Abstract

Energy efficient buildings are unimaginable without highly insulating thermal envelopes. Mineral wool among others is a popular material for thermal insulation. Architects and engineers usually use the data given by the manufacturer in the specification of the material for their building physical design. Such data are obtained from laboratory measurements, carried out on non-aged, and dry samples. However, moisture could affect the thermal performance of insulation materials and may affect the durability too. In the research, we examined stone mineral wool hardboard thermal insulations, which were obtained from a flat roof. The samples looked differently: some of them were in good condition and maintained their load bearing capability, but some were spoiled and soft. We measured and compared the used samples’ thermal conductivity, sorption isotherm and deformation under compressive force to new etalon samples. We also investigated the reason behind the lack of load bearing durability of the built-in and spoiled mineral wool boards using scanning electron microscopy and derivatography. In our study, we show how built-in conditions changed the thermal and mechanical properties and thermal performance of the mineral wool insulation layer, which could degrade by up to 40% in terms of thermal resistance under built-in conditions due to certain spoiling and production mistakes of mineral wool.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The consumed energy by buildings, consisting of residential and commercial end users, accounts for 20.1% of the total energy demand worldwide, and this percentage is expected to increase by an average of 1.5% annually between 2012 and 2040 [1]. Therefore, thermal insulation of new and post-insulation of existing buildings is an extremely important area. It reduces the energy demand of buildings and saves carbon emissions [2]. The concept of energy efficient, nearly/net zero energy buildings are unthinkable without highly insulated thermal envelopes. The EU has set a long-term target of reducing greenhouse gas emissions by 80–95%, when compared to 1990 levels, until 2050 [3]. Therefore, building regulations and the requirements of performance certifications of buildings are constantly tightened within the EU [4]. Issuing tougher and tougher thermal insulation standard requirements for new and existing buildings is inevitable. Nowadays, architects and engineers can choose from many different types of thermal insulations [5, 6] to fulfill the energy performance requirements. If we analyze the market for the insulation materials, it is clear that the most popular products are the artificial materials and mineral wool products represent about 50–55% and plastic foams about 40–45% of the total production [7]. To obtain the necessary data for designers, the examination of the thermal properties (e.g., effective thermal conductivity) of building materials and structures is very important [8], although the manufacturers present only the declared thermal properties of their newly produced materials. In material datasheets (technical specifications), declared thermal conductivity obtained mainly under dry material conditions, because thermal properties are favorable, when the sample is not moist. Thermal properties of insulation materials increase (deteriorate) by increase in the moisture content [9]. Nevertheless, thermal insulation remains dry only in the rarest case under built-in conditions. ISO 10456 [10] standard mentions three type of corrections for built-in thermal insulations. The standard contains temperature and moisture conversion coefficients, which can be used to convert declared thermal conductivity of materials to design values. In contrast, the standard only mentions aging conversion coefficient, but does not contain any further information. Thermal insulation producers therefore usually state that their materials’ thermal properties were measured under aged conditions and the performance of their material does not worsen by time; hence, there is no need of additional aging conversion during the design process. In this research paper, we are going to challenge this general statement. Our hypothesis is that moisture (mainly water vapor) under built-in conditions could change the thermal and mechanical properties of certain types of thermal insulations. In our paper, mineral wool insulation is chosen for examination.

Research papers dealt with the effect on the thermal conductivity of insulators when moisture is present. Karamanos et al. showed models and calculation of heat transfer within the fibrous insulator, incorporating the wetness of the material [11]. Jerman and Cerny show that increasing the moisture content in stone wool products leads to significant degradation of thermal conductivity [12]. Vrána and Björk researched the condensation and frost formation possibilities in stone wool products and demonstrated that moisture content has an upward trend with decreasing density of the material sample [13]. However, under normal conditions (relative humidity between 45 and 55%) as Jerman and Cerny’s research also shows the hard and soft stone wools’ moisture content is in the range of 0.01–0.02%, which does not cause major difference in the measured thermal properties [12]. Based on Keresztessy’s research [14], in the early 1990s and the now withdrawn Hungarian standard about designing of buildings and building envelopes [15], an additional 25% correction factor on the thermal conductivity was recommended. It was explained by the construction conditions for thermal insulation boards installed into flat roofs in a single layer with flat joints without mounting. Unfortunately, the standard’s value claimed to apply both mineral types: wool and polystyrene products depending only on the mounting of the boards. In 2014, Szodrai and Lakatos presented how the moistening time and vapor content effect the thermal conductivity of a mineral wool insulating board under laboratory conditions [16]. In a previous research, Simon et al. examined dry, soaked and humidified stone wool samples in laboratory and observed that mechanical properties are dramatically degraded when the stone wool samples were in a desiccator for 72 h in 100% relative humidity [17]. Nagy and Simon investigated the energy and hygrothermal performance of built-in mineral wool thermal insulation by using monitoring measurements and found that mineral wool out of rock on the façade wall as part of the external thermal insulation composite system showed almost 3% lower thermal performance under built-in conditions than the designed values. Besides that, glass mineral wool attic insulation showed 14% higher thermal conductivity than the declared catalog value due to moisture increase in the material during the heating period [18]. Italian researchers assessed the hygrothermal performance of glass mineral wool insulation, which was installed into masonry cavity walls 25 years prior to the research. The glass wool showed degradation in its polymer binder and decrease in the hydrophobicity of the material which lead to the increase in thermal conductivity by about 12% [19]. Zafar et al. examined the chemical changes occurring in the mineral wool products due to aging. Aged and unaged samples were investigated with a monochromatic Al K-alpha X-ray source. XPS survey spectra of the surface of the aged samples showed some significant changes in atomic composition compared to the unaged samples [20].

In the present research, we are dealing with stone mineral wool hardboard thermal insulations, suitable for walkable roofs. We examined samples taken out from a roof, which shows different conditions: some of the samples were in good condition, but some were spoiled. We compared the samples hygrothermal and mechanical properties to new samples and analyzed what could be the reason behind the degraded durability of the installed mineral wool boards by using scanning electron microscopy and derivatography. We then show how these examined properties change the thermal performance of the insulation layer.

Materials and methods

During the summer of 2014, the refurbishment of the roof above a secondary school in Hungary was undertaken by using 10-cm-thick rigid boards of mineral fiber thermal insulation to be covered by a polyvinyl chloride (PVC) membrane. Yet, within a few weeks after the layers were in place, some of the newly installed thermal insulation lost rigidity, the roof surface became soft and the repair was rejected. A question rose regarding the thermal insulating capability of such a softened hardboard which has a decreased resilience: Is there a possibility of the formation of thermal bridges or not, in case the roof is in the non-walking low pitched category? We took samples from the roof, and the research was based on the investigation of three different kinds of sample groups consisting of three samples each of the same manufacturer but of different origin as follows:

brand new sample (marked E for “Etalon”), and was never built-in;

built-in, but having load bearing capacity close to the declared (marked B for “Built-in”);

built-in, and having lost most of its load bearing capacity (marked S for “Spoiled”).

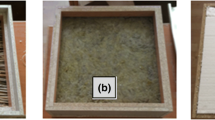

Three approximately 150 mm × 150 mm specimens from each sample of about 100 mm original nominal thickness were cut for the investigation. The hardboard consists of two layers: an about 20 mm thick harder (top) and about 80 mm thick softer one (bottom). A post-testing picture of the specimens is in Fig. 1, where we can observe the relatively sound surface of the bottom (soft) side of samples E and B, while the surface of sample S in the middle is significantly showing the signs of failure.

The tested samples were stored in a fridge before the measurement until steady mass. The temperature chamber was set to 10 °C and by magnesium nitrate salt solution created 57% relative humidity in the closed space besides the samples. Therefore, the samples were preconditioned close to the average built-in hygrothermal condition in winter season [18].

In the research, thermal conductivity of the mineral wool samples was measured using a guarded hot plate instrument (see Fig. 2a). There are many different available techniques to measure the thermal conductivity of a building material [21]. As it was mentioned earlier, these stone wool samples were inhomogeneous; they are built up of a harder and a softer layer. Therefore, a fast measurement of the thermal conductivity like transient plane or line source methods would not offer a reliable, precise result. We chose guarded hot plate method, because the Taurus TLP 300 DTX apparatus offers the measuring procedure up to 120 mm thickness with guarded hot plate method to determine the thermal conductivity and thermal resistance of building components, insulation and other materials. When the specimen is a composition of vertical layers, Taurus instrument is able to measure the thermal conductivity of the composite sample in the range of 0.01–0.5 W m−1 K−1 by measuring the temperature difference on the hot and cold side of the sample and heat flow through the layers. The measuring area is 50 mm × 50 mm in the center of the sample; however, the sample size needs to be in the range of 100 mm × 100 mm to 300 mm × 300 mm to provide undisturbed one-dimensional steady-state heat flow to occur in the measured section. If a sample is smaller than the maximum size, additional edge protection to its sides is needed to measure accurately. The device is also equipped with an insulated test chamber to avoid external thermal influences and with air-cooled Peltier temperature plates to get the sample mean temperature in the range between 0 and 60 °C. The guarded hot plate is furnished with electrical lifting device and digital pressure and sample thickness measurement too.

The measurements were carried out according to EN 12664 [22] and EN 12667 [23] standards, with single specimen configuration. The thermal conductivity of the stone fiber insulating board is determined by using the following Eq. (1):

where Φ is the average power supplied to the metering section of the heating unit, d is the specimen’s thickness, A is the measuring area (2500 mm2), and T1 and T2 are the average hot side and cold side surface temperatures measured by 5 thermocouples on each side at the measuring area. Before the thermal conductivity measurements, at several points the sizes of the samples and the masses were determined. The next step was to wrap the top and bottom of the specimens with a thin PE foil and the sides (for edge protection) by aluminum foil to avoid moisture transfer or drying during the measuring process. The prepared samples were inserted into soft thermal insulating glass wool frame (λ = 0.044 W m−1 K−1) which was needed for additional thermal edge protection, because the samples were smaller than 300 mm × 300 mm (Fig. 2b). These steps are necessary in order to carry out accurate measurements of stone mineral wool samples if using the guarded hot plate method, and we have chosen and placed the glass wool frame material and the foils so that they do not affect the results of the mechanical and thermal measurements.

After the necessary “dressing up” of the conditioned specimen, it was placed into the measuring instrument, and a distributed constant force was applied on its surface, which has caused at first an immediate initial compression, which has increased by time. The load level was chosen according to the first Spoiled sample’s 10% strain. The actual specimen thickness is automatically measured by the calibrated instrument. This compression force did not produce visible deformation on the Etalon and the unharmed, Built-in samples. After about 4 h, the loaded thickness of the specimen has stabilized, and during this time the sample was pre-tempered. The cold plate temperature was set to 5 °C and the hot plate temperature was 15 °C, resulting a mean specimen temperature around 10 °C. After the mean temperature of the sample was stabilized, thermal measurements started. Each sample was measured in 5 temperature steps, with mean temperatures of 10 °C, 15 °C, 20 °C, 25 °C and 30 °C. From the measured results, we evaluated the results to 10 °C and 23 °C average mean temperature.

After the thermal conductivity measurement, 400 N compression force was applied to the samples to examine their mechanical behavior. This force value was chosen because of the limitation of the guarded hot plate instruments pressure plate. We would like to note that to obtain the hardboards required 0.04 N mm−2 stress, around 900 N should have been applied, for which we did not have enough capacity in our instrument. Note: The stress induced by the applied 400 N force is still more than three times as much as what would normally act on the insulating materials surface in a usual structure.

We measured the hygroscopic sorption behavior of the stone mineral wool samples according to ISO 12571 [24]. The measurements were carried out with a Novasina Labmaster AW instrument (Fig. 2a). Salt solutions were placed into the instrument’s stable temperature conditioned chamber with the samples, and after the equilibrium of the relative humidity inside the chamber, we measured the mass of the conditioned samples. Six relative humidity steps were tested on each sample, around 18%, 38%, 58%, 78%, 88% and 98%.

To understand the possible cause of the measured results, we made scanning electron microscope (SEM) images using a JEOL JSM 6380LA instrument (Fig. 3b). We also investigated the mineral wool samples under built-in moist (57% relative humidity preconditioned to 10 °C temperature chamber) conditions by using a MOM Q-1500 D derivatograph instrument (Fig. 3c). This equipment is able to automatically examine and register four parameters, which are the temperature (T) curve, which is showing the actual temperature of the material in the range of the measurement 20–900 °C, and the heating rate was 10 °C min−1. The second parameter is the differential thermal analysis (DTA) curve, showing the temperature difference between the sample material and of an inert reference material (Al2O3) resulting the enthalpy change curve in the tested material. We also obtained the thermogravimetric (TG) curve, following the mass changes as the temperature increases and its first derivative, called the derivative thermogravimetric (DTG) curve. This curve emphasizes on the exact temperatures at which mass changes occur. From these curves, we can detect differences between the three kinds of samples and between dry and moist conditions.

Results and discussion

Before we measured the thermal conductivity of the examined mineral wool samples, each specimen was preconditioned in 10 °C and 57% relative humidity. The moist masses of the samples are summarized in Table 1. Each sample is about of the same size, but because the thermal conductivity measurement occurred in compressed state, we evaluated the compressed moist densities of the samples. Each sample was compressed with a 150 N force, which gave S1 specimen 10% strain. Etalon samples showed a modest, almost negligible strain under compression. Built-in samples have compressed between 1 and 1.5% of their original thickness, while Spoiled samples showed degraded load bearing properties and compressed between 10 and 16.3%. Table 1 also shows the compressed moist density of the specimens. It is visible that Etalon samples’ compressed density is between the range of 0.124–0.137 g cm−3, while Built-in samples are between 0.126 and 0.150 g cm−3. Spoiled samples, however, show significantly less density than Etalon and Built-in samples; they were between 0.101 and 0.114 g cm−3. This phenomenon will be investigated in the later parts of the article.

Thermal conductivity and sorption isotherms

After the preconditioning, samples were placed into the guarded hot plate. Compression force was applied, and the samples were tempered for about 4 h in the instrument. After the tempering process, each specimen was measured. After the measurements, thermal conductivity of the mineral wools was evaluated, and results were calculated to obtain them at 10 °C and 23 °C. The results are plotted in Fig. 4. It is observable that thermal conductivity shows strong correlation with the density of the samples. Spoiled samples had the lowest thermal conductivity, because their density was the lowest from all. These samples did not show any effect on the temperature change either. On the other hand, if we examine Etalon and Built-in samples, the results show that Built-in specimens had higher average thermal conductivity than the Etalon ones. It could happen due to their higher density. These two sample groups show the effect of temperature; higher temperature resulted in higher thermal conductivity. It is also visible on Fig. 4 that the R2 of the linear trend line we fitted only to show the tendency of the measured values is above 0.96 in the case of Etalon samples, but lower than 0.91 in the case of Built-in and Spoiled samples. The lowest R2 is obtained on 23 °C, Spoiled with 0.80 and 10 °C Built-in samples with 0.54.

Built-in samples’ thermal conductivity showed grater differences in the results shown in Fig. 4. Table 2 contains both the individual and averaged values of each sample group. The possible explanation of the higher thermal conductivity of the Built-in samples is the moisture content of the measured samples. Higher moisture content results in higher thermal conductivity. We measured the hygroscopic adsorption of the samples, and the averaged values are shown in Fig. 5. Built-in mineral wool could take up slightly more water vapor from air if compared to new Etalon materials. However, the Spoiled samples showed significantly more capability to take up moisture. Thermal conductivity results of Built-in samples could be explained with the increased sorption performance of the samples. However, the sorption isotherm of the Spoiled samples did not explain the measured thermal conductance, because if the samples could take up more moisture, they should end up with even higher thermal conductivity than the Built-in ones. We have to note that Fig. 5 shows the moisture content in mass percent; therefore, the mass of moisture taken from humid air by the sample is compared to the measured sample’s dry mass. Spoiled samples had the lowest dry density among the samples, which needs to be further investigated in the article.

Compression and thermal resistance

Right after the thermal conductivity measurements, each sample was compressed with 400 N force which was equal to 0.018 N mm−2 stress on the surface of the samples. The deformation of the samples and the average strain can be read in Table 3. Thermal conductivity of the samples was also measured in this compressed state, but results did not differ significantly (the differences were smaller than the relative error of the measuring instrument); even the Spoiled samples had the same average thermal conductivity of 0.036 W m−1 K−1.

Etalon and Built-in samples behaved similarly under 400 N compression; the average strain was 3.2% and 3.6%, respectively. Nevertheless, the Spoiled samples showed outstanding deformation, the samples changed their thickness between 56 and 83%. The average strain of the Spoiled samples was 68%. If we calculate the thermal resistance of the samples by using the measured thermal conductance at 10 °C with the 150 N and 400 N compressed thicknesses, we get interesting results. The thermal resistance of the 150 N compressed specimens shows almost similar results to the others; they are both between the range of 2.25 m2 K W−1–2.73 m2 K W−1. Built-in samples seem to have slightly lower thermal resistance, than the other samples. But when we calculated the thermal resistances by using the 400 N compressed thickness, the results became more interesting. Etalon and Built-in samples lost only small amount of their resistance, but Spoiled samples, due to their incredible strain, lost up to 40% compared to their previous results. Based on these, even if Spoiled samples had lower thermal conductivity than the Etalons, if they are under compression, they lose a huge amount from their insulation performance. The results are summarized in Table 4.

SEM and derivatography

To investigate the composition of the samples, we made scanning electron microscopy (SEM) on selected specimens. On the SEM images, the condition of the fibers and the resin drops are visible. We also measured diameters of the fibers on the 750× magnified images, which showed no difference between the fibers of Etalon (Fig. 6), Built-in (Fig. 7) and Spoiled (Fig. 8) samples. The diameters of the fibers were measured to be between 1 μm and 25 μm; the usual diameter seemed to be about 6–8 μm in the samples. The fibers were randomly oriented in the examined area of the mineral wools. As in literature discussed earlier [25], when researchers examined new and deterioration-free mineral wool samples under SEM, the visible surface of fibers is covered completely with a film of polymeric additives. However, in our case, it is visible that the surface of the fibers was smoother in the Etalon samples if compared to the others. The SEM images showed that the bonding resin between the fibers is about the same in the Etalon and in the Built-in samples, but there was less amount of resin between the fibers of the Spoiled samples. The missing resin could be responsible for the lower density of those samples and the poor mechanical performance too.

When aqueous PF resin is used as a binder, the curing circumstances (cure kinetics) bear of high importance from the thermal insulating material manufacturers side, because curing is an energy and time-consuming process, and manufacturers are trying to optimize their energy consumption as much as possible [26]. They want to be as sustainable and energy efficient as they can, but sparing on the curing process has drawbacks. However, setting of the appropriate curing time is essential for thermal stability of the binder [27]. If the binder has not polymerized properly due to energy saving, too short curing time or by production failure, then in the presence of water vapor (like normal, everyday built-in conditions), the aqueous PF resin softens to a far more extent level than if the polymerization would have been completed. Therefore, it would be unable to serve its binding function any further and the mineral wool loose from its mechanical properties.

After the SEM examination, derivatography was performed on small amount of samples (10 mg) from the previously examined specimens. In the process of the experiment, the tested material is continuously heated at a constant rate; the changes of its mass which are occurring due to the heat are registered. During the heating up process by reaching the characteristic temperature of certain components, either thermal loss or heat effect can be detected depending on that if endothermic or exothermic chemical reaction takes place in the material. Regarding a big portion of the solids, certain transitions occur, while their mass changes, which are in most cases due to chemical transformations. Curing and decomposition of binding resins are mostly exothermic chemical reactions.

Based on what is registered during the experiment, it is possible to detect the evaporation of water, chemical reactions or decomposition, as such also to identify the composition of the materials, the presence or the lack of certain components. Figure 9 shows the DTA curves of the analyzed samples. The most interesting peaks on the DTA curves marked with number 1. Peak 1 shows the decomposition of the polymerized resin binder, which was water-based PF resin as mentioned earlier. If we compare the DTA curves of the Etalon, Built-in and Spoiled samples together, it is visible that Spoiled samples have almost no peak 1, which means that there was almost no resin to decompose. This explains the low density and poor compression resistance of the analyzed Spoiled samples. Observing Fig. 10, it is also visible that while the Etalon sample looses about 53% of its mass, both Built-in and Spoiled samples loose more than 63% which means that vapor-treated samples tend to decompose more due to elevated temperature. Figure 11 shows the DTG curves of the analyzed samples. Peak 1 is also visible in the DTG curves at 460 °C. It is also observable that the DTG curve of the Etalon sample and the Built-in sample developed similarly during the experiment except around peak 1 temperature, while the DTG curve of the Spoiled sample showed more mass loss before peak 1 as well.

A possible construction technological problem of highly insulated buildings

If such a fibrous material which loses load bearing capacity due to moisture is installed into a floating floor structure of an RC building, then the overlaying layers may crack and get damaged due to differential loadings. The authors have experienced such failures which usually occur in the corners of rooms, where concentrated loading is more frequent than in the middle of the hall. Out of such mechanical failure, this may cause failure in the body sound insulating capability of the layer. Such damages can reduce the life cycle of buildings and increase the cost of the operation during the service. Therefore, the quality control of the mineral wool insulation boards should be done with increased attention to avoid such damages in highly insulated energy efficient buildings. The deficiency of the poor hygrothermal and mechanical performance quality may easily be detected prior to building the mineral wool into the structure by putting a small amount of sample into a chamber with 100% relative humidity for a couple of hours. After the vapor treatment, if the mineral wool feels too soft by pressing it with fingers, the decision can be made to avoid the material. If the material remains hard, then we can trust in the good quality.

Conclusions

In the article, we examined three different sets of samples out of the same mineral wool product. Two of the sample sets were built-in into the same roof; however, one of the samples spoiled and lost almost all of its mechanical performance, while the other built-in sample kept its load baring capacity. The third sample was new and became the Etalon and measured to be compared with to the Built-in and Spoiled samples. We measured the thermal conductivity of the samples and found that built-in and still load bearing samples had higher values than brand new Etalon samples, while the Spoiled samples had lower thermal conductivity. The thermal conductivity showed correlation with density and moisture content of the mineral wool specimens. The sorption isotherms of the samples showed that built-in samples can take up more moisture from humid air than new samples.

Although Spoiled samples had low density and thermal conductivity, under compression, their thermal resistance was the lowest and worst because of the high strain they produced. Spoiled samples had significantly lower resin content (which was responsible for the lower density) than Etalon or built-in samples, which was proved using SEM and thermal analysis. Spoiled samples had not 100% polymerized resin, which therefore softened under the treatment of water vapor of the built-in conditions and lost most of their mechanical performance.

References

International Energy Outlook 2016, U.S. Energy Information Administration (EIA), Washington, USA, 2016.

MacKay JCD. Sustainable Energy—without the hot air. Cambridge, United Kingdom: UIT Cambridge Ltd; 2009.

Energy Roadmap 2050. European Commission, Brussels, Belgium, 2011.

Arcipowska A, Anagnostopoulos F, Mariottini F, Kunkel S. Energy performance certificates across The EU: a mapping of national approaches. Brussels, Belgium: Buildings Performance Institute Europe (BPIE); 2014.

Asdrubali F, D’alessandro F, D’alessandro S. A review of unconventional sustainable building insulation materials. Sust Mater Technol. 2015;4:1–17.

Schiavoni S, D’alessandro F, Bianchi F, Asdrubali F. Insulation materials for the building sector: a review and comparative analysis. Renew Sust Energ Rev. 2016;62:988–1011.

Bozsaky D. The historical development of thermal insulation materials. Period Polytech Arch. 2010;41:49–56.

Lakatos Á. Effect of the placement of aerogel insulation in the heat transfer properties. J Therm Anal Calorim. 2017;133:321–7.

Lakatos Á. Moisture induced changes in the building physics parameters of insulation materials. Sci Technol Built Environ. 2016;22:252–60.

MSZ EN ISO 10456:2008 Building materials and products. Hygrothermal properties. Tabulated design values and procedures for determining declared and design thermal values (ISO 10456:2007), Hungarian Standard Institute, 2008.

Karamanos A, Hadiarakou S, Papadopoulos AM. The impact of temperature and moisture on the thermal performance of stone wool. Energ Build. 2008;40:1402–11.

Jerman M, Cerny R. Effect of moisture content on heat and moisture transport and storage properties of thermal insulation materials. Energ Build. 2012;53:39–46.

Vrána T, Björk F. Frost formation and condensation in stone–wool insulations. Const Build Mater. 2009;23:1775–87.

Keresztessy É. Context of product data bases in energy efficient architecture. Period Polytech Arch. 2012;43:11–5.

MSZ 04-140-2:1991 Power engineering. Dimensioning calculuses of buildings and building envelope structures, Hungarian Standard Institute, 1991.

Szodrai F, Lakatos Á. Measurements of the thermal conductivities of some commonly used insulating materials after wetting. Environ Eng Manag J. 2014;13:2881–6.

Simon TK, Mlinárik L, Vargha V. Effect of water vapor on the compressive strength of a mineral wool insulation board. J Build Phys. 2015;39:285–94.

Nagy B, Simon TK. Energy and hygrothermal performance of built-in mineral wool thermal insulations. MATEC Web Conf. 2018;163:08001.

Stazia F, Tittarelli F, Politia G, Di Pernac C, Munafòa P. Assessment of the actual hygrothermal performance of glass mineral wool insulation applied 25 years ago in masonry cavity walls. Energ Build. 2014;68:292–304.

Zafar A, Schjødt-Thomsen J, Sodhi R, De Kubber D. The use of XPS to investigate the ageing mechanism of the phenol-urea-formaldehyde (PUF) binder coated mineral fibers. In: Proceedings of the 18th international conference on composite materials, ICC Jeju, Korea, 2011.

Cha J, Seo J, Kim S. Building materials thermal conductivity measurement and correlation with heat flow meter, laser flash analysis and TCi. J Therm Anal Calorim. 2012;109:295–300.

MSZ EN 12664:2001 Thermal performance of building materials and products. Determination of thermal resistance by means of guarded hot plate and heat flow meter methods. Dry and moist products of medium and low thermal resistance, Hungarian Standard Institute, 2001.

MSZ EN 12667:2001 Thermal performance of building materials and products. Determination of thermal resistance by means of guarded hot plate and heat flow meter methods. Products of high and medium thermal resistance, Hungarian Standard Institute, 2001.

MSZ EN ISO 12571:2013 Hygrothermal performance of building materials and products. Determination of hygroscopic sorption properties (ISO 12571:2013), Hungarian Standard Institute, 2013.

Krasnovskiha MP, Maksimovichb NG, Vaismanc Ya I, Ketovc AA. Thermal stability of mineral-wool heat-insulating materials. Russ J Appl Chem. 2014;87:1430–4.

Lei Y, Wu Q, Lian K. Cure kinetics of aqueous phenol–formaldehyde resins used for oriented strandboard manufacturing: analytical technique. J Appl Polym Sci. 2006;100:1642–50.

Balcerowiak W, Gryta M, Kaledkowsky B. Thermal stability of binder for mineral wool insulations. J Therm Anal Calorim. 1995;43:299–303.

Acknowledgements

Open access funding provided by Budapest University of Technology and Economics (BME). The study was supported by the ÚNKP-17-3 New National Excellence Program of the Ministry of Human Capacities. The authors gratefully acknowledge Lilla Mlinárik, Bence Vincze and their help and contribution to the research. Support of Grant BME FIKP-VÍZ by EMMI is kindly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Nagy, B., Simon, T.K. & Nemes, R. Effect of built-in mineral wool insulations durability on its thermal and mechanical performance. J Therm Anal Calorim 139, 169–181 (2020). https://doi.org/10.1007/s10973-019-08384-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08384-5