Abstract

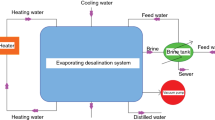

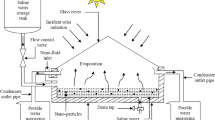

Water scarcity and environmental impacts of blowdown within steam power plants are among the important growing concerns. In order to solve these problems, applying a zero liquid discharge (ZLD) system for treating the brine of the power plants and reusing this water is crucial. In this study, the process of a ZLD system is evaluated by using energy and exergy analyses. The ZLD system was designed to recover brines to demineralize water, which consists of four main parts including vacuum evaporator, roots pump, heat exchanger, and circulation pump. The effects of the dimensional and operating parameters on the freshwater flow rate, exergy efficiency, and the consumption power are investigated. When volume of the evaporator is 7 m3, with increase in total evaporation time from 1 to 3 h, total power consumption decreased from 106.16 to 99.52 kW h and freshwater production reduced from 5914.62 to 2048.52 L h−1. The amount of produced freshwater flow rate is independent of the recirculating flow rate and is a function of the evaporator’s volume. Therefore, in volumes of 3, 5, and 7 m3, the produced freshwater flow rate is constant at about 1300, 2200, and 3070, respectively. Also, the results showed that when increasing the concentration of the brine in the range of 2000–30,000 ppm, the flow rate of the produced freshwater decreases from 3377 to 2911 L h−1 and the total power consumption reduced from 113.28 to 96.42 kW h. Moreover, by increasing the volume of vacuum evaporator, freshwater flow rate rises. Increasing the freshwater flow rate has a dramatic influence on the early working cycles. Since the evaporation is a cyclic process, the exergy efficiency of the roots pump and heat exchanger improves, while the exergy efficiency of the vacuum evaporator decreases versus increasing working cycles.

Similar content being viewed by others

Abbreviations

- c :

-

Specific heat capacity (J kg−1 K−1)

- \(e\) :

-

Specific exergy

- \(\dot{E}_{\text{D}}\) :

-

Exergy destruction (kW)

- X :

-

Salinity ratio

- s :

-

Entropy (kJ kg−1 K−1)

- t :

-

Time (s)

- T :

-

Temperature (K)

- P :

-

Pressure (kPa)

- h :

-

Enthalpy (kJ kg−1)

- R :

-

Gas constant (kJ kg−1 K−1)

- y :

-

Mole fraction

- \(\dot{Q}\) :

-

Heat transferred (kW)

- \(\dot{W}\) :

-

Power (kW)

- m :

-

Mass (kg)

- \(\dot{m}\) :

-

Flow rate (kg−1 s−1)

- \(\eta\) :

-

Isentropic efficiency

- 0:

-

Reference ambient condition

- ke:

-

Kinetic exergy

- po:

-

Potential exergy

- ph:

-

Physical exergy

- ch:

-

Chemical exergy

- is:

-

Isentropic

- PHX:

-

Preheat heat exchanger

- DP:

-

Distillate pump

- CrP:

-

Circulation pump

- HX:

-

Heat exchanger

- RP:

-

Roots pump

- EV:

-

Evaporator vacuum

- FWP:

-

Feed water pump

- CFWH:

-

Close feed water heater

- OFWH:

-

Open feed water heater

- SH:

-

Superheater

- SG:

-

Steam generator

- PH:

-

Preheater

- HPT:

-

High-pressure turbine

- LPT:

-

Low pressure turbine

- RH:

-

Reheat

- ST:

-

Storage tank

- FWT:

-

Feed water tank

- PHE:

-

Preheat exchanger

- HE:

-

Heat exchanger

References

Di Fraia S, Massarotti N, Vanoli L. A novel energy assessment of urban wastewater treatment plants. Energy Convers Manag. 2018;163:304–13. https://doi.org/10.1016/J.ENCONMAN.2018.02.058.

Song J, Yang W, Li Z, Higano Y, Wang X. Discovering the energy, economic and environmental potentials of urban wastes: an input–output model for a metropolis case. Energy Convers Manag. 2016;114:168–79. https://doi.org/10.1016/J.ENCONMAN.2016.02.014.

Yang Y, Zhu J, Zhu G, Yang L, Zhu Y. The effect of high temperature on syngas production by immediate pyrolysis of wet sewage sludge with sawdust. J Therm Anal Calorim. 2018;132:1783–94. https://doi.org/10.1007/s10973-018-7143-9.

Naeimi A, Bidi M, Ahmadi MH, Kumar R, Sadeghzadeh M, Alhuyi Nazari M. Design and exergy analysis of waste heat recovery system and gas engine for power generation in Tehran cement factory. Therm Sci Eng Prog. 2019;9:299–307. https://doi.org/10.1016/j.tsep.2018.12.007.

Nakoa K, Rahaoui K, Date A, Akbarzadeh A. Sustainable Zero Liquid Discharge desalination (SZLDD). Sol Energy. 2016;135:337–47. https://doi.org/10.1016/J.SOLENER.2016.05.047.

Naseri A, Bidi M, Ahmadi M, Saidur R. Exergy analysis of a hydrogen and water production process by a solar-driven transcritical CO2 power cycle with Stirling engine. J Clean Prod. 2017;158:165–81. https://doi.org/10.1016/J.JCLEPRO.2017.05.005.

Han D, He WF, Yue C, Pu WH. Study on desalination of zero-emission system based on mechanical vapor compression. Appl Energy. 2017;185:1490–6. https://doi.org/10.1016/J.APENERGY.2015.12.061.

Mohammadi A, Ashouri M, Ahmadi MH, Bidi M, Sadeghzadeh M, Ming T. Thermoeconomic analysis and multiobjective optimization of a combined gas turbine, steam, and organic Rankine cycle. Energy Sci Eng. 2018;6:506–22. https://doi.org/10.1002/ese3.227.

Bidabadi M, Akbari Vakilabadi M, Khoeini Poorfar A, Monteiro E, Rouboa A, Rahbari A. Mathematical modeling of premixed counterflow combustion of organic dust cloud. Renew Energy. 2016;92:376–84. https://doi.org/10.1016/J.RENENE.2016.02.002.

Bidabadi M, Vakilabadi MA, Esmaeilnejad A. Strain rate effect on microorganic dust flame in a premixed counterflow. Heat Transf Res. 2015;46:1–11. https://doi.org/10.1615/heattransres.2014005471.

Rahbari A, Wong K-F, Vakilabadi MA, Poorfar AK, Afzalabadi A. Theoretical investigation of particle behavior on flame propagation in lycopodium dust cloud. J Energy Resour Technol. 2016;139:12202–7.

Dabiri S, Khodabandeh E, Poorfar AK, Mashayekhi R, Toghraie D, Abadian Zade SA. Parametric investigation of thermal characteristic in trapezoidal cavity receiver for a linear Fresnel solar collector concentrator. Energy. 2018;153:17–26. https://doi.org/10.1016/J.ENERGY.2018.04.025.

Khodabandeh E, Safaei MR, Akbari S, Akbari OA, Alrashed AAAA. Application of nanofluid to improve the thermal performance of horizontal spiral coil utilized in solar ponds: geometric study. Renew Energy. 2018;122:1–16. https://doi.org/10.1016/J.RENENE.2018.01.023.

Ashrafi ZN, Ghasemian M, Shahrestani MI, Khodabandeh E, Sedaghat A. Evaluation of hydrogen production from harvesting wind energy at high altitudes in Iran by three extrapolating Weibull methods. Int J Hydr Energy. 2018;43:3110–32. https://doi.org/10.1016/J.IJHYDENE.2017.12.154.

Akbari Vakiabadi M, Bidi M. Technical and economical evaluation of grid-connected renewable power generation system for a residential urban area. Int J Low-Carbon Technol. 2019;14:1–13. https://doi.org/10.1093/ijlct/cty053.

Vakilabadi MA, Bidi M, Najafi AF, Ahmadi MH. Exergy analysis of a hybrid solar-fossil fuel power plant. Energy Sci Eng. 2019;7:146–61. https://doi.org/10.1002/ese3.265.

Farahbod F, Mowla D, Jafari Nasr MR, Soltanieh M. Experimental study of a solar desalination pond as second stage in proposed zero discharge desalination process. Sol Energy. 2013;97:138–46. https://doi.org/10.1016/J.SOLENER.2013.02.033.

Açıkkalp E, Hepbasli A, Yucer CT, Karakoc TH. Advanced life cycle integrated exergoeconomic analysis of building heating systems: an application and proposing new indices. J Clean Prod. 2018;195:851–60. https://doi.org/10.1016/J.JCLEPRO.2018.05.239.

Açıkkalp E, Yucer CT, Hepbasli A, Karakoc TH. Advanced low exergy (ADLOWEX) modeling and analysis of a building from the primary energy transformation to the environment. Energy Build. 2014;81:281–6. https://doi.org/10.1016/J.ENBUILD.2014.06.024.

Karakoc T, Açıkkalp E, Altuntaş Ö, Yilanli M. Aircraft fuel system energy and exergy analysis under hot day conditions. Int J Exergy. 2018;25:152. https://doi.org/10.1504/IJEX.2018.10010741.

Erol GO, Açıkkalp E, Hepbasli A. Performance assessment of an ice rink refrigeration system through advanced exergoeconomic analysis method. Energy Build. 2017;138:118–26. https://doi.org/10.1016/J.ENBUILD.2016.12.025.

Ekici S, Altuntaş Ö, Açıkkalp E, Söğüt Z, Karakoc T. Assessment of thermodynamic performance and exergetic-sustainability of turboprop engine based on exergetic indicators using mixture of kerosene and methanol. Int J Exergy. 2015. https://doi.org/10.1504/ijex.2016.075666.

Şöhret Y, Açikkalp E, Hepbasli A, Karakoc TH. Advanced exergy analysis of an aircraft gas turbine engine: splitting exergy destructions into parts. Energy. 2015;90:1219–28. https://doi.org/10.1016/j.energy.2015.06.071.

Açıkkalp E, Hepbasli A, Yucer CT, Karakoc TH. Advanced exergoenvironmental assessment of a building from the primary energy transformation to the environment. Energy Build. 2015;89:1–8. https://doi.org/10.1016/J.ENBUILD.2014.12.020.

Açıkkalp E, Yucer CT, Hepbasli A, Karakoc TH. Advanced low exergoeconomic (ALEXERGO) assessment of a building along with its heating system at various stages. Energy Build. 2015;87:66–73. https://doi.org/10.1016/J.ENBUILD.2014.11.020.

Açıkkalp E, Yamık H, Caner N, Açıkkalp E. Energy and exergy evaluation of an air separation facility: a case study. Sep Sci Technol. 2014. https://doi.org/10.1080/01496395.2014.907316.

Açikkalp E, Aras H, Hepbasli A. Advanced exergy analysis of a trigeneration system with a diesel-gas engine operating in a refrigerator plant building. Energy Build. 2014;80:268–75. https://doi.org/10.1016/j.enbuild.2014.05.029.

Açikkalp E, Aras H, Hepbasli A. Advanced exergoeconomic analysis of a trigeneration system using a diesel-gas engine. Appl Therm Eng. 2014;67:388–95. https://doi.org/10.1016/j.applthermaleng.2014.03.005.

Açikkalp E, Aras H, Hepbasli A. Advanced exergy analysis of an electricity-generating facility using natural gas. Energy Convers Manag. 2014;82:146–53. https://doi.org/10.1016/j.enconman.2014.03.006.

Açikkalp E, Aras H, Hepbasli A. Advanced exergoenvironmental assessment of a natural gas-fired electricity generating facility. Energy Convers Manag. 2014;81:112–9. https://doi.org/10.1016/j.enconman.2014.02.011.

Açikkalp E, Aras H, Hepbasli A. Advanced exergoeconomic analysis of an electricity-generating facility that operates with natural gas. Energy Convers Manag. 2014;78:452–60. https://doi.org/10.1016/j.enconman.2013.11.003.

Kaushik SC, Singh OK. Estimation of chemical exergy of solid, liquid and gaseous fuels used in thermal power plants. J Therm Anal Calorim. 2014;115:903–8. https://doi.org/10.1007/s10973-013-3323-9.

Sheshpoli MA, Ajarostaghi SSM, Delavar MA. Thermodynamic analysis of waste heat recovery from hybrid system of proton exchange membrane fuel cell and vapor compression refrigeration cycle by recuperative organic Rankine cycle. J Therm Anal Calorim. 2019;135:1699–712. https://doi.org/10.1007/s10973-018-7338-0.

Shams Ghoreishi SM, Akbari Vakilabadi M, Bidi M, Khoeini Poorfar A, Sadeghzadeh M, Ahmadi MH, et al. Analysis, economical and technical enhancement of an organic Rankine cycle recovering waste heat from an exhaust gas stream. Energy Sci Eng. 2019. https://doi.org/10.1002/ese3.274.

Ksepko E, Klimontko J, Kwiecinska A. Industrial wastewater treatment wastes used as oxygen carriers in energy generation processes. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08214-8.

Lee S, Esfahani IJ, Ifaei P, Moya W, Yoo C. Thermo-environ-economic modeling and optimization of an integrated wastewater treatment plant with a combined heat and power generation system. Energy Convers Manag. 2017;142:385–401. https://doi.org/10.1016/J.ENCONMAN.2017.03.060.

Audah N, Ghaddar N, Ghali K. Optimized solar-powered liquid desiccant system to supply building fresh water and cooling needs. Appl Energy. 2011;88:3726–36. https://doi.org/10.1016/J.APENERGY.2011.04.028.

Xiong R, Wei C. Current status and technology trends of Zero Liquid Discharge at coal chemical industry in China. J Water Process Eng. 2017;19:346–51. https://doi.org/10.1016/J.JWPE.2017.09.005.

Yao J, Wen D, Shen J, Wang J. Zero discharge process for dyeing wastewater treatment. J Water Process Eng. 2016;11:98–103. https://doi.org/10.1016/J.JWPE.2016.03.012.

Demirbaş A. Biomass resource facilities and biomass conversion processing for fuels and chemicals. Energy Convers Manag. 2001;42:1357–78. https://doi.org/10.1016/S0196-8904(00)00137-0.

Johannsen P, Karlapudi R, Reinhold G. High pressure reverse osmosis for wastewater minimization and Zero Liquid Discharge applications. Desalination. 2006;199:84–5. https://doi.org/10.1016/j.desal.2006.03.021.

Ahmadi MH, Alhuyi Nazari M, Sadeghzadeh M, Pourfayaz F, Ghazvini M, Ming T, et al. Thermodynamic and economic analysis of performance evaluation of all the thermal power plants: a review. Energy Sci Eng. 2019;7:30–65. https://doi.org/10.1002/ese3.223.

Ifaei P, Ataei A, Yoo C. Thermoeconomic and environmental analyses of a low water consumption combined steam power plant and refrigeration chillers-Part 2: thermoeconomic and environmental analysis. Energy Convers Manag. 2016;123:625–42. https://doi.org/10.1016/J.ENCONMAN.2016.06.030.

Ifaei P, Rashidi J, Yoo C. Thermoeconomic and environmental analyses of a low water consumption combined steam power plant and refrigeration chillers—Part 1: energy and economic modelling and analysis. Energy Convers Manag. 2016;123:610–24. https://doi.org/10.1016/J.ENCONMAN.2016.06.036.

Akbari Vakilabadi M, Bidi M, Najafi AF. Energy, Exergy analysis and optimization of solar thermal power plant with adding heat and water recovery system. Energy Convers Manag. 2018;171:1639–50. https://doi.org/10.1016/J.ENCONMAN.2018.06.094.

Wang D, Bao A, Kunc W, Liss W. Coal power plant flue gas waste heat and water recovery. Appl Energy. 2012;91:341–8. https://doi.org/10.1016/J.APENERGY.2011.10.003.

Seigworth A, Ludlum R, Reahl E. Case study: integrating membrane processes with evaporation to achieve economical Zero Liquid Discharge at the Doswell Combined Cycle Facility. Desalination. 1995;102:81–6. https://doi.org/10.1016/0011-9164(95)00044-3.

Petrov P, Charters W, Wallschläger JD. Identification and determination of selenosulfate and selenocyanate in flue gas desulfurization waters. Environ Sci Technol. 2011;46:1716–23. https://doi.org/10.1021/es202529w.

Córdoba P. Status of flue gas desulphurisation (FGD) systems from coal-fired power plants: overview of the physic-chemical control processes of wet limestone FGDs. Fuel. 2015;144:274–86. https://doi.org/10.1016/J.FUEL.2014.12.065.

Barrow H, Pope CW. Droplet evaporation with reference to the effectiveness of water-mist cooling. Appl Energy. 2007;84:404–12. https://doi.org/10.1016/J.APENERGY.2006.09.007.

Chow LC, Chung JN. Evaporation of water into a laminar stream of air and superheated steam. Int J Heat Mass Transf. 1983;26:373–80. https://doi.org/10.1016/0017-9310(83)90041-8.

Ahmadi MH, Sameti M, Pourkiaei SM, Ming T, Pourfayaz F, Chamkha AJ, et al. Multi-objective performance optimization of irreversible molten carbonate fuel cell–Stirling heat engine–reverse osmosis and thermodynamic assessment with ecological objective approach. Energy Sci Eng. 2018;6:783–96. https://doi.org/10.1002/ese3.252.

Ahmadi MH, Jokar MA, Ming T, Feidt M, Pourfayaz F, Astaraei FR. Multi-objective performance optimization of irreversible molten carbonate fuel cell–Braysson heat engine and thermodynamic analysis with ecological objective approach. Energy. 2018;144:707–22. https://doi.org/10.1016/J.ENERGY.2017.12.028.

Kotas TJ, Tadeusz J. The exergy method of thermal plant analysis. London: Butterworths; 1985.

Ahmadi M, Sadaghiani SM, Pourfayaz F, Ghazvini M, Mahian O, Mehrpooya M, et al. Energy and exergy analyses of a solid oxide fuel cell-gas turbine-organic rankine cycle power plant with liquefied natural gas as heat sink. Entropy. 2018;20:484. https://doi.org/10.3390/e20070484.

Mohammadi A, Ahmadi MH, Bidi M, Ghazvini M, Ming T. Exergy and economic analyses of replacing feedwater heaters in a Rankine cycle with parabolic trough collectors. Energy Rep. 2018;4:243–51. https://doi.org/10.1016/J.EGYR.2018.03.001.

Kanoglu M, Dincer I, Rosen MA. Understanding energy and exergy efficiencies for improved energy management in power plants. Energy Pol. 2007;35:3967–78. https://doi.org/10.1016/J.ENPOL.2007.01.015.

Ameri M, Ahmadi P. The study of ambient temperature effects on exergy losses of a heat recovery steam generator. In: Proceedings of international conference on power engineering, Hang Zhou: 2007.

Vandani AMK, Bidi M, Ahmadi F. Exergy analysis and evolutionary optimization of boiler blowdown heat recovery in steam power plants. Energy Convers Manag. 2015;106:1–9. https://doi.org/10.1016/J.ENCONMAN.2015.09.018.

Lemmon EW, Huber ML, Mclinden MO. NIST reference fluid thermodynamic and transport properties—REFPROP 9.0. 2010.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Akbari Vakilabadi, M., Bidi, M., Najafi, A.F. et al. Energy, Exergy analysis and performance evaluation of a vacuum evaporator for solar thermal power plant Zero Liquid Discharge Systems. J Therm Anal Calorim 139, 1275–1290 (2020). https://doi.org/10.1007/s10973-019-08463-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08463-7