Abstract

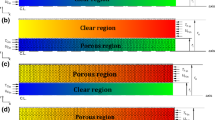

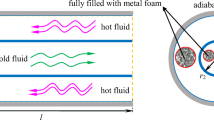

This is a numerical study of heat transfer and flow in a counter-flow sinusoidal parallel-plate heat exchanger using metal foam in the channels’ divergent sections. The cold water fluid with Reynolds number of 100 and hot oil fluid with Reynolds number of 2 enter the downer and upper channels of the heat exchanger, respectively. The sinusoidal heat exchanger is investigated with two-wave amplitudes (0.3 and 0.6 cm), two wavelengths (6 and 12 cm) inserting the porous media with three particle diameters (0.1, 0.05 and 0.01 mm) and three thicknesses (A/3, 2A/3, and A). Darcy–Brinkman–Forchheimer and local thermal non-equilibrium models are used. To evaluate the increased heat transfer versus the increased pumping power, a dimensionless number called performance evaluation criteria (PEC) has been defined in the current study. The obtained results showed that the heat transfer rate, effectiveness and overall heat transfer coefficient of the heat exchanger are increased up to 19.2%, and the PEC number is enhanced to 1.171 in the optimum case with wave amplitude, wavelength, metal foam particle diameter and thickness equal to 0.6 cm, 6 cm, 0.01 mm and 2A/3, respectively. Moreover, since the metal foam is embedded in the wake region of the heat exchanger or channels’ divergent sections, its effect on pumping power is subtle, which is an advantage of using the porous medium at these regions.

Similar content being viewed by others

Abbreviations

- A :

-

Wave amplitude (m)

- A r :

-

Area (m2)

- a sf :

-

Fluid-to-solid specific area

- C :

-

Specific heat capacity (J kg−1 K−1)

- d p :

-

Particle diameter (m)

- Da :

-

Darcy number

- h :

-

Heat transfer coefficient (W m−2 K−1)

- h c :

-

Channel height (m)

- h p :

-

Porous thickness (m)

- h sf :

-

Fluid-to-solid heat transfer coefficient

- K :

-

Permeability (m2)

- k :

-

Thermal conductivity (W m−1 K−1)

- k eff :

-

Effective thermal conductivity (W m−1 K−1)

- k ef :

-

Effective thermal conductivity of porous region solid phase (W m−1 K−1)

- k es :

-

Effective thermal conductivity of porous region fluid phase (W m−1 K−1)

- k er :

-

Ratio of effective solid thermal conductivity to that of fluid

- l :

-

Length of the channel (m)

- Nu :

-

Nusselt number

- Nu x :

-

Local Nusselt number

- PEC:

-

Performance evaluation criteria

- p :

-

Pressure (Pa)

- Pr :

-

Prandtl number

- q :

-

Heat transfer rate (W)

- Re :

-

Reynolds number

- T :

-

Temperature (K)

- u :

-

x-direction velocity (m s−1)

- v :

-

y-direction velocity (m s−1)

- W p :

-

Pumping power

- \(\theta\) :

-

Dimensionless temperature

- \(\vartheta\) :

-

Cinematic viscosity (m2 s−1)

- \(\mu\) :

-

Dynamic viscosity (kg ms−1)

- \(\rho\) :

-

Density kg m−3

- \(\varepsilon\) :

-

Porosity

- eff:

-

Effective

- en:

-

Entrance

- ex:

-

Exit

- f:

-

Fluid

- i:

-

Inlet

- o:

-

Outlet

- pl:

-

Plain heat exchanger

- s:

-

Solid

- w:

-

Wall

References

Kumar JP, Umavathi JC, Chamkha AJ, Pop I. Fully-developed free-convective flow of micropolar and viscous fluids in a vertical channel. Appl Math Model. 2010;34(5):1175–86.

Umavathi JC, Chamkha AJ, Mateen A, Al-Mudhaf A. Unsteady two-fluid flow and heat transfer in a horizontal channel. Heat Mass Transf. 2005;42(2):81.

Arabpour A, Karimipour A, Toghraie D, Akbari OA. Investigation into the effects of slip boundary condition on nanofluid flow in a double-layer microchannel. J Therm Anal Calorim. 2018;131(3):2975–91.

Chamkha AJ, Khaled A-RA. Similarity solutions for hydromagnetic mixed convection heat and mass transfer for Hiemenz flow through porous media. Int J Numer Methods Heat Fluid Flow. 2000;10(1):94–115.

Barnoon P, Toghraie D, Eslami F, Mehmandoust B. Entropy generation analysis of different nanofluid flows in the space between two concentric horizontal pipes in the presence of magnetic field: single-phase and two-phase approaches. Comput Math Appl. 2019;77(3):662–92.

Hosseinnezhad R, Akbari OA, Afrouzi HH, Biglarian M, Koveiti A, Toghraie D. Numerical study of turbulent nanofluid heat transfer in a tubular heat exchanger with twin twisted-tape inserts. J Therm Anal Calorim. 2018;132(1):741–59.

Chamkha AJ. Non-Darcy fully developed mixed convection in a porous medium channel with heat generation/absorption and hydromagnetic effects. Numer Heat Transf Part A Appl. 1997;32(6):653–75.

Oveissi S, Eftekhari SA, Toghraie D. Longitudinal vibration and instabilities of carbon nanotubes conveying fluid considering size effects of nanoflow and nanostructure. Physica E. 2016;83:164–73.

Barnoon P, Toghraie D, Dehkordi RB, Abed H. MHD mixed convection and entropy generation in a lid-driven cavity with rotating cylinders filled by a nanofluid using two phase mixture model. J Magn Magn Mat. 2019;483:224–48.

Noorian H, Toghraie D, Azimian AR. The effects of surface roughness geometry of flow undergoing Poiseuille flow by molecular dynamics simulation. Heat Mass Transf. 2014;50(1):95–104.

Reddy PS, Chamkha AJ. Soret and Dufour effects on MHD convective flow of Al2O3–water and TiO2–water nanofluids past a stretching sheet in porous media with heat generation/absorption. Adv Powder Technol. 2016;27(4):1207–18.

Chamkha AJ. Double-diffusive convection in a porous enclosure with cooperating temperature and concentration gradients and heat generation or absorption effects. Numer Heat Transf Part A Appl. 2002;41(1):65–87.

Karbasifar B, Akbari M, Toghraie D. Mixed convection of Water-Aluminum oxide nanofluid in an inclined lid-driven cavity containing a hot elliptical centric cylinder. Int J Heat Mass Transf. 2018;116:1237–49.

Toosi MH, Siavashi M. Two-phase mixture numerical simulation of natural convection of nanofluid flow in a cavity partially filled with porous media to enhance heat transfer. J Mol Liq. 2017;238:553–69.

Siavashi M, Rostami A. Two-phase simulation of non-Newtonian nanofluid natural convection in a circular annulus partially or completely filled with porous media. Int J Mech Sci. 2017;133:689–703.

Siavashi M, Karimi K, Xiong Q, Doranehgard MH. Numerical analysis of mixed convection of two-phase non-Newtonian nanofluid flow inside a partially porous square enclosure with a rotating cylinder. J Therm Anal Calorim. 2019;137(1):267–87.

Siavashi M, Bahrami HRT, Aminian E, Saffari H. Numerical analysis on forced convection enhancement in an annulus using porous ribs and nanoparticle addition to base fluid. J Cent South Univ. 2019;26(5):1089–98.

Maghsoudi P, Siavashi M. Application of nanofluid and optimization of pore size arrangement of heterogeneous porous media to enhance mixed convection inside a two-sided lid-driven cavity. J Therm Anal Calorim. 2019;135(2):947–61.

Siavashi M, Bahrami HRT, Aminian E. Optimization of heat transfer enhancement and pumping power of a heat exchanger tube using nanofluid with gradient and multi-layered porous foams. Appl Therm Eng. 2018;138:465–74.

Saeedi AH, Akbari M, Toghraie D. An experimental study on rheological behavior of a nanofluid containing oxide nanoparticle and proposing a new correlation. Physica E. 2018;99:285–93.

Siavashi M, Yousofvand R, Rezanejad S. Nanofluid and porous fins effect on natural convection and entropy generation of flow inside a cavity. Adv Powder Technol. 2018;29(1):142–56.

Afrouzi HH, Ahmadian M, Moshfegh A, Toghraie D, Javadzadegan A. Statistical analysis of pulsating non-Newtonian flow in a corrugated channel using Lattice-Boltzmann method. Physica A. 2019;535:122486.

Chamkha AJ, Khaled A-RA. Hydromagnetic combined heat and mass transfer by natural convection from a permeable surface embedded in a fluid-saturated porous medium. Int J Numer Methods Heat Fluid Flow. 2000;10(5):455–77.

Umavathi JC, Chamkha AJ, Sridhar KSR. Generalized plain Couette flow and heat transfer in a composite channel. Transp Porous Media. 2010;85(1):157–69.

Pourdel H, Afrouzi HH, Akbari OA, Miansari M, Toghraie D, Marzban A. Numerical investigation of turbulent flow and heat transfer in flat tube. J Therm Anal Calorim. 2019;135(6):3471–83.

Siavashi M, Joibary SMM. Numerical performance analysis of a counter-flow double-pipe heat exchanger with using nanofluid and both sides partly filled with porous media. J Therm Anal Calorim. 2019;135(2):1595–610.

Afshari A, Akbari M, Toghraie D, Yazdi ME. Experimental investigation of rheological behavior of the hybrid nanofluid of MWCNT–alumina/water (80%)–ethylene-glycol (20%). J Therm Anal Calorim. 2018;132(2):1001–15.

Takhar HS, Chamkha AJ, Nath G. Unsteady flow and heat transfer on a semi-infinite flat plate with an aligned magnetic field. Int J Eng Sci. 1999;37(13):1723–36.

Shen B, Yan H, Sunden B, Xue H, Xie G. Forced convection and heat transfer of water-cooled microchannel heat sinks with various structured metal foams. Int J Heat Mass Transf. 2017;113:1043–53.

Abadi GB, Kim KC. Experimental heat transfer and pressure drop in a metal-foam-filled tube heat exchanger. Exp Therm Fluid Sci. 2017;82:42–9.

Heydari A, et al. The effect of attack angle of triangular ribs on heat transfer of nanofluids in a microchannel. J Therm Anal Calorim. 2018;131(3):2893–912.

Behnampour A, et al. Analysis of heat transfer and nanofluid fluid flow in microchannels with trapezoidal, rectangular and triangular shaped ribs. Phys E Low Dimens Syst Nanostruct. 2017;91:15–31.

Rashad AM, Armaghani T, Chamkha AJ, Mansour MA. Entropy generation and MHD natural convection of a nanofluid in an inclined square porous cavity: effects of a heat sink and source size and location. Chin J Phys. 2018;56(1):193–211.

Akbarzadeh M, Rashidi S, Karimi N, Omar N. First and second laws of thermodynamics analysis of nanofluid flow inside a heat exchanger duct with wavy walls and a porous insert. J Therm Anal Calorim. 2018;135:1–18.

Najafi Amel A, Kouravand S, Zarafshan P, Kermani AM, Khashehchi M. Study the heat recovery performance of micro and nano metfoam regenerators in alpha type stirling engine conditions. Nanoscale Microscale Thermophys Eng. 2018;22(2):137–51.

Lu W, Zhang T, Yang M, Wu Y. Analytical solutions of force convective heat transfer in plate heat exchangers partially filled with metal foams. Int J Heat Mass Transf. 2017;110:476–81.

Javadzadegan JA, Motaharpour SH, Moshfegh A, Akbari OA, Afrouzi HH, Toghraie D. Lattice-Boltzmann method for analysis of combined forced convection and radiation heat transfer in a channel with sinusoidal distribution on walls. Physica A. 2019;526:121066.

Tan WC, Saw LH, San Thiam H, Xuan J, Cai Z, Yew MC. Overview of porous media/metal foam application in fuel cells and solar power systems. Renew Sustain Energy Rev. 2018;96:181–97.

Varol Y, Oztop HF. Control of buoyancy-induced temperature and flow fields with an embedded adiabatic thin plate in porous triangular cavities. Appl Therm Eng. 2009;29(2–3):558–66.

Oztop HF, Al-Salem K, Varol Y, Pop I. Natural convection heat transfer in a partially opened cavity filled with porous media. Int J Heat Mass Transf. 2011;54(11–12):2253–61.

Varol Y, Oztop HF, Varol A. Free convection in porous media filled right-angle triangular enclosures. Int Commun Heat Mass Transf. 2006;33(10):1190–7.

Shrestha P, et al. Hydrophilic microporous layer coatings for polymer electrolyte membrane fuel cells operating without anode humidification. J Power Sources. 2018;402:468–82.

Leeuwner MJ, Patra A, Wilkinson DP, Gyenge EL. Graphene and reduced graphene oxide based microporous layers for high-performance proton-exchange membrane fuel cells under varied humidity operation. J Power Sources. 2019;423:192–202.

Xia C, Wei Z, Yuan H, Li Q, Yang Z. POD analysis of the wake behind a circular cylinder coated with porous media. J Vis. 2018;21(6):965–85.

Sarlak R, Yousefzadeh S, Akbari OA, Toghraie D, Sarlak S. The investigation of simultaneous heat transfer of water/Al2O3 nanofluid in a close enclosure by applying homogeneous magnetic field. Int J Mech Sci. 2017;133:674–88.

Naito H, Fukagata K. Numerical simulation of flow around a circular cylinder having porous surface. Phys Fluids. 2012;24(11):117102.

Bhattacharyya S, Singh AK. Reduction in drag and vortex shedding frequency through porous sheath around a circular cylinder. Int J Numer Methods Fluids. 2011;65(6):683–98.

Tian Z, Arasteh H, Parsian A, Karimipour A, Safaei MR, Nguyen TK. Estimate the shear rate & apparent viscosity of multi-phased non-Newtonian hybrid nanofluids via new developed Support Vector Machine method coupled with sensitivity analysis. Phys A Stat Mech Appl. 2019;523:122456.

Khashan SA, Al-Amiri AM, Al-Nimr MA. Assessment of the local thermal non-equilibrium condition in developing forced convection flows through fluid-saturated porous tubes. Appl Therm Eng. 2005;25(10):1429–45.

Al-Sumaily GF, Sheridan J, Thompson MC. Validation of thermal equilibrium assumption in forced convection steady and pulsatile flows over a cylinder embedded in a porous channel. Int Commun Heat Mass Transf. 2013;43:30–8.

Xu HJ, Qu ZG, Tao WQ. Numerical investigation on self-coupling heat transfer in a counter-flow double-pipe heat exchanger filled with metallic foams. Appl Therm Eng. 2014;66(1–2):43–54.

Xu HJ, Gong L, Zhao CY, Yang YH, Xu ZG. Analytical considerations of local thermal non-equilibrium conditions for thermal transport in metal foams. Int J Therm Sci. 2015;95:73–87.

Lin W, Xie G, Yuan J, Sundén B. Comparison and analysis of heat transfer in aluminum foam using local thermal equilibrium or nonequilibrium model. Heat Transf Eng. 2016;37(3–4):314–22.

Chen X, Tavakkoli F, Vafai K. Analysis and characterization of metal foam-filled double-pipe heat exchangers. Numer Heat Transf Part A Appl. 2015;68(10):1031–49.

Mahdavi M, Saffar-Avval M, Tiari S, Mansoori Z. Entropy generation and heat transfer numerical analysis in pipes partially filled with porous medium. Int J Heat Mass Transf. 2014;79:496–506.

Shirvan KM, Ellahi R, Mirzakhanlari S, Mamourian M. Enhancement of heat transfer and heat exchanger effectiveness in a double pipe heat exchanger filled with porous media: numerical simulation and sensitivity analysis of turbulent fluid flow. Appl Therm Eng. 2016;109:761–74.

Chikh S, Allouache N. Optimal performance of an annular heat exchanger with a porous insert for a turbulent flow. Appl Therm Eng. 2016;104:222–30.

Mohamad AA. Heat transfer enhancements in heat exchangers fitted with porous media part I: constant wall temperature. Int J Therm Sci. 2003;42(4):385–95.

Huang ZF, Nakayama A, Yang K, Yang C, Liu W. Enhancing heat transfer in the core flow by using porous medium insert in a tube. Int J Heat Mass Transf. 2010;53(5–6):1164–74.

Targui N, Kahalerras H. Analysis of fluid flow and heat transfer in a double pipe heat exchanger with porous structures. Energy Convers Manag. 2008;49(11):3217–29.

Arasteh H, Salimpour MR, Tavakoli MR. Optimal distribution of metal foam inserts in a double-pipe heat exchanger. Int J Numer Methods Heat Fluid Flow. 2018;29:1322–3142.

Alazmi B, Vafai K. Analysis of variants within the porous media transport models. J Heat Transf. 2000;122(2):303–26.

Torabi M, Zhang K, Yang G, Wang J, Wu P. Heat transfer and entropy generation analyses in a channel partially filled with porous media using local thermal non-equilibrium model. Energy. 2015;82:922–38.

Mahmoudi Y, Maerefat M. Analytical investigation of heat transfer enhancement in a channel partially filled with a porous material under local thermal non-equilibrium condition. Int J Therm Sci. 2011;50(12):2386–401.

Mahmoudi Y, Karimi N. Numerical investigation of heat transfer enhancement in a pipe partially filled with a porous material under local thermal non-equilibrium condition. Int J Heat Mass Transf. 2014;68:161–73.

Yang K, Chen H, Wang J. Analysis of heat transfer and entropy generation in a channel partially filled with N-layer porous media. J Heat Transf. 2018;140(8):82601.

Arasteh H, Mashayekhi R, Toghraie D, Karimipour A, Bahiraei M, Rahbari A. Optimal arrangements of a heat sink partially filled with multilayered porous media employing hybrid nanofluid. J Therm Anal Calorim. 2019;137(3):1045–58.

Akbarzadeh M, Maghrebi MJ. Combined effects of corrugated walls and porous inserts on performance improvement in a heat exchanger channel. Int J Therm Sci. 2018;127:266–76.

Asiaei S, Zadehkafi A, Siavashi M. Multi-layered porous foam effects on heat transfer and entropy generation of nanofluid mixed convection inside a two-sided lid-driven enclosure with internal heating. Transp Porous Media. 2019;126(1):223–47.

Pourrahmani H, Moghimi M, Siavashi M, Shirbani M. Sensitivity analysis and performance evaluation of the PEMFC using wave-like porous ribs. Appl Therm Eng. 2019;150:433–44.

Arabpour A, Karimipour A, Toghraie D. The study of heat transfer and laminar flow of kerosene/multi-walled carbon nanotubes (MWCNTs) nanofluid in the microchannel heat sink with slip boundary condition. J Therm Anal Calorim. 2018;131(2):1553–66.

Siavashi M, Rasam H, Izadi A. Similarity solution of air and nanofluid impingement cooling of a cylindrical porous heat sink. J Therm Anal Calorim. 2019;135(2):1399–415.

Siavashi M, Bahrami HRT, Saffari H. Numerical investigation of porous rib arrangement on heat transfer and entropy generation of nanofluid flow in an annulus using a two-phase mixture model. Numer Heat Transf Part A Appl. 2017;71(12):1251–73.

Khoshvaght-Aliabadi M. Influence of different design parameters and Al2O3-water nanofluid flow on heat transfer and flow characteristics of sinusoidal-corrugated channels. Energy Convers Manag. 2014;88:96–105.

Khoshvaght-Aliabadi M, Sahamiyan M, Hesampour M, Sartipzadeh O. Experimental study on cooling performance of sinusoidal–wavy minichannel heat sink. Appl Therm Eng. 2016;92:50–61.

Valinataj-Bahnemiri P, Ramiar A, Manavi SA, Mozaffari A. Heat transfer optimization of two phase modeling of nanofluid in a sinusoidal wavy channel using Artificial Bee Colony technique. Eng Sci Technol Int J. 2015;18(4):727–37.

Nazari S, Toghraie D. Numerical simulation of heat transfer and fluid flow of water–CuO Nanofluid in a sinusoidal channel with a porous medium. Phys E Low Dimens Syst Nanostruct. 2017;87:134–40.

Habibi MR, Salimpour MR. Numerical study of nanofluid convective heat transfer in sinusoidal tubes. Heat Transf Eng. 2018;40:1–9.

Toghraie D, Abdollah MMD, Pourfattah F, Akbari OA, Ruhani B. Numerical investigation of flow and heat transfer characteristics in smooth, sinusoidal and zigzag-shaped microchannel with and without nanofluid. J Therm Anal Calorim. 2018;131(2):1757–66.

Hosseini M, Afrouzi HH, Arasteh H, Toghraie D. Energy analysis of a proton exchange membrane fuel cell (PEMFC) with an open-ended anode using agglomerate model: a CFD study. Energy. 2019;188:116090.

Park J, Matsubara M, Li X. Application of lattice Boltzmann method to a micro-scale flow simulation in the porous electrode of a PEM fuel cell. J Power Sources. 2007;173(1):404–14.

Pasaogullari U, Wang C-Y. Two-phase transport and the role of micro-porous layer in polymer electrolyte fuel cells. Electrochim Acta. 2004;49(25):4359–69.

Atiyeh HK, Karan K, Peppley B, Phoenix A, Halliop E, Pharoah J. Experimental investigation of the role of a microporous layer on the water transport and performance of a PEM fuel cell. J Power Sources. 2007;170(1):111–21.

Ozden A, Shahgaldi S, Zhao J, Li X, Hamdullahpur F. Assessment of graphene as an alternative microporous layer material for proton exchange membrane fuel cells. Fuel. 2018;215:726–34.

Ozden A, Shahgaldi S, Li X, Hamdullahpur F. A graphene-based microporous layer for proton exchange membrane fuel cells: characterization and performance comparison. Renew Energy. 2018;126:485–94.

Jia R, Hu J. Analysis of a counter flow parallel-plate heat exchanger. In: ASEE 2014 zone I conference, University of Bridgeport, Bridgeport, CT, USA; 2014.

Nield DA, Bejan A. Convection in porous media, vol. 24. New York: Springer; 2006.

Toghraie D, Mashayekhi R, Arasteh H, Sheykhi S, Niknejadi M, Chamkha AJ. Two-phase investigation of water–Al2O3 nanofluid in a micro concentric annulus under non-uniform heat flux boundary conditions. Int J Numer Methods Heat Fluid Flow. 2019. https://doi.org/10.1108/HFF-11-2018-0628.

Arasteh H, Mashayekhi R, Goodarzi M, Motaharpour SH, Dahari M, Toghraie D. Heat and fluid flow analysis of metal foam embedded in a double-layered sinusoidal heat sink under local thermal non-equilibrium condition using nanofluid. J Therm Anal Calorim. 2019;138(2):1461–76.

Miansari M, Valipour MA, Arasteh H, Toghraie D. Energy and exergy analysis and optimization of helically grooved shell and tube heat exchangers by using Taguchi experimental design. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08653-3.

Toghaniyan A, Zarringhalam M, Akbari OA, Shabani GAS, Toghraie D. Application of lattice Boltzmann method and spinodal decomposition phenomenon for simulating two-phase thermal flows. Phys A Stat Mech Appl. 2018;509:673–89.

Moradi A, Toghraie D, Isfahani AHM, Hosseinian A. An experimental study on MWCNT–water nanofluids flow and heat transfer in double-pipe heat exchanger using porous media. J Therm Anal Calorim. 2019;137(5):1797–807.

Toghraie D, Mahmoudi M, Akbari OA, Pourfattah F, Heydari M. The effect of using water/CuO nanofluid and L-shaped porous ribs on the performance evaluation criterion of microchannels. J Therm Anal Calorim. 2019;135(1):145–59.

Jourabian M, Darzi AAR, Toghraie D, Ali Akbari O. Melting process in porous media around two hot cylinders: numerical study using the lattice Boltzmann method. Phys A Stat Mech Appl. 2018;509:316–35.

Barnoon P, Toghraie D. Numerical investigation of laminar flow and heat transfer of non-Newtonian nanofluid within a porous medium. Powder Technol. 2018;325:78–91.

Wang C-C, Chen C-K. Forced convection in a wavy-wall channel. Int J Heat Mass Transf. 2002;45(12):2587–95.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Arasteh, H., Mashayekhi, R., Ghaneifar, M. et al. Heat transfer enhancement in a counter-flow sinusoidal parallel-plate heat exchanger partially filled with porous media using metal foam in the channels’ divergent sections. J Therm Anal Calorim 141, 1669–1685 (2020). https://doi.org/10.1007/s10973-019-08870-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08870-w