Abstract

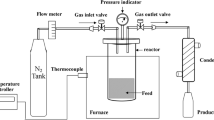

The search for a drop-in fuel obtained from residual biomass or oilseed that does not compete with food, as Pachira aquatica Aubl. oil has been imputing the research. This work focused on the characterization and application of the support (KIT-6) catalyst (Mo/KIT-6) in pyrolysis of the waste frying and P. Aquatica Aubl. oil through a kinetic study by thermogravimetry (TGA/DTG) technique and thermogravimetry coupled with Fourier-transform infrared spectrophotometer (TGA-FTIR). The supports and catalysts were characterized by different techniques such as X-ray diffraction, thermal analysis (TGA/DTG), adsorption and desorption of N2 and scanning electron microscopy coupled with energy-dispersive X-ray analysis (EDS). The support and catalyst presented good structural organization and textured properties, showing that the structuring of KIT-6 was achieved and that in the impregnated form, Mo/KIT-6 presented the Mo dispersion by the surface of the support. Kinetic study pyrolysis of oils was performed using the iso-conversional method proposed by Kissinger–Akahira–Sunose which was applied to determine the activation energy (Ea) of without (thermal pyrolysis) and with the catalyst (thermal/catalytic pyrolysis) in the study. The presence of catalysts on volatilization/pyrolysis of oils showed no significant reduction in activation energy (< 10 kJ mol−1), considering the 50% conversion. In TG-FTIR, the results observed that the presence of Mo/KIT-6 promotes deoxygenation, which is enough to improve the quality of bio-oil obtained.

Similar content being viewed by others

References

Nigam PS, Singh A. Production of liquid biofuels from renewable resources. Progress Energy Combust Sci. 2011. https://doi.org/10.1016/j.pecs.2010.01.003.

Gumisiriza R, Hawumba JF, Okure M, Hensel O. Biomass waste-to-energy valorization technologies: a review case for banana processing in Uganda. Biotechnol Biofuels. 2017. https://doi.org/10.1186/s13068-016-0689-5.

Jacobson K, Maherua KC, Dalai AK. Bio-oil valorization: a review. Renew Sustain Energy Rev. 2013. https://doi.org/10.1016/j.rser.2012.04.028.

Wu L, Guo S, Wang C, Yang Z. Production of alkanes (C7–C29) from different part of poplar tree via direct deoxy-liquefaction. Bioresour Technol. 2009. https://doi.org/10.5424/fs/2012212-02634.

Qiang L, Wen-Zhi L, Xi-Feng Z. Overview of fuel properties of biomass fast pyrolysis oils. Energy Convers Manag. 2009. https://doi.org/10.1021/ef034067u.

Bridgwater AV. Catalysis in thermal biomass conversion. Appl Catal A. 1994. https://doi.org/10.1016/0926-860X(94)80278-5.

Bridgwater AV, Peacoke GVC. Fast pyrolysis processes for biomass. Renew Sustain Energy Rev. 2000;1:10. https://doi.org/10.1016/S1364-0321(99)00007-6.

Mohan D, Pittman CU, Steele PH. Pyrolysis of wood/biomass for bio-oil: a critical review. Energy Fuels. 2009. https://doi.org/10.1021/ef0502397.

Williams PT, Nugranad N. Comparison of products from the pyrolysis and catalytic pyrolysis of rice husks. Energy. 2000. https://doi.org/10.1016/S0360-5442(00)00009-8.

Chew TL, Bhatia S. Effect of catalyst additives on the production of biofuels from palm oil cracking in a transport riser reactor. Bioresour Technol. 2009. https://doi.org/10.1016/j.biortech.2008.12.021.

Zhang L, Hu G. Supply chain design and operational planning models for biomass to drop-in fuel production. Biomass Bioenergy. 2013. https://doi.org/10.1016/j.biombioe.2013.08.016.

Falahati M, Ma’Mani L, Saboury AA, Shafiee A, Foroumadi A, Badiei AR. Aminopropyl-functionalized cubic Ia3d mesoporous sílica nanoparticle as an efficient support for immobilization for superoxide dismutase. Biochem Biophys Acta. 2011. https://doi.org/10.1016/j.bbapap.2011.04.005.

Soni K, Rana BS, Sinha AK, Bhaumik A, Nandi M, Kumar M, Dhar GM. 3-D ordered mesoporous KIT-6 support for effective hydrodesulfurization catalysts. Appl Catal B. 2009;1:10. https://doi.org/10.1016/j.apcatb.2009.02.010.

Soni K, Mouli KC, Dalai AK, Adjaye J. Influence of frame connectivity of SBA-15 and KIT-6 supported NiMo catalysts for hydrotreating of gas oil. Catalysis. 2010. https://doi.org/10.1007/s10562-010-0317-0.

Boulaoued A, Fechete I, Donnio B, Bernard D, Turek P, Garin F. Mo/KIT-6, Fe/KIT-6 and Mo–Fe/KIT-6 as new types of heterogeneous catalysts for the conversion of MCP. Microporous Mesoporous Mater. 2012. https://doi.org/10.1016/j.micromeso.2012.01.028.

Lan H, Xiao X, Yuan S, Zhang B, Zhou G, Jiang Y. Synergistic Effect of Mo–Fe bimetal oxides promoting catalytic conversion of glycerol to allyl alcohol. Catal Lett. 2017. https://doi.org/10.1007/s10562-017-2124-3.

Qian L, Ren Y, Liu T, Pan D, Wang H, Chen G. Influence of KIT-6’s pore structure on its surface properties evaluated by inverse gas chromatography. Chem Eng J. 2012. https://doi.org/10.1016/j.cej.2012.09.110.

Duan A, Lia T, Zhao Z, Liua B, Zhou X, Jiang G, Liu J, Wei Y, Pan H. Synthesis of hierarchically porous L-KIT-6 silica–alumina material and the super catalytic performances for hydrodesulfurization of benzothiophene. Appl Catal B. 2015. https://doi.org/10.1016/j.apcatb.2014.10.078.

Simacek P, Kubicka D, Sebor G, Pospisil M. Fuel properties of hydroprocessed rapeseed oil. Fuel. 2010. https://doi.org/10.1016/j.fuel.2009.09.017.

Kubicka D, Kaluza L. Deoxygenation of vegetable oils over sulfided Ni, Mo and NiMo catalysts. Appl Catal A. 2010. https://doi.org/10.1016/j.apcata.2009.10.034.

Kok MV, Topa E. Thermal characterization and model-free kinetics of biodiesel sample. J Therm Anal Calorim. 2015. https://doi.org/10.1007/s10973-015-4814-7.

Twaiq FA, Mohamed AR, Bhatia S. Liquid hydrocarbon fuels from palm oil by catalytic cracking over aluminosilicate mesoporous catalysts with various Si/Al ratios. Microporous Mesoporous Mater. 2003. https://doi.org/10.1016/j.micromeso.2003.06.001.

Ooi Y, Zakaria R, Mohamed AR, Bhatia S. Synthesis of composite material MCM-41/beta and its catalytic performance in waste used palm oil cracking. Appl Catal A Gen. 2004. https://doi.org/10.1016/j.apcata.2004.05.011.

de Oliveira Maiax Maia D, de Souzachagas AM, de Morais Araújo AM, de Mendonça AV, de Lima Ferreira IM, Lemos FCD, Araujo AS, Fernandes VJ, Gondim AD. Catalytic pyrolysis of glycerol in the presence of Nickel(II) Schiff base complex supported in SBA-15: kinetic and products (TG–FTIR and PY-CG/MS). Thermochim Acta. 2018;669:160–8.

Kleitz F, Choi SH, Ryoo R. Cubic Ia3d large mesoporous silica: synthesis and replication to platinum nanowires, carbon nanorods and carbon nanotubes. Chem Commun. 2003;17:2136–7. https://doi.org/10.1039/b306504a.

Kissinger HE. Variation of peak temperature with heating rate in differential thermal analysis. J Res Natl Bur Stand. 1956;57(4):2712–2716. https://nvlpubs.nist.gov/nistpubs/jres/057/jresv57n4p217_a1b.pdf.

Akahira T, Sunose T. Method of determining activation deterioration constant of electrical insulating materials. Res Rep Chiba Inst Technol. 1971;16:22–31.

Vyazovkin S, Burnham AK, Criado JM, Perez-Maqueda LA, Popescu C, Sbirrazzuoli N. ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta. 2011;520:1–19.

Liu Y, Shi J, Chen J, Ye Q, Hua Pan, Shao Z, Shi Y. Dynamic performance of CO2 adsorption with tetraethylenepentamine-loaded KIT-6. Microporous Mesoporous Mater. 2010. https://doi.org/10.1016/j.micromeso.2010.05.002.

Selvaraj M, Kawi S, Park DW, Ha CS, Merit JA. Synthesis of well-ordered two-dimensional mesoporous niobium silicate materials with enhanced hydrothermal stability and catalytic activity. Phys Chem. 2009. https://doi.org/10.1021/jp811334r.

Liu X, Tian B, Yu C, Gao F, Xie S, Tu B, Che R, Peng LM, Zhao D. Room-temperature synthesis in acidic media of large-pore three-dimensional bicontinuous mesoporous silica with Ia3d symmetry. Angew Chem. 2012. https://doi.org/10.1002/1521-3757(20021018)114:20%3c4032:AID-ANGE4032%3e3.0.CO;2-6.

Ramanathan A, Maheswari R, Barich DH, Subramaniam B. Niobium incorporated mesoporous silicate, Nb-KIT-6: synthesis and characterization. Microporous Mesoporous Mater. 2014. https://doi.org/10.1016/j.micromeso.2014.02.019.

Subramaniyan K, Arumugam P. Sulfated niobia supported on KIT-6 as a catalyst for transesterification of groundnut oil. J Porous Mater. 2016. https://doi.org/10.1007/s10934-015-0118-3.

Atchudan R, Joo J, Pandurangan A. An efficient synthesis of graphenated carbon nanotubes over the tailored mesoporous molecular sieves by chemical vapor deposition. Mater Res Bull. 2013. https://doi.org/10.1016/j.materresbull.2013.02.048.

Dai W, Zheng M, Zhao Y, Liao S, Ji G, Cao J. Template synthesis of three-dimensional cubic ordered mesoporous carbon with tunable pore sizes. Nanoscale Res Lett. 2010. https://doi.org/10.1007/s11671-009-9450-3.

Subramaniyan K, Arumugam P. Sulfated niobia supported on KIT-6 as a catalyst for transesterification of groundnut oil. J Porous Mater. 2016;23:639–46. https://doi.org/10.1007/s10934-015-0118-3.

Subhan F, Aslan S, Yan Z, Ikram M, Rehman S. Enhanced desulfurization characteristics of Cu-KIT-6 for thiophene. Microporous Mesoporous Mater. 2014. https://doi.org/10.1016/j.micromeso.2014.08.018.

Kishor R, Ghoshal AK. APTES grafted ordered mesoporous silica KIT-6 for CO2 adsorption. Chem Eng J. 2015. https://doi.org/10.1016/j.cej.2014.10.039.

Varfolomeev AM, Nagrimanov RN, Galukhin AV, Vakhin AV, Solomonov BN, Nurgaliev DK, Kok MV. Contribution of thermal analysis and kinetics of Siberian and Tatarstan regions crude oils for in situ combustion process. J Therm Anal Calorim. 2015. https://doi.org/10.1007/s10973-015-4892-6.

Kok MV, Topa E. Thermal characterization and model-free kinetics of biodiesel sample. J Therm Anal Calorim. 2015. https://doi.org/10.1007/s10973-015-4814-7.

Figen AK, Ismail O, Piski S. Devolatilization non-isothermal kinetic analysis of agricultural stalks and application of TG-FT/IR analysis. J Therm Anal Calorim. 2012. https://doi.org/10.1007/s10973-011-1959-x.

Twaiq FA, Mohamed AR, Bhatia S. Liquid hydrocarbon fuels from palm oil by catalytic cracking over aluminosilicate mesoporous catalysts with various Si/Al ratios. Microporous Mesoporous Mater. 2003. https://doi.org/10.1016/j.micromeso.2003.06.001.

Ooi Y, Zakaria R, Mohamed AR, Bhatia S. Synthesis of composite material MCM-41/Beta and its catalytic performance in waste used palm oil cracking. Appl Catal A Gen. 2004. https://doi.org/10.1016/j.micromeso.2003.06.001.

Acknowledgements

Authors gratefully acknowledge the CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnologico) for financial support, PPGQ/UFRN (Programa de Pós Graduação em Química) and Chemistry Institute/UFRN for facilities and analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Mendonça Júnior, A.V., de Morais Araújo, A.M., Fernandes, V.J. et al. Comparative study of the thermo-catalytic degradation of waste frying and Pachira aquatica Aubl. oil in the presence of Mo/KIT-6. J Therm Anal Calorim 139, 535–544 (2020). https://doi.org/10.1007/s10973-019-08390-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08390-7