Abstract

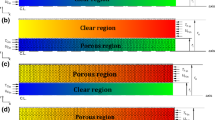

In the present paper, the first and second laws of thermodynamics are utilized to select the optimized position of porous insert to achieve maximum heat transfer and minimum pressure drop and entropy generation inside a double-pipe heat exchanger. Four different porous inserts configuration are considered in the heat exchanger, where the porous layers are placed at the core of the inner tube, wall of the inner tube, and inner or outer walls on outer tube for these cases. In addition, the effects of Darcy number and thermal conductivity of porous material on entropy generation, heat transfer enhancement and pressure drop penalty are investigated. The flow and heat transfer are modeled using Computational fluid dynamics. It was found that for outer tube of a double-pipe heat exchanger, placing the porous layer in the inner wall creates larger pressure drops. For inner tube, it is better to place the porous layer at the center, while for outer one, it is better to insert the porous layer at inner wall (interface wall) to achieve the higher values of heat transfer rate. Moreover, the thermal and viscous entropy generations are more pronounced for the cases, where the porous substrate is not located at the core of the heat exchanger.

Similar content being viewed by others

Abbreviations

- A :

-

Surface area (m2)

- C F :

-

Forchheimer coefficient (–)

- Be :

-

Bejan number (–)

- C p :

-

Specific heat at constant pressure (J kg−1 K−1)

- D h :

-

Hydraulic diameter (m)

- Da :

-

Darcy number (–)

- E :

-

Heat exchanger effectiveness (–)

- k :

-

Thermal conductivity (W m−1 K−1)

- K :

-

Permeability of the porous medium (m2)

- K r :

-

Thermal conductivity ratio (–)

- L :

-

Length of the heat exchanger (m)

- N g :

-

Dimensionless local volumetric entropy generation rate (–)

- N t :

-

Dimensionless total entropy generation rate (–)

- P :

-

Pressure (Pa)

- ∆p :

-

Pressure drop (Pa)

- Pr :

-

Prandtl number (–)

- Q :

-

Power (W)

- r :

-

Radius (m)

- R :

-

Radius ratio (–)

- Re :

-

Reynolds number (–)

- S :

-

Thickness of the porous substrate (m)

- S gen :

-

Entropy generation rate (W m−3 K−1)

- T:

-

Temperature (K)

- U c, U h :

-

Inlet velocity of cold and hot fluids (m s−1)

- U :

-

Overall heat transfer coefficient (W m−2 K−1)

- u, v :

-

Velocity component in x and y directions, respectively (m s−1)

- x, y :

-

Rectangular coordinates components (m)

- α :

-

Thermal diffusivity of the fluid (m2 s−1)

- ε :

-

Porosity (–)

- μ :

-

Dynamic viscosity (kg ms−1)

- ν :

-

Kinematic viscosity (m2 s−1)

- ρ :

-

Density of the fluid (kg m−3)

- θ :

-

Non-dimensional temperature (–)

- eff:

-

Effective

- c:

-

Cold

- f:

-

Fluid

- h:

-

Hot

- I:

-

Inner

- O:

-

Outer

- R:

-

Ratio

- S:

-

Solid

- 0:

-

Heat exchanger with no insert

References

Hosseinnejad R, Hosseini M, Farhadi M. Turbulent heat transfer in tubular heat exchangers with twisted tape. J Therm Anal Calorim. 2018;135:1863–9.

Khajeh Arzani H, Amiri A, Khajeh Arzani H, Bin Rozali S, Kazi SN, Badarudin A. Toward improved heat transfer performance of annular heat exchangers with water/ethylene glycol-based nanofluids containing graphene nanoplatelets. J Therm Anal Calorim. 2016;126:1427–36.

Chumpia A, Hooman K. Performance of tubular aluminum foam heat exchangers in multiple row bundles. J Therm Anal Calorim. 2018;135:1813–22.

Omidi M, Farhadi M, Jafari M. A comprehensive review on double pipe heat exchangers. Appl Therm Eng. 2017;110:1075–90.

Maddah H, Alizadeh M, Ghasemi N, Wan Alwi SR. Experimental study of Al2O3/water nanofluid turbulent heat transfer enhancement in the horizontal double pipes fitted with modified twisted tapes. Int J Heat Mass Transf. 2014;78:1042–54.

Iqbal Z, Syed KS, Ishaq M. Fin design for conjugate heat transfer optimization in double pipe. Int J Therm Sci. 2015;94:242–58.

Sheikholeslami M, Ganji DD. Heat transfer improvement in a double pipe heat exchanger by means of perforated turbulators. Energ Convers Manage. 2016;127:112–23.

El Maakoul A, Laknizi A, Saadeddine S, Abdellah AB, Meziane M, El Metoui M. Numerical design and investigation of heat transfer enhancement and performance for an annulus with continuous helical baffles in a double-pipe heat exchanger. Energ Convers Manage. 2017;133:76–86.

Ellahi R, Reza M, Akbar NS. Study of peristaltic flow of nanofluid with entropy generation in a porous medium. J Porous Media. 2017;20:461–78.

Mahmoudi Y, Karimi N. Numerical investigation of heat transfer enhancement in a pipe partially filled with a porous material under local thermal non-equilibrium condition. Int J Heat Mass Transf. 2014;68:161–73.

Torabi M, Karimi N, Zhang K, Peterson GP. Generation of entropy and forced convection of heat in a conduit partially filled with porous media—local thermal non-equilibrium and exothermicity effects. Appl Therm Eng. 2016;106:518–36.

Dickson C, Torabi M, Karimi N. First and second law analyses of nanofluid forced convection in a partially-filled porous channel—the effects of local thermal non-equilibrium and internal heat sources. Appl Therm Eng. 2016;103:459–80.

Torabi N, Dickson C, Karimi N. Theoretical investigation of entropy generation and heat transfer by forced convection of copper–water nanofluid in a porous channel—local thermal non-equilibrium and partial filling effects. Powder Technol. 2016;301:234–54.

Du YP, Qu ZG, Zhao CY, Tao WQ. Numerical study of conjugated heat transfer in metal foam filled double-pipe. Int J Heat Mass Transf. 2010;53:4899–907.

Xu HJ, Qu ZG, Tao WQ. Numerical investigation on self-coupling heat transfer in a counter-flow double-pipe heat exchanger filled with metallic foams. Appl Therm Eng. 2014;66:43–54.

Targui N, Kahalerras H. Analysis of fluid flow and heat transfer in a double pipe heat exchanger with porous structures. Energ Convers Manage. 2008;49:3217–29.

Targui N, Kahalerras H. Analysis of a double pipe heat exchanger performance by use of porous baffles and pulsating flow. Energ Convers Manage. 2013;76:43–54.

Alkam MK, Al-Nimr MA. Improving the performance of double-pipe heat exchangers by using porous substrates. Int J Heat Mass Transf. 1999;42:3609–18.

Mamourian M, Milani Shirvan K, Ellahi R, Rahimi AB. Optimization of mixed convection heat transfer with entropy generation in a wavy surface square lid-driven cavity by means of Taguchi approach. Int J Heat Mass Transf. 2016;120:544–54.

Akbar NS, Reza M, Ellahi R. Endoscopic effects with entropy generation analysis in peristalsis for the thermal conductivity of H2O + Cu nanofluid. J Appl Fluid Mech. 2016;9:1721–30.

Zeeshan A, Hassan M, Ellahi R, Nawaz M. Shape effect of nanosize particles in unsteady mixed convection flow of nanofluid over disk with entropy generation. Proc Inst Mech Eng E. 2017;231:871–9.

Ellahi R, Alamri SZ, Basit A, Majeed A. Effects of MHD and slip on heat transfer boundary layer flow over a moving plate based on specific entropy generation. J Taibah Univ Sci. 2018;12:476482.

Ellahi R, Hassan M, Zeeshan A. Shape effects of nanosize particles in Cu–H2O nanofluid on entropy generation. Int J Heat Mass Transf. 2015;81:449–56.

Ellahi R, Hassan M, Zeeshan A, Khan AA. The shape effects of nanoparticles suspended in HFE-7100 over wedge with entropy generation and mixed convection. Appl Nanosci. 2016;6:641–51.

Siavashi M, Talesh Bahrami HR, Saffari H. Numerical investigation of flow characteristics, heat transfer and entropy generation of nanofluid flow inside an annular pipe partially or completely filled with porous media using two-phase mixture model. Energy. 2015;93:2451–66.

Kurtbas I, Celik N, Dinçer I. Exergy transfer in a porous rectangular channel. Energy. 2010;35:451–60.

Torabi M, Karimi N, Zhang K. Heat transfer and second law analyses of forced convection in a channel partially filled by porous media and featuring internal heat sources. Energy. 2015;93:106–27.

Komurgoz G, Arikoglu A, Ozkol I. Analysis of the magnetic effect on entropy generation in an inclined channel partially filled with a porous medium. Num Heat Transf Part A. 2012;61:786–99.

Karimi N, Agbo D, Talat Khan A, Younger PL. On the effects of exothermicity and endothermicity upon the temperature fields in a partially-filled porous channel. Int J Therm Sci. 2015;96:128–48.

Allouache N, Chikh S. Second law analysis in a partly porous double pipe heat exchanger. J of Appl Mech. 2006;73:60–5.

Minkowycz WJ, Haji-Sheikh A, Vafai K. On departure from local thermal equilibrium in porous media due to a rapidly changing heat source: the Sparrow number. Int J Heat Mass Transf. 1999;42:3373–85.

Akbarzadeh M, Maghrebi MJ. Combined effects of corrugated walls and porous inserts on performance improvement in a heat exchanger channel. Int J Therm Sci. 2018;127:266–76.

Gorman JM, Krautbauer KR, Sparrow EM. Thermal and fluid flow first-principles numerical design of an enhanced double pipe heat exchanger. Appl Therm Eng. 2016;107:194–206.

Kahalerras H, Targui N. Numerical analysis of heat transfer enhancement in a double pipe heat exchanger with porous fins. Int J Numer Method Heat Fluid Flow. 2008;18:593–617.

Ingham DB, Pop I. Transport phenomena in porous media III, vol. 3. Amsterdam: Elsevier; 2005.

Ucar E, Mobedi M, Pop I. Effect of inserted porous layer located at a wall of a parallel plate channel on forced convection heat transfer. Transp Porous Med. 2013;98:35–57.

Dukhan N, Bagci O, Ozdemir M. Thermal development in open-cell metal foam: an experiment with constant wall heat flux. Int J Heat Mass Transf. 2015;85:825–59.

Bejan A. Entropy generation through heat and fluid flow. New York: Wiley; 1982.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Akbarzadeh, M., Rashidi, S., Keshmiri, A. et al. The optimum position of porous insert for a double-pipe heat exchanger based on entropy generation and thermal analysis. J Therm Anal Calorim 139, 411–426 (2020). https://doi.org/10.1007/s10973-019-08362-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08362-x