-0