Abstract

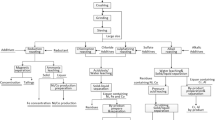

It was recently demonstrated that the extraction of major elements from South African Platinum Group Metals (PGM) tailings can be achieved via thermochemical treatment with ammonium sulphate followed by aqueous dissolution. The current study uses the insight gained from the previous work and investigates and compares major element extraction efficiencies obtained using ammonium sulphate and three other ammonium salts (ammonium bisulphate vs ammonium chloride vs ammonium nitrate) as extracting agents at five different temperatures (350–550 °C). Overall, ammonium sulphate was the most promising reagent for the co-extraction of major elements, with the best extraction efficiencies achieved for aluminium (ca. 60%) and calcium (ca. 80%), alongside chromium (ca. 29%), iron (ca. 35%), magnesium (ca. 25%) and silicon (ca. 32%). In contrast, ammonium chloride and ammonium nitrate extracted smaller quantities of these elements, in particular chromium which was hardly extracted (≤ 1.2%), whereas calcium was nearly equally extracted for all salts (70–80%). It could not be ascertained whether the plagioclase phase, as anorthite, reacted with ammonium salts during the thermochemical step, but it was found to dissolve nearly completely during the acid leaching step in the absence of thermochemical processing. This phase was the main contributor to calcium and aluminium in solution. The greatest effect of temperature was on the flowability characteristic of the reaction product after treatment rather than on elemental extraction efficiencies. Thermochemical treatment using ammonium sulphate represents the most promising route for extracting valuable elements from PGM tailings, which could be subsequently converted into value-added products.

(Source for data obtained at 550 °C: [6])

(Figure C1 adapted and modified from [6])

Similar content being viewed by others

References

Golev A, Lebre E, Corder G. The contribution of mining to the emerging circular economy—AusIMM Bulletin. AusIMM Bull. 2016. https://www.ausimmbulletin.com/feature/the-contribution-of-mining-to-the-emerging-circular-economy. Accessed Aug 2016.

Schreck M, Wagner J. Incentivizing secondary raw material markets for sustainable waste management. Waste Manag. 2017;67:354–9.

ETP SMR High Level Group. Strategic research and innovation agenda. European Technology Platform for Sustainable Mineral Resources (ETP SMR). 2013; p. 40.

Department of Science and Technology. National waste R&D and innovation roadmap for South Africa: phase 2 waste RDI roadmap. Trends in waste management and priority waste streams for the Waste RDI Roadmap. Department of Science and Technology: Pretoria. 2014; p. 47.

Meyer NA, Vögeli JU, Becker M, Broadhurst JL, Reid DL, Franzidis JP. Mineral carbonation of PGM mine tailings for CO2 storage in South Africa: a case study. Miner Eng. 2014;59:45–51.

Mohamed S, van der Merwe EM, Altermann W, Doucet FJ. Process development for elemental recovery from PGM tailings by thermochemical treatment: preliminary major element extraction studies using ammonium sulphate as extracting agent. Waste Manag. 2016;50:334–45.

Mohamed S, van der Merwe EM, Altermann W, Doucet FJ. Addendum to “Process development for elemental recovery from PGM tailings by thermochemical treatment: preliminary major element extraction studies using ammonium sulphate as extracting agent” [Waste Manage. 50 (2016) 334–345]. Waste Manag. 2017;66:222–4.

Liu Y, Naidu R. Hidden values in bauxite residue (red mud): recovery of metals. Waste Manag. 2014;34:2662–73.

Ma D, Wang Z, Guo M, Zhang M, Liu J. Feasible conversion of solid waste bauxite tailings into highly crystalline 4A zeolite with valuable application. Waste Manag. 2014;34:2365–72.

Chmielewski AG, Wawszczak D, Brykała M. Possibility of uranium and rare metal recovery in the Polish copper mining industry. Hydrometallurgy. 2016;159:12–8.

Muthukannan V, Praveen K, Natesan B. Fabrication and characterization of magnetite/reduced graphene oxide composite incurred from iron ore tailings for high performance application. Mater Chem Phys. 2015;162:400–7.

Ben Ghacham A, Cecchi E, Pasquier L-C, Blais J-F, Mercier G. CO2 sequestration using waste concrete and anorthosite tailings by direct mineral carbonation in gas–solid–liquid and gas–solid routes. J Environ Manag. 2015;163:70–7.

Vogeli J, Reid DL, Becker M, Broadhurst J, Franzidis JP. Investigation of the potential for mineral carbonation of PGM tailings in South Africa. Miner Eng. 2011;24:1348–56.

Jubilee Platinum. 2015. http://www.jubileeplatinum.com/investors-and-media/announcements/2015/15-dec-2015.php. Accessed 12 Feb 2016.

Implats. Mineral resource and mineral reserve statement 2015. 2015. http://financialresults.co.za/2015/implats-minerals-report-2015/chromium.php. Accessed 12 Feb 2016.

Creamer M. Northam initiates R100m tailings retreatment project. In: Mining weekly. 2017. http://www.miningweekly.com/article/northam-initiates-r100m-tailings-retreatment-project-2017-08-28/rep_id:3650. Accessed 30 Aug 2017.

Doucet FJ. Scoping study on CO2 mineralization technologies. Contract Report No CGS-2011-007, commissioned by the South African Centre for Carbon Capture and Storage. 2011; p. 88.

Doucet FJ, Mohamed S, Neyt N, Castleman BA, van der Merwe EM. Thermochemical processing of a South African ultrafine coal fly ash using ammonium sulphate as extracting agent for aluminium extraction. Hydrometallurgy. 2016;166:174–84.

van der Merwe EM, Gray CL, Castleman BA, Mohamed S, Kruger RA, Doucet FJ. Ammonium sulphate and/or ammonium bisulphate as extracting agents for the recovery of aluminium from ultrafine coal fly ash. Hydrometallurgy. 2017;171:185–90.

Barnardo D. Aluminium. In: Wilson MGC, Anhaeusser CR, editors. The mineral resources of South Africa. 6th ed. Pretoria: Council for Geoscience; 1998. p. 46–52.

Romão IS, Gando-Ferreira LM, da Silva MMVG, Zevenhoven R. CO2 sequestration with serpentinite and metaperidotite from Northeast Portugal. Miner Eng. 2016;94:104–14.

D’yachenko AN, Kraidenko RI. Processing oxide-sulfide copper ores using ammonium chloride. Russ J Non-Ferrous Met. 2010;51:377–81.

Andreev AA, D’yachenko AN, Kraidenko RI. Processing of oxidized nickel ores with ammonium chloride. Theor Found Chem Eng. 2011;45:521.

Nadirov RK, Syzdykova LI, Zhussupova AK, Usserbaev MT. Recovery of value metals from copper smelter slag by ammonium chloride treatment. Int J Miner Process. 2013;124:145–9.

Eales HV. The Bushveld Complex, an introduction to the geology and setting of the Bushveld Complex. Pretoria: Council for Geoscience; 2014. p. 214.

Erdey L, Gal S, Liptay G. Thermoanalytical properties of analytical-grade reagents: ammonium salts. Talanta. 1964;11:913–40.

Kosova DA, Emelina AL, Bykov MA. Phase transitions of some sulfur-containing ammonium salts. Thermochim Acta. 2014;595:61–6.

Olszak-Humienik M. On the thermal stability of some ammonium salts. Thermochim Acta. 2001;378:107–12.

Chi R, Zhang X, Zhu G, Zhou ZA, Wu Y, Wang C, et al. Recovery of rare earth from bastnasite by ammonium chloride roasting with fluorine deactivation. Miner Eng. 2004;17:1037–43.

Chaturvedi S, Dave PN. Review on thermal decomposition of ammonium nitrate. J Energ Mater. 2013;31:1–26.

Gunawan R, Zhang D. Thermal stability and kinetics of decomposition of ammonium nitrate in the presence of pyrite. J Hazard Mater. 2009;165:751–8.

Izato Y, Miyake A. Thermal decomposition of molten ammonium nitrate (AN). J Therm Anal Calorim. 2015;122:595–600.

Romão IS, Gando-Ferreira LM, Zevenhoven R. Combined extraction of metals and production of Mg(OH)2 for CO2 sequestration from nickel mine ore and overburden. Miner Eng. 2013;53:167–70.

Romão I, Gando-Ferreira LM, Zevenhoven R. Separation and recovery of valuable metals extracted from serpentinite during the production of Mg(OH)2 for CO2 sequestration. Miner Eng. 2015;77:25–33.

Nduagu E, Björklöf T, Fagerlund J, Wärnå J, Geerlings H, Zevenhoven R. Production of magnesium hydroxide from magnesium silicate for the purpose of CO2 mineralisation-Part 1: application to Finnish serpentinite. Miner Eng. 2012;30:75–86.

Nagaishi T, Ishiyama S, Matsumoto M, Yoshinaga S. Reactions between ammonium sulphate and metal oxides (metal = Cr, Mn and Fe) and thermal decomposition of the products. J Therm Anal. 1984;29:121–9.

Bayer G, Kahr G, Müller-Vonmoos M. Reactions of ammonium sulphates with kaolinite and other silicate and oxide minerals. Clay Miner. 1982;17:271–83.

Crouse KA, Badri M. Thermal studies on chromium (II) salts. Thermochim Acta. 1991;177:239–51.

Tagawa H. Thermal decomposition temperatures of metal sulfates. Thermochim Acta. 1984;80:23–33.

Jambor JL, Grew ES, Roberts AC. New mineral names. Am Miner. 1996;81:1513–8.

Debbarma M, Das S, Saha M. Effect of reducing agents on the structure of zinc oxide under microwave irradiation. Adv Manuf. 2013;1:183–6.

Highfield J, Lim H, Fagerlund J, Zevenhoven R. Mechanochemical processing of serpentine with ammonium salts under ambient conditions for CO2 mineralization. RSC Adv. 2012;2:6542–8.

Romão I, Slotte M, Gando-Ferreira LM, Zevenhoven R. CO2 sequestration with magnesium silicates—exergetic performance assessment. Chem Eng Res Des. 2014;92:3072–82.

Oxley JC, Smith JL, Rogers E, Yu M. Ammonium nitrate: thermal stability and explosivity modifiers. Thermochim Acta. 2002;384:23–45.

Cagnina S, Rotureau P, Adamo C. Study of incompatibility of ammonium nitrate and its mechanism of decomposition by theoretical approach. AIDIC. 2013;31:823–8.

Nduagu EI, Highfield J, Chen J, Zevenhoven R. Mechanisms of serpentine-ammonium sulfate reactions: towards higher efficiencies in flux recovery and Mg extraction for CO2 mineral sequestration. RSC Adv. 2014;4:64494–505.

Jariwala M, Crawford J, LeCaptain DJ. In situ Raman spectroscopic analysis of the regeneration of ammonium hydrogen sulfate from ammonium sulfate. Ind Eng Chem Res. 2007;46:4900–5.

Lee CT, Sohn HY. Recovery of synthetic rutile and iron oxide from ilmenite ore by sulfation with ammonium sulfate. Ind Eng Chem Res. 1989;28:1802–8.

Kiyoura R, Urano K. Mechanism, kinetics, and equilibrium of thermal decomposition of ammonium sulfate. Ind Eng Chem Process Des Dev. 1970;9:489–94.

Acknowledgements

This work is based on research supported by the Council for Geoscience, the South African Department of Mineral Resources (DMR), the University of Pretoria, and the Geological Society of South Africa (GSSA) Ante the GSSA REI Fund. S. M. was supported by a Masters’ Block Grant Free Standing Scholarship from the National Research Foundation (Grant Nos. 96849, 85528) of South Africa (NRF). Any opinion, finding, conclusion or recommendation expressed in this material is that of the authors and the NRF does not accept any liability in this regard.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Wladyslaw Altermann: Kumba-Exxaro chair.

Electronic supplementary material

Below is the link to the electronic supplementary material.

10973_2019_8233_MOESM1_ESM.docx

Supplementary Figure 1. Elemental extraction efficiencies when leaching MTtct generated with all four salts at 550 °C (MT45–75/salt of 2:6) in ultra-pure water at 25 °C and 95 °C for 1 h and 6 h. (3 g MTtct/500 mL; 850 rpm) (DOCX 662 kb)

Rights and permissions

About this article

Cite this article

Mohamed, S., Lehong, K., van der Merwe, E.M. et al. Thermochemical treatment of platinum group metal tailings with ammonium salts for major element recovery. J Therm Anal Calorim 138, 2015–2033 (2019). https://doi.org/10.1007/s10973-019-08233-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08233-5