Abstract

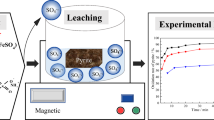

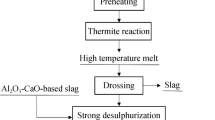

In this study, the goal was to find lower temperature for separating the Zn and Fe content of ZnFe2O4 by sulfation reaction than previously achieved and to study the various reaction steps of sulfation. Hence, the reaction of ZnFe2O4 with Mohr’s salt containing iron(II), i.e., (NH4)2Fe(SO4)2·6H2O, and ammonium iron alum containing Fe(III), i.e., NH4Fe(SO4)2·12H2O, was studied. At first, the thermal decomposition of precursor salts in air was studied by TG/DTA-MS to find the proper temperature for sulfation. Then ZnFe2SO4/precursor salt mixtures with ratios 1:2 and 1:5 were prepared and annealed at 400, 425 and 450 °C. The solubility of the products obtained at different annealing temperatures in water (e.g., ZnSO4, FeSO4, Fe2(SO4)3) and in HCl (Fe2O3, ZnO, Fex(OH)ySO4, Znv(OH)wSO4 basic sulfates) was studied. The morphology and structure of the starting materials was investigated by SEM, XRD and FTIR, the crystalline phases after each annealing and washing step were studied by XRD. The Fe in the starting materials and the products obtained at 425 °C was measured by Mössbauer. Based on the obtained results, it was demonstrated that the sulfation reaction with ammonium iron sulfates could be performed at lower temperatures than with iron sulfates. It was possible to detect the reaction intermediates and to obtain information about the reaction intermediates. With our sulfation reaction, depending on the reaction conditions, it is possible to obtain Fe2O3 as final product, but the Zn and Fe metals can be obtained also as sulfates. Our results open up further possibilities to recycle the ZnFe2O4 waste material.

Similar content being viewed by others

References

General galvanizing paractice. Hot Dip Galvanizers Associacion, London; 1965.

Kazinczy B, Kótai L, Gács I, Szentmihályi K, Sándor Z, Holly S. Study on ammoniacal leaching of zinc from sludges containing iron and zinc hydroxides. Hung J Ind Chem. 2000;28:207–10.

Arsenovic M, Radojevic Z, Stankovic S. Removal of toxic metals from industrial sludge by fixing in brick structure. Constr Build Mater. 2012;37:7–14.

Yakornov SA, Grudinsky PI, Dyubanov VG, Leont’ev LI, Kozlov PA, Ivakin DA. Thermodynamic analysis of zinc ferrite decomposition in electric arc furnace dust by lime. Russ J Non-Ferrous Met. 2017;58:586–90.

Junca E, Grillo FF, Restivo TAG, de Oliveira JR, Espinosa DCR, Tenório JAS. Kinetic investigation of synthetic zinc ferrite reduction by hydrogen. J Therm Anal Calorim. 2017;129:1215–23.

Kazinczy B, Kótai L, Sajó IE, Holly S, Lázár K, Jakab E, Gács I, Szentmihályi K. Phase relations and heat-induced chemical processes in sludges os Hot-dip galvanization. Ind Eng Chem Res. 2002;41:720–5.

Kazinczy B, Kótai L, Gács I, Sajó IE, Sreedhar B, Lázár K. Study of the preparation of zinc(II)zerrite and ZnO from zinc- and iron-containing industrial wastes. Ind Eng Chem Res. 2003;42:318–22.

Saini A, Kótai L, Sajó IE, Szilágyi IM, Lázár K, May Z, Fazekas P, Gács I, Sharma V, Banerji KK. Solid phase sulphatizing of znc-ferrite spinel with iron sulphates as an environmental friendly way for recovering zinc. Eur Chem Bull. 2012;1:7–13.

Nagaishi T, Ishiyama S, Matsumoto M, Yoshinaga S. Reactions between ammonium-sulphate and metal oxides (Cr, Mn, Fe) and thermal decomposition of the products. J Therm Anal. 1984;29:121–9.

Mohai I, Szépvölgyi J, Bertóti I, Mohai M, Gubicza J, Ungár T. Thermal plasma synthesis of zinc ferrite nanopowders. Solid State Ion. 2001;163:141–2.

Mohai I, Szépvölgyi J, Károly Z, Mohai M, Babijevszkaja IZ, Krenev VA. Reduction of metallurgical wastes in an RF thermal plasma reactor. Plasma Chem Plasma Process. 2001;21:547.

Boyanov BS. Interaction of (NH4)2SO4 and FeSO4 with metal oxides and ferrites. Thermochim Acta. 1994;240:225.

Jiang GM, Peng B, Liang YJ, Chai LY, Wang QW, Li QZ, Hu M. Recovery of valuable metals from zinc leaching residue by sulfate roasting and water leaching. Trans Nonferrous Met Soc Chin (Eng Ed). 2017;27:1180–7.

Pinto BV, Ferreira APG, Cavalheiro ETG. A mechanism proposal for fluoxetine thermal decomposition. J Therm Anal Calorim. 2017;130:1553–9.

Opuchovic O, Niznansky D, Kareiva A. Thermoanalytical (TG/DSC/EVG-GC-MS) characterization of the lanthanide (Ho) iron garnet formation in sol–gel. J Therm Anal Calorim. 2017;130:1085–94.

Krishnan GS, Murali N, Ahamed AJ. Structural transformation, thermal endurance, and identification of evolved gases during heat treatment processes of carbon fiber polymer precursors focusing on the stereoregularity. J Therm Anal Calorim. 2017;130:1553–9.

Podkoscielna B, Sobiesiak M. Characteristics of thermal behavior of photoluminescent copolymers studied by the TG/DTG/FTIR coupled method. J Therm Anal Calorim. 2016;125:625–31.

Rogulska M, Kultys AJ. Aliphatic polycarbonate-based thermoplastic polyurethane elastomers containing diphenyl sulfide units. Therm Anal Calorim. 2016;126:225–43.

Diyuk VE, Mariychuk RT, Lisnyak VV. Barothermal preparation and characterization of micro-mesoporous activated carbons Textural studies, thermal destruction and evolved gas analysis with TG-TPD-IR technique. J Therm Anal Calorim. 2016;124:1119–30.

Bartyzel A, Sztanke M, Sztanke K. Thermal studies of analgesic active 8-aryl-2,6,7,8-tetrahydroimidazo[2,1-c][1,2,4]triazine-3,4-diones. J Therm Anal Calorim. 2016;123:2053–60.

Ambrozini B, Cervini P, Cavalheiro ETG. Thermal behavior of the beta-blocker propranolol. J Therm Anal Calorim. 2016;123:1013–7.

Papadopoulos C, Cristovao B, Ferenc W, Hatzidimitriou A, Vecchio Ciprioti S, Risoluti R, Lalia-Kantouri M. Thermoanalytical, magnetic and structural investigation of neutral Co(II) complexes with 2,2’-dipyridylamine and salicylaldehydes. J Therm Anal Calorim. 2016;123:717–29.

Mihaiu S, Szilagyi IM, Atkinson I, Mocioiu OC, Hunyadi D, Pandele-Cusu J, Toader A, Munteanu C, Boyadjiev S, Madarasz J, Pokol G, Zaharescu M. Thermal study on the synthesis of the doped ZnO to be used in TCO films. J Therm Anal Calorim. 2016;124:71–80.

Liu L, Zhang G, Wang L, Huang T, Qin L. Highly active S-modified ZnFe2O4 heterogeneous catalyst and its photo-fenton behavior under UV–Visible irradiation. Ind Eng Chem Res. 2011;50:7219–27.

Nyquist RA, Kagel RO. Infrared spectra of inorganic compounds. New York: Acedemic Press; 1971.

Music S, Saric A, Popovic S, Nomura K, Sawada T. Forced hydrolysis of Fe3+ ions in NH4Fe(SO4)2 solutions containing Urotropine. Croat Chem Acta. 2000;73:541–67.

Frank E, Varriale MC, Bristotti A. Mössbauer studies of the thermal decomposition of iron(II) ammonium sulphate hexahydrate. J Therm Anal. 1979;17:141–50.

Lopez-Delgado A, Lopez FA. Thermal decomposition of ferric and ammonium sulfates obtained by bio-oxidation of water pickling liquors with Thiobacillus ferrooxidans. J Mater Sci. 1995;30:5130–8.

Nakamura H, Hara Y, Osada H. The thermal decomposition of ammonium sulfate and its reaction with iron(III) oxide. Nippon Kagaku Kaishi. 1980;5:706–10.

Kocsis T, Magyari J, Sajó IE, Pasinszki T, Homonnay Z, Szilágyi IM, Farkas A, May Z, Effenberger H, Szakáll S, Pawar RP, Kótai K. Evidence of quasi-intramolecular redox reactions during thermal decomposition of ammonium hydroxodisulphitoferriate(III), (NH4)2[Fe(OH)(SO3)2]·H2O. J Therm Anal Calorim. 2018;132:493–502.

Oliviera AC, Garg VK. Mössbauer aqueous frozen solution and thermal decomposititon studies of Fe(NH4SO4)2·6H2O. Radiochem Radioanal Lett. 1974;18:43–8.

Kopcewicz K, Kotlicji A, Szefer M. Mössbauer study of proton irradiation effects in hydrated iron(II) ammoniumm sulfate and iron(III) ammonium aluminate. Phys Status Solidi. 1975;14:4159.

Housley RM. Investigation of magnetic relaxation effects in Fe(NO3)3·9H2O and NH4Fe(SO4)2·12H2O by Mössbauer-effect spectroscopy. J Appl Phys. 1967;38:1287–9.

Zboril R, Mashlan M, Petridis D, Krausova D, Pikal P. The role of intermediates in the process of red ferric pigment manufacture from FeSO4·7H2O. Hyperfine Interact. 2002;139(140):437–45.

Pelovski Y, Petkova V, Nikolov S. Study of the mechanisam of the thermochemical decomposition of ferrous sulphate monohydrate. Thermochim Acta. 1996;274:273–80.

Umetsu Y, Tozawa K, Sasaki K. The hydrolysis of ferric sulphate solutions at elevated temperatures. Can Metall Q. 1977;116:111–7.

Acknowledgements

I. M. Szilágyi acknowledges a János Bolyai Research Fellowship of the Hungarian Academy of Sciences and an ÚNKP-18-4-BME-238 Grant supported by the New National Excellence Program of the Ministry of Human Capacities, Hungary. An NRDI K 124212 and an NRDI TNN_16 123631 Grant are acknowledged. The research within Project No. VEKOP-2.3.2-16-2017-00013 and GINOP-2.2.1-15-2017-00084 was supported by the European Union and the State of Hungary, co-financed by the European Regional Development Fund. The research reported in this paper was supported by the Higher Education Excellence Program of the Ministry of Human Capacities in the frame of Nanotechnology and Materials Science research area of Budapest University of Technology (BME FIKP-NAT).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fekete, F., Lázár, K., Keszler, A.M. et al. Recycling the industrial waste ZnFe2O4 from hot-dip galvanization sludge. J Therm Anal Calorim 134, 1863–1872 (2018). https://doi.org/10.1007/s10973-018-7849-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7849-8