Abstract

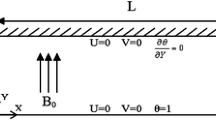

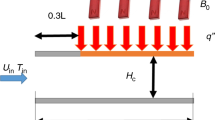

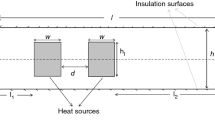

Numerical studies of laminar forced convective heat transfer and fluid flow in a 2D louvered microchannel with Al2O3/water nanofluids are performed by the lattice Boltzmann method (LBM). Eight louvers are arranged in tandem within the single-pass microchannel. The Reynolds number based on channel hydraulic diameter and bulk mean velocity ranges from 100 to 400, where the Al2O3 fraction varies from 0 to 4%. A double distribution function approach is adopted for modeling fluid flow and heat transfer. Code validations are performed by comparing the streamwise Nusselt number (Nu) profiles and Fanning friction factors of the present LBM and those of the analytical solutions. Good agreements are obtained. Simulated results show that the louver microstructure can disturb the core flow and guide coolant toward the heated walls, thus enhancing the heat transfer significantly. Furthermore, the addition of nanoparticles in microchannels can also augment the heat transfer, but it creates an unnoticeable pressure loss. With both the louver microstructure and nanofluid, a maximum overall Nu enhancement of 7.06 is found relative to that of the fully developed smooth channel.

Similar content being viewed by others

Abbreviations

- \(\varvec{c}_{\text{k}}\) :

-

Discrete lattice velocity vectors

- c p :

-

Specific heat capacity (J kg−1 K−1)

- c s :

-

Dimensionless speed of sound

- d :

-

Particle diameter (m)

- D h :

-

Hydraulic diameter, 2H (m)

- f :

-

Fanning friction factor

- \(\bar{f}\) :

-

Average Fanning friction factor

- f 0 :

-

Fanning friction factor for the fully developed laminar flow in two-dimensional smooth channel

- f k :

-

Distribution function for velocity

- f eq :

-

Equilibrium distribution function for velocity

- g k :

-

Distribution function for energy

- g eqk :

-

Equilibrium distribution function for velocity

- H :

-

Height of channel (m)

- H s :

-

Height of louver microstructures (m)

- k :

-

Thermal conductivity (W m−1 K−1)

- L :

-

Length of channel (m)

- Nu :

-

Nusselt number

- \(\overline{Nu}\) :

-

Average Nusselt number

- \(Nu_{0}\) :

-

Nusselt number for the fully developed laminar flow in two-dimensional smooth channel

- \(P\) :

-

Pressure (Pa)

- Pr :

-

Prandtl number = ν/α

- Re :

-

Reynolds number = ρfumDh/μf

- T :

-

Temperature (K)

- TPF:

-

Thermal performance factor

- \(\varvec{u}\) :

-

Velocity vector (m s−1)

- u :

-

Streamwise velocity component (m s−1)

- v :

-

Transverse velocity component (m s−1)

- w k :

-

Weighting factors

- \(\varvec{x}\) :

-

Position lattice vectors (m)

- x :

-

Streamwise coordinate (m)

- y :

-

Transverse coordinate (m)

- \(X^{*}\) :

-

Dimensionless coordinates (x/Dh)

- \(Y^{*}\) :

-

Dimensionless coordinates (y/Dh)

- α :

-

Thermal diffusion coefficient (m2 s−1)

- μ :

-

Dynamic viscosity (kg m−1 s−1)

- ν :

-

Kinematic viscosity (m2 s−1)

- ρ :

-

Density (kg m−3)

- τ ν :

-

Dimensionless relaxation time for fk

- τ c :

-

Dimensionless relaxation time for gk

- ϕ :

-

Particle volume fraction

- bf:

-

Base fluid

- in:

-

Inlet

- m:

-

Mean

- nf:

-

Nanofluid

- out:

-

Outlet

- p:

-

Particle

- w:

-

Wall

References

Tuckerman DB, Pease RFW. High-performance heat sinking for VLSI. IEEE Electron Device Lett. 1981;2(5):126–9.

Webb BW, Ramadhyani S. Conjugate heat transfer in a channel with staggered ribs. Int J Heat Mass Transf. 1985;28(9):1679–87.

Croce G, D’agaro P, Nonino C. Three-dimensional roughness effect on microchannel heat transfer and pressure drop. Int J Heat Mass Transf. 2007;50(25):5249–59.

Desrues T, Marty P, Fourmigué JF. Numerical prediction of heat transfer and pressure drop in three-dimensional channels with alternated opposed ribs. Appl Therm Eng. 2012;45:52–63.

Rahman MM, Injeti P. Heat transfer in microtube or microchannel with protrusions. Front Heat Mass Transf. 2011;2(1):013003.

Chai L, Xia GD, Wang HS. Numerical study of laminar flow and heat transfer in microchannel heat sink with offset ribs on sidewalls. Appl Therm Eng. 2016;92:32–41.

Liu Y, Cui J, Li W, Zhang N. Effect of surface microstructure on microchannel heat transfer performance. J Heat Transf. 2011;133:124501.

Gong L, Kota K, Tao W, Joshi Y. Parametric numerical study of flow and heat transfer in microchannels with wavy walls. J. Heat Transf. 2011;133(5):051702-1–-10.

Ghaedamini H, Lee PS, Teo CJ. Developing forced convection in converging–diverging microchannels. Int J Heat Mass Transf. 2013;65:491–9.

Patankar SV, Liu CH, Sparrow EM. Fully developed flow and heat transfer in ducts having streamwise-periodic variations of cross-sectional area. J Heat Transf. 1977;99(2):180–6.

Kelkar KM, Patankar SV. Numerical prediction of flow and heat transfer in a parallel plate channel with staggered fins. J Heat Transf. 1987;109(1):25–30.

Cheng CH, Hung WH. Numerical prediction for laminar forced convection in parallel-plate channels with transverse fin arrays. Int J Heat Mass Transf. 1991;34(11):2739–49.

Mousavi SS, Hooman K. Heat and fluid flow in entrance region of a channel with staggered baffles. Energy Convers Manag. 2006;47(15):2011–9.

Liu C, Teng JT, Chu JC, Chiu YL, Huang S, Jin S, Pan HH. Experimental investigations on liquid flow and heat transfer in rectangular microchannel with longitudinal vortex generators. Int J Heat Mass Transf. 2011;54(13):3069–80.

Ebrahimi A, Roohi E, Kheradmand S. Numerical study of liquid flow and heat transfer in rectangular microchannel with longitudinal vortex generators. Appl Therm Eng. 2015;78:576–83.

Sripattanapipat S, Promvonge P. Numerical analysis of laminar heat transfer in a channel with diamond-shaped baffles. Int Commun Heat Mass Transf. 2009;36(1):32–8.

Saidur R, Leong KY, Mohammad H. A review on applications and challenges of nanofluids. Renew Sustain Energy Rev. 2011;15(3):1646–68.

Choi SUS, Eastman JA. Enhancing thermal conductivity of fluids with nanoparticles. In: International Mechanical Engineering Congress and Exhibition; 1995. p. 99–106.

Wang XQ, Mujumdar AS. Heat transfer characteristics of nanofluids: a review. Int J Therm Sci. 2007;46(1):1–19.

Li J, Li Z, Wang B. Experimental viscosity measurements for copper oxide nanoparticle suspensions. Tsinghua Sci Technol. 2002;7(2):198–201.

Mintsa HA, Roy G, Nguyen CT, Doucet D. New temperature dependent thermal conductivity data for water-based nanofluids. Int J Therm Sci. 2009;48(2):363–71.

Chon CH, Kihm KD, Lee SP, Choi SU. Empirical correlation finding the role of temperature and particle size for nanofluid (Al2O3) thermal conductivity enhancement. Appl Phys Lett. 2005;87(15):153107.

Nguyen CT, Desgranges F, Roy G, Galanis N, Maré T, Boucher S, Mintsa HA. Temperature and particle-size dependent viscosity data for water-based nanofluids–hysteresis phenomenon. Int J Heat Fluid Flow. 2007;28(6):1492–506.

Maiga SEB, Palm SJ, Nguyen CT, Roy G, Galanis N. Heat transfer enhancement by using nanofluids in forced convection flows. Int J Heat Fluid Flow. 2005;26(4):530–46.

Yang YT, Lai FH. Numerical study of flow and heat transfer characteristics of alumina-water nanofluids in a microchannel using the lattice Boltzmann method. Int Commun Heat Mass Transf. 2011;38(5):607–14.

Akbari OA, Toghraie D, Karimipour A, Safaei MR, Goodarzi M, Alipour H, Dahari M. Investigation of rib’s height effect on heat transfer and flow parameters of laminar water–Al2O3 nanofluid in a rib-microchannel. Appl Math Comput. 2016;290:135–53.

Ghale ZY, Haghshenasfard M, Esfahany MN. Investigation of nanofluids heat transfer in a ribbed microchannel heat sink using single-phase and multiphase CFD models. Int Commun Heat Mass Transf. 2015;68:122–9.

Liou TM, Wang CS. Large eddy simulation of rotating turbulent flows and heat transfer by the lattice Boltzmann method. Phys Fluids. 2018;30(1):015106.

Raghuraman DRS, Raj RTK, Nagarajan PK, Rao BVA. Influence of aspect ratio on the thermal performance of rectangular shaped micro channel heat sink using CFD code. Alexandria Eng J. 2017;56(1):43–54.

Aparecido JB, Cotta RM. Thermally developing laminar flow inside rectangular ducts. Int J Heat Mass Transf. 1990;33(2):341–7.

Qian YH, D’Humières D, Lallemand P. Lattice BGK models for Navier–Stokes equation. Europhys Lett. 1992;17(6):479.

Zou Q, He X. On pressure and velocity boundary conditions for the lattice Boltzmann BGK model. Phys Fluids. 1997;9(6):1591–8.

Incropera FP. Liquid cooling of electronic devices by single-phase convection. Hoboken: Wiley-Interscience; 1999.

Gherasim I, Roy G, Nguyen CT, Vo-Ngoc D. Experimental investigation of nanofluids in confined laminar radial flows. Int J Therm Sci. 2009;48(8):1486–93.

Bergman TL, Incropera FP. Fundamentals of heat and mass transfer. Hoboken: Wiley; 2011.

Bejan A. Convection heat transfer. Hoboken: Wiley; 2013.

Acknowledgements

The present study is sponsored by the Ministry of Science and Technology of Taiwan under Contract: MOST105-2221-E-007-058-MY3. The National Center for High-performance Computing is also acknowledged for providing computer resources.

Author information

Authors and Affiliations

Corresponding author

Appendix: boundary conditions for D2Q9 lattice model

Appendix: boundary conditions for D2Q9 lattice model

For LBM, the macroscopic boundary conditions have to be reformulated in the kinetic form. At the inlet, the Zou and He boundary conditions [32] for velocity distribution functions are adopted as

Similarly, unknown inlet temperature distribution functions are given by

At the outlet, the unknown velocity and temperature distribution functions are extrapolated by

and

To model the solid walls and obstacles, bounce back schemes for velocity distribution functions are applied, i.e.

and

For the temperature boundary condition on the top and bottom walls, the unknown distribution functions can be written as

and

Rights and permissions

About this article

Cite this article

Liou, TM., Wei, TC. & Wang, CS. Investigation of nanofluids on heat transfer enhancement in a louvered microchannel with lattice Boltzmann method. J Therm Anal Calorim 135, 751–762 (2019). https://doi.org/10.1007/s10973-018-7299-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7299-3