Abstract

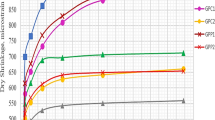

The article analyses the peculiarities of the combined effect on hydration process of the following pozzolanic additives: metakaolin waste (MW), material generated in the manufacture of expanded glass granules (GEG) and fluidized bed cracking catalyst waste (FCCW), as well as melamine-based superplasticizer (SP). Mixes with and without GEG containing two types of waste were tested. Peculiarities of hydration process were evaluated from the results of calorimetry, SEM and mechanical properties tests. The effect of pozzolanic additives and SP was analysed according to strength activity index (SAI). Test results revealed that synergistic effect of MW and FCCW was significant and practically relevant. These pozzolanic additives have a different effect on hydration process, yet when both waste materials are used together, it is possible to control the progress of hydration process. Besides, specimens with GEG and additive of both waste materials demonstrated the highest SAI index. The results of calorimetry tests of cement paste and plaster modified with plasticizer were different. Active metakaolin particles present on GEG surface significantly slow down the hydration process.

Similar content being viewed by others

References

Hurley J. A UK Market survey for foam glass. Glass: research and development final report. The waste and resources action programme, WRAP report; 2003.

Limbachiya MC. Sustainable waste management and recycling: glass waste. In: Proceedings of international conference organized by Concrete and Masonry Research Group, held at Kingston University. London: Thomas Telford Publishing; 2004.

Limbachiya MC, Meddah MS, Fotiadou S. Performance of granulated foam glass concrete. Constr Build Mater. 2012;28:759–68.

Zhao J, Li D, Liao S, Wang D, Wang H, Yan P. Influence of mechanical grinding on pozzolanic characteristics of circulating fluidized bed fly ash (CFA) and resulting consequences on hydration and hardening properties of blended cement. J Therm Anal Calorim. 2018;132:1459–70.

Palou M, Kuzielova E, Žemlička M, Novotný R, Másilko J. The effect of metakaolin upon the formation of ettringite in metakaolin–lime–gypsum ternary systems. J Therm Anal Calorim. 2018;133:77–86.

Federico LM. Waste glass—a supplementary cementitious material. A thesis, McMaster University Hamilton, Ontario; 2016.

Bumanis G, Bajare D, Locs J, Korjakins A. Alkali-silica reactivity of foam glass granules in structure of lightweight concrete. Constr Build Mater. 2013;47:274–81.

Sha W, Pereira GB. Differential scanning calorimetry study of ordinary Portland cement paste containing metakaolin and theoretical approach of metakaolin activity. Cem Concr Compos. 2001;23:455–61.

Wilinnska I, Pacewska B. Influence of selected activating methods on hydration processes of mixtures containing high and very high amount of fly ash. J Therm Anal Calorim. 2018;133:823–43.

Kuzielova E, Žemlička M, Novotny R, Palou MT. Simultaneous effect of silica fume, metakaolin and ground granulated blast-furnace slag on the hydration of multicomponent cementitious binders. J Therm Anal Calorim. 2019;136:1527–37.

Trusilewicz NL. Thermal stability of Friedel’s salt from metakaolin origin by DSC and HTXRD techniques. J Therm Anal Calorim. 2018;134:371–80.

Pacewska B, Bukowska M, Wilinska I, Swat M. Modification of the properties of concrete by a new pozzolan—a waste catalyst from the catalytic process in a fluidized bed. Cem Concr Res. 2002;32(1):145–52.

Pacewska B, Wilinska I, Bukowska M, Nocun-Wczelik W. Effect of waste aluminosilicate material on cement hydration and properties of cement mortars. Cem Concr Res. 2002;32:1823–30.

Paya J, Monzo J, Borrachero MV, Velázquez S. Evaluation of the pozzolanic activity of fluid catalytic cracking catalyst residue (FC3R). Thermogravimetric analysis studies on FC3R-portland cement pastes. Cem Concr Res. 2003;33(4):603–9.

Paya J, Monzo J, Borrachero MV. Fluid catalytic cracking catalyst residue (FC3R) an excellent mineral by-product for improving early-strength development of cement mixtures. Cem Concr Res. 1999;29(11):1773–9.

Pacewska B, Wilińska I, Bukowska M, Blonkowski G, Nocuń-Wczelik W. An attempt to improve the pozzolanic activity of waste aluminosilicate catalyst. J Therm Anal Calorim. 2004;7(1):133–42.

Al-Jabri K, Baawain M, Taha R, Al-Kamyani ZS, Al-Shamsi K, Ishtieh A. Potential use of FCC spent catalyst as partial replacement of cement or sand in cement mortars. Constr Build Mater. 2013;39:77–81.

Hsiu-Liang C, Yun-Sheng T, Kung-Chung H. Spent FCC catalyst as a pozzolanic material for high-performance mortars. Cem Concr Compos. 2004;26:657–64.

Lomas MG, Rojas MIS, Frias M. Pozzolanic reaction of a spent fluid catalytic cracking catalyst in FCC-cement mortars. J Therm Anal Calorim. 2007;90(2):443–7.

Saika NJ, Sengupta P, Gogoi PK, Borthakur PC. Hydration behaviour of lime-co-calcined kaolin-petroleum effluent treatment plant sludge. Cem Concr Res. 2002;32(2):297–302.

Rashad AM. Metakaolin as cementitious material: history, scours, production and composition—a comprehensive overview. Constr Build Mater. 2013;41:303–18.

Kamseu E, Cannio M, Obonyo EA, Tobias F, Bignozzi MC, Sglavo VB, Leonelli C. Metakaolin-based inorganic polymer composite: effects of fine aggregate composition and structure on porosity evolution, microstructure and mechanical properties. Cem Concr Compos. 2014;53:258–69.

Amer AA, El-Hoseny S. Properties and performance of metakaolin pozzolanic cement pastes. J Therm Anal Calorim. 2017;129:33–44.

Vejmelkova E, Pavlikova M, Keppert M, Kersner Z, Rovnanikova P, Ondracek M. High performance concrete with Czech metakaolin: experimental analysis of strength, toughness and durability characteristics. Constr Build Mater. 2010;24:1404–11.

Gruber KA, Ramlochan T, Boddy A, Hooton RD, Thomas MDA. Increasing concrete durability with high-reactivity metakaolin. Cem Concr Compos. 2001;23:479–84.

Souri A, Kazemi-Kamyab H, Snellings R, Naghizadeh R, Golestani-Fard F, Scrivener K. Pozzolanic activity of mechanochemically and thermally activated kaolins in cement. Cem Concr Res. 2015;77:47–59.

Poon CS, Kou SC, Lam L. Compressive strength, chloride diffusivity and pore structure of high performance metakaolin and silica fume concrete. Constr Build Mater. 2006;20:858–65.

Menhosh A, Wang Y, Wang Y, Augusthus-Nelson L. Long term durability properties of concrete modified with metakaolin and polymer admixture. Constr Build Mater. 2018;172(30):41–51.

Krajci L, Mojumdar SC, Janotka I, Puertas F, Palacios M, Kuliffayova M. Performance of composites with metakaolin-blended cements. J Therm Anal Calorim. 2015;119:851–63.

Bai J, Wild S, Ware JA, Sabir BB. Using neural networks to predict workability of concrete incorporating metakaolin and fly ash. Adv Eng Softw. 2003;34:663–9.

Bai J, Wild S, Sabir BB. Sorptivity and strength of air-cured and water-cured PC–PFA–MK concrete and the influence of binder composition on carbonation depth. Cem Concr Res. 2002;32:1813–21.

Plank J, Sakai E, Miao CW, Yu C, Hong JX. Chemical admixtures—chemistry, applications and their impact on concrete microstructure and durability. Cem Concr Res. 2015;78:81–99.

Kismi M, Saint-Arroman JC, Mounanga P. Minimizing water dosage of superplasticized mortars and concretes for a given consistency. Constr Build Mater. 2012;28:747–58.

Cody AM, Lee H, Cody RD, Spry PG. The effects of chemical environment on the nucleation, growth, and stability of ettringite [Ca3Al(OH)6]2(SO4)3·26H2O. Cem Concr Res. 2004;34:869–81.

Shi C, Zhang G, He T, Li Y. Effects of superplasticizers on the stability and morphology of ettringite. Constr Build Mater. 2016;112:261–6.

Wutz K. Advanced polymers for monolithic refractories. In: Proceedings of the biennial wordwide congress on refractories UNITECR; 2001. p. 85–97.

Antonovič V, Baltrėnas P, Aleknevičius N, Pundienė I, Stonys R. Modification of petrochemical fluid catalytic cracking catalyst waste properties by treatment in high temperature. In: 10th international conference modern building materials, structures and techniques, vol. 1; 2010. p. 6–12.

Donatello S, Tyrer M, Cheeseman CR. Comparison of test methods to assess pozzolanic activity. Cem Concr Res. 2010;32:121–7.

Cyr M, Lawrence P, Ringot E. Efficiency of mineral admixtures in mortars: quantification of the physical and chemical effects of fine admixtures in relation with compressive strength. Cem Concr Res. 2006;36(2):264–77.

Šeputyte-Jucike J, Kligys M, Sinica M. The effects of modifying additives and chemical admixtures on the properties of porous fresh and hardened cement paste. Constr Build Mater. 2016;127:679–91.

Costa C, Marques P. Low-carbon cement with waste oil-cracking catalyst incorporation. In: IEEE-IAS/PCA 54th cement industry technical conference; 2012.

Han S, Yan PY, Liu RG. Study on the hydration product of cement in early age using TEM. Sci China Technol Sci. 2012;55(8):2284–90.

El-Gamal SMA, Abo-El-Enein SA, El-Hosiny FI, Amin MS, Ramadan M. Thermal resistance, microstructure and mechanical properties of type I Portland cement pastes containing low-cost nanoparticles. J Therm Anal Calorim. 2018;131:949–68.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Antonovič, V., Sikarskas, D., Malaiškienė, J. et al. Effect of pozzolanic waste materials on hydration peculiarities of Portland cement and granulated expanded glass-based plaster. J Therm Anal Calorim 138, 4127–4137 (2019). https://doi.org/10.1007/s10973-019-08464-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08464-6