Abstract

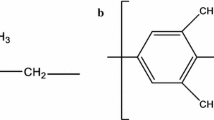

The influence of blending ratio and trifluoropropyl polyhedral oligomeric silsesquioxane (POSS) on microstructure, melt and cold crystallization behavior, thermomechanical and thermal stability of melt-blended polylactic acid/thermoplastic polyurethane (PLA/TPU) blends was investigated using various techniques. Morphological observations (TEM and EDX) showed that POSS nanoparticles have a good dispersion state throughout the matrix and localize in both phases and also at the blend interface. POSS nanoparticles hindered the melt crystallization of PLA while enhancing the degree of cold crystallinity of PLA. In addition, the dispersed TPU droplets in PLA matrix induced a nucleation effect on melt crystallization of PLA, especially at low contents. On the contrary, the cold crystallization temperature of PLA shifted to a higher temperature in the presence of TPU phase, but the degree of crystallinity improved in the case of heating with a low rate. Although the addition of TPU to PLA resulted in a decrement in onset degradation temperature, the samples degraded in wider ranges than neat PLA. The onset degradation temperature of samples in inert ambient was declined by the addition of POSS due to its low thermal stability. These nanoparticles slightly enhanced the thermal stability of PLA-rich samples in air ambient but had no sensible effect on TPU-rich samples. The storage modulus values of the PLA/TPU blends gradually decreased with increasing TPU content. In addition, incorporation of POSS nanoparticles, generally, increased the values of storage modulus but reduced the glass transition temperature, proving the lubrication effect of POSS nanoparticles.

Similar content being viewed by others

References

Luckachan GE, Pillai CKS. Biodegradable polymers—a review on recent trends and emerging perspectives. J Polym Environ. 2011;19:637–76.

Griffith LG, Naughton G. Tissue engineering—current challenges and expanding opportunities. Science. 2002;295:1009–14.

Aghjeh MR, Kazerouni Y, Otadi M, Khonakdar HA, Jafari SH, Ebadi-Dehaghani H, Mousavi SH. A combined experimental and theoretical approach to quantitative assessment of microstructure in PLA/PP/Organo-Clay nanocomposites; wide-angle x-ray scattering and rheological analysis. Compos Part B Eng. 2018;137:235–46.

Liu H, Zhang J. Research progress in toughening modification of poly(lactic acid). J Polym Sci Part B Polym Phys. 2011;49:1051–83.

Ho C-H, Wang C-H, Lin C-I, Lee Y-D. Synthesis and characterization of TPO–PLA copolymer and its behavior as compatibilizer for PLA/TPO blends. Polymer. 2008;49:3902–10.

López-Rodríguez N, López-Arraiza A, Meaurio E, Sarasua JR. Crystallization, morphology, and mechanical behavior of polylactide/poly(ε-caprolactone) blends. Polym Eng Sci. 2006;46:1299–308.

Luyt AS, Kelnar I. Effect of blend ratio and nanofiller localization on the thermal degradation of graphite nanoplatelets-modified PLA/PCL. J Therm Anal Calorim. 2018;43:1–10.

Agari Y, Sakai K, Kano Y, Nomura R. Preparation and properties of the biodegradable graded blend of poly(L-lactic acid) and poly(ethylene oxide). J Polym Sci Part B Polym Phys. 2007;45:2972–81.

Li K, Peng J, Turng L-S, Huang H-X. Dynamic rheological behavior and morphology of polylactide/poly(butylenesadipate-co-terephthalate) blends with various composition ratios. Adv Polym Technol. 2011;30:150–7.

Al-Itry R, Lamnawar K, Maazouz A. Rheological, morphological, and interfacial properties of compatibilized PLA/PBAT blends. Rheol Acta. 2014;53:501–17.

Aghjeh MR, Nazari M, Khonakdar HA, Jafari SH, Wagenknecht U, Heinrich G. In depth analysis of micro-mechanism of mechanical property alternations in PLA/EVA/clay nanocomposites: a combined theoretical and experimental approach. Mater Des. 2015;88:1277–89.

Li Y, Shimizu H. Toughening of polylactide by melt blending with a biodegradable poly(ether)urethane elastomer. Macromol Biosci. 2007;7:921–8.

Zhao F, Huang HX, Zhang SD. Largely toughening biodegradable poly(lactic acid)/thermoplastic polyurethane blends by adding MDI. J Appl Polym Sci. 2015;132:42511.

Finnigan B, Martin D, Halley P, Truss R, Campbell K. Morphology and properties of thermoplastic polyurethane nanocomposites incorporating hydrophilic layered silicates. Polymer. 2004;45:2249–60.

Seyfi J, Jafari SH, Khonakdar HA, Sadeghi GMM, Zohuri G, Hejazi I, Simon F. Fabrication of robust and thermally stable superhydrophobic nanocomposite coatings based on thermoplastic polyurethane and silica nanoparticles. Appl Surf Sci. 2015;347:224–30.

Jiao C, Wang H, Chen X, Tang G. Flame retardant and thermal degradation properties of flame retardant thermoplastic Polyurethane based on HGM@[EOOEMIm] [BF 4]. J Therm Anal Calorim. 2019;135:3141–52.

Jing X, Mi HY, Peng XF, Turng LS. The morphology, properties, and shape memory behavior of polylactic acid/thermoplastic polyurethane blends. Polym Eng Sci. 2015;55:70–80.

Han JJ, Huang HX. Preparation and characterization of biodegradable polylactide/thermoplastic polyurethane elastomer blends. J Appl Polym Sci. 2011;120:3217–23.

Jia S, Wang Z, Zhu Y, Chen L, Fu L. Composites of poly(lactic) acid/thermoplastic polyurethane/mica with compatibilizer: morphology, miscibility and interphase. RSC Adv. 2015;5:98915–24.

Kaynak C, Meyva Y. Use of maleic anhydride compatibilization to improve toughness and other properties of polylactide blended with thermoplastic elastomers. Polym Adv Technol. 2014;25:1622–32.

Hong H, Yang L, Yuan Y, Qu X, Chen F, Wei J, Liu C. Preparation, rheological properties and primary cytocompatibility of TPU/PLA blends as biomedical materials. J Wuhan Univ Technol Mater Sci Ed. 2016;31:211–8.

Jašo V, Glenn G, Klamczynski A, Petrović ZS. Biodegradability study of polylactic acid/thermoplastic polyurethane blends. Polym Test. 2015;47:1–3.

Lai S-M, Wu W-L, Wang Y-J. Annealing effect on the shape memory properties of polylactic acid (PLA)/thermoplastic polyurethane (TPU) bio-based blends. J Polym Res. 2016;23:99.

Barmouz M, Behravesh AH. Statistical and experimental investigation on low density microcellular foaming of PLA-TPU/cellulose nano-fiber bio-nanocomposites. Polym Test. 2017;7:300–13.

Kelnar I, Kratochvil J, Fortelny I, Kapralkova L, Zhigunov A, Nevoralova M, Kotrisova M, Khunova V. Influence of clay-nanofiller geometry on the structure and properties of poly(lactic acid)/thermoplastic polyurethane nanocomposites. RSC Adv. 2016;6:30755–62.

Chen Q, Mangadlao JD, Wallat J, De Leon A, Pokorski JK, Advincula RC. 3D printing biocompatible polyurethane/poly(lactic acid)/graphene oxide nanocomposites: anisotropic properties. ACS Appl Mater Interfaces. 2017;9:4015–23.

Yu F, Huang H-X. Simultaneously toughening and reinforcing poly(lactic acid)/thermoplastic polyurethane blend via enhancing interfacial adhesion by hydrophobic silica nanoparticles. Polym Test. 2015;45:107–13.

Li G, Wang L, Ni H, Pittman C Jr. Polyhedral oligomeric silsesquioxane (POSS) polymers and copolymers: a review. J Inorg Organomet Polym. 2001;11:123–54.

Kuo S-W, Chang F-C. POSS related polymer nanocomposites. Prog Polym Sci. 2011;36:1649–96.

Joshi M, Butola BS. Polymeric nanocomposites—polyhedral oligomeric silsesquioxanes (POSS) as hybrid nanofiller. J Macromol Sci Part C. 2004;44:389–410.

Phillips SH, Haddad TS, Tomczak SJ. Developments in nanoscience: polyhedral oligomericsilsesquioxane (POSS)-polymers. Curr Opin Solid State Mater Sci. 2004;8:21–9.

Wu J, Mather PT, Polymers POSS. Physical properties and biomaterials applications. Polym Rev. 2009;49:25–63.

Ayandele E, Sarkar B, Alexandridis P. Polyhedral oligomeric silsesquioxane (POSS)-containing polymer nanocomposites. Nanomaterials. 2012;2:445–75.

Turan D, Sirin H, Ozkoc G. Effects of POSS particles on the mechanical, thermal, and morphological properties of PLA and plasticised PLA. J Appl Polym Sci. 2011;121:1067–75.

Kodal M, Sirin H, Ozkoc G. Effects of reactive and nonreactive POSS types on the mechanical, thermal, and morphological properties of plasticized poly(lactic acid). Polym Eng Sci. 2014;54:264–75.

Aghjeh MR, Asadi V, Mehdijabbar P, Khonakdar HA, Jafari SH. Application of linear rheology in determination of nanoclay localization in PLA/EVA/Clay nanocomposites: correlation with microstructure and thermal properties. Compos B Eng. 2016;86:273–84.

Yazdaninia A, Khonakdar HA, Jafari SH, Asadi V. Influence of trifluoropropyl-POSS nanoparticles on the microstructure, rheological, thermal and thermomechanical properties of PLA. RSC Adv. 2016;6:37149–59.

Yu J, Qiu Z. Preparation and properties of biodegradable poly(l-lactide)/octamethyl-polyhedral oligomeric silsesquioxanes nanocomposites with enhanced crystallization rate via simple melt compounding. ACS Appl Mater Interfaces. 2011;3:890–7.

Pan H, Qiu Z. Biodegradable poly(l-lactide)/polyhedral oligomeric silsesquioxanes nanocomposites: enhanced crystallization. Mech Prop Hydrolytic Degrad Macromol. 2010;43:1499–506.

Asadi V, Jafari SH, Khonakdar HA, Häußler L, Wagenknecht U. Poly(ethylene succinate) nanocomposites containing inorganic WS2 nanotubes with improved thermal properties: a kinetic study. Compos B Eng. 2016;98:496–507.

Asadi V, Jafari SH, Khonakdar HA, Hauler L, Wagenknecht U. Incorporation of inorganic fullerene-like WS2 into poly(ethylene succinate) to prepare novel biodegradable nanocomposites: a study on isothermal and dynamic crystallization. RSC Adv. 2016;6:4925–35.

Kratochvil J, Kelnar I. Non-isothermal kinetics of cold crystallization in multicomponent PLA/thermoplastic polyurethane/nanofiller system. J Therm Anal Calorim. 2017;130:3043–52.

Liu Y, Sun Y, Zeng F, Chen Y, Li Q, Yu B, Liu W. Morphology, crystallization, thermal, and mechanical properties of poly(vinylidene fluoride) films filled with different concentrations of polyhedral oligomericsilsesquioxane. Polym Eng Sci. 2013;53:1364–73.

Mabry JM, Vij A, Iacono ST, Viers BD. Fluorinated polyhedral oligomeric silsesquioxanes (F-POSS). Angew Chem Int Ed. 2008;47:4137–40.

Aghjeh MR, Khonakdar HA, Jafari SH. Application of mean-field theory in PP/EVA blends by focusing on dynamic mechanical properties in correlation with miscibility analysis. Compos B Eng. 2015;79:74–82.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yazdaninia, A., Jafari, S.H., Ehsani, M. et al. An assessment on the effect of trifluoropropyl-POSS and blend composition on morphological, thermal and thermomechanical properties of PLA/TPU. J Therm Anal Calorim 139, 279–292 (2020). https://doi.org/10.1007/s10973-019-08409-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08409-z